The textile industry is undergoing a transformative shift, with flat knitting machines at the forefront of producing high-quality, versatile, and sustainable fabrics. Whether you’re a small-scale designer crafting bespoke garments, a large-scale manufacturer meeting global demand, or a business exploring technical textiles, choosing the right flat knitting machine manufacturer is pivotal to your success. This comprehensive guide is designed to help you understand flat knitting machines, their applications, and why Changhua stands out as a trusted partner in 2025. We’ll dive into the mechanics, benefits, and top considerations for selecting a manufacturer, spotlighting our innovative machines at Changhua with actionable insights to inspire your inquiry.

What Are Flat Knitting Machines?

Flat knitting machines are specialized textile manufacturing tools that produce flat, weft-knitted fabrics. Unlike circular knitting machines, which create tubular fabrics, flat knitting machines excel at crafting intricate patterns and shapes, making them ideal for producing sweaters, scarves, cardigans, shoe uppers, and technical textiles. These machines utilize a needle bed, sinkers, and a carriage to form stitches, offering unmatched flexibility for both simple and complex designs.

Flat knitting machines come in various configurations, including manual, semi-automatic, and fully computerized models. Advanced versions, like those we offer at Changhua, integrate digital controls, automated yarn feeding, and tension systems for seamless, high-speed production. Their versatility spans multiple industries, including fashion, automotive, medical textiles, and home furnishings, making them indispensable for modern textile production.

Why Flat Knitting Machines Matter in 2025

In today's fast-paced textile industry, flat knitting machines are revolutionizing production with their ability to create high-quality, customizable fabrics efficiently. Here's why they're essential:

Versatility: They support a wide range of applications, from fashion apparel to technical textiles.

Precision: Computerized systems ensure intricate patterns and consistent quality.

Sustainability: Seamless knitting and intelligent programming reduce material waste and energy consumption.

Efficiency: High-speed production and automation lower labor costs and boost output.

Whether you’re a startup or an established brand, investing in the right flat knitting machine can elevate your production capabilities and market competitiveness.

Key Features of Professional Flat Knitting Machines

When evaluating flat knitting machines, several technical features define their performance and suitability for your needs. Here’s a breakdown of the critical components and capabilities to look for:

1. Knitting Technology

Modern flat knitting machines support advanced techniques like jacquard, intarsia, tuck, and pointelle. These capabilities allow for intricate designs and textures, catering to diverse applications from fashion to technical textiles.

2. Needle Type

Double latch needles are standard, enabling complex patterns and seamless transitions between colors and textures. High-quality needles ensure durability and precision.

3. Control Systems

Computerized control systems, often integrated with CAD software, provide precise pattern programming and real-time monitoring. This reduces manual intervention and enhances production accuracy.

4. Production Speed

High-speed models, like those in our Changhua lineup, can achieve knitting speeds of up to 1.6 m/s, significantly boosting output for large-scale manufacturers.

5. Fabric Width

Machines offer varying fabric widths (typically 36–100 inches), accommodating everything from narrow scarves to wide home textiles.

6. Automation and Motorization

Automated yarn feeders and motor-driven carriages streamline operations, reducing labor costs and improving efficiency.

7. Sustainability Features

Eco-friendly designs, such as seamless knitting and energy-efficient programming, align with global sustainability goals, minimizing waste and power consumption.

Why Choosing the Right Manufacturer Matters

Selecting a professional flat knitting machine manufacturer is a strategic decision that impacts your production quality, efficiency, and profitability. Here’s why your choice matters:

Quality and Durability: High-quality machines reduce downtime and maintenance costs, ensuring long-term reliability.

Technological Innovation: Leading manufacturers integrate AI, IoT, and digital controls to enhance customization and efficiency.

Cost Efficiency: The right machine balances upfront costs with long-term savings through reduced labor and material waste.

After-Sales Support: Reputable manufacturers provide training, technical support, and spare parts to minimize disruptions.

Sustainability: Eco-conscious machines align with regulatory and consumer demands for sustainable practices.

At Changhua, we understand these priorities and have built a reputation for delivering innovative, reliable, and sustainable flat knitting machines. Let’s explore why our company stands out as a global leader.

Why Choose Changhua as Your Flat Knitting Machine Manufacturer?

Based in Changshu, Jiangsu—the heart of China’s apparel industry—Changhua Smart Manufacturing Technology Co., Ltd. has over 20 years of experience in revolutionizing textile production. Our commitment to quality, innovation, and customer satisfaction makes us a trusted partner for businesses worldwide, from Europe to Asia and the USA. Here’s why Changhua is the ideal choice for your flat knitting machine needs in 2025:

1. Proven Expertise

With over two decades in the industry, we've honed our craft to deliver machines that meet the highest standards of precision and durability. Our experience ensures that every machine is built to withstand rigorous production demands.

2. Cutting-Edge Technology

Our machines integrate advanced features like high-performance sinkers, dynamic stitch control, and motor-driven carriages. These innovations enable complex designs and high-speed production while maintaining quality.

3. Comprehensive Product Range

We offer a diverse lineup of flat knitting machines tailored to various applications, from seamless garments to technical textiles. Whether you’re producing sweaters, collars, or shoe uppers, we have a solution for you.

4. Exceptional After-Sales Support

We provide 24/7 technical assistance, on-site training, and fast delivery (15–30 days) to ensure your operations run smoothly. Our global network ensures spare parts are readily available, minimizing downtime.

5. Commitment to Sustainability

Our machines are designed with eco-friendly features, such as seamless knitting to reduce waste and intelligent programming to lower energy consumption. By choosing Changhua, you’re investing in sustainable manufacturing.

6. Competitive Pricing

We offer high-quality machines at competitive prices, ensuring a strong return on investment through faster production, reduced labor costs, and minimal material waste.

Ready to explore how Changhua can transform your textile production? Contact us today to discuss your needs and request our comprehensive PDF guide, Changhua Flat Knitting Machine.pdf, or our One-Stop Programmes.pptx for a detailed overview of our solutions.

Changhua's Flat Knitting Machine Lineup: Tailored Solutions for Every Need

Our extensive range of flat knitting machines is designed to meet the diverse needs of textile businesses, from small-scale designers to large manufacturers. Below, we highlight our flagship models, each engineered for specific applications with cutting-edge technology. Click the links to explore detailed specifications and see how our machines can elevate your production.

Whole Garment Flat Knitting Machine

Our Whole Garment Flat Knitting Machine is a game-changer for producing seamless, fully fashioned garments. By knitting complete garments in a single operation, this machine eliminates the need for post-production stitching, reducing waste and labor costs. Key features include:

Seamless Production: Creates finished garments with no seams, enhancing comfort and aesthetics.

High-Speed Rollers: Achieves knitting speeds of up to 1.6 m/s for maximum efficiency.

Dynamic Stitch Control: Ensures precise stitch formation for flawless fabrics.

Applications: Ideal for fashion apparel, sportswear, and medical textiles.

Why Choose This Machine? Perfect for businesses aiming to streamline production and embrace sustainable practices. Request a quote today to see how this machine can boost your ROI.

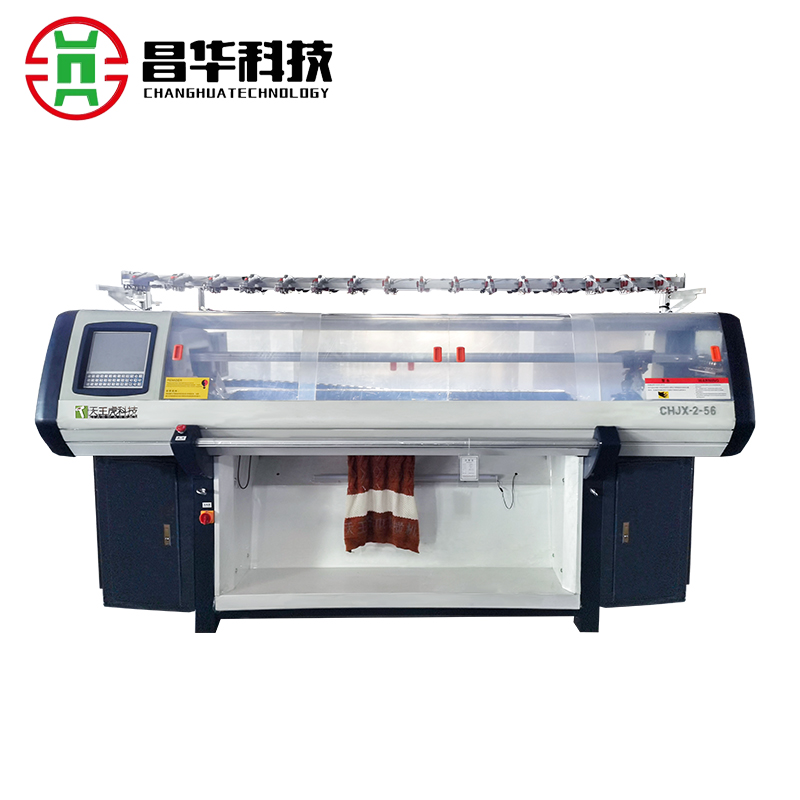

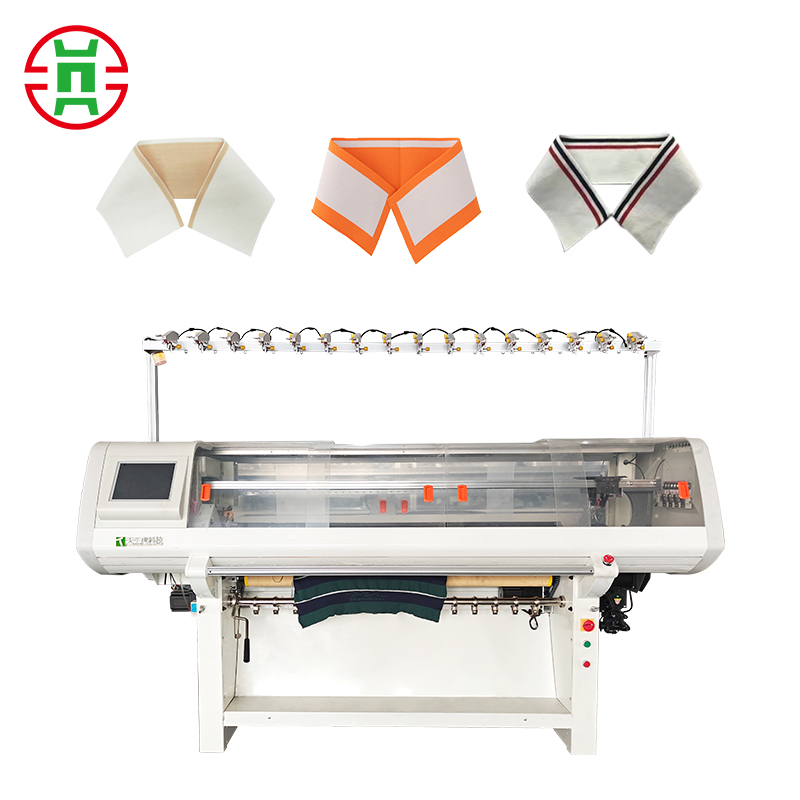

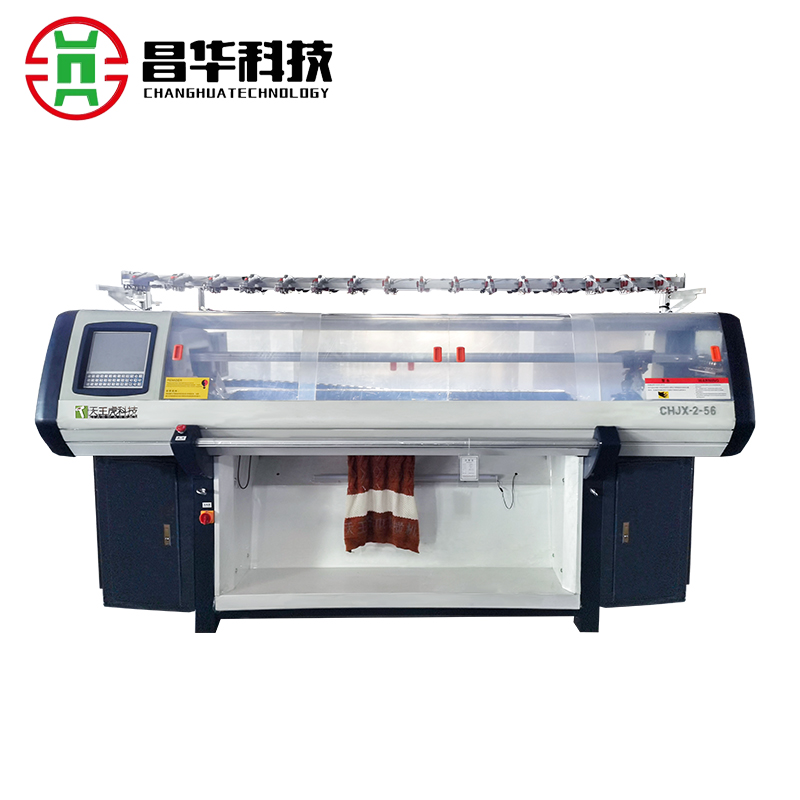

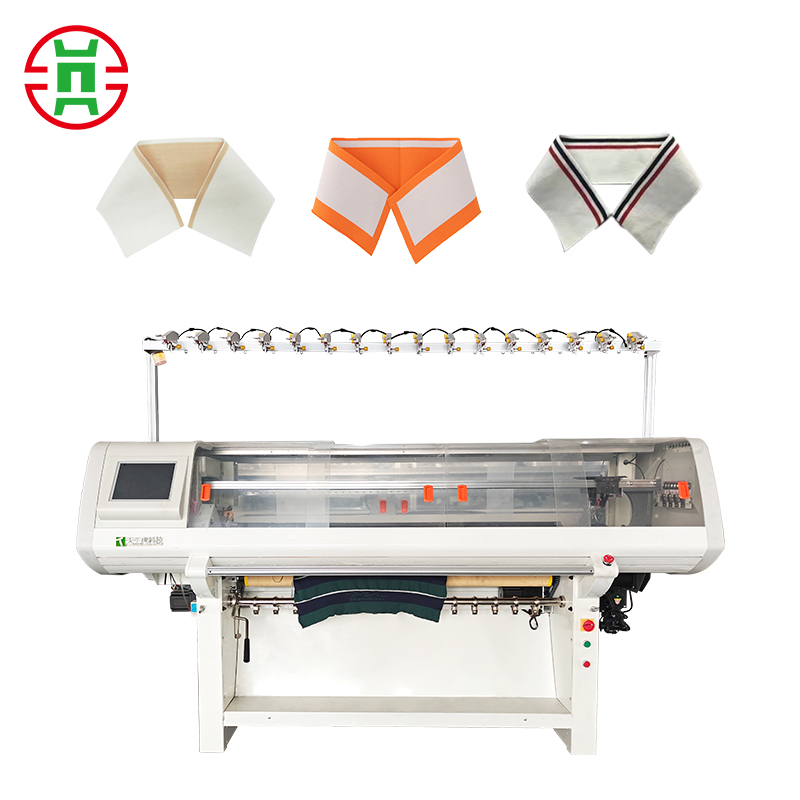

Collar Knitting Machine

Our Collar Knitting Machine is engineered for precision in producing collars and ribs. It ensures straight, flat, and high-quality outputs, making it a favorite for apparel manufacturers. Key features include:

Programmable Racking: Supports 1–2 needle adjustments for customizable designs.

Combined Cam System: Enables knit, rest, and tuck techniques for versatile patterns.

High-Performance Sinker: Enhances stitch quality and consistency.

Applications: Perfect for producing collars, cuffs, and ribs for sweaters and shirts.

Why Choose This Machine? Its user-friendly design and precision make it ideal for both beginners and seasoned manufacturers. Contact us to learn more about integrating this machine into your production line.

Shoe Upper Knitting Machine

Our Shoe Upper Knitting Machine is tailored for the footwear industry, producing seamless, durable uppers for athletic and fashion shoes. Key features include:

3D Knitting Technology: Creates complex, lightweight designs with minimal waste.

High-Speed Production: Supports high-volume output for large-scale manufacturers.

Motor-Driven Carriage: Enhances flexibility for intricate patterns like jacquard and intarsia.

Applications: Perfect for sportswear, casual footwear, and technical textiles.

Why Choose This Machine? Its advanced technology and sustainability features make it ideal for footwear brands aiming to stay ahead in 2025. Request a demo to see it in action.

Comparing Changhua to Other Leading Manufacturers

While many manufacturers offer flat knitting machines, Changhua’s combination of innovation, affordability, and customer support sets us apart. Here’s how we compare to other industry leaders in 2025:

SHIMA SEIKI (Japan)

SHIMA SEIKI is renowned for its high-end, fully fashioned machines and advanced software like SHIMA KnitManager™. While their precision is unmatched, their machines come with a higher price tag and require technical expertise. Changhua offers comparable features at a more competitive price, making our machines accessible to a broader range of businesses.

Karl Mayer (Germany)

Karl Mayer excels in warp and flat knitting machines, particularly for technical textiles. However, their focus is less on fashion applications compared to Changhua’s versatile range, which caters to both apparel and technical textiles with user-friendly designs.

Stoll (Germany)

Stoll is a leader in high-end, technologically advanced machines. While their quality is exceptional, their cost can be prohibitive for smaller businesses. Changhua provides similar advanced features, such as computerized controls and seamless knitting, at a more cost-effective price point.

Why Changhua Stands Out: Our machines combine cutting-edge technology, competitive pricing, and global support, making us the ideal choice for businesses of all sizes.  Download our PDF guide to compare our models and see why Changhua is trusted worldwide.

Download our PDF guide to compare our models and see why Changhua is trusted worldwide.

How to Choose the Right Flat Knitting Machine for Your Business

Selecting the perfect flat knitting machine depends on your production goals, budget, and application needs. Here are key factors to consider:

1. Production Scale

2. Application Needs

Choose a machine tailored to your industry:

3. Automation Level

Computerized machines, like our GE series, offer superior efficiency and precision but require a higher investment. Semi-automatic models are cost-effective for hands-on production.

4. After-Sales Support

Choose a manufacturer with robust support. At Changhua, we provide 24/7 technical assistance, on-site training, and fast spare parts delivery to ensure minimal downtime.

5. Budget and ROI

While cost is a factor, focus on long-term savings. Our machines offer competitive pricing with high ROI through faster production and reduced waste. Contact us for a customized quote tailored to your budget.

The Future of Flat Knitting Machines in 2025

The flat knitting machine market is poised for significant growth through 2033, driven by trends like automation, 3D knitting, and sustainability. Here’s what to expect:

Automation and Industry 4.0: AI and IoT integration will enhance real-time monitoring and predictive maintenance, as seen in our latest models.

3D Knitting: This technology, featured in our Shoe Upper Knitting Machine, allows for complex, waste-free designs.

Sustainability: Seamless knitting and energy-efficient programming, like those in our Whole Garment Flat Knitting Machine, align with eco-conscious consumer demands.

Customization: The rise of on-demand manufacturing favors flexible machines like ours, capable of small-batch production with intricate patterns.

By partnering with Changhua, you’re investing in future-ready technology that keeps you ahead of industry trends.  Request our One-Stop Programmes.pptx to explore how our machines align with 2025’s market demands.

Request our One-Stop Programmes.pptx to explore how our machines align with 2025’s market demands.

Take the Next Step with Changhua

Investing in a flat knitting machine is a significant decision that can transform your textile production. At Changhua, we’re committed to helping you achieve your goals with innovative, reliable, and sustainable solutions. Our machines, from the Whole Garment Flat Knitting Machine to the Shoe Upper Knitting Machine, are designed to deliver exceptional results across industries.

Ready to elevate your production? Here’s how to get started:

Explore Our Machines: Visit our website to browse our full range of flat knitting machines.

Request a Quote: Contact our team for a customized solution tailored to your needs. Get a Quote

Download Our Guides: Access our PDF and PPTX resources for in-depth insights.  Download Now

Download Now

Schedule a Demo: See our machines in action and discuss your requirements with our experts.

Don’t miss out on the opportunity to partner with a global leader in flat knitting technology.

Reach out today to learn how Changhua can drive your success in 2025 and beyond. Let’s knit the future together

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe