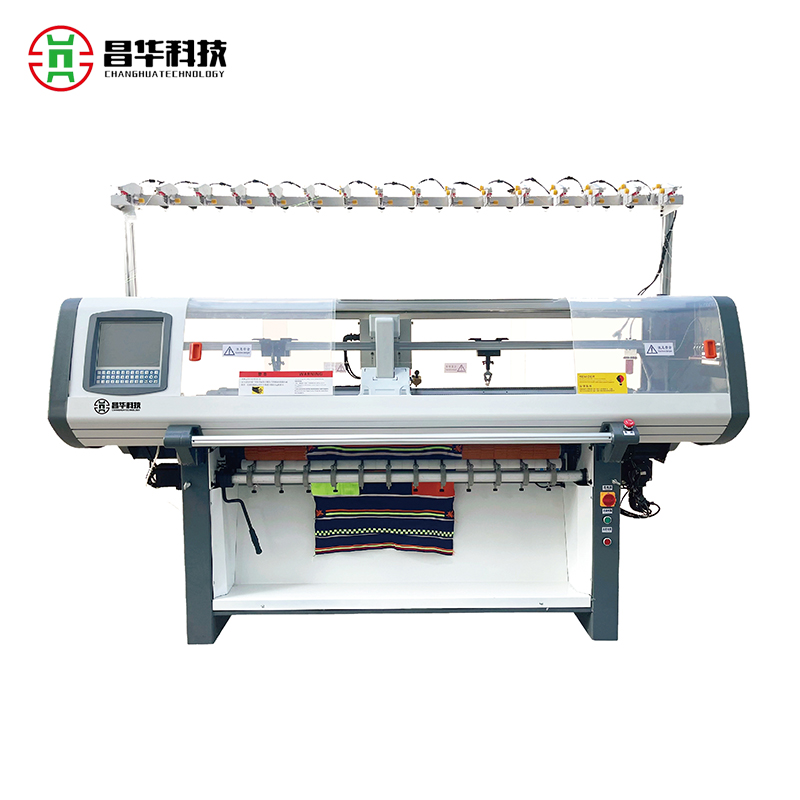

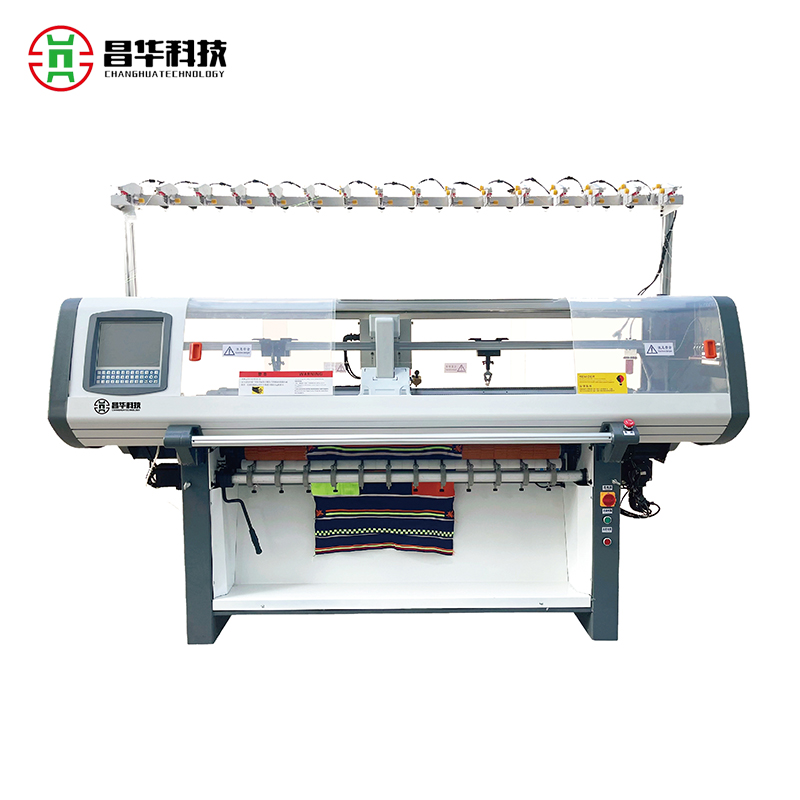

68 Inch Double System Collar Knitting Machine Description

The Collar Knitting Machine is Specially designed for knitting collar and rib; through the extreme requirements in straightness, flatness and precision of machine parts such as bed-base, guide rail, needle-bed, cam-board and cams. We solved these problems that fabric lines grain is not clear, two edges of collar are different and flatness is not enough. We make it possible to produce high-quality plain-knitting collar by using computerized jacquard machine. Changhua Collar Knitting Machine .pdf

Changhua Collar Knitting Machine .pdf

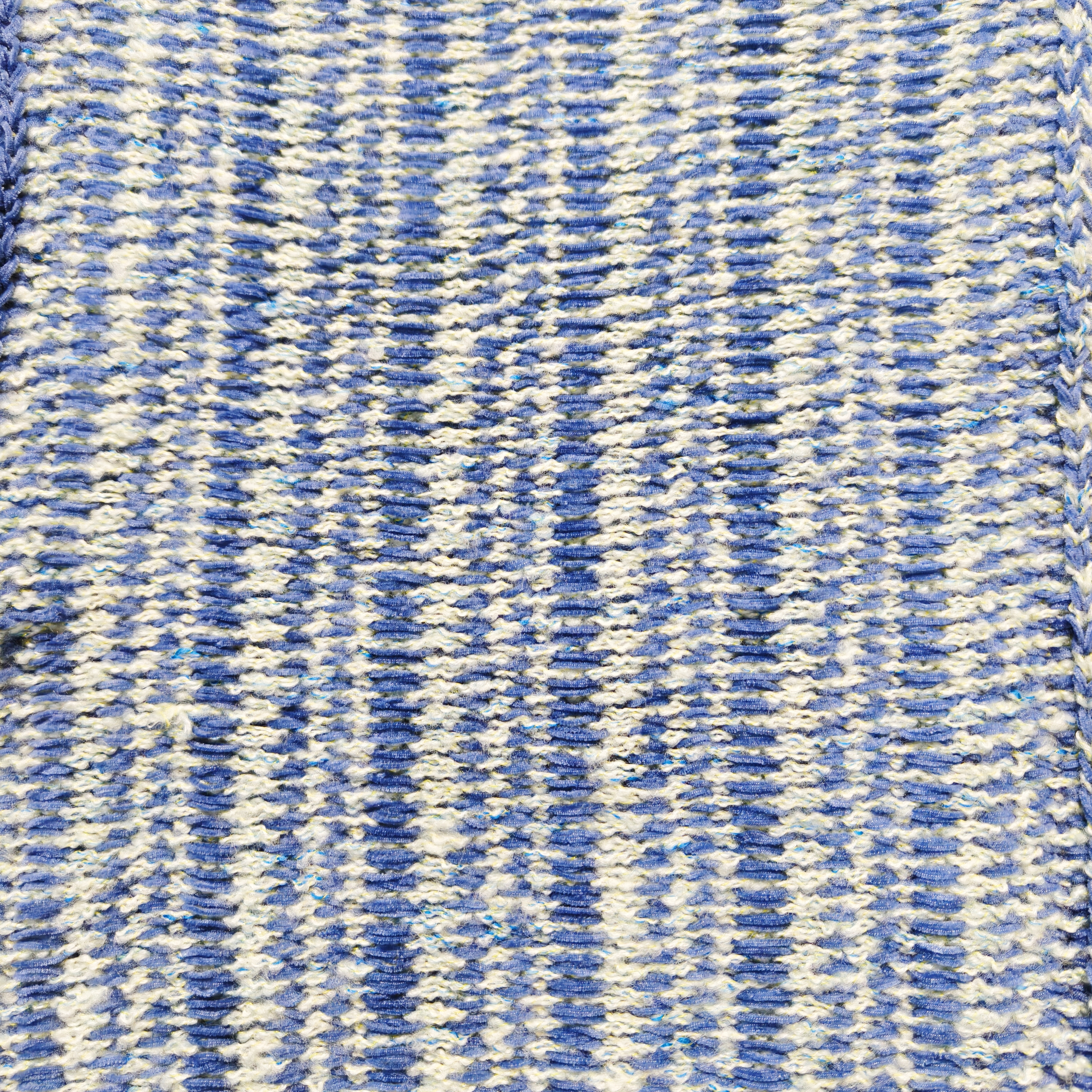

Collar Knitting Machine-White

Collar Knitting Machine-Blue

Changhua 68-inch Dual-System Fully Automatic Collar Weaving Machine (Computerized Flat Knitting Machine) Product Introduction

1. Professional Collar Manufacturing Expert

The Changhua 68-inch Dual-System Fully Automatic Collar Weaving Machine (Computerized Flat Knitting Machine) is a specialized machine developed specifically for the production of high-end collars. This machine features a custom 68-inch (172 cm) working width and dual-system synchronous knitting technology, perfectly adapting to the demands of various complex collar crafting processes. Equipped with a seventh-generation intelligent collar control system, it supports a database of over 200 standard collar shapes, enabling precise knitting of everything from round necks and V-necks to unique and creative collars.

2. Core Technology Advantages

Dual-System Collar Knitting

The main system handles the main knitting process, while the auxiliary system focuses on the collar processing, increasing production efficiency by 60%.

Intelligent Collar Recognition

The AI vision system automatically identifies collar features and adjusts knitting parameters in real time.

High-Precision Forming

Utilizing 0.02mm precision control technology, the collar curvature error is guaranteed to within ±0.3mm.

Versatile Adaptability

Compatible with a variety of materials, including wool, cotton, blends, and elastane.

Energy-Saving and High-Efficiency

Energy consumption is 40% lower than traditional equipment, and noise levels are kept below 60 decibels.

3. Professional Applications and Services

This machine is designed for the following scenarios:

High-End Collar Knitting: Meeting the stringent collar requirements of luxury brands

Professional Workwear Production: Accurately achieving standard collar shapes for uniforms

Creative Design Studio: Supporting designers in creating unique collar designs

Changhua Technology offers: √ 5-year warranty on core components √ Free collar craftsmanship training √ Lifetime technical consulting √ 48-hour emergency response

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe