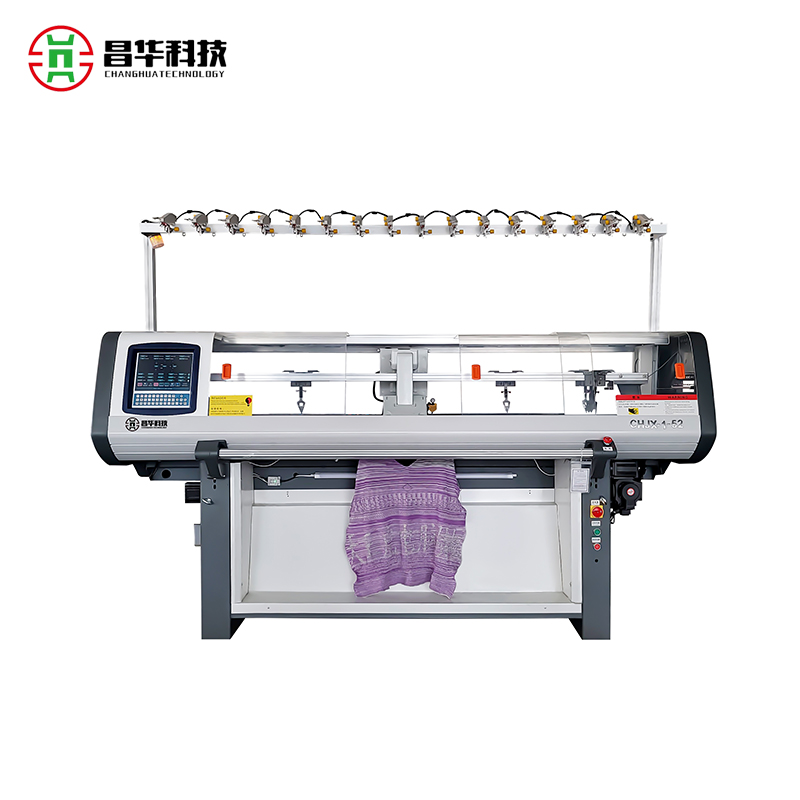

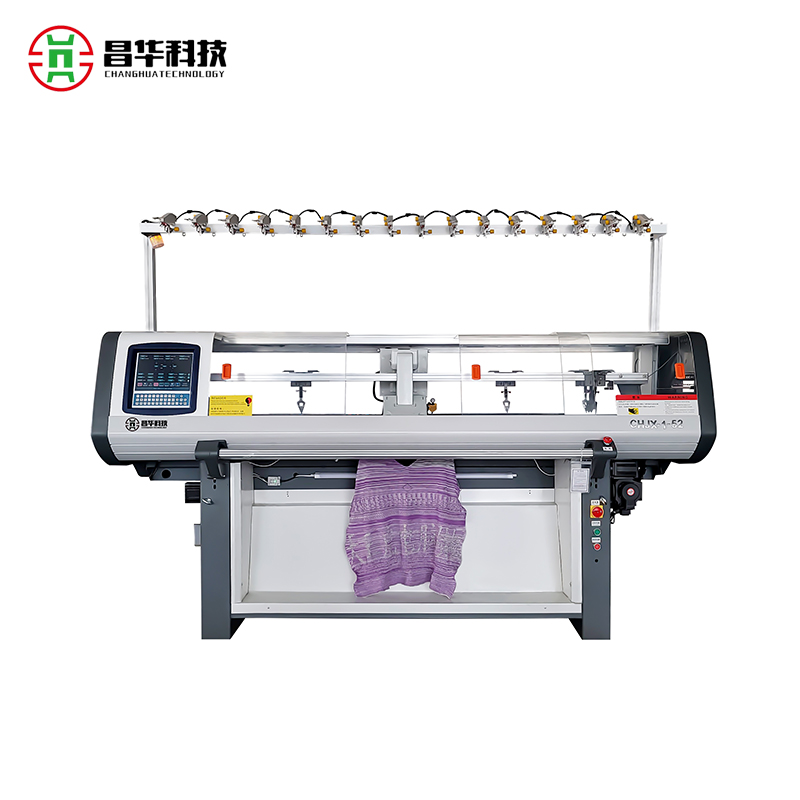

52 Inch Single System Sweater Flat Knitting Machine Description

The single-system flat knitting machine with milling-type needle bed. insert type needle bed(optional). Non-waste yarn COMB device(optional). This series adopts digital technology, which can realize the functions of the transfer truck, hole picking, jacquard, needle narrowing, and other regular pattern knitting functions of the flat knitting machine.This series can weave basic knitting patterns(full needle, single side, etc..), multi-color irregular jacquard, and twisted weft knitting.This series is suitable for knitting sweaters, blankets, scarfs, hats, and clothing accessories. Changhua Sweater Flat Knitting Machine.pdf

Changhua Sweater Flat Knitting Machine.pdf

Single System-Blue

Single System-White

Product Overview

Changhua 52-inch single-system fully automatic sweater computer flat knitting machine is a high-performance, intelligent knitting equipment designed for efficient production of various types of sweaters and knitted garments. This model adopts an advanced computer control system and is equipped with a 52-inch wide knitting platform. It is suitable for small-batch customization and large-scale production needs, and can meet the knitting requirements of different yarn materials and complex patterns.

This machine is known for its high precision and high stability. It is suitable for a variety of raw materials such as wool, cotton yarn, and blended yarn. It is widely used in garment factories, knitwear processing companies, and personalized customization studios. Its single-system design reduces the complexity of operation while ensuring production efficiency, making it an ideal choice for small and medium-sized enterprises.

Core functions and advantages

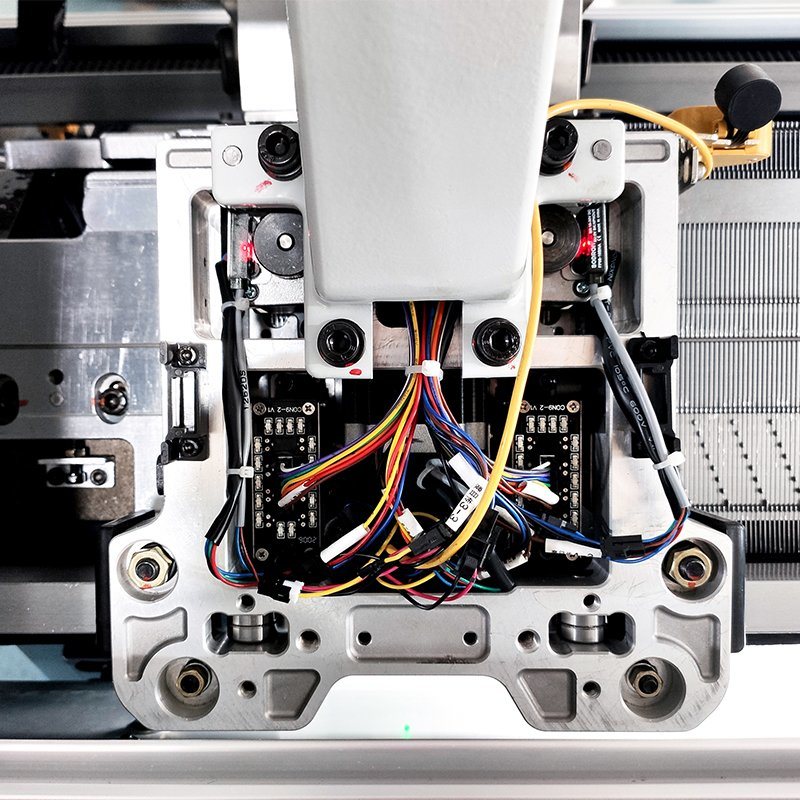

1. Fully automatic computer control

Equipped with an intelligent operating system, it supports pattern design, program editing, and real-time monitoring. Users can easily adjust knitting parameters through the touch screen to achieve complex jacquard, hollowing, twisting, and other processes.

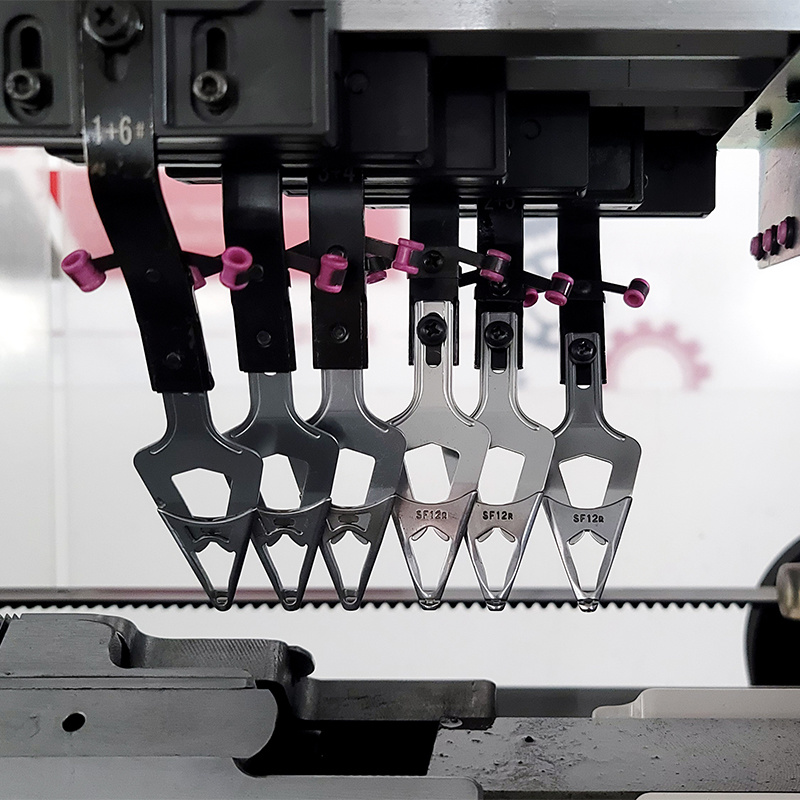

2. Efficient and stable knitting

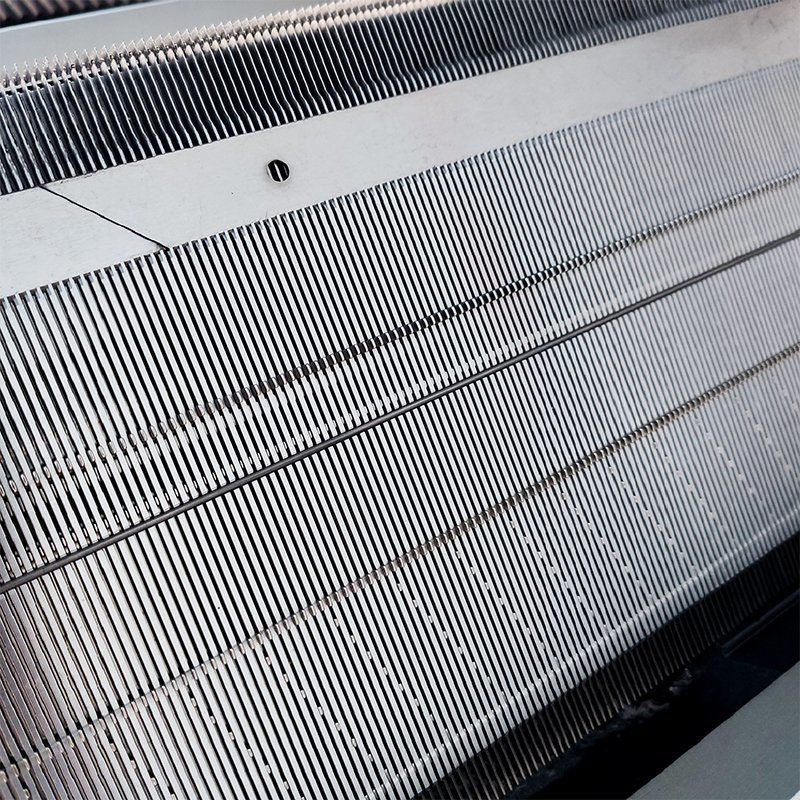

The 52-inch wide head design, coupled with a high-precision servo motor drive, ensures the stability of the needle bed under high-speed operation, reduces problems such as yarn breakage and missed needles, and improves the yield rate.

3. Multifunctional adaptability

Supports single-sided and double-sided knitting, intarsia, and return knitting processes, and can produce a variety of organizational structures such as plain stitch, ribbing, and beading to meet the diverse needs of fashionable sweaters.

4. Energy saving and low consumption

Energy-saving motors and optimized transmission systems are used to reduce energy consumption and noise, meeting the environmental protection requirements of modern factories.

Technical parameters and after-sales service

Weaving width: 52 inches (132 cm)

Needle gauge: 5G-12G (optional)

Control system: industrial-grade computer, supports USB import of patterns

Applicable yarn: 3Nm-12Nm

Power supply: 220V/380V, 50Hz

Changhua provides lifetime technical support and 2-year core component warranty, and is equipped with a professional training team to ensure that users can get started quickly. In addition, multiple service outlets across the country provide timely maintenance and parts supply to ensure worry-free production.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe