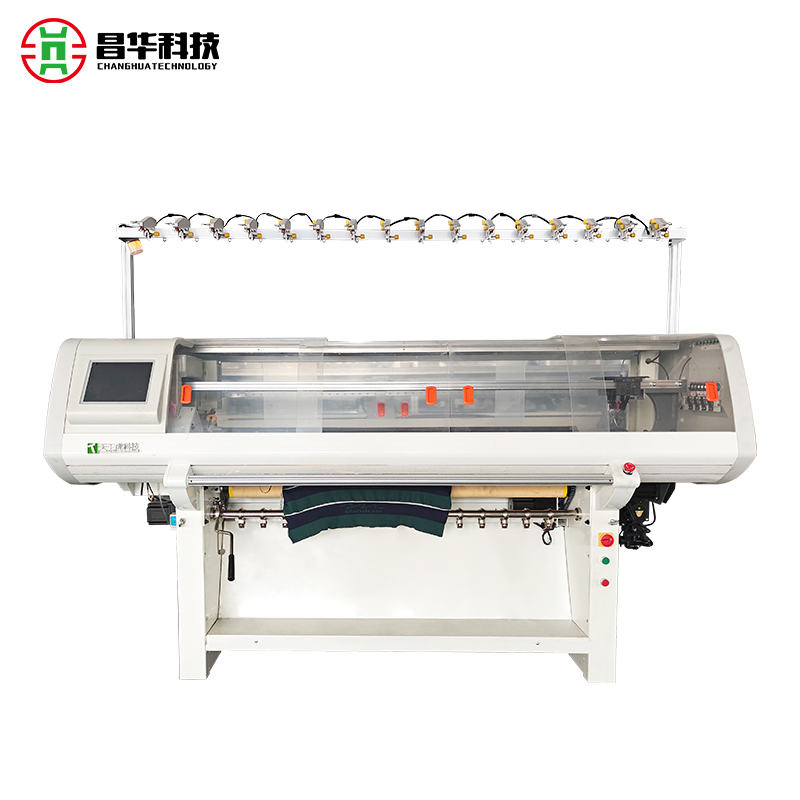

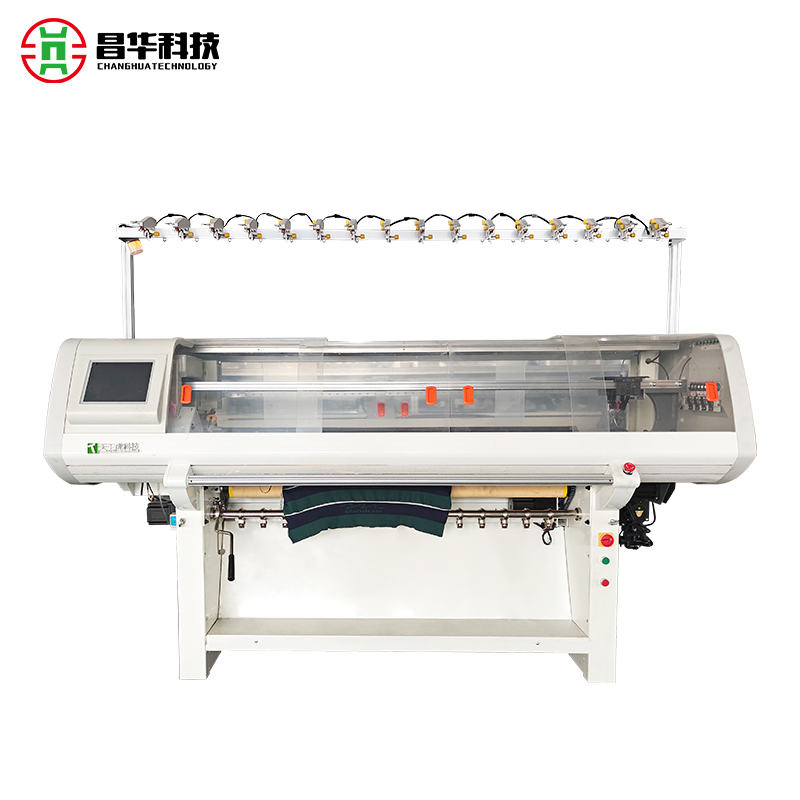

80 Inch Single System Collar Knitting Machine Description

The Collar Knitting Machine is Specially designed for knitting collar and rib; through the extreme requirements in straightness, flatness and precision of machine parts such as bed-base, guide rail, needle-bed, cam-board and cams. We solved these problems that fabric lines grain is not clear, two edges of collar are different and flatness is not enough. We make it possible to produce high-quality plain-knitting collar by using computerized jacquard machine. Changhua collar knitting machine .pdf

Changhua collar knitting machine .pdf

Changhua 80-inch Single-System Fully Automatic Collar Weaving Machine (Center Flat Knitting Machine) Product Introduction

1. An Innovator in Professional Collar Manufacturing

The Changhua 80-inch Single-System Fully Automatic Collar Weaving Machine (Center Flat Knitting Machine) is the company's latest professional collar production equipment launched in 2024. This machine features an industry-leading 80-inch (203 cm) ultra-wide width design and high-precision single-system knitting technology, specifically developed for high-volume, high-quality collar production. Equipped with an eighth-generation intelligent collar control system and a 19-inch industrial-grade touchscreen, it supports a database of over 300 standard collar types, covering a full range of product categories, from basic styles to creative designs.

2. Breakthrough Technological Advantages

Ultra-Wide Efficient Production

An 80-inch working width can simultaneously produce 8-10 standard collars, with a daily production capacity exceeding 5,000 pieces.

Intelligent Single System Optimization

Utilizing a next-generation single-system architecture, operating efficiency is 45% higher than traditional models.

Precise Collar Control

A 0.01mm-level high-precision sensor ensures collar curvature error within ±0.2mm.

Versatile Yarn Compatibility

Supports multiple needle gauges from 5G to 18G, perfectly adapting to a variety of raw materials, from cashmere to functional fibers.

Energy-Saving and Environmentally Friendly Design

Energy consumption is reduced by 35%, and noise levels are kept below 58 decibels, meeting international environmental standards.

3. Professional Applications and Service Innovations

This model is designed for the following professional scenarios:

Collar Design Support for Large Apparel Groups: Meeting the collar design needs of companies with annual production volumes exceeding one million pieces.

Standardized Production of Professional Attire: Accurately achieving collar standards for various types of uniforms.

High-end Custom Workshop: Supports designers in realizing their unique collar designs

Changhua Technology offers: √ 5-year warranty for the entire machine √ Free collar shaping training √ Lifetime remote technical support √ 24-hour rapid response

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe