Three System Computerized Knitting Machine Manufacturer & Supplier

Changshu Changhua Smart Manufacturing Technology Co., Ltd. is located in Changshu, Jiangsu, the birthplace of the clothing industry. It is a professional large-scale knitting garment machinery manufacturer, which has been developing for more than 20 years, with independent research and creation.

Company Profile

Changhua Technology is a high-tech enterprise focusing on the research and development, production and sales of computer flat knitting machines (computer knitting flat knitting machines), and is committed to providing intelligent and efficient knitting equipment solutions for the global textile industry. The company has many years of technical accumulation and industry experience, and its products are widely used in sweaters, knitted garments, footwear, household goods and other fields, with customers in China and overseas markets.

Changhua Technology takes technological innovation and quality priority as its core competitiveness, continuously optimizes product performance, and promotes the automation upgrade of the knitting industry. The company has a complete production base, a professional R&D team and a strict quality inspection system to ensure that each equipment has high stability and long life.

Core products and technical advantages

1. Full range of computer flat knitting machine products

Changhua Technology provides computer flat knitting machines of various specifications, including single-system, dual-system and multi-system models, with knitting widths ranging from 36 inches to 72 inches, which can meet different production needs. The main products such as the 52-inch single-system fully automatic sweater flat knitting machine are highly recognized by the market for their high cost performance and stable performance.

2. Intelligent control system

The computerized flat knitting machine control system independently developed by the company supports complex pattern programming, real-time monitoring and remote maintenance, has a friendly operation interface, can adapt to a variety of yarns, and improves production flexibility and efficiency.

3. Energy-saving and efficient design

The servo motor drive and optimized transmission structure are used to reduce energy consumption and noise, meet the environmental protection requirements of modern factories, and at the same time improve the stability of equipment operation and reduce maintenance costs.

Market application and service system

1. Global market layout

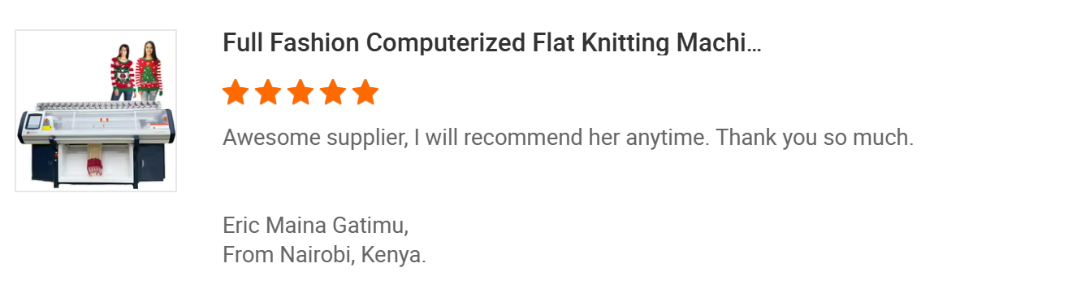

Changhua Technology's equipment not only occupies an important share in the domestic market, but is also exported to Southeast Asia, South America, the Middle East and other regions, helping global knitting companies to improve their competitiveness.

2. Industry solutions

For different customers such as garment factories, knitwear processing companies, and custom studios, we provide personalized equipment configuration and process support to help customers achieve efficient production.

3. Complete after-sales service

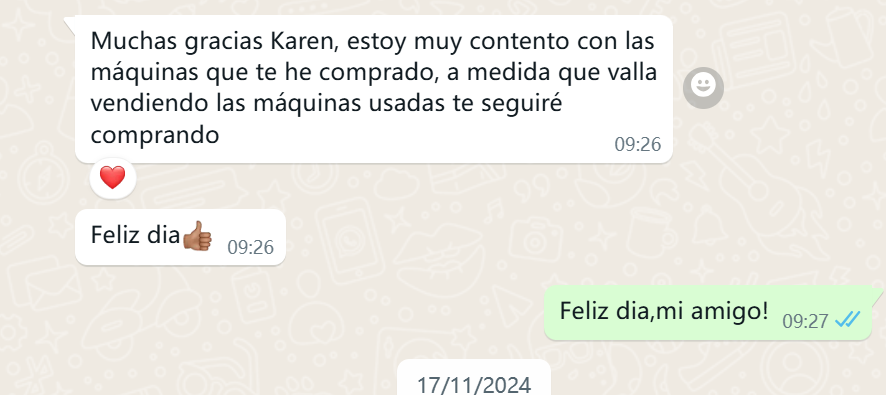

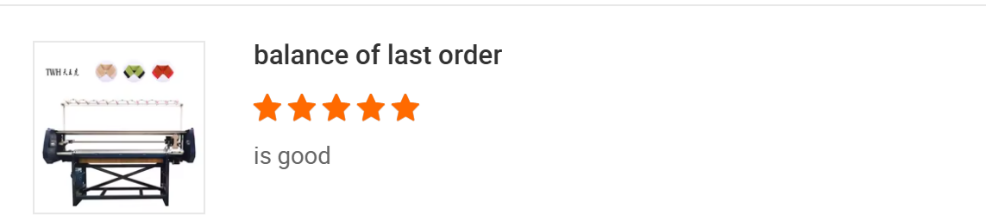

The company has established a 24-hour response mechanism to provide equipment installation, operation training, technical support and lifelong maintenance to ensure that customers have worry-free production.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe