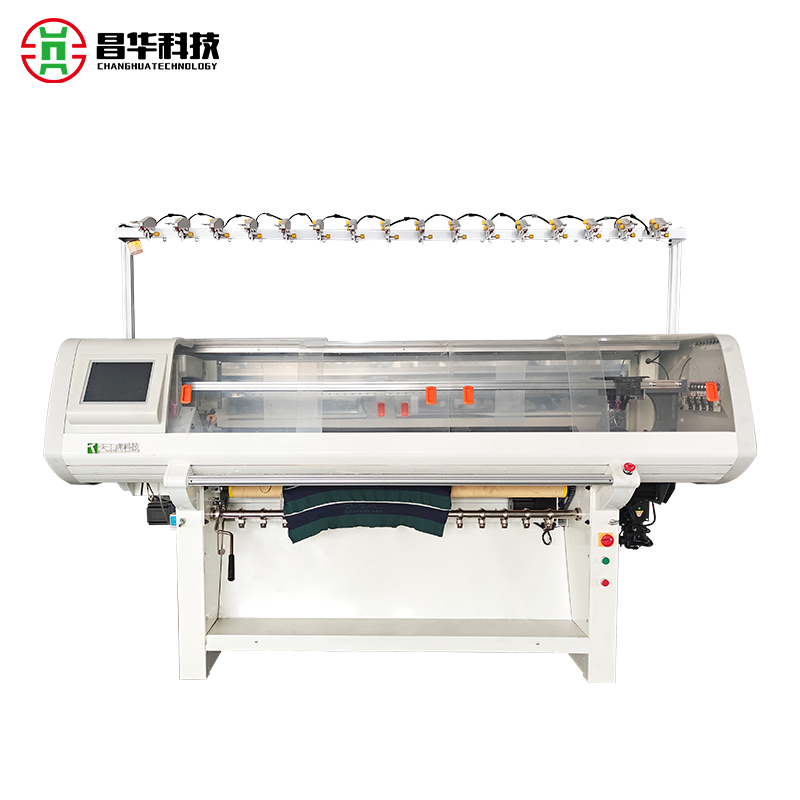

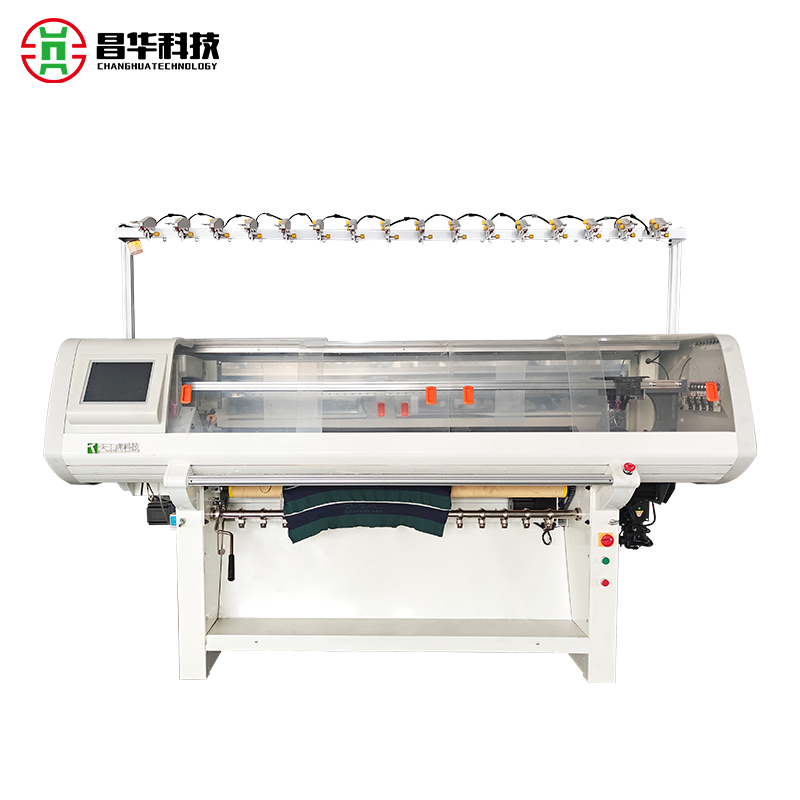

100 Inch Three System Collar Knitting Machine Description

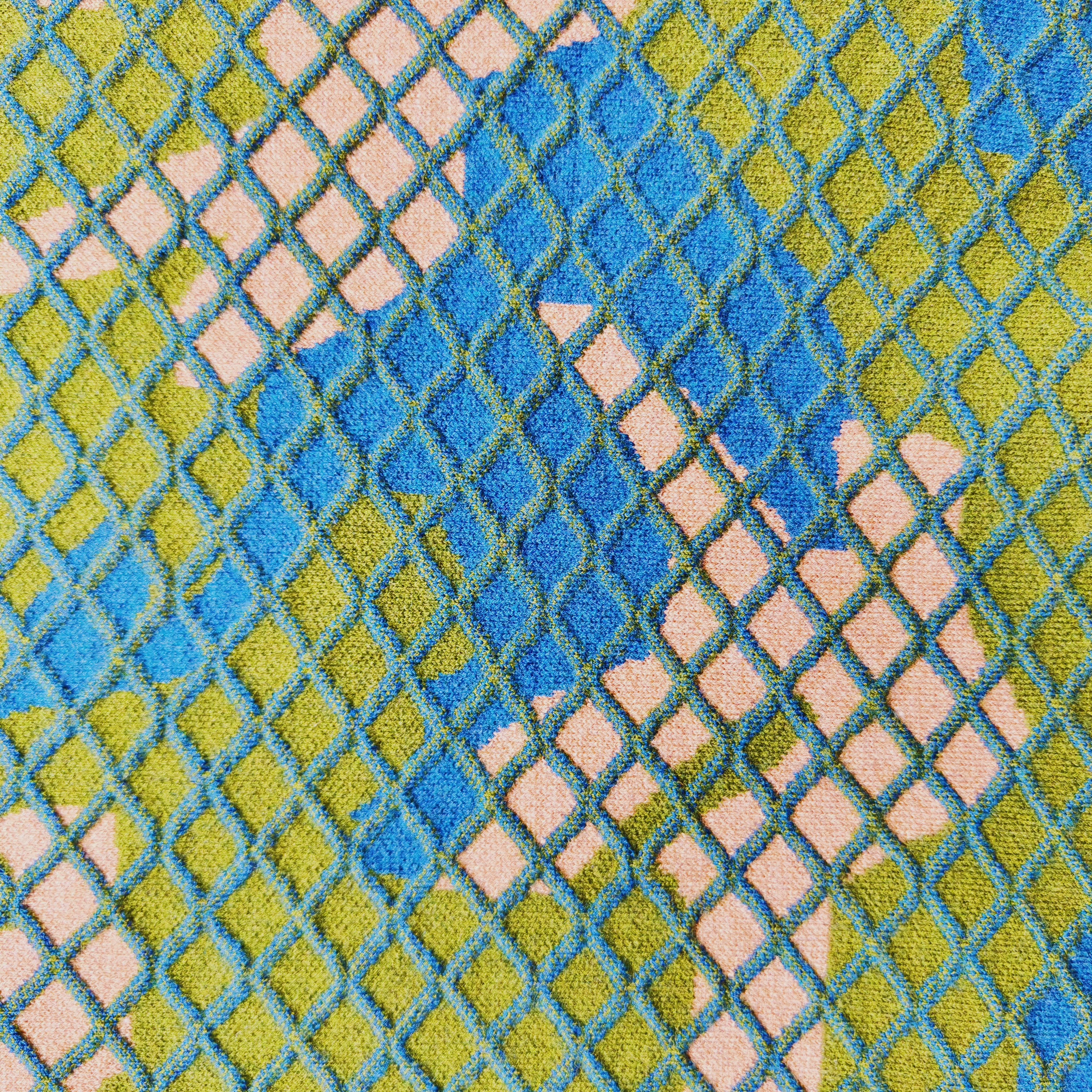

The Collar Knitting Machine is Specially designed for knitting collar and rib; through the extreme requirements in straightness, flatness and precision of machine parts such as bed-base, guide rail, needle-bed, cam-board and cams. We solved these problems that fabric lines grain is not clear, two edges of collar are different and flatness is not enough. We make it possible to produce high-quality plain-knitting collar by using computerized jacquard machine. Changhua collar knitting machine .pdf

Changhua collar knitting machine .pdf

Changhua 100-inch Three-System Fully Automatic Collar Weaving Machine (Center Flat Knitting Machine) Product Introduction

1. Industry-Disruptive Technological Breakthrough

The Changhua 100-inch Three-System Fully Automatic Collar Weaving Machine (Center Flat Knitting Machine), launched in 2024, is the world's first specialized ultra-wide collar production machine. It utilizes revolutionary three-system collaborative knitting technology. Equipped with the industry's largest 100-inch (254 cm) ultra-wide knitting platform and a ninth-generation AI intelligent control system, it achieves an ultimate accuracy of ±0.01mm, redefining the standard for collar production. The machine innovatively integrates three functional modules: knitting, forming, and quality inspection, increasing traditional collar production efficiency by 500%.

2. Six Core Competitive Advantages

Three-System Intelligent Collaboration

The main system is responsible for the main weaving process, the auxiliary system focuses on fine processing, and the quality inspection system provides real-time monitoring. Daily collar production exceeds 8,000.

Ultra-Wide Efficient Production

A 100-inch working width can simultaneously produce 12-15 standard collars, meeting the needs of ultra-large-scale production.

AI Visual Quality Inspection

Integrated high-precision industrial cameras enable automatic detection of micron-level defects.

Fully Automatic Intelligent Machine Adjustment

Automatically optimizes process parameters through big data analysis, reducing changeover time to 5 minutes.

Multi-Function Material Adaptation

Supports a full range of needle gauges from 3 to 24G, perfectly handling a full range of yarns from cashmere to carbon fiber.

Green Intelligent Manufacturing Benchmark

Energy consumption is reduced by 65%, and scrap rate is kept below 0.5%.

3. Globally Leading Application Solutions

This model is designed for the following scenarios:

Global Apparel Giants: Meeting the global supply chain needs of fast fashion brands such as ZARA and UNIQLO.

National Strategic Project: Supporting the production of functional collars for specialized fields such as military and aerospace.

Future Lab: Conducting cutting-edge research in 4D smart collars and bio-textiles.

Changhua Technology offers:

√ Industry-first 8-year extended warranty

√ Exclusive "Platinum" VIP service

√ 24/7 global technical support

√ Lifetime free system upgrades

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe