80 Inch Whole Garment Computerized Flat Knitting Machine Description

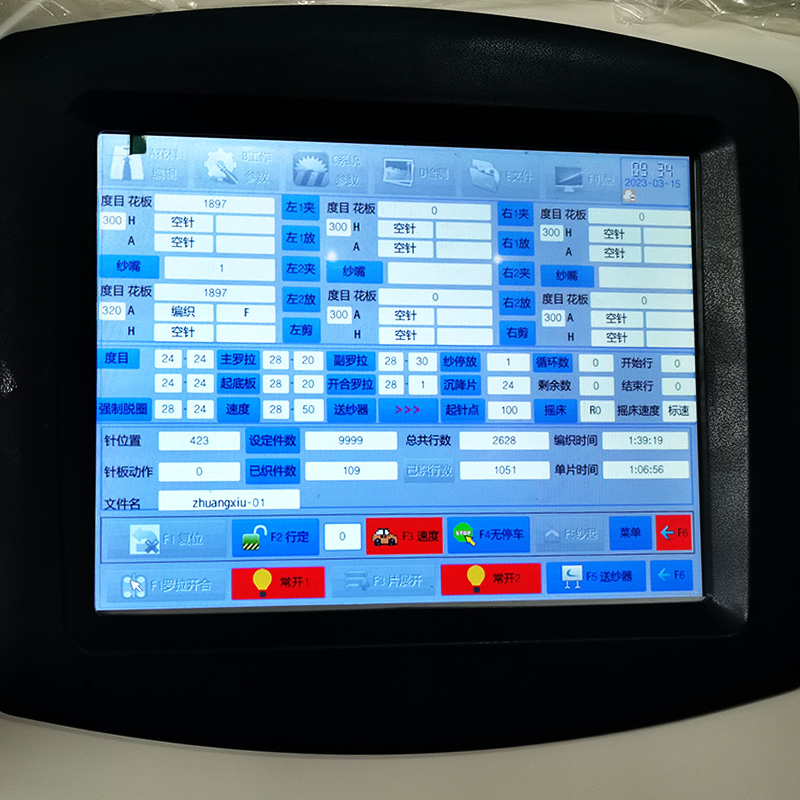

The Whole Garment Flat Knitting Machine with 5.0 inch motor control small carriage: High efficiency, good stability, alarm when abnormal, prevent needle crash.

Fully formed combined roller: The transverse tension and front and rear bed are separately controlled. lt can realize the independent control of a variety of pulling forces and front and rear beds in one line, and meet the pulling force requirements of different organizations. lt is a necessary configuration for whole garment.

Bilateral needle closure: The left and right sides of the same row receive the needle at the same time, high speed and efficiency.

Dynamic density: Different stitch in one row

Force loop-off technology: Avoid stitch missing problem

Zero waiting racking: Transfer and knit occurs synchronous, more efficient.

Various kinds of knitting: Pointelle, tuck, intarsia,full needle, all kinds of jacquard, apparent shape, open needle, hidden shape and so on

Wide application: Use wool, cashmere, cotton, chemicalfiber, silk and all kinds of blended yarn.

Longer life: Needle plate is oiled automatically to reduce the wear between needle and needle bed and prolong service life. Changhua whole garment sweater flat knitting machine.pdf

Changhua whole garment sweater flat knitting machine.pdf

Changhua 80-inch Fully Automatic Computerized Flat Knitting Machine Product Introduction

1. Revolution in Garment Manufacturing Technology

The Changhua 80-inch Fully Automatic Computerized Flat Knitting Machine utilizes revolutionary "yarn-in, garment-out" integrated technology and features an ultra-wide 80-inch (203 cm) working width. This machine integrates the entire knitting, sewing, and ironing process, and is equipped with a ninth-generation AI intelligent control system, achieving precision control of ±0.01mm. Its daily production capacity reaches 8,000 finished garments, increasing production efficiency by 500% compared to traditional processes.

2. Six Core Advantages

Fully Automated Process:

Seven processes are integrated into one, directly producing marketable garments.

Intelligent Pattern Adaptation:

AI algorithms automatically adjust sizing with an error of ≤±0.5cm.

Ultra-Efficient Production:

A single machine replaces five traditional machines, reducing labor requirements by 85%.

Precision Molding System:

0.01mm-level sensors ensure the quality of each garment.

Multi-Function Process Library:

Over 200 pre-set garment processes support complex styles.

Green Smart Manufacturing:

Energy consumption reduced by 55%, scrap rate <1%.

3. Intelligent Production Solutions

This model is designed for:

Changhua Technology provides: √ 7-year extended warranty √ Intelligent operation and maintenance system √ Process upgrade services √ 24-hour technical support

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe