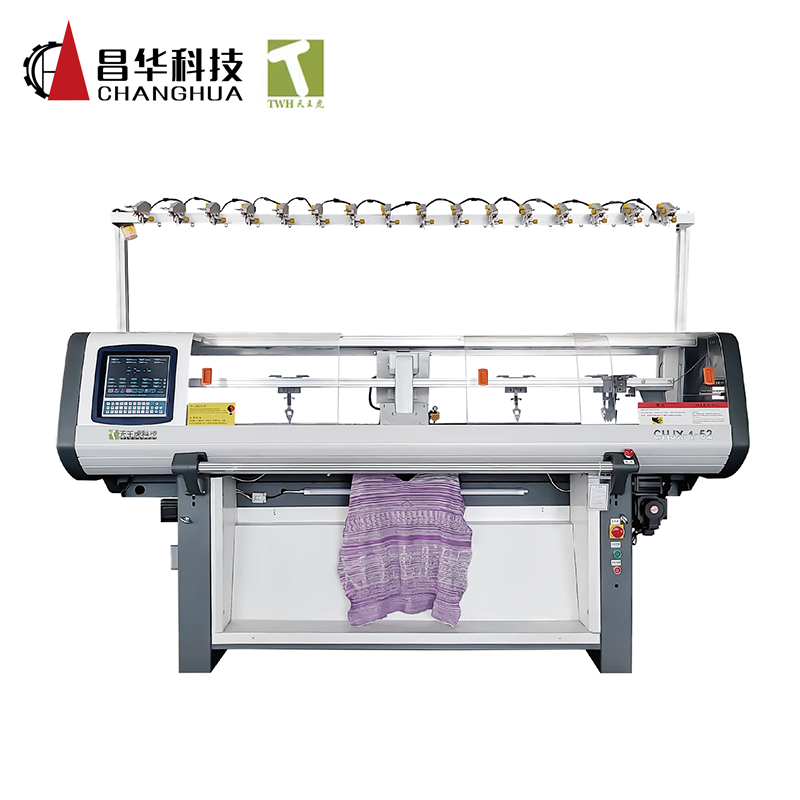

60 Inch Single System Hat Flat Knitting Machine Description

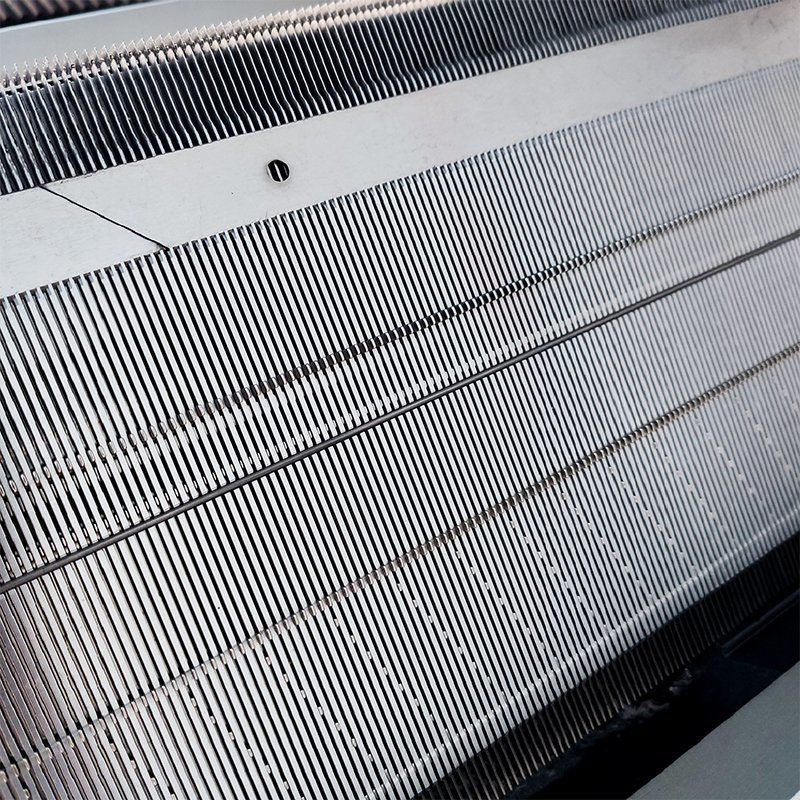

The single-system flat knitting machine with milling-type needle bed. insert type needle bed(optional). Non-waste yarn COMB device(optional). This series adopts digital technology, which can realize the functions of the transfer truck, hole picking, jacquard, needle narrowing, and other regular pattern knitting functions of the flat knitting machine. This series can weave basic knitting patterns(full needle, single side, etc..), multi-color irregular jacquard, and twisted weft knitting. This series is suitable for knitting sweaters, blankets, scarfs, hats, and clothing accessories. Changhua Single System Hat knitting machine.pdf

Changhua Single System Hat knitting machine.pdf

Changhua 60-inch Single-System Fully Automatic Knitted Hat Computerized Flat Knitting Machine Product Introduction

1. An Innovator in Professional Knitted Hat Production

The Changhua 60-inch Single-System Fully Automatic Knitted Hat Computerized Flat Knitting Machine, launched in 2023, is a professional-grade hat production machine. Featuring an optimized 60-inch (152 cm) width and high-precision single-system knitting technology, this machine is designed specifically for medium- to large-scale hat manufacturers. Equipped with the eighth-generation intelligent hat shape control system, it supports over 200 standard hat shape presets, covering a full range of product categories from basic to complex designs, redefining the standard for knitted hat production efficiency.

2. Six Core Competitive Advantages

Ultra-Wide Efficient Production

A 60-inch working width can produce 6-8 standard hats simultaneously, with a daily production capacity exceeding 3,000 hats.

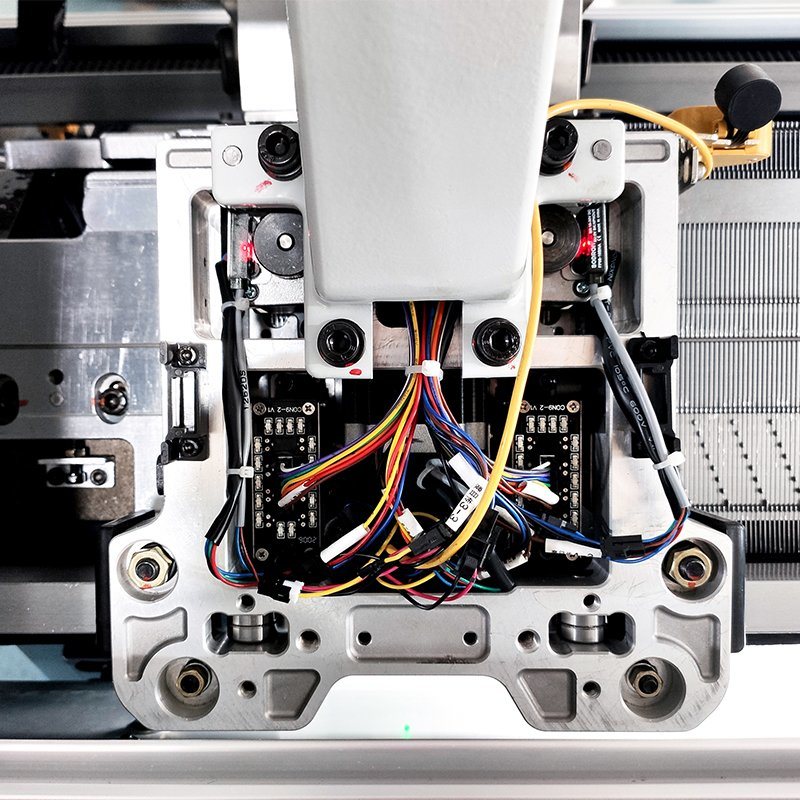

Intelligent Single System Optimization

The next-generation single system architecture improves operating efficiency by 50% compared to traditional models.

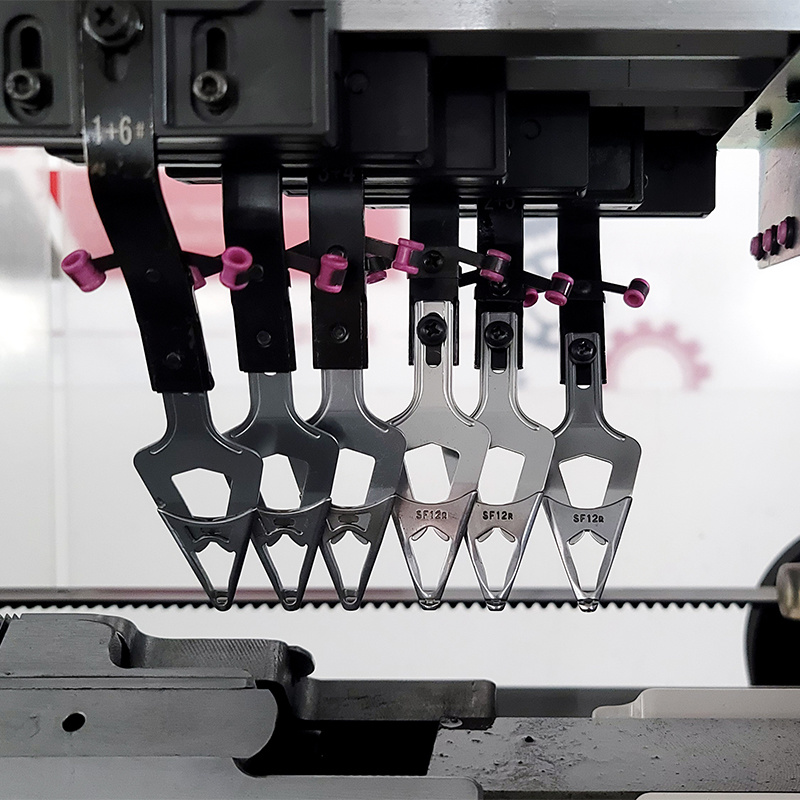

Precision Forming Control

A 0.02mm high-precision sensor ensures hat curvature error within ±0.3mm.

Versatile Adaptability

Supports multiple needle gauges from 5 to 16G, perfectly adapting to wool, cotton, linen, and functional fibers.

AI Intelligent Detection

An integrated visual recognition system enables automated detection of micron-level defects.

Energy-Saving and Environmentally Friendly Design

Energy consumption is reduced by 45%, and noise levels are kept below 60 decibels.

3. Professional Applications and Value-Added Services

This model is designed for the following professional scenarios:

Large-Scale Headwear Production: Meets the production needs of top-tier companies with annual production volumes exceeding one million.

Sports Brand Support: Accurately achieves standardized production of various sports hat styles.

Fashion Creative Workshop: Supports designers in creating unique hat shapes

Changhua Technology offers: √ 4-year warranty on all hats √ Free hat shaping training √ Lifetime remote technical support √ 48-hour rapid response

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe