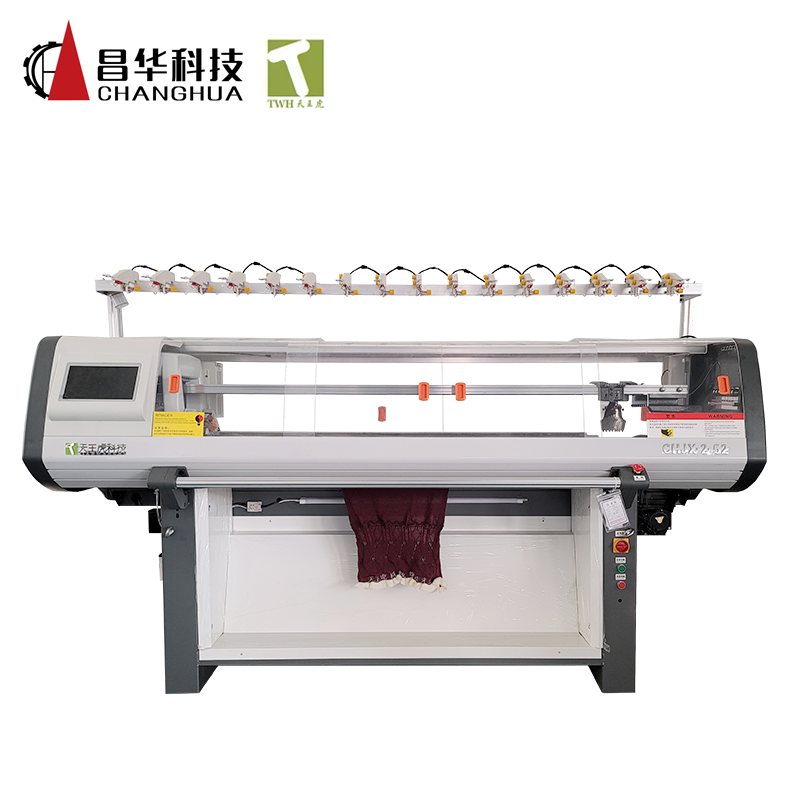

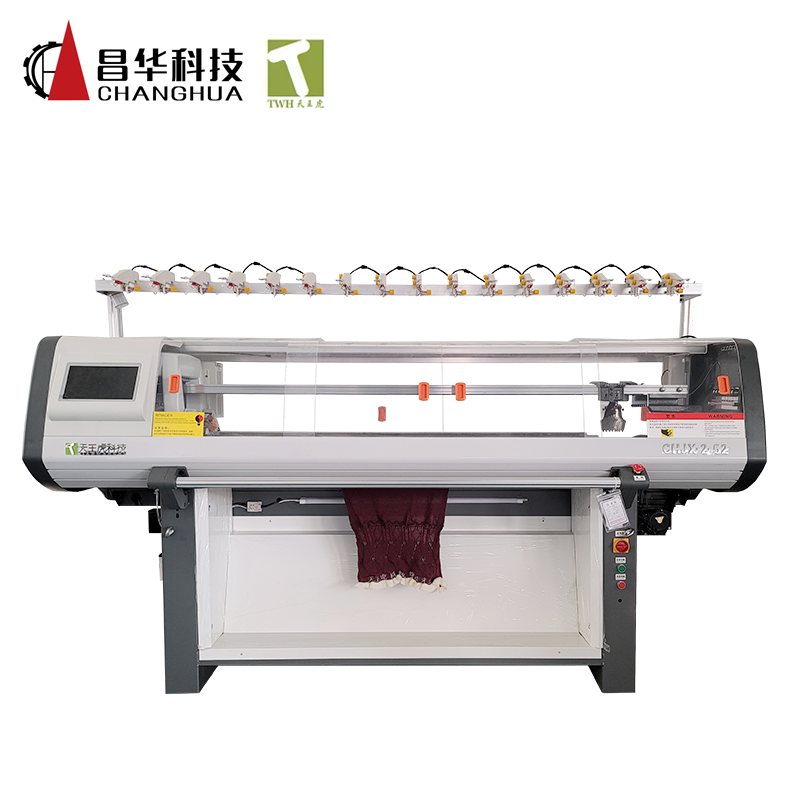

52 Inch Simple Double System Hat Knitting Machine Description

The simple double system flat knitting machine with milling type needle bed. Insert type needle bed (optional). non-waste yarn COMB device (optional). This series adopts digital technology, which can realize the functions of transfer, tuck, hole picking, jacquard, needle narrowing, and other regular pattern knitting functions of the flat knitting machine. The machine can automatically scan the knitting file before starting knitting and automatically select the system suitable for the pattern, thus genuinely realizing the fast rotation of the machine carriage with high speed and high efficiency. Changhua Simple double system hat knitting machine.pdf

Changhua Simple double system hat knitting machine.pdf

Changhua 52-inch Direct-Double System Fully Automatic Knitted Hat Computerized Flat Knitting Machine Product Introduction

1. Professional Knitted Hat Manufacturing Expert

The Changhua 52-inch Direct-Double System Fully Automatic Knitted Hat Computerized Flat Knitting Machine is a professional-grade production machine developed specifically for hats. This machine features an optimized 52-inch (132 cm) width design and innovatively incorporates direct-drive dual-system technology, perfectly adapting to the production needs of all types of knitted hats. Equipped with a seventh-generation intelligent hat pattern control system, it supports a database of over 150 standard hat patterns, covering a full range of product categories, from basic styles to complex designs.

2. Five Core Competitive Advantages

Direct-Drive Dual-System Efficient Production

The dual systems operate synchronously, increasing production efficiency by 70% compared to a single system and enabling daily production capacity exceeding 2,500 hats.

Intelligent Hat Shape Recognition

The AI vision system automatically identifies hat shape features and adjusts knitting parameters in real time.

Precision Molding Technology

Utilizing 0.03mm high-precision control, the hat shape curvature error is ensured to within ±0.5mm.

Versatile Yarn Compatibility

Supports multiple needle gauges from 5-14G, perfectly adapting to functional yarns such as wool and blends.

Energy-Saving and Quiet Design

Energy consumption is reduced by 40%, with noise levels kept below 62 decibels.

3. Professional Applications and Service Guarantee

This model is designed for the following scenarios:

Professional hat manufacturers: Meeting the needs of large-scale standardized production

Sports brand production: Accurately meeting the technical requirements of various sports hat shapes

Fashion designer studios: Supporting the R&D and prototyping of creative hat shapes

Changhua Technology provides:

√ 3-year warranty for the entire machine

√ Free hat molding training

√ Lifetime remote technical support

√ 24-hour rapid response

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe