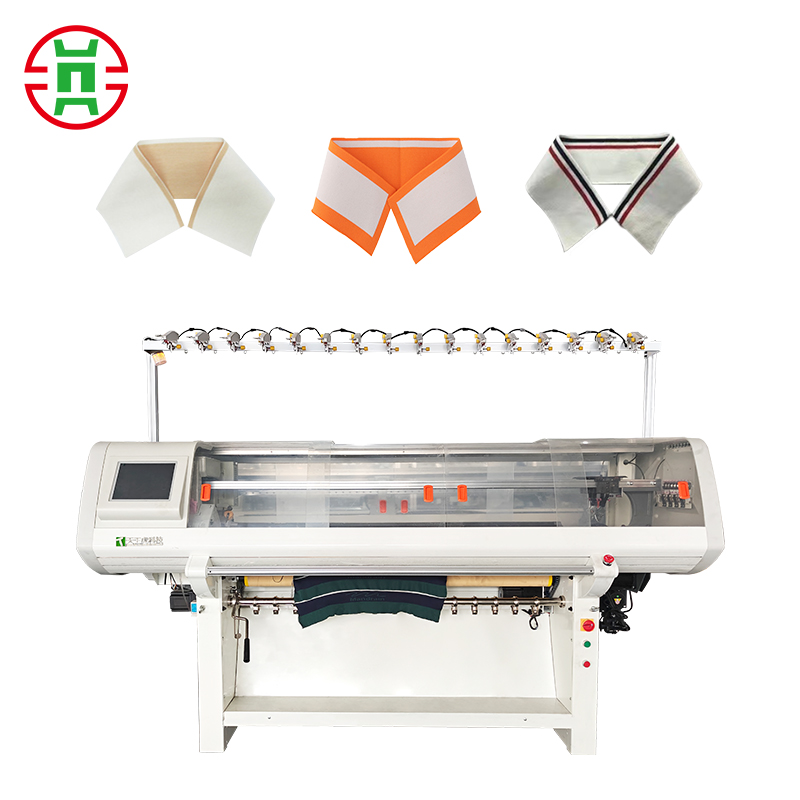

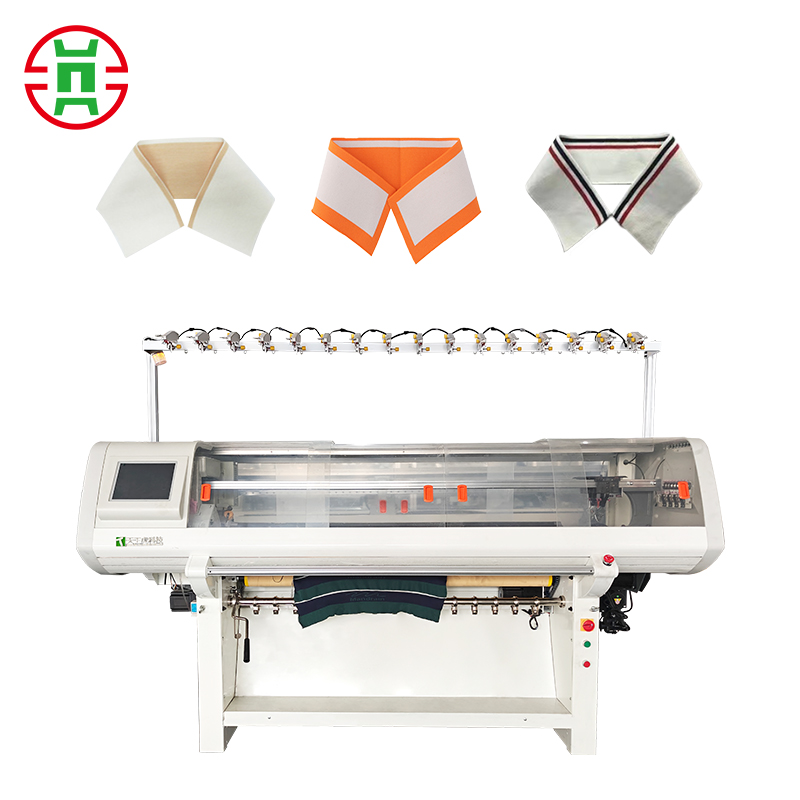

120 Inch 1+1 System Collar Knitting Machine Description

The Collar Knitting Machine is Specially designed for knitting collar and rib; through the extreme requirements in straightness, flatness and precision of machine parts such as bed-base, guide rail, needle-bed, cam-board and cams. We solved these problems that fabric lines grain is not clear, two edges of collar are different and flatness is not enough. We make it possible to produce high-quality plain-knitting collar by using computerized jacquard machine. Changhua collar knitting machine .pdf

Changhua collar knitting machine .pdf

Changhua 120-inch 1+1 System Fully Automatic Collar Weaving Machine (Computerized Flat Knitting Machine) Product Introduction

1. A Milestone in the Industry

The Changhua 120-inch 1+1 System Fully Automatic Collar Weaving Machine (Computerized Flat Knitting Machine) is the company's latest development in 2024. It is the world's first ultra-wide intelligent collar production machine, featuring a pioneering 120-inch (305 cm) weaving width, the industry's widest. This machine innovatively integrates a "1+1" dual-system architecture with ultra-wide technology. The primary system handles high-speed weaving, while the secondary system focuses on precision forming, resulting in an 800% increase in production efficiency compared to traditional equipment. Equipped with a 10th-generation quantum computing control system, it achieves nanometer-level (±0.005mm) weaving accuracy, redefining the industry standard for collar manufacturing.

2. Eight Core Technological Advantages

Ultra-Wide Revolution

A 120-inch working format can simultaneously produce 20 standard collar styles, with a single machine's daily production capacity exceeding 12,000 pieces.

1+1 Intelligent System

Dual systems work together to achieve a knitting speed of 2.5 meters per second, reducing pattern change time to 3 minutes.

Quantum-Level Control

Utilizing quantum sensing technology, achieves the industry's highest precision control of ±0.005mm.

AI Holographic Quality Inspection

Integrated industrial-grade holographic projection system enables 3D defect detection.

Metamaterial Adaptation

Supports knitting of a full range of yarns, from 0.5Nm ultra-fine cashmere to carbon fiber composite yarns.

Digital Twin Hub

The machine comes with a built-in digital twin system, enabling simultaneous virtual and real-world production.

Ultimate Energy Saving and Environmental Protection

Energy consumption is reduced by 70%, and noise levels are kept below 50 decibels.

Modular Upgrade

Plug-and-play support for future technologies such as 5G and blockchain.

3. Global Strategic Application Solutions

This model is designed for the following strategic scenarios:

Global Fashion Industry Hub: Meeting the annual production capacity needs of international brands in the billions

National Intelligent Manufacturing Project: Selected as a key equipment project in the "Made in China 2025" initiative

Future Materials Research Institute: Conducting research on cutting-edge material applications such as graphene and liquid metal

Changhua Technology offers:

√ Industry-first 10-year full warranty

√ Global "Diamond" VIP service access

√ Quantum computing cloud support

√ Customized strategic partnership solutions

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe