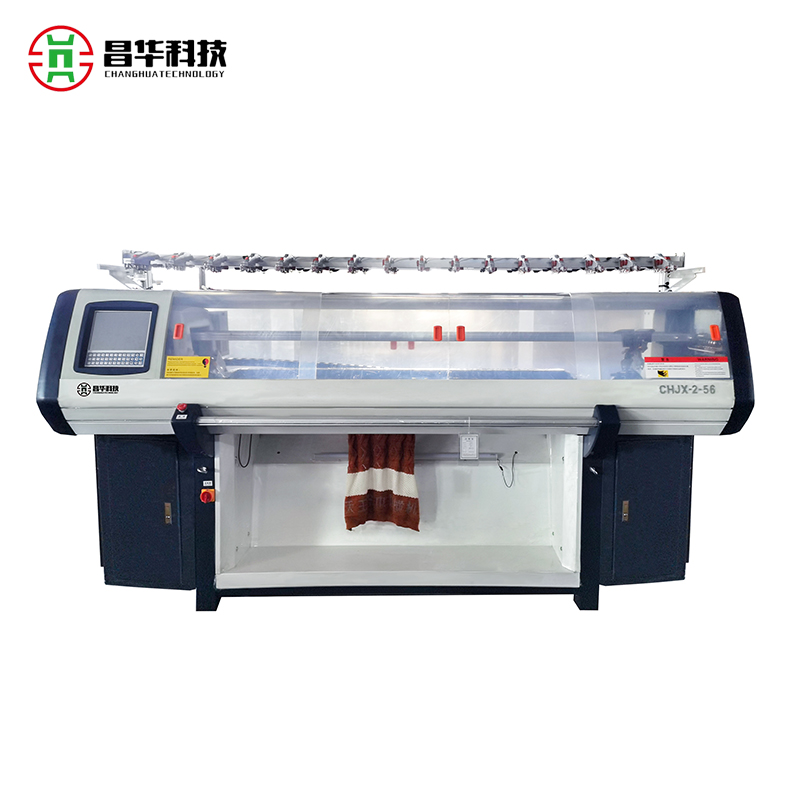

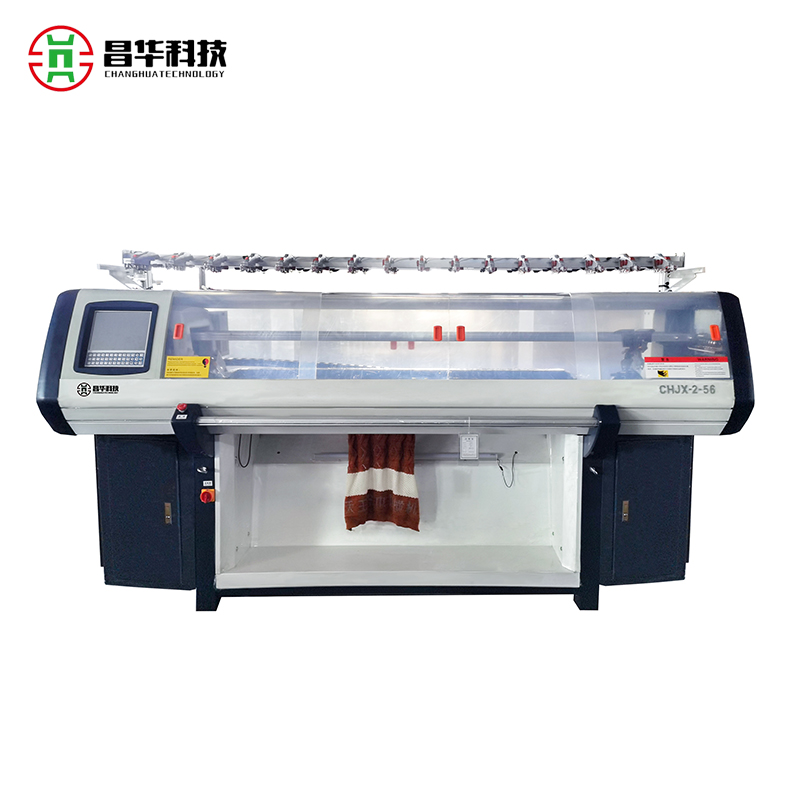

60 Inch Double System Sweater Knitting Machine Description

Double system has high roller, high-performance sinker, dynamic stitch, motor control reserving carriage, digital technology, high-speed and efficient, to achieve pointelle, tuck, jacquard, intarsia, full needle jacquard, apparent shape, hidden shape, and other irregular patterns, which is suitable for wool, cashmere, cotton, chemical fiber, silk and all kinds of blended yarn, the production of sweaters, blanket, scarfs, gloves, hats and knitted apparel accessories. Changhua Double System Sweater Knitting Machine.pdf

Changhua Double System Sweater Knitting Machine.pdf

Double System HP-Blue

Double System HP-White

1. Product positioning and technological breakthroughs

Changhua's 60-inch dual-system fully automatic sweater computer flat knitting machine is the company's latest high-end intelligent knitting equipment. It adopts the industry-leading dual-system synchronous knitting technology and can achieve a knitting speed of up to 1.6 meters per second. This model is equipped with a 60-inch (152 cm) ultra-wide knitting platform, supports 5G-18G multiple needle gauge configurations, and is perfectly suitable for various yarn raw materials from cashmere to functional fibers. The equipment is equipped with a new generation of intelligent control system, and the computing speed is 40% higher than the previous generation, achieving the industry's top needle position accuracy of ±0.03mm.

2. Core Competitive Advantages

Dual-system efficient production

Two independent knitting systems work together, and the production efficiency is increased by 80% compared with the single-system model, and the daily production capacity can reach up to 450 standard sweaters

Intelligent knitting system

Equipped with 16-way intelligent yarn mouth, with automatic tension adjustment, yarn break self-detection and intelligent deviation correction functions, the yarn utilization rate is as high as 98%

Multi-function process integration

Built-in 300+ preset pattern library, support three-dimensional jacquard, partial knitting, idling and other complex processes one-click call

Energy-saving and environmentally friendly design

Adopting permanent magnet synchronous direct drive technology, energy consumption is reduced by 45%, noise is controlled below 58 decibels, and meets the national first-level energy efficiency standard

3. Service guarantee

Changhua Technology provides: √ 3-year warranty service for the whole machine √ Free on-site technical training √ Lifetime software upgrade support √ 48-hour rapid response mechanism

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe