In today’s fast-paced textile and apparel industry, efficiency, precision, and adaptability are not just advantages—they are necessities. For businesses looking to scale production, improve product quality, or enter new markets, investing in a computerized flat knitting machine is a pivotal decision. However, the real challenge lies not in recognizing the need for such technology, but in identifying a reliable computerized flat knitting machine manufacturer who can deliver robust, innovative, and cost-effective solutions.

This comprehensive guide is designed to walk you through the key considerations when selecting a manufacturer, highlight the essential features of modern computerized flat knitting machines, and introduce you to a trusted industry leader—Changhua Knitting Machine. By the end of this article, you will have a clear roadmap to make an informed investment that boosts your productivity and profitability.

Understanding Computerized Flat Knitting Machines

Before diving into the selection criteria for a manufacturer, let's establish what a computerized flat knitting machine is and why it has become indispensable.

What is a Computerized Flat Knitting Machine?

A

computerized flat knitting machine is an electronically controlled device used to produce knitted fabrics, garments, and technical textiles. Unlike manual or mechanical knitting machines, these advanced systems are driven by computer programs, allowing for unparalleled precision, complex patterning, and automated operation. They can produce everything from simple jerseys to intricate 3D knitted structures, entire garments (whole garment knitting), and specialized fabrics for automotive, medical, or sportswear applications.

Key Components and Technologies:

Control System: The brain of the machine, often featuring a user-friendly touchscreen interface for designing and inputting knitting programs.

Knitting Systems (Heads): Determine the number of independent knitting carriages. Multi-system machines (like 2-system or 3-system) significantly increase speed by performing multiple operations simultaneously.

Needle Bed: The surface where knitting occurs. The width (e.g., 72-inch, 100-inch, 120-inch) defines the maximum fabric width or the size of panels that can be knitted.

Yarn Feeding System: Advanced servo-driven feeders that ensure consistent yarn tension, crucial for high-quality fabric.

Fabric Take-Down System: Gently and consistently pulls down the knitted fabric to maintain stitch uniformity.

Why Upgrade to a Computerized Machine?

Design Freedom: Create complex jacquards, intarsia, cables, and 3D shapes with ease.

Reduced Waste: Precise yarn control and whole-garment technology minimize material waste.

Labor Efficiency: One operator can manage multiple machines, reducing reliance on highly skilled hand-knitters.

Consistency & Quality: Automated processes eliminate human error, ensuring every product meets exact specifications.

Speed to Market: Rapid prototyping and fast production cycles help respond quickly to fashion trends.

Critical Factors in Choosing a Reliable Manufacturer

Selecting the right manufacturer is as important as selecting the right machine. Here are the non-negotiable factors to evaluate:

1. Industry Experience and Reputation

Look for a manufacturer with a substantial track record. Longevity in the market often correlates with accumulated technical know-how, refined processes, and a proven ability to adapt to industry changes. Research their history, read case studies, and look for testimonials from clients in similar sectors.

2. Technological Innovation and R&D Capability

The textile machinery field is constantly evolving. A reliable manufacturer invests heavily in Research and Development (R&D) to improve machine speed, reliability, user-friendliness, and capabilities. Inquire about their recent innovations and patent holdings.

3. Manufacturing Quality and Standards

The durability and precision of a machine are determined by its build quality. Manufacturers should use high-grade components (like German or Japanese bearings and guides) and adhere to strict international quality control standards (like CE certification). Ask about their production facility and quality assurance protocols.

4. Range of Products and Customization

Your needs are unique. Whether you need a machine for fine-gauge sweaters, bulky blankets, or technical textiles, the manufacturer should offer a versatile range of models with different widths, systems, and gauges. The ability to provide custom solutions is a significant plus.

5. Comprehensive After-Sales Support

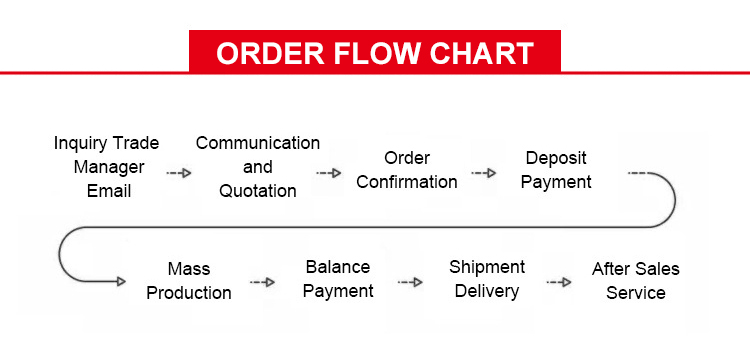

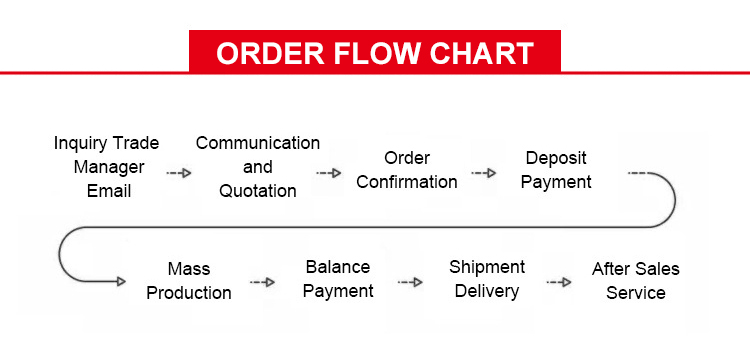

This is arguably the most critical factor. A machine is a long-term investment. Ensure the manufacturer offers:

Professional Installation & Commissioning

Thorough On-site Training for your operators and technicians

Easily Available Spare Parts with a global logistics network

Responsive Technical Support via phone, email, and remote diagnostics

Regular Software Updates to keep your machine's capabilities current

6. Transparent Pricing and Value

While price is a consideration, the lowest upfront cost can lead to higher long-term expenses due to downtime, poor quality, or lack of support. Seek a manufacturer that offers clear, competitive pricing and demonstrates overall value through machine longevity, efficiency, and support.

Why Changhua Stands Out as Your Trusted Partner

After understanding what to look for, it’s time to introduce a manufacturer that embodies all these qualities. For decades, Changhua Knitting Machine has been at the forefront of designing and manufacturing top-tier computerized flat knitting machines for a global clientele.

Our Story: A Legacy of Innovation

Founded with a vision to democratize advanced knitting technology, Changhua has grown from a dedicated team of engineers into an internationally recognized brand. Our journey is driven by a simple mission: to provide reliable, high-performance, and accessible knitting solutions that empower our customers' growth. We bridge the gap between cutting-edge technology and practical, day-to-day production needs.

Our Commitment to Excellence

In-House R&D: Our dedicated engineering team continuously innovates, ensuring our machines integrate the latest advancements in motion control, software, and mechanical design.

Quality-Centric Manufacturing: Every Changhua machine is assembled in our state-of-the-art facility with premium components, undergoing rigorous testing before shipment.

Global Support Network: We have established service centers and partnerships worldwide to ensure our customers receive prompt and effective support, no matter where they are located.

Customer-Centric Approach: We view our customers as partners. From the initial inquiry to years after installation, our team is committed to your success.

Discover Our Range of Solutions

We offer a diverse portfolio to suit various production scales and product types. **Explore our full range on our official website: https://www.changhua-knitting-machine.com/**. Let’s delve into a few standout models that showcase our capabilities.

Exploring Key Changhua Computerized Flat Knitting Machine Models

1. The Compact Powerhouse: 72-inch Single System Machine

Ideal for startups, sampling, and small-scale production of high-quality items.

Model Page: 72-inch Single System Computerized Flat Knitting Machine

Overview:

This model is the perfect entry point into computerized flat knitting. Its 72-inch (183 cm) width is versatile for many garment panels and accessories. The single, robust knitting system provides excellent reliability and ease of operation for mastering computerized knitting fundamentals.

Key Features and Advantages:

User-Friendly Operation: Perfect for training new operators and transitioning from manual machines.

Space-Efficient Design: Requires less factory floor space, ideal for smaller workshops.

Cost-Effective Investment: Delivers the core benefits of computerization at an accessible price point.

Excellent for Sampling: Allows for quick and cost-effective prototyping of designs before large-scale runs.

Who is it for? Fashion designers, small boutique knitwear brands, vocational training schools, and businesses adding sampling capabilities.

2. The High-Speed Producer: 100-inch Three System Machine

Engineered for demanding production environments where output and versatility are key.

Model Page: 100-inch Three System Computerized Knitting Machine

Overview:

This is a workhorse model designed for significant productivity gains. The 100-inch (254 cm) wide bed allows for larger panels or multiple pieces side-by-side. The revolutionary three independent knitting systems enable simultaneous knitting operations, dramatically increasing output compared to single or double-system machines.

Key Features and Advantages:

Triple the Productivity: Three systems work in concert to drastically reduce knitting time for complex patterns.

Wide-Format Flexibility: Produce oversized blankets, wide panels for home textiles, or multiple garment pieces in one cycle.

Advanced Stitch Control: Achieve a vast array of knit structures, from basic knits and purls to complex transfer stitches.

Robust Construction: Built for 24/7 industrial operation with minimal downtime.

Who is it for? Medium to large garment manufacturers, contract knitters, producers of home textiles, and technical fabric mills.

3. The Ultimate Performer: 120-inch 2 + 2 System Machine

The flagship solution for maximum flexibility and production of sophisticated whole garments.

Model Page: 120-inch 2 + 2 System Computerized Flat Knitting Machine

Overview:

This top-of-the-line model represents the pinnacle of our engineering. It features a massive 120-inch (305 cm) needle bed configured with two independent knitting systems, each with two carriages. This architecture provides unmatched flexibility for producing entire garments (sweaters, cardigans) with minimal seaming or vast widths of fabric.

Key Features and Advantages:

Whole Garment Knitting: Seamlessly knit complete garments, reducing labor-intensive linking and sewing stages.

Unparalleled Speed & Flexibility: The 2+2 system configuration allows for highly efficient patterning and ribbing.

Ideal for Bulk Yarns: Excellent for knitting fashionable bulky knitwear and blankets with superior speed.

Future-Proof Investment: Equipped with the most advanced software and hardware for tackling the most complex knitting challenges of today and tomorrow.

Who is it for? Large-scale apparel brands specializing in premium knitwear, advanced whole-garment producers, and manufacturers of high-end technical and smart textiles.

The Tangible Advantages of Choosing Changhua Machines

Beyond the specifications, what truly matters is the real-world performance and value our machines bring to your factory floor.

1. Superior Software for Intuitive Design

Our proprietary software suite translates creative designs into flawless machine instructions. With features for easy pattern creation, colorway management, and efficient yarn consumption calculation, we reduce the learning curve and empower your designers.

2. Unmatched Energy Efficiency

We engineer our machines with high-efficiency servo motors and intelligent power management systems. This significantly reduces electricity consumption compared to older models, lowering your operational costs and environmental footprint.

3. Built for Durability and Easy Maintenance

We use hardened steel for critical parts like needle beds and carriages. Our modular design philosophy makes routine maintenance and any necessary repairs straightforward, minimizing machine downtime—the enemy of productivity.

4. Seamless Integration Potential

Changhua machines are designed to fit into modern, automated production lines. With standard data interfaces, they can be connected to factory ERP/MES systems for real-time production monitoring and data collection.

Your Next Steps: From Consideration to Consultation

Finding a reliable manufacturer is a journey, and we are here to guide you through the final steps.

1. Deep Dive with Our Resources:

We encourage you to visit our website and explore the detailed pages for each machine model. Download our technical brochures and specification PDFs to compare models side-by-side.

[Download Our Comprehensive Guide to Choosing a Flat Knitting Machine (PDF)]

[Download Our Comprehensive Guide to Choosing a Flat Knitting Machine (PDF)]

2. Schedule a Virtual or Live Demo:

Seeing is believing. Contact us to arrange a live video demonstration of the specific model you are interested in. We can showcase its features, run your sample patterns, and answer your questions in real-time.

3. Engage in a Technical Dialogue:

Reach out to our sales engineering team. Discuss your current production challenges, your target products, and your growth goals. Our experts can provide a tailored recommendation on the most suitable Changhua machine for your operation.

4. Discuss Financing and Support Plans:

We can provide information on flexible financing options and detail our comprehensive after-sales service package, giving you complete peace of mind.

Conclusion: Partner with Confidence

In the quest to find a reliable computerized flat knitting machine manufacturer, due diligence is crucial. You need a partner who offers not just a machine, but a complete solution built on quality, innovation, and unwavering support.

Changhua Knitting Machine stands ready to be that partner. From our compact 72-inch model to our industrial-grade 120-inch powerhouse, we have a proven solution to elevate your knitting production.

Ready to transform your knitwear production capabilities? The most reliable machine and the perfect manufacturing partner are just a conversation away. Visit our website or contact our expert team today to request a quote, schedule a demonstration, or simply start a conversation about your needs. Let's build the future of knitting, together.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe