The textile industry has undergone a revolutionary transformation with the advent of computerized flat knitting machines. These sophisticated devices have replaced traditional manual knitting methods, offering unprecedented precision, speed, and versatility. For manufacturers, fashion designers, and textile entrepreneurs worldwide, importing these machines represents a significant investment in production capabilities and future growth.

China has emerged as the global manufacturing hub for textile machinery, producing approximately 70% of the world's knitting machines. The competitive pricing, technological advancements, and scalable production capabilities make Chinese manufacturers particularly attractive to international buyers. However, navigating the import process requires careful consideration of multiple factors to ensure you receive equipment that meets your specific production needs and quality standards.

Key Considerations When Importing from China

1. Machine Specifications and Technical Parameters

Before committing to any purchase, thoroughly examine the technical specifications of the computerized flat knitting machine. Key parameters include:

Needle bed width: Ranging from 72 inches to over 100 inches, depending on your production requirements

Number of systems: Single, double, or triple systems that determine production speed

Gauge range: The number of needles per inch, affecting the fineness of knitted fabric

Yarn carrier configuration: Determines color and yarn type capabilities

Maximum speed: Measured in courses per minute

Control system: Software capabilities and user interface

2. Quality Assurance and Manufacturing Standards

Quality inconsistencies can plague international machinery imports. Ensure your supplier adheres to international standards such as ISO 9001 for quality management and CE certification for European market compliance. Request detailed information about:

Materials used in critical components

Quality control processes during manufacturing

Testing protocols before shipment

Warranty coverage and duration

Availability of spare parts

3. Software and Technical Support

The computerized aspect of these machines makes software capabilities crucial. Evaluate:

Programming software: User-friendliness and compatibility with standard file formats

Design capabilities: Integration with CAD systems

Technical support: Availability of remote assistance and on-site service

Training provisions: Operator training resources and documentation

Software updates: Regularity and cost of system upgrades

4. Supplier Reliability and Reputation

Research potential suppliers thoroughly by:

Checking business licenses and export credentials

Verifying factory audits and certifications

Reading customer testimonials and case studies

Requesting references from existing international clients

Assessing communication responsiveness and English proficiency

5. Logistics and After-Sales Service

Import logistics present unique challenges:

Shipping arrangements: FOB, CIF, or EXW terms

Customs clearance: Documentation requirements and import duties

Installation: Availability of technical personnel for machine setup

Maintenance: Service network in your region

Parts availability: Lead times for critical spare components

Introducing Changhua Knitting Machine: Your Trusted Partner

Among the numerous manufacturers in China, one company has consistently distinguished itself through quality, innovation, and customer-centric service: Changhua Knitting Machine. With over two decades of specialization in computerized flat knitting technology, we have established ourselves as a leader in the industry, exporting to more than 40 countries worldwide.

Why International Buyers Choose Our Company

Proven Expertise and Innovation

Our company began as a specialized workshop in the heart of China's textile region and has evolved into a technologically advanced manufacturing enterprise. We invest approximately 8% of our annual revenue into research and development, ensuring our machines incorporate the latest advancements in knitting technology, automation, and energy efficiency.

Comprehensive Quality Control

We implement a rigorous quality management system that exceeds international standards. Every Changhua machine undergoes 72 hours of continuous testing before leaving our factory. Our quality control team performs over 200 checkpoints throughout the manufacturing process, from material selection to final assembly.

Global Support Network

Understanding the challenges of international imports, we have developed a comprehensive support system that includes:

Multilingual technical documentation and software interfaces

24/7 remote support with average response time under 2 hours

Certified technicians available for international installation and training

Strategic spare parts warehouses in key regions including Europe, South America, and Southeast Asia

Regular software updates and technical upgrades for existing customers

Customization Capabilities

Unlike many manufacturers who offer only standard configurations, our engineering team works directly with clients to develop customized solutions. Whether you need specialized yarn feeders, unique stitch capabilities, or integration with existing production systems, we can tailor our machines to your specific requirements.

Explore Our Advanced Computerized Flat Knitting Machines

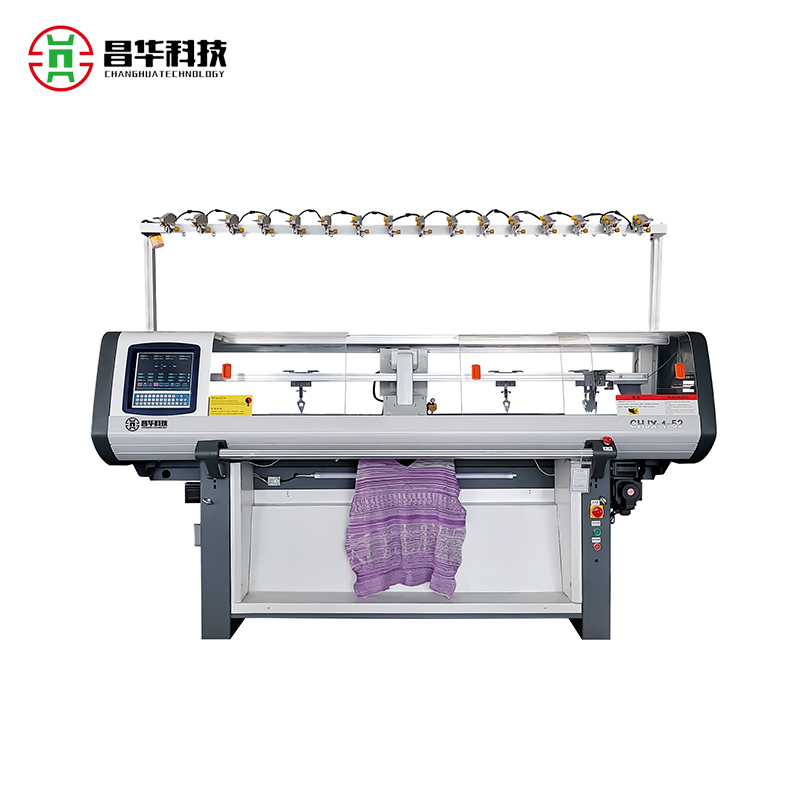

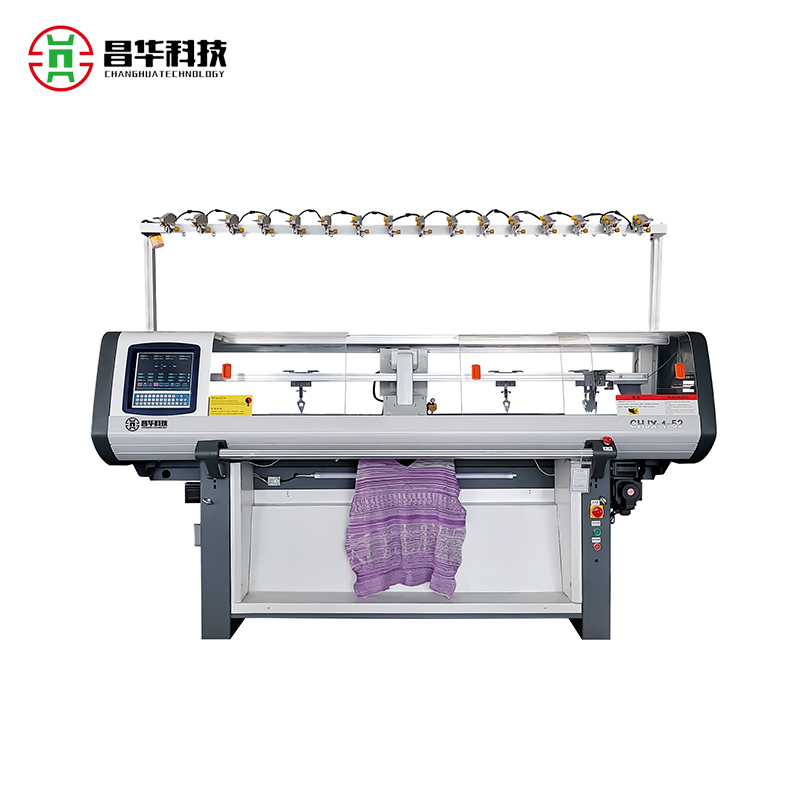

1. Changhua 72-inch Single System Computerized Flat Knitting Machine

Ideal for: Startups, small workshops, and specialized production

Our 72-inch model represents the perfect entry point into automated knitting production. Despite its compact size, this machine delivers professional results with features typically found in larger, more expensive models.

Key Features:

Precision Engineering: High-precision linear guides and servo motors ensure consistent stitch quality

Intuitive Software: User-friendly interface with pre-programmed patterns and easy customization

Energy Efficient: Consumes 30% less power than comparable machines in its class

Versatile Applications: Suitable for sweaters, scarves, blankets, and technical textiles

Technical Specifications:

Working width: 72 inches (183 cm)

Gauge range: 3-12 gauge per inch

Maximum speed: 1.2 meters per second

Yarn carriers: 4 standard (expandable to 8)

Memory capacity: 500+ patterns

Compact yet powerful 72-inch model perfect for diverse knitting applications

Production Advantages:

This model excels in small-batch production and prototyping. The quick setup and pattern change capabilities allow manufacturers to respond rapidly to market trends. Our clients report an average increase of 40% in production efficiency compared to manual methods, with payback periods typically under 18 months.

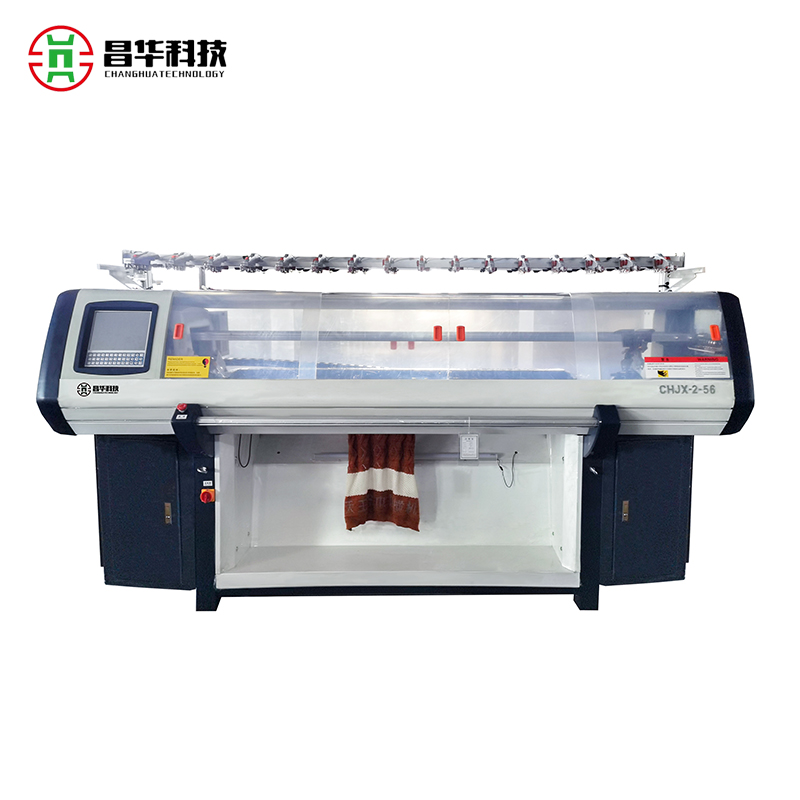

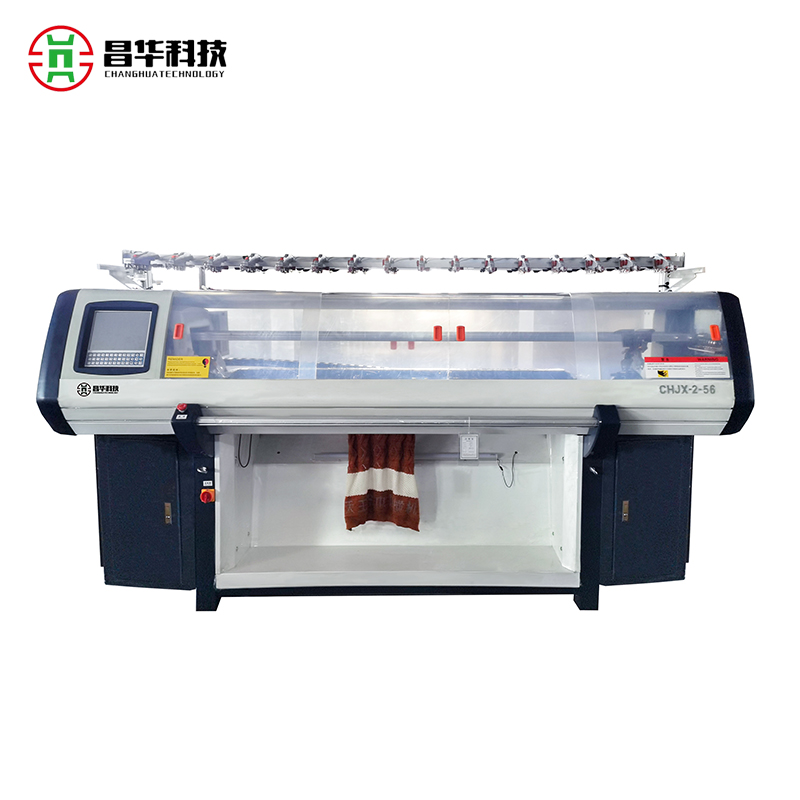

2. Changhua 80-inch Double System Computerized Knitting Machine

Ideal for: Medium-scale production facilities and growing businesses

The 80-inch double system machine represents our best-selling model, striking the perfect balance between production capacity, versatility, and investment value. This workhorse has become the foundation of successful knitting operations worldwide.

Key Features:

Dual System Design: Two independent carriage systems for increased production speed

Advanced Tension Control: Automatic yarn tension monitoring and adjustment

Multi-color Capability: Seamless integration of up to 8 colors without manual intervention

Stitch Diversity: Capable of producing complex stitches including cables, jacquard, and intarsia

Technical Specifications:

Working width: 80 inches (203 cm)

Gauge range: 3-14 needles per inch

Maximum speed: 1.5 meters per second

Yarn carriers: 8 standard (expandable to 12)

Memory capacity: 1,000+ patterns

Interested in learning how our 80-inch model can transform your production capabilities? Our technical team can provide a customized production analysis based on your specific requirements.

3. Changhua 100-inch Three System Computerized Knitting Machine

Ideal for: Large-scale production facilities and industrial manufacturers

For operations requiring maximum output and advanced capabilities, our 100-inch three system machine represents the pinnacle of flat knitting technology. This industrial-grade equipment delivers unparalleled production efficiency for high-volume manufacturers.

Key Features:

Triple System Configuration: Three independent carriage systems for maximum productivity

Industrial Durability: Reinforced frame and commercial-grade components for 24/7 operation

Advanced Connectivity: IoT capabilities for integration with factory management systems

Automated Features: Self-cleaning, automatic lubrication, and predictive maintenance alerts

Technical Specifications:

Working width: 100 inches (254 cm)

Gauge range: 3-18 needles per inch

Maximum speed: 1.8 meters per second

Yarn carriers: 12 standard (expandable to 16)

Memory capacity: 2,000+ patterns

Industrial-scale 100-inch model designed for high-volume production environments

The Changhua Advantage: Beyond the Machines

Comprehensive Training Programs

We understand that advanced technology requires skilled operators. Our training programs include:

Online certification courses: Self-paced learning modules for ongoing skill development

Advanced technique workshops: Specialized training for complex patterns and techniques

Train-the-trainer programs: Enable knowledge transfer within your organization

Unmatched Technical Support

Our commitment extends far beyond the initial sale:

Dedicated account manager: Single point of contact for all your needs

Preventive maintenance schedules: Customized plans to maximize machine lifespan

Software updates: Regular enhancements at no additional cost for warranty period

Emergency response: Priority support for production-critical issues

Sustainable and Efficient Operations

Modern manufacturers increasingly prioritize sustainability, and our machines support these goals:

Energy-efficient motors: Reduce power consumption by 25-40% compared to previous generations

Precision yarn control: Minimize waste through optimized tension and feeding systems

Longevity and durability: Built to last with easily replaceable modular components

Recyclability: Design for disassembly at end of service life

Navigating the Import Process with Changhua

Step-by-Step Import Guidance

Importing machinery from China involves multiple steps, but with our experienced team guiding you, the process becomes straightforward:

Initial Consultation: We discuss your production requirements, facility specifications, and budget parameters

Machine Selection: Our experts recommend the optimal model and configuration

Quotation and Terms: Detailed pricing with transparent breakdown of all costs

Factory Acceptance Test: You're invited to witness your machine's testing before shipment

Logistics Coordination: We handle documentation, shipping, and customs clearance support

Installation and Commissioning: Our technicians ensure proper setup and initial operation

Training and Handover: Comprehensive training for your operational team

Avoiding Common Import Pitfalls

Based on our experience with hundreds of international clients, we help you avoid these common issues:

Underestimating total costs: We provide all-inclusive quotations with no hidden fees

Technical compatibility: We verify electrical specifications and facility requirements

Spare parts planning: We recommend essential spare parts inventory based on your usage

Cultural and communication barriers: Our multilingual team ensures clear understanding

After-sales support expectations: We establish clear service level agreements upfront

Are you concerned about navigating international machinery imports? Our dedicated export team has guided clients through thousands of successful shipments and can provide references from your region.

Success Stories: Global Clients Using Changhua Machines

European Fashion Manufacturer Increases Production 300%

A premium knitwear producer in Italy replaced their aging equipment with six Changhua 80-inch double system machines. The result was a 300% increase in production capacity while reducing labor requirements by 40%. The precision of our machines allowed them to maintain their high-quality standards while meeting increased demand.

South American Startup Grows from Garage to Factory

A entrepreneurial team in Colombia began with a single Changhua 72-inch machine in a garage workspace. Within three years, they expanded to eight machines and now operate a full-scale manufacturing facility serving both domestic and export markets. Their success story highlights how starting with the right equipment can fuel rapid growth.

Asian Technical Textiles Leader Chooses Changhua

A manufacturer of advanced technical textiles in South Korea selected our 100-inch three system machines for their new production line. The machines' precision and reliability were critical for producing specialized fabrics for medical and automotive applications. The client particularly valued our ability to customize certain functions for their unique requirements.

Making Your Investment Decision: Final Checklist

Before finalizing your purchase of a computerized flat knitting machine from China, ensure you have addressed these critical points:

Technical Verification

Confirmed electrical specifications match your facility

Verified machine dimensions fit your workspace

Ensured software compatibility with your design systems

Validated production capacity meets your requirements

Confirmed gauge range suits your product line

Supplier Due Diligence

Verified manufacturer certifications and licenses

Checked references from similar clients

Confirmed warranty terms and coverage

Evaluated after-sales support capabilities

Assessed spare parts availability and pricing

Financial Considerations

Calculated total landed cost (machine, shipping, duties, installation)

Projected ROI based on realistic production scenarios

Explored financing options if needed

Budgeted for initial spare parts and training

Considered potential production savings and quality improvements

Logistics Planning

Understood shipping timelines and lead times

Prepared facility for machine installation

Arranged for local technical support if needed

Planned operator training schedule

Developed initial production ramp-up plan

Conclusion: Your Path to Advanced Knitting Production

Importing computerized flat knitting machines from China represents a strategic investment in your manufacturing future. The combination of advanced technology, competitive pricing, and scalable production capabilities makes this an attractive option for businesses at every stage of growth.

At Changhua Knitting Machine, we have dedicated ourselves to not just manufacturing excellent equipment, but to building lasting partnerships with our clients worldwide. Our machines represent the culmination of decades of specialized experience, continuous innovation, and unwavering commitment to quality.

Ready to transform your knitting production capabilities? Whether you're establishing your first automated knitting operation or expanding an existing facility, our team stands ready to guide you through every step of the process—from initial consultation to ongoing support.

Let us help you select the perfect computerized flat knitting machine to meet your production goals, budget, and growth ambitions. With Changhua as your partner, you're investing in more than machinery—you're investing in a foundation for sustainable growth and manufacturing excellence.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe