The textile and apparel industry is undergoing a profound transformation, driven by digitalization, automation, and an insatiable demand for both customization and sustainability. At the heart of this revolution is a workhorse that has evolved dramatically: the Computerized Flat Knitting Machine. Once limited to basic sweater panels, today's advanced machines are sophisticated manufacturing platforms capable of producing everything from seamless whole garments (3D knitting) to technical textiles with embedded electronics.

For manufacturers, brands, and designers, staying ahead means understanding the technological trends that are reshaping production floors. This comprehensive guide delves into the key innovations defining the next generation of flat knitting technology and explores how leveraging these advancements can be your competitive edge.

The Engine of Innovation: Key Technology Trends

Let's break down the core technological trends that are making computerized flat knitting machines smarter, faster, and more versatile than ever before.

Whole Garment (3D Knitting) and Seamless Technology

Gone are the days of knitting separate panels and sewing them together. Whole garment technology, pioneered by industry leaders and now accessible on various platforms, allows a complete garment to be knitted in a single, seamless piece directly on the machine.

How it Works: Advanced needle beds, multiple knitting systems, and sophisticated software control allow the machine to knit complex three-dimensional structures, incorporating sleeves, body, and collar in one continuous process.

Impact: This eliminates cutting waste (promoting sustainability), reduces labor-intensive sewing steps, and enhances garment comfort by removing seams. It's ideal for premium knitwear, activewear, and intimate apparel.

Advanced Software, AI, and IoT Integration

The "brain" of the machine has seen the most significant upgrade. Modern flat knitting is as much about software as it is about hardware.

CAD/CAM Systems: Intuitive, cloud-connected design software allows for rapid prototyping, complex pattern creation, and easy modification of designs. Files are sent directly to the machine.

Artificial Intelligence (AI): AI algorithms are being integrated for predictive maintenance (flagging potential part failures before they happen), optimizing yarn tension dynamically, and even automatically correcting minor errors during the knitting process.

Internet of Things (IoT): Machines are now nodes in a smart factory network. They relay real-time data on production status, efficiency (OEE), and downtime to central dashboards, enabling remote monitoring and data-driven decision-making.

Multi-System and High-Speed Configurations

Productivity is paramount. To meet this demand, manufacturers have developed machines with multiple independent knitting systems (carriages).

Trend: While dual-system machines are standard, triple-system and even quadruple-system machines are becoming more prevalent. These systems can work in tandem or independently, drastically increasing output, especially for complex patterns or whole garment production.

High-Speed Drives: Enhanced servo motors and optimized carriage paths enable faster movement without compromising stitch quality, pushing the boundaries of stitches per minute.

Sustainability-Driven Innovations

The industry's green shift is a major driver of innovation.

Waste Reduction: Whole garment knitting is a prime example. Additionally, software optimization minimizes yarn usage during patterning.

Material Flexibility: Modern machines can handle a vast range of yarns, including recycled polyester, organic cotton, and even innovative bio-based or biodegradable fibers, allowing brands to meet eco-conscious consumer demands.

Energy Efficiency: New generation machines feature energy-saving motors, LED lighting, and smart power-down modes during idle times.

Versatility for Technical Textiles

The application of flat knitting is expanding far beyond fashion.

Applications: Medical textiles (e.g., compression garments, implants), automotive interiors (seat covers, acoustic panels), composite preforms for aerospace, and smart textiles with conductive yarns are all now within reach.

Machine Requirements: This demands extreme precision, ability to handle specialty/tough yarns, and software capable of generating complex structural knits.

Ready to see how these global trends translate into tangible, reliable machinery for your factory? The gap between innovation and practical, profitable application is bridged by choosing the right technology partner.

Your Strategic Partner in Knitting Innovation: Changhua Knitting Machine

In a landscape filled with complex choices, Changhua Knitting Machine stands as a beacon of reliability, innovation, and value. For decades, we have dedicated ourselves not just to manufacturing machines, but to engineering solutions that empower our clients' growth.

Our Philosophy: We believe that cutting-edge technology should be accessible, robust, and directly linked to improving your bottom line. Our team of engineers and technicians works relentlessly to incorporate the latest trends—like whole garment knitting and IoT readiness—into a range of machines known for their durability, user-friendliness, and exceptional ROI.

Why Global Manufacturers Trust Changhua:

Proven Expertise: Years of specialization have given us deep, practical insight into the real-world challenges of knit production.

Quality Engineering: We use high-grade components and rigorous testing protocols to ensure our machines perform consistently under demanding factory conditions.

Comprehensive Support: From installation and training to ongoing technical support and spare parts, our partnership extends far beyond the initial sale.

Forward-Thinking Portfolio: Our product lineup is continuously evolved to embed the trends discussed in Part 1, giving you a future-proof asset.

Explore our story and our full commitment to the knitting industry on our official website: https://www.changhua-knitting-machine.com/.

Curious about which specific Changhua model can turn these industry trends into your daily reality? Let's examine the machines that are setting new standards on production floors worldwide.

Changhua Machines: Where Technology Meets Application

Our product range is designed to cater to diverse needs, from high-volume panel production to the most intricate seamless garments. Here are three stellar examples of how we embody modern knitting trends.

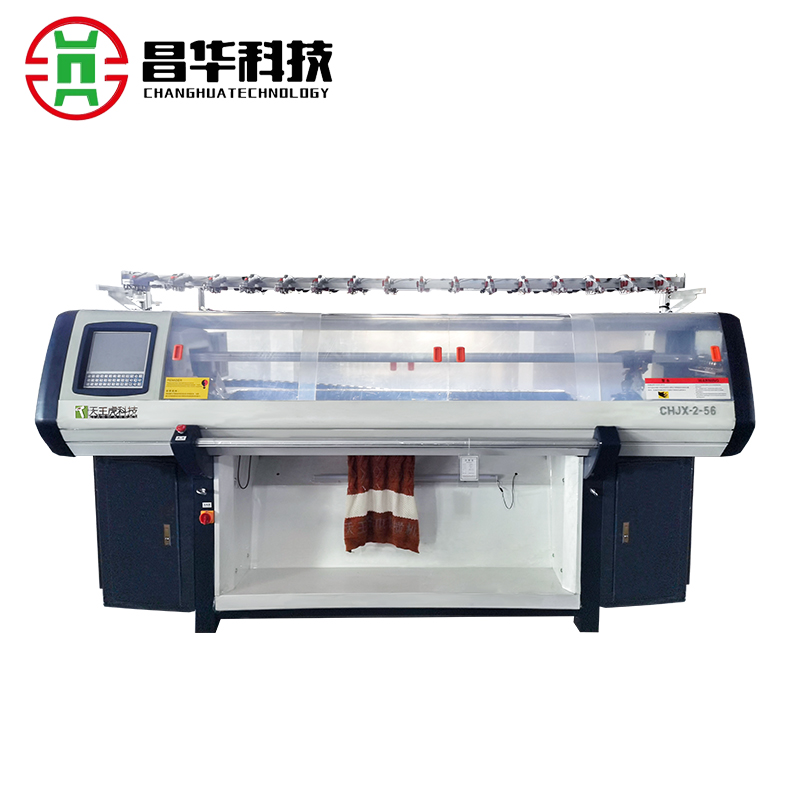

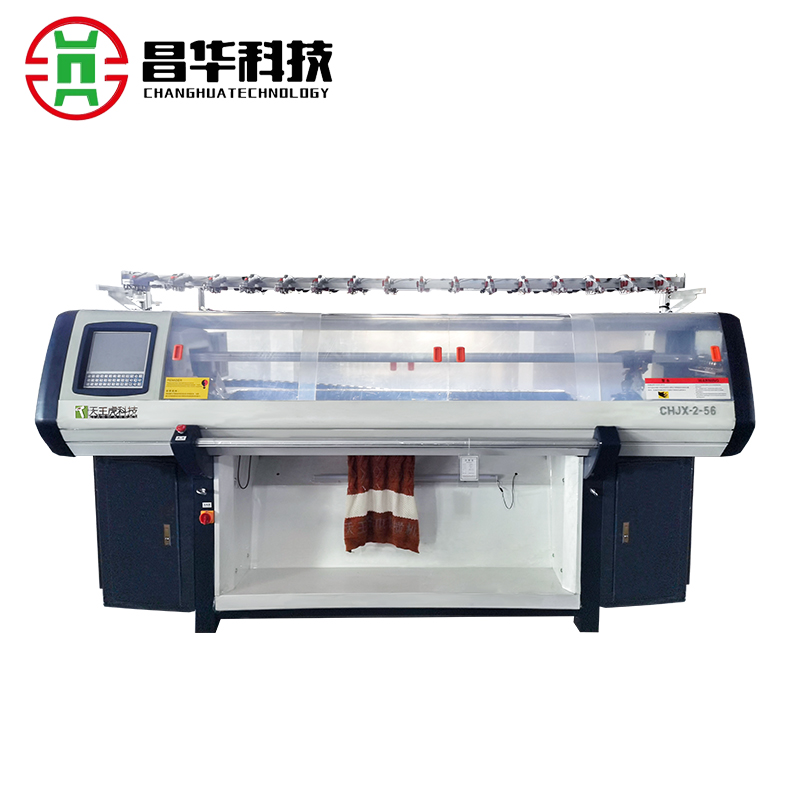

The Productivity Powerhouse: Changhua 80-Inch Double System Computerized Knitting Machine

For factories focused on efficiency and versatility in producing high-quality knit panels (for sweaters, cardigans, scarves, etc.), this machine is an industry favorite.

Core Technology: It features a robust dual knitting system, allowing for complex colorwork, cables, and jacquard patterns at impressive speeds. Its 80-inch needle bed provides ample width for larger panels or multiple pieces.

Trend Alignment: It integrates advanced digital tension control and user-friendly software for pattern design and management, ensuring consistent quality and quick changeovers between jobs.

Ideal For: Medium to large-scale apparel manufacturers looking to upgrade their capability without moving into full 3D knitting.

Discover the detailed specifications and operational advantages of this productivity workhorse here: 80-inch Double System Computerized Knitting Machine.

The Advanced Workhorse: Changhua 100-Inch Three System Computerized Knitting Machine

When your operation demands a significant leap in output and capability, this model answers the call. It represents the pinnacle of traditional flat knitting for panels and intricate fabrics.

Core Technology: The triple independent knitting systems are a game-changer. This configuration can dramatically increase production speed for complex patterns or enable the use of multiple yarn types in a single pass.

Trend Alignment: This machine is built for high-speed performance and equipped with sophisticated software that handles the most demanding designs. Its large 100-inch bed is perfect for home textiles, wide panels, or technical fabrics.

Ideal For: Producers of high-end fashion knitwear, technical textiles, or any operation where maximizing output on complex patterns is critical.

Learn how the triple-system advantage can revolutionize your production line: 100-inch Three System Computerized Knitting Machine.

The Future, Today: Changhua 80-Inch Whole Garment Computerized Flat Knitting Machine

This is where Changhua truly showcases its innovative prowess. This machine brings the revolutionary trend of seamless whole garment (3D knitting) within your reach.

Core Technology: Specifically engineered for complete garment knitting, it can produce a finished sweater, dress, or accessory with minimal or no sewing. It incorporates advanced stitch transfer capabilities and precise loop control to shape 3D structures.

Trend Alignment: It is the direct embodiment of sustainability (zero cut-and-sew waste), customization, and digital manufacturing. It connects directly to advanced CAD systems, allowing you to prototype and produce on-demand.

Ideal For: Brands and manufacturers targeting the premium knitwear market, activewear labels, and forward-thinking businesses looking to adopt on-demand, sustainable production models.

Step into the future of knitting and see the seamless potential for your brand: 80-inch Whole Garment Computerized Flat Knitting Machine.

The Tangible Changhua Advantage: Beyond the Spec Sheet

Choosing a Changhua machine means investing in a suite of benefits designed for long-term success:

Unmatched Durability & Low Maintenance: Our machines are built with industrial-grade components for 24/7 operation, minimizing unplanned downtime and maintenance costs.

Intuitive Operation: We prioritize user experience. Our software interfaces and machine controls are designed to reduce the learning curve for your operators.

Superior Stitch Quality & Consistency: Precision engineering ensures even tension, sharp stitch definition, and flawless fabric quality across every production run.

Scalability and Future-Proofing: Whether you start with a dual-system or dive into whole garment knitting, our technology provides a platform you can grow with.

Direct Manufacturer Support: Dealing directly with Changhua means clear communication, responsive service, and a partner genuinely invested in your productivity.

Video Overview: See a Changhua whole garment machine in action.

Conclusion: Weaving Your Success with the Right Technology

The evolution of computerized flat knitting is unlocking unprecedented levels of creativity, efficiency, and sustainability. Understanding these trends is the first step. The crucial next step is implementing them with machinery that is reliable, supported, and delivers a clear return on investment.

Changhua Knitting Machine embodies this bridge between innovation and practical application. We don't just sell machines; we provide the tools to reduce your waste, accelerate your production, expand your design possibilities, and ultimately, strengthen your market position.

Your next project, your next breakthrough in knit production, starts with a conversation. Let's discuss how our technology can be tailored to your specific needs.

Contact Our Expert Team Today for a Personalized Consultation and Quote.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe