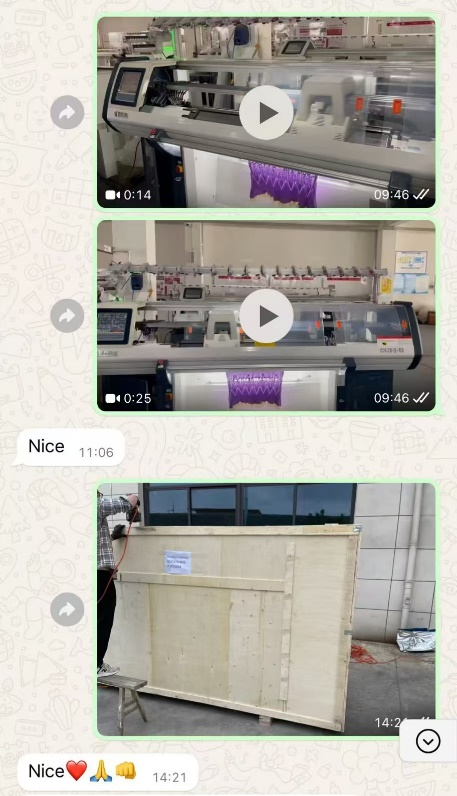

60 Inch Three System Sweater Knitting Machine Description

Three system flat knitting machine, this series have two models: with comb and without comb, with digital technology, it could implement the rib transfer jacquard, needle narrowing and other weaving functions. Also, it can knit basic knitting (full needle, single side) the weft knitted fabric like cable stitch. this applies to spun silk, synthetic filament, wool, acrylic, blending yarn and other materials, sweaters, blanket, scarfs, hats and clothing accessories. Changhua Three System Sweater Knitting Machine.pdf

Changhua Three System Sweater Knitting Machine.pdf

Changhua 60-inch Three-System Fully Automatic Sweater Computerized Flat Knitting Machine Product Introduction

1. Technological Breakthroughs and Product Positioning

The Changhua 60-inch Three-System Fully Automatic Sweater Computerized Flat Knitting Machine is the company's latest flagship knitting equipment. It utilizes revolutionary three-system synchronous knitting technology, pushing production efficiency to new heights. Equipped with an ultra-wide 60-inch (152 cm) knitting platform and a next-generation intelligent control system, this machine boasts a 60% increase in computing speed compared to dual-system models, achieving an industry-leading accuracy of ±0.02mm, redefining the standard for high-end sweater production.

II. Core Competitive Advantages

Three-System Collaborative Knitting

Three independent knitting systems intelligently collaborate, increasing production efficiency by 50% compared to a dual-system system, with a daily production capacity exceeding 600 standard sweaters.

Intelligent Process Center

Equipped with a 24-way intelligent yarn feeder system, it integrates automatic tension compensation, yarn break prediction, and intelligent deviation correction, achieving a yarn utilization rate of 99.2%.

All-Round Process Platform

A built-in library of over 500 preset processes supports highly complex techniques such as six-color jacquard, 3D relief, and partial knitting.

Extreme Energy-Saving Design

Utilizing three permanent magnet direct drive technologies, it reduces energy consumption by 50% and keeps noise levels below 55 decibels.

III. Application Scenarios and Service Innovations

This model is designed for the following scenarios:

Ultra-large-scale intelligent manufacturing: Supports factory digital upgrades, with an annual production capacity of up to 200,000 pieces per machine.

Premium luxury goods production: Meets the demand for exquisite craftsmanship from brands like Hermès and Chanel.

Future Materials R&D: Provides knitting solutions for aerospace-grade smart textiles.

Changhua Technology's Commitment:

√ 5-year extended warranty for the entire machine

√ Dedicated on-site engineer service

√ Lifetime free software upgrades

√ 24-hour global response

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe