Fashionable sweaters are a staple in wardrobes worldwide, blending style, comfort, and versatility. Whether it's a chunky cable-knit pullover, a sleek cashmere cardigan, or a trendy jacquard-patterned sweater, the technology behind these garments is both fascinating and sophisticated. The primary machine used to create these stylish pieces is the flat knitting machine, a versatile and innovative tool that has revolutionized the textile industry. In this comprehensive guide, we'll explore the mechanics of flat knitting machines, their applications in creating fashionable sweaters, and why Changhua, a leading manufacturer, is the go-to choice for businesses seeking cutting-edge knitting technology.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

What Is a Flat Knitting Machine?

A flat knitting machine is a specialized textile manufacturing device designed to produce flat knitted fabrics. Unlike circular knitting machines, which create tubular fabrics, flat knitting machines work with needles arranged in a straight line or slight arc, allowing for intricate patterns, textures, and shapes. These machines are ideal for crafting garments like sweaters, scarves, and cardigans, where complex designs and precise shaping are essential.

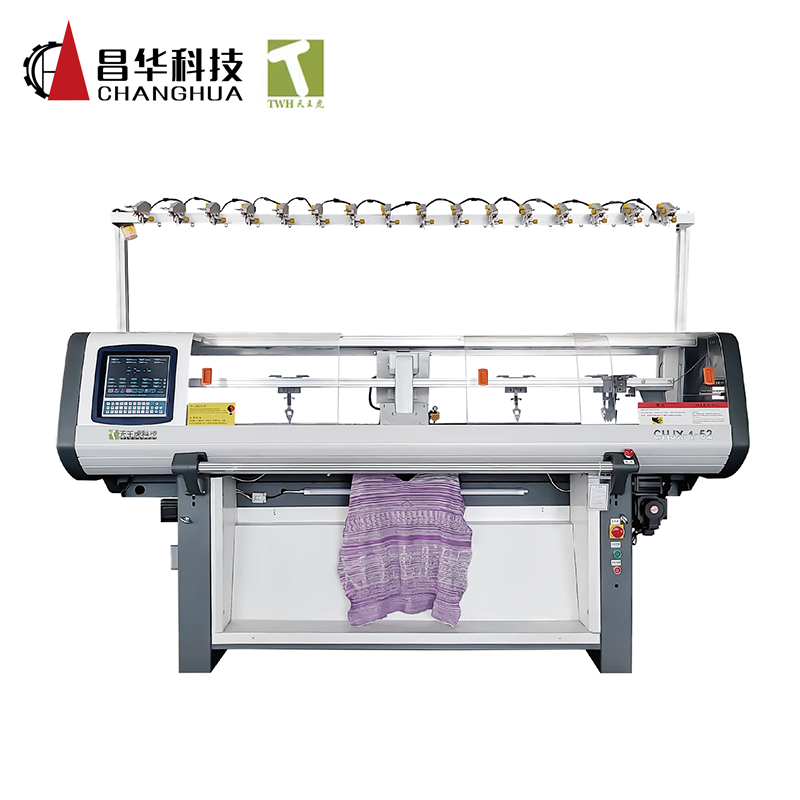

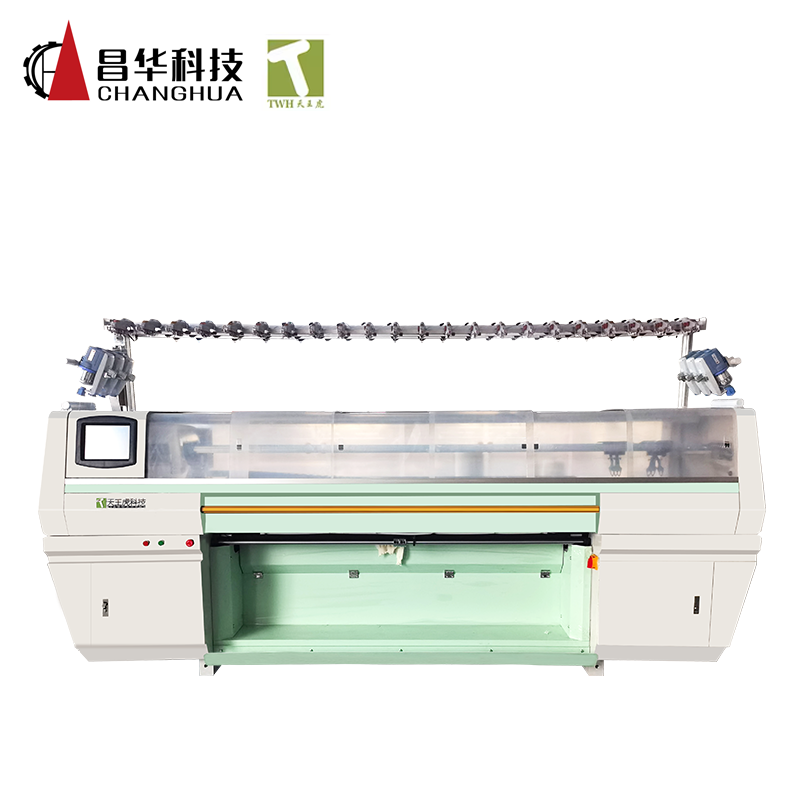

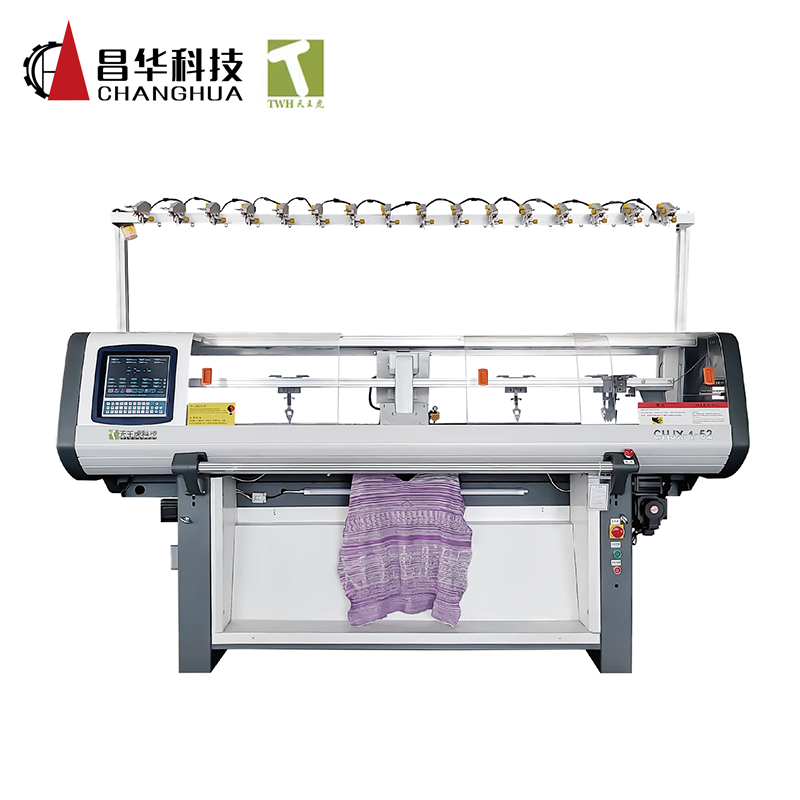

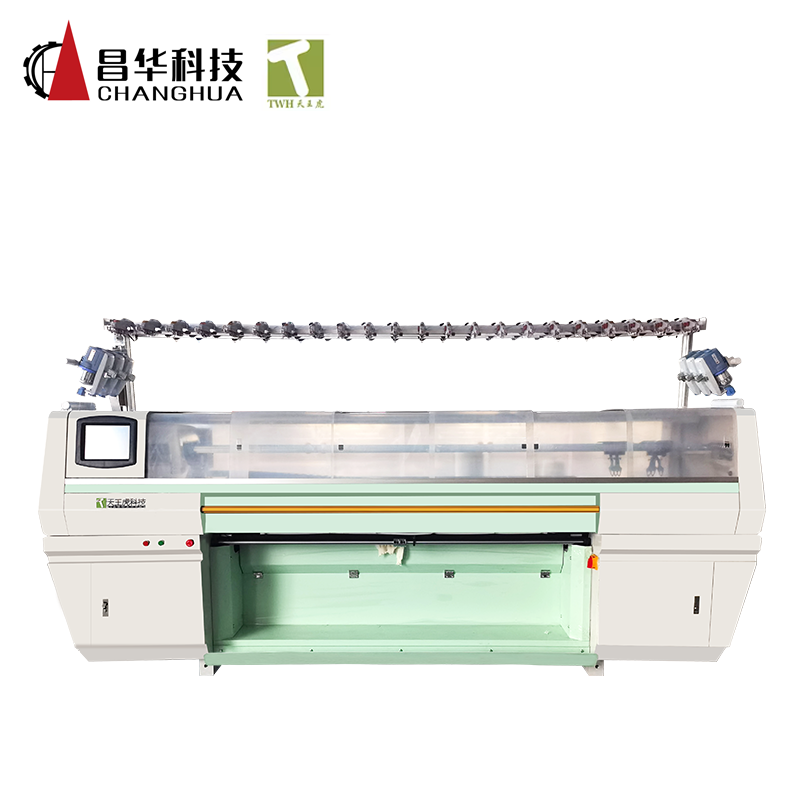

Flat knitting machines operate by moving a carriage across a needle bed, manipulating yarn to form stitches. Modern computerized models, such as those produced by Changhua, use advanced software to program patterns, adjust tension, and create seamless garments with minimal human intervention. This technology ensures high-quality output and efficiency, making flat knitting machines a cornerstone of the fashion industry.

How Do Flat Knitting Machines Work?

Needles

Form the stitches by interlocking yarn loops.

Sinkers

Hold the fabric in place during knitting.

Carriage

Moves across the needle bed, controlling needle movements. Yarn Feeders: Supply yarn to the needles for stitching.

In computerized flat knitting machines, these components are controlled by sophisticated software that allows for precise pattern creation. For example, a designer can input a jacquard pattern or a cable-knit design, and the machine will execute it with accuracy. This automation reduces labor costs and ensures consistency, which is crucial for producing fashionable sweaters at scale.

Types of Flat Knitting Machines

Semi-Automatic Flat Knitting Machines

Combine automated stitching with manual adjustments, offering a balance of control and efficiency.

Computerized Flat Knitting Machines

Fully automated with digital controls, these are the gold standard for producing complex, fashionable sweaters.

Whole Garment Flat Knitting Machines

Create seamless garments in one continuous process, reducing waste and post-production assembly.

Applications of Flat Knitting Machines in Fashion

Cable-Knit Sweaters

Known for their textured, braided patterns, these are a timeless fashion staple.

Jacquard Sweaters

Feature multicolored, intricate patterns, perfect for bold, trendy designs.

Whole Garment Sweaters

Seamless designs that enhance comfort and durability.

The versatility of flat knitting machines allows manufacturers to experiment with different yarns (wool, cotton, cashmere, synthetic blends) and stitch techniques (tuck, pointelle, intarsia), catering to diverse fashion trends.

Beyond Sweaters: Other Fashion Applications

Scarves and Shawls

Intricate patterns and lightweight fabrics for stylish accessories.

Hats and Beanies

Customizable shapes and textures for seasonal collections.

Shoe Uppers

Flexible, breathable fabrics for athletic and casual footwear.

Sustainability and Customization

In today's eco-conscious fashion industry, flat knitting machines offer significant advantages. Whole garment knitting, for instance, produces sweaters with minimal fabric waste, as the entire garment is knitted in one piece without cutting or sewing. This reduces material costs and aligns with sustainable manufacturing practices.

Additionally, flat knitting machines support on-demand production, allowing brands to create small batches or custom designs. This flexibility is perfect for catering to niche markets or offering personalized sweaters, a growing trend among consumers seeking unique fashion pieces.

Why Choose Changhua Flat Knitting Machines?

When it comes to selecting a flat knitting machine for producing fashionable sweaters, Changhua stands out as a trusted industry leader. Based in Changshu, Jiangsu, China, Changhua has over 20 years of experience in manufacturing high-quality knitting machinery. Their commitment to innovation, reliability, and customer satisfaction makes them the ideal choice for businesses worldwide.

Changhua's Cutting-Edge Technology

Double System Technology

Enhances efficiency with high-speed stitching and dynamic stitch control, perfect for complex patterns like jacquard and intarsia.

Whole Garment Knitting

Produces seamless sweaters with minimal waste, ideal for sustainable fashion brands.

User-Friendly Software

Intuitive design software allows for easy pattern creation and customization.

Versatile Yarn Compatibility

Supports wool, cashmere, cotton, silk, and blended yarns, catering to diverse sweater styles.

Why Changhua Stands Out

20+ Years of Expertise

Changhua's long-standing experience ensures reliable, high-quality machines.

Global Reach

Trusted by brands in Europe, the USA, and Asia, Changhua offers worldwide support.

R&D Innovation

Continuous investment in research and development keeps Changhua at the forefront of knitting technology.

Comprehensive Support

From installation and training to maintenance, Changhua provides end-to-end customer service.

Conclusion

Flat knitting machines are the heart of fashionable sweater production, offering unmatched versatility, efficiency, and creativity. From intricate cable knits to seamless whole garments, these machines empower designers and manufacturers to meet the demands of today's fashion-conscious consumers. Changhua, with its innovative technology and commitment to quality, is the ideal partner for businesses looking to elevate their knitwear production.

Whether you're a startup or an established brand, investing in a Changhua flat knitting machine will streamline your operations, reduce waste, and unlock endless design possibilities. Visit Changhua's website to explore their range of machines and start creating fashionable sweaters that captivate your audience.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe