In the fast-paced world of textile manufacturing, industrial knitting machines are the backbone of efficient, high-quality production. Whether you're a small-scale designer crafting bespoke garments or a large manufacturer producing thousands of sweaters, socks, or technical textiles, choosing the right knitting machine supplier is critical to your success. This comprehensive guide dives deep into the world of industrial knitting machines, offering insights into their types, applications, and benefits, while highlighting why Changhua stands out as a trusted supplier. We'll also showcase specific machines from our product range to help you make an informed decision.You can download our comprehensive PDF guide on the Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

What Are Industrial Knitting Machines?

Industrial knitting machines are advanced pieces of equipment designed to automate and streamline the production of knitted fabrics and garments. Unlike manual or domestic knitting machines, these industrial-grade systems are engineered for high-speed, large-scale production, delivering precision, consistency, and versatility. They are used across various industries, including fashion, automotive, medical textiles, and home furnishings, to create everything from sweaters and scarves to 3D-knitted shoe uppers and technical fabrics.

Industrial knitting machines are advanced pieces of equipment designed to automate and streamline the production of knitted fabrics and garments. Unlike manual or domestic knitting machines, these industrial-grade systems are engineered for high-speed, large-scale production, delivering precision, consistency, and versatility. They are used across various industries, including fashion, automotive, medical textiles, and home furnishings, to create everything from sweaters and scarves to 3D-knitted shoe uppers and technical fabrics.

Types of Industrial Knitting Machines

Industrial knitting machines come in two primary categories: circular knitting machines and flat knitting machines. Each type serves distinct purposes based on the desired fabric structure and production goals.

Circular Knitting Machines

Circular knitting machines produce seamless, tubular fabrics, making them ideal for items like t-shirts, socks, and leggings. These machines are known for their high-speed output and ability to handle continuous production. They are widely used in mass production due to their efficiency and ability to create fabrics with consistent quality.

Flat Knitting Machines

Flat knitting machines, on the other hand, create flat, weft-knitted fabrics that are perfect for sweaters, scarves, collars, and technical textiles. These machines offer greater flexibility in pattern design and are often used for customized or small-batch production. Fully computerized flat knitting machines, like those offered by Changhua, allow for intricate designs and seamless integration with modern design software.

Why Invest in Industrial Knitting Machines?

Investing in an industrial knitting machine can transform your production process. Here are some key benefits:

Efficiency: Automated knitting machines significantly reduce production time compared to manual methods.

Precision: Computerized systems ensure consistent stitch quality and pattern accuracy.

Versatility: Modern machines can handle a wide range of yarns, patterns, and fabric types.

Cost-Effectiveness: While the initial investment may be significant, the long-term savings in labor and production costs are substantial.

Sustainability: Advanced machines optimize yarn usage and reduce waste, contributing to eco-friendly manufacturing.

Why Choose Changhua as Your Industrial Knitting Machine Supplier?

When it comes to selecting a reliable supplier, Changhua stands out as a leader in the textile machinery industry. Located in Changshu, Jiangsu—the heart of China's apparel industry—Changshu Changhua Smart Manufacturing Technology Co., Ltd. has over 20 years of experience in designing and producing high-quality knitting machines. Our brands, including "Changhua," "Tiangong," "King Tiger," and "Miao’s Craftsman," are synonymous with innovation, durability, and customer satisfaction.

Our Commitment to Quality and Innovation

At Changhua, we believe that quality and innovation are the cornerstones of success. Our mission is to modernize the knitting industry through cutting-edge technology and customer-centric solutions. Here’s why manufacturers worldwide choose us:

Advanced Technology: Our machines incorporate fast, intelligent programming to enhance efficiency and reduce energy consumption.

Durability: Built with high-quality materials, our machines are designed for long-lasting stability and performance.

Global Reach: We serve clients in over 30 countries, including China, India, Bangladesh, Mexico, Southeast Asia, the Middle East, Europe, and the United States.

Responsive Support: Our technical staff is available 24/7 to provide support, ensuring minimal downtime for your operations.

Sustainability: We prioritize eco-friendly manufacturing processes, helping our clients reduce waste and energy usage.

Comprehensive Product Range

Changhua offers a wide range of knitting machines, including flat knitting machines, glove machines, and hosiery machines. Our flat knitting machines, in particular, are renowned for their versatility and precision, making them ideal for producing high-quality garments and technical textiles.

Exploring Changhua's Flat Knitting Machines

Our flat knitting machines are designed to meet the diverse needs of modern textile manufacturers. Below, we highlight some of our top models, each engineered to deliver exceptional performance. For detailed specifications, visit our Flat Knitting Machine page.

Computerized Sweater Knitting Machine

Our Computerized Sweater Knitting Machine is a flagship product designed for high-speed, high-precision sweater production. This machine is perfect for manufacturers looking to produce intricate designs with minimal manual intervention.

Our Computerized Sweater Knitting Machine is a flagship product designed for high-speed, high-precision sweater production. This machine is perfect for manufacturers looking to produce intricate designs with minimal manual intervention. Key Features:

Fully computerized control for precise pattern creation.

Supports a wide range of yarns, including cotton, wool, and synthetic blends.

High-speed knitting for increased productivity.

Energy-efficient design to reduce operational costs.

Applications:

Ideal for producing sweaters, cardigans, and other knitwear with complex patterns like jacquard or intarsia.

Suitable for both small-batch and large-scale production.

Semi-Automatic Flat Knitting Machine

For businesses seeking a balance between automation and manual control, our Semi-Automatic Flat Knitting Machine is an excellent choice. This machine combines automated needle movements with operator-controlled tasks like yarn feeding and tension adjustments.

For businesses seeking a balance between automation and manual control, our Semi-Automatic Flat Knitting Machine is an excellent choice. This machine combines automated needle movements with operator-controlled tasks like yarn feeding and tension adjustments. Key Features:

Hybrid operation for flexibility in production.

Cost-effective compared to fully automatic systems.

Capable of producing a variety of stitch types, including tuck and semi-jacquard.

Easy to operate, making it ideal for small to medium-sized businesses.

Applications:

Perfect for producing collars, ribs, and small-batch knitwear.

Widely used by designers and manufacturers who need customizable patterns.

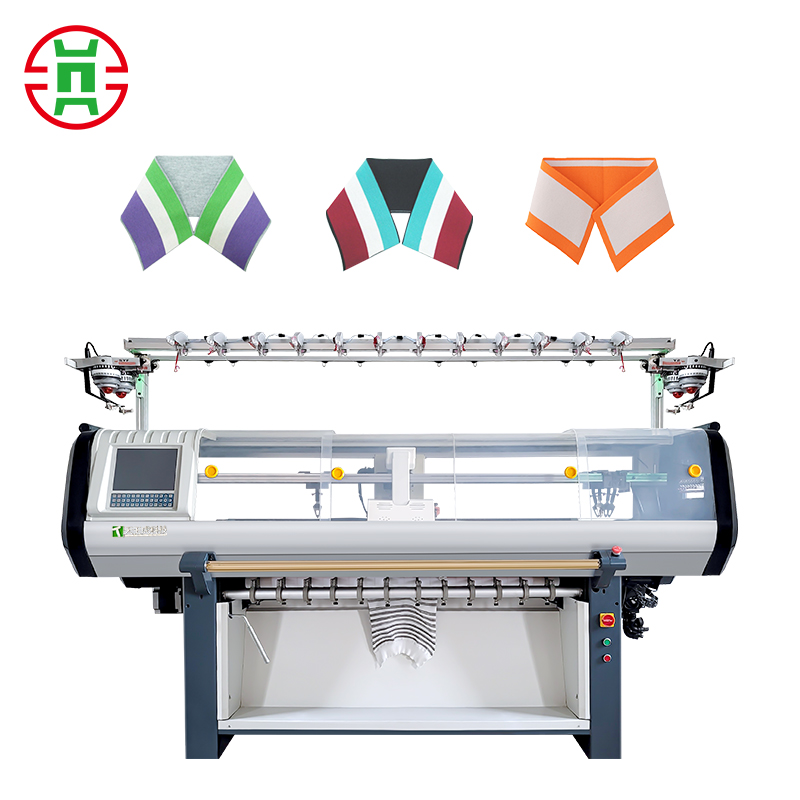

Collar Flat Knitting Machine

Our Collar Flat Knitting Machine is specifically designed to address common challenges in collar and rib production, such as uneven edges and insufficient flatness. This machine is a must-have for manufacturers producing high-quality shirts and sweaters.

Our Collar Flat Knitting Machine is specifically designed to address common challenges in collar and rib production, such as uneven edges and insufficient flatness. This machine is a must-have for manufacturers producing high-quality shirts and sweaters. Key Features:

Specialized needle beds for precise collar and rib knitting.

Automated pattern control for consistent quality.

Compact design for easy integration into existing production lines.

High-speed operation for increased output.

Applications:

Ideal for producing collars, cuffs, and ribs for shirts, sweaters, and jackets.

Suitable for both fashion and workwear industries.

How to Choose the Right Industrial Knitting Machine

Selecting the right knitting machine depends on several factors, including your production goals, budget, and target market. Here are some key considerations to guide your decision:

1. Production Volume

2. Fabric Type

Fashion Garments: Machines like our Sweater Knitting Machine are ideal for producing intricate patterns and high-quality knitwear.

Technical Textiles: For automotive or medical textiles, choose machines with advanced programming capabilities to handle specialized materials.

3. Automation Level

Fully Automated: Best for high-speed, large-scale production with minimal manual intervention.

Semi-Automated: Offers a balance of automation and manual control, ideal for customized or small-batch production.

4. Budget

While fully computerized machines have a higher upfront cost, they offer long-term savings through efficiency and reduced labor costs.

Semi-automatic machines are more budget-friendly for businesses with limited capital.

5. Supplier Reputation

The Benefits of Partnering with Changhua

Partnering with Changhua means more than just purchasing a knitting machine—it’s about building a long-term relationship with a trusted supplier. Here’s what sets us apart:

Cutting-Edge Technology

Our machines are equipped with the latest advancements in knitting technology, including intelligent programming and energy-efficient designs. This ensures you stay ahead in a competitive market.

Global Support Network

With clients in over 30 countries, we have a robust global support network. Our technical team is available 24/7 to assist with installation, troubleshooting, and maintenance.

Custom Solutions

We understand that every manufacturer has unique needs. That’s why we offer customized solutions, from machine configurations to tailored training programs.

Fast Delivery

Our average delivery time is 15-30 days, ensuring you can start production as soon as possible.

Commitment to Sustainability

We prioritize eco-friendly manufacturing practices, helping you reduce waste and energy consumption while maintaining high-quality output.

Applications of Changhua's Knitting Machines

Our knitting machines are versatile and cater to a wide range of industries. Here are some key applications:

Fashion and Apparel

From sweaters and scarves to socks and hats, our machines produce high-quality garments with intricate patterns and consistent quality. The Computerized Sweater Knitting Machine is particularly popular in the fashion industry for its ability to create complex designs.

Automotive Textiles

Our machines are used to produce durable, high-quality fabrics for car seats, headrests, and interior mats. The precision of our Collar Flat Knitting Machine ensures consistent branding and aesthetic appeal.

Medical Textiles

Flat knitting machines are ideal for producing medical textiles like bandages and compression garments. Our machines’ ability to handle specialized materials makes them a top choice for this sector.

Home Furnishings

From blankets to upholstery fabrics, our machines deliver the durability and quality needed for home furnishing applications.

How to Maintain Your Industrial Knitting Machine

Proper maintenance is crucial to ensuring the longevity and performance of your knitting machine. Here are some tips:

Regular Cleaning: Remove dust and debris from needle beds and yarn feeders to prevent jams.

Lubrication: Use manufacturer-recommended lubricants to keep moving parts running smoothly.

Software Updates: For computerized machines, ensure the software is up to date to access the latest features and bug fixes.

Routine Inspections: Check for worn parts and replace them promptly to avoid downtime.

Operator Training: Ensure your staff is trained to operate and maintain the machine correctly.

Changhua provides comprehensive maintenance guides and 24/7 technical support to keep your machines in top condition.

The Future of Industrial Knitting Machines

The knitting industry is evolving rapidly, with trends like 3D knitting, smart textiles, and sustainable manufacturing shaping the future. At Changhua, we're at the forefront of these innovations, developing machines that support advanced techniques like knit-to-shape and seamless knitting. Our R&D team is constantly exploring new ways to enhance efficiency, reduce waste, and integrate digital technologies into our machines.

Trends to Watch

3D Knitting: Creates seamless, waste-free garments, reducing production time and material costs.

Smart Textiles: Integrates electronics into fabrics for applications like wearable technology.

Automation: Fully computerized machines are becoming the standard for high-speed, large-scale production.

Sustainability: Eco-friendly machines that minimize energy and yarn waste are in high demand.

Why Changhua Is Your Trusted Partner

With over 20 years of experience, Changhua has established itself as a global leader in knitting machinery. Our commitment to quality, innovation, and customer satisfaction sets us apart in a competitive market. Whether you’re looking to upgrade your production line or start a new textile business, our machines and support services are designed to help you succeed.

Contact Us Today

Ready to take your textile production to the next level? Contact Changhua today to discuss your needs and explore our range of industrial knitting machines.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe