Knitting machines have revolutionized the textile industry, enabling faster, more efficient production of fabrics and garments. Among the various types of knitting machines, flat knitting machines and circular knitting machines are the most widely used, each serving distinct purposes based on their design and functionality. Understanding the differences between these two types of machines is crucial for manufacturers, designers, and hobbyists looking to select the right equipment for their needs. This comprehensive guide explores the mechanics, applications, and advantages of flat and circular knitting machines, with a special focus on computerized flat knitting machines and how Changhua Knitting Machines stand out in the market.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

What is the Difference Between a Flat Knitting Machine and a Circular Knitting Machine?

Flat Knitting Machines: Design and Mechanics

Flat knitting machines operate on a flat needle bed, where needles are arranged in a linear formation. The machine uses a carriage that moves back and forth across the needle bed, manipulating the needles to create stitches. The yarn is fed through guides, and the needles are controlled either manually, mechanically, or via computer systems in modern models.

Needle Bed

A flat surface with grooves that house the knitting needles.

Carriage

Moves horizontally to activate needles and form stitches.

Yarn Guides

Ensure precise yarn feeding.

Cam System or Computer Control

Dictates needle movement for pattern creation.

Operation

The needles move horizontally and vertically to form flat fabric panels. Modern flat knitting machines, particularly computerized flat knitting machines, use digital controls to achieve intricate patterns and shapes with high precision.

Circular Knitting Machines: Design and Mechanics

Circular knitting machines, as the name suggests, operate in a continuous circular motion. They feature a cylindrical needle bed (or knitting head) with needles arranged in a circular formation. The cylinder rotates, and yarn is fed through sinkers and guides to produce a seamless tubular fabric.

Cylinder

The rotating component that holds the needles.

Sinkers

Assist in holding the fabric and forming stitches.

Yarn Feeders

Supply yarn to the needles.

Cam System

Controls needle movement.

Operation

The needles move in a circular path, creating a continuous tube of fabric. Circular knitting machines are designed for high-speed production and are less flexible in terms of pattern complexity compared to flat knitting machines.

Applications of Flat and Circular Knitting Machines

Flat Knitting Machines

Fashion Industry

Used for producing high-end garments like sweaters, cardigans, and dresses with intricate patterns. Their ability to create seamless garments (e.g., WHOLEGARMENT technology) reduces waste and labor costs.

Technical Textiles

Employed in healthcare (medical bandages), automotive (seat covers), and home décor (upholstery, blankets).

Customization

Ideal for small-batch production and personalized designs due to their flexibility.

Circular Knitting Machines

Mass Production

Widely used for producing large quantities of apparel like T-shirts, sportswear, and underwear.

Hosiery and Socks

Specialized circular machines create seamless socks and stockings.

Industrial Textiles

Used for producing fabrics for mattresses, agro-textiles, and geo-textiles.

Computer Flat Knitting Machine: The Future of Knitting

What is a Computer Flat Knitting Machine?

A computerized flat knitting machine is an advanced version of the traditional flat knitting machine, equipped with digital controls and software for precise pattern creation and automation. These machines integrate Computer-Aided Design (CAD) systems, allowing designers to input patterns directly into the machine, which then executes them with high accuracy.

Key Features

Digital Control Systems

Enable complex stitch patterns, including jacquard, intarsia, and 3D shaping.

Automation

Reduces manual intervention, increasing efficiency and consistency.

Multi-System Capability

Machines with 2, 3, or 4 systems can knit multiple colors or patterns simultaneously.

Seamless Knitting

Advanced models produce fully fashioned garments without the need for cutting or sewing.

Advantages

Precision

Ensures uniformity in patterns and measurements.

Versatility

Supports a wide range of yarns and fabric types.

Efficiency

Reduces production time and labor costs.

Sustainability

Minimizes material waste through precise yarn usage.

Why Choose a Computer Flat Knitting Machine?

Design Flexibility

Create intricate patterns and shapes that are difficult to achieve with circular knitting machines.

Reduced Lead Times

Automation speeds up production, allowing faster delivery to market.

Cost Savings

Efficient yarn usage and seamless knitting reduce material and labor costs.

Sustainability

Seamless knitting technologies minimize fabric waste, aligning with eco-friendly manufacturing trends.

Why Choose Changhua Knitting Machines?

When it comes to computerized flat knitting machines, Changhua stands out as a trusted manufacturer with over 20 years of experience in the industry. Based in China, Changhua is committed to delivering high-quality, innovative knitting solutions that cater to diverse market needs. Here's why Changhua is the go-to choice for textile manufacturers worldwide:

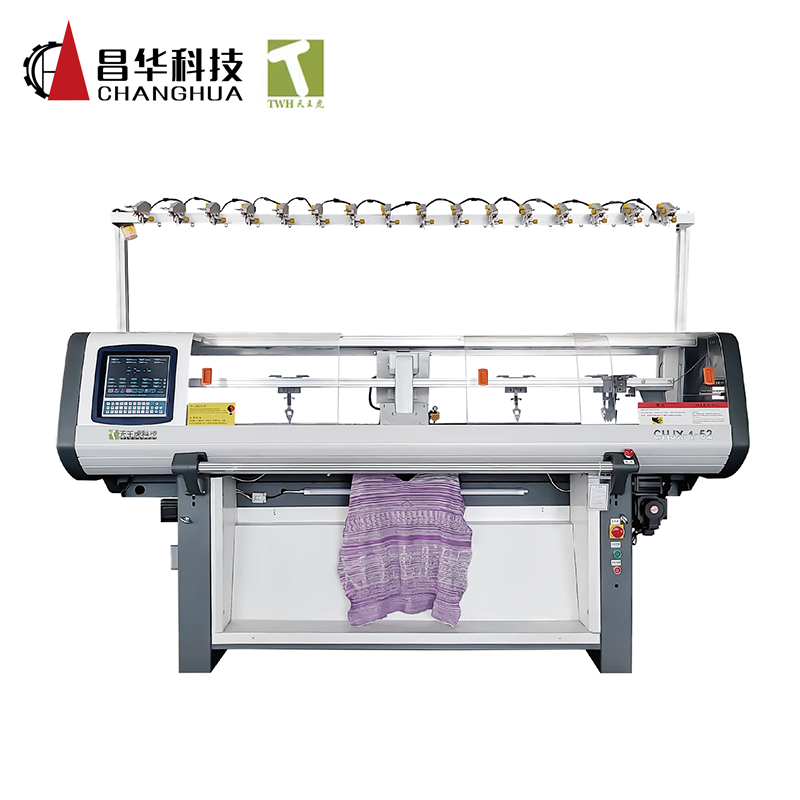

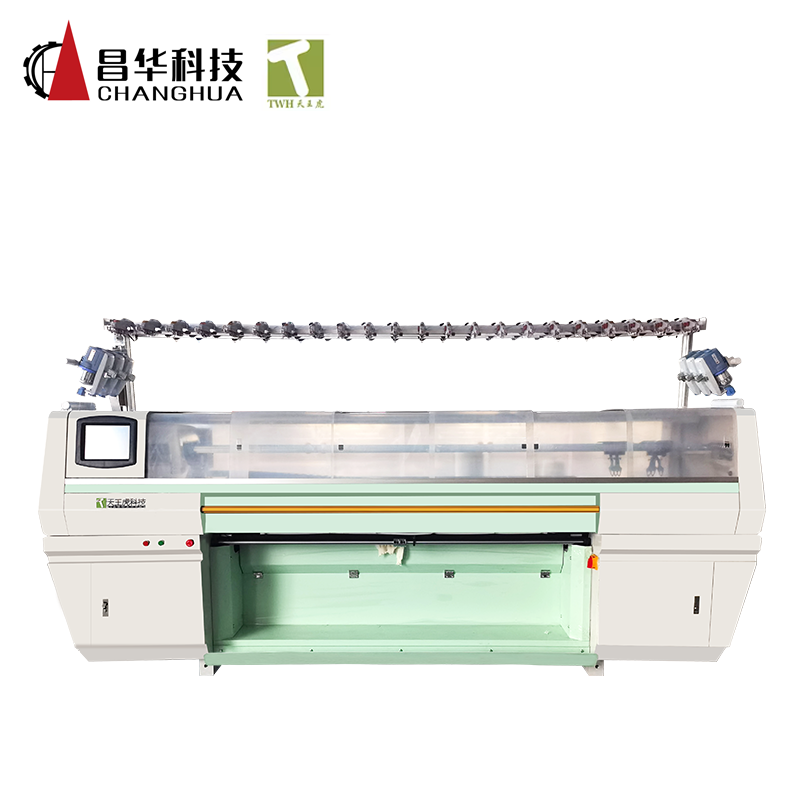

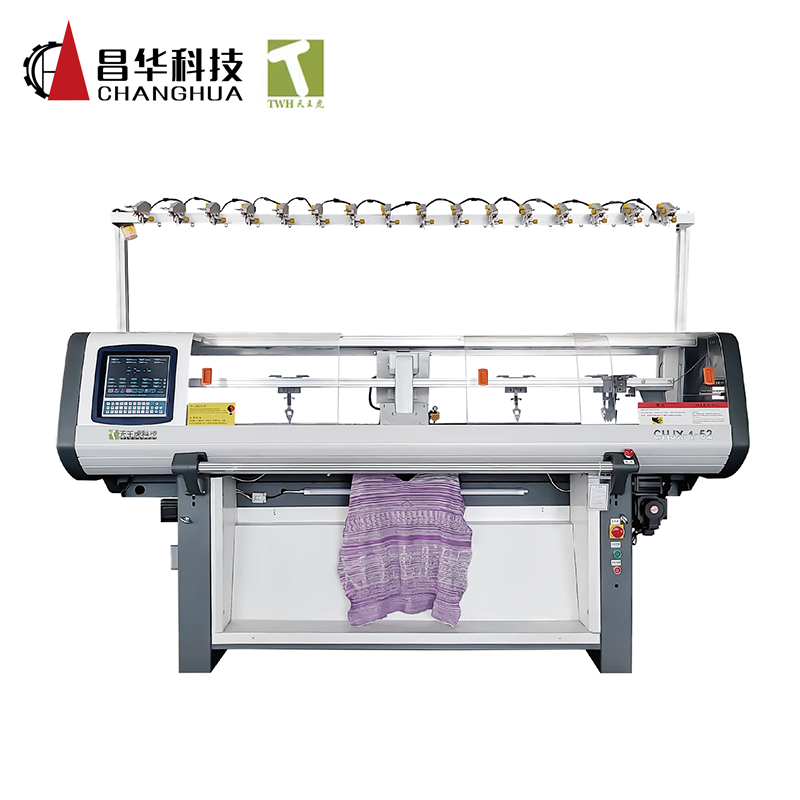

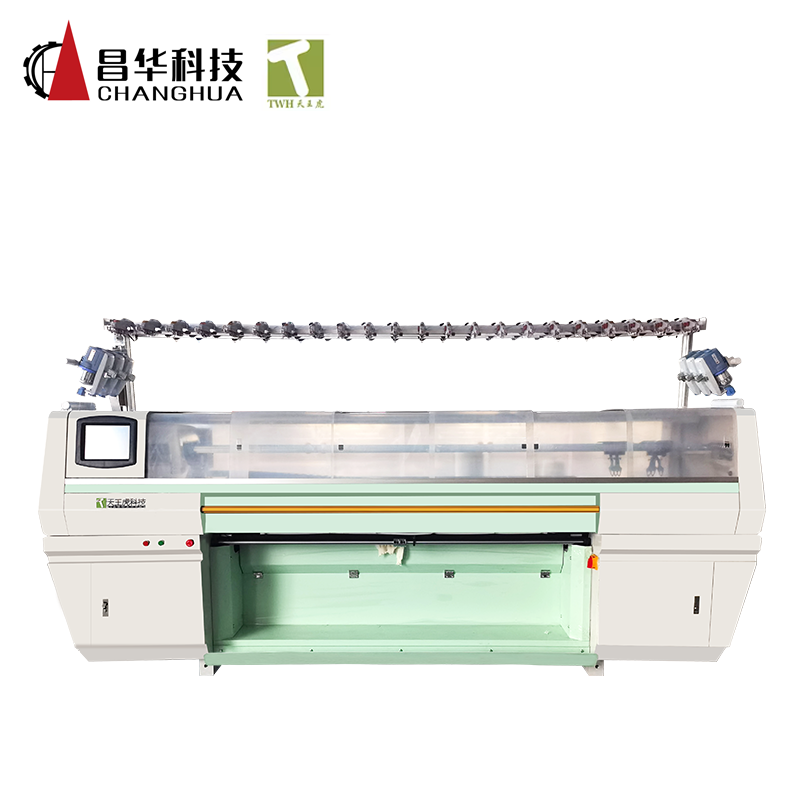

Changhua's Computerized Flat Knitting Machines

Changhua offers a wide range of computerized flat knitting machines designed for precision, efficiency, and versatility. Their machines are engineered to meet the demands of modern textile production, from fashion to technical applications.

Sweater Knitting Machine

Produces high-quality sweaters with complex patterns, ideal for fashion brands seeking premium knitwear.

Collar and Rib Knitting Machine

Specially designed for knitting collars and ribs with exceptional straightness, flatness, and precision. Changhua's machines address common issues like unclear fabric grain and uneven edges, ensuring top-quality output.

Whole Garment Flat Knitting Machine

Enables seamless garment production, reducing waste and labor costs while delivering finished products ready for market.

Why Changhua Stands Out

Quality and Reputation

Changhua prioritizes quality, ensuring every machine meets stringent standards for durability and performance.

Innovation

The company invests in research and development to stay ahead of industry trends, offering cutting-edge solutions like 3D knitting and seamless garment production.

Global Reach

Changhua’s machines are used by manufacturers worldwide, from small-scale producers to large fashion houses.

Customer Support

Comprehensive after-sales service, including maintenance guidance and technical support, ensures long-term customer satisfaction.

Conclusion

The choice between a flat knitting machine and a circular knitting machine depends on your production goals, design requirements, and target market. Flat knitting machines, particularly computerized flat knitting machines, offer unmatched flexibility and precision, making them ideal for high-end fashion, technical textiles, and customized products. Circular knitting machines, on the other hand, excel in high-speed, large-scale production of uniform fabrics like T-shirts and socks.

For manufacturers seeking the best in computerized flat knitting technology, Changhua Knitting Machines is a trusted partner. With a commitment to quality, innovation, and sustainability, Changhua's machines empower businesses to create exceptional knitwear and technical textiles with efficiency and precision. Whether you're producing seamless garments, intricate sweaters, or cutting-edge shoe uppers, Changhua has the solution to elevate your production.

Ready to elevate your production? Contact us, or download our  product catalog.pdf. With Changhua, you're not just buying a machine—you're investing in innovation, reliability, and growth.

product catalog.pdf. With Changhua, you're not just buying a machine—you're investing in innovation, reliability, and growth.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe