The textile industry has undergone a remarkable transformation with the advent of computerized flat knitting machines, particularly those manufactured in China. These advanced machines have redefined efficiency, precision, and versatility in knitting, making them indispensable for businesses worldwide. In this comprehensive guide, we'll explore the mechanics, applications, and benefits of computerized flat knitting machines from China, with a special focus on knitting machines for sale that cater to diverse industries. We'll also spotlight Changhua, a leading manufacturer in China, whose innovative machines are setting industry benchmarks.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

What is a Computerized Flat Knitting Machine?

A computerized flat knitting machine is a high-tech device designed to produce flat knitted fabrics with unparalleled precision. Unlike traditional manual or hand-driven knitting machines, these modern systems leverage advanced computer controls to automate the knitting process. This allows for intricate patterns, complex designs, and consistent quality that manual methods cannot match. The flatbed design, equipped with linearly arranged needles, enables the creation of flat fabric pieces, which are ideal for garments, accessories, and sports.

How Do They Work?

Gauge

Determines the distance between needles, affecting stitch tightness and fabric texture. Options range from 3G to 18G, catering to fine or coarse yarns.

Knitting Speed

Measured in stitches per minute, with high-speed models reaching up to 1.6m/sec for high-volume production.

Pattern Capabilities

From basic stitches (plain, rib) to complex jacquard, intarsia, and 3D designs, these machines handle diverse patterns.

Automation

Features like automatic yarn feeding, stitch selection, and fabric takedown reduce manual intervention, boosting efficiency.

Applications Across Industries

Garment Industry

Garment Industry Producing sweaters, cardigans, T-shirts, and polo shirts with customized designs and precise fits.

Automotive Textiles

Crafting car seat covers, liners, and other interior components.

Home Textiles

Creating blankets, curtains, tablecloths, and pillowcases with intricate patterns.

Fashion

Automotive

Home Furnishings

Knitting Machines for Sale: Exploring Your Options

Types of Computerized Flat Knitting Machines for Sale

Single System Machines

Features: Ideal for small-scale production, these machines offer basic knitting functions like plain stitch, rib, and simple jacquard.

Best For: Startups, home textile producers, or businesses focusing on simpler designs.

Double System Machines

Features: Equipped with two knitting systems, these machines handle complex patterns like intarsia and multi-color jacquard with higher efficiency.

Best For: Medium to large garment manufacturers producing sweaters, scarves, and hats.

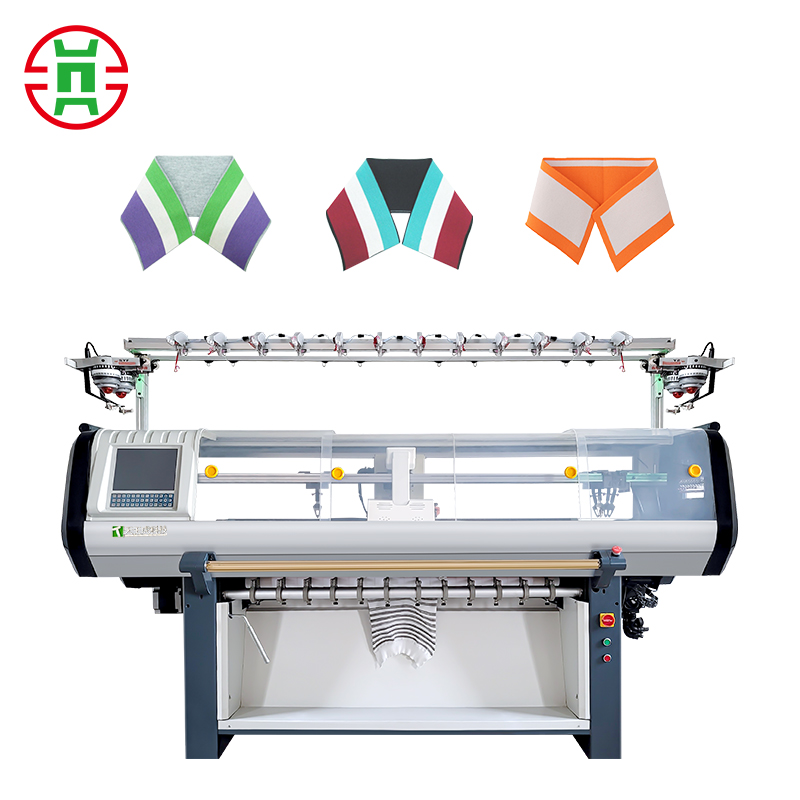

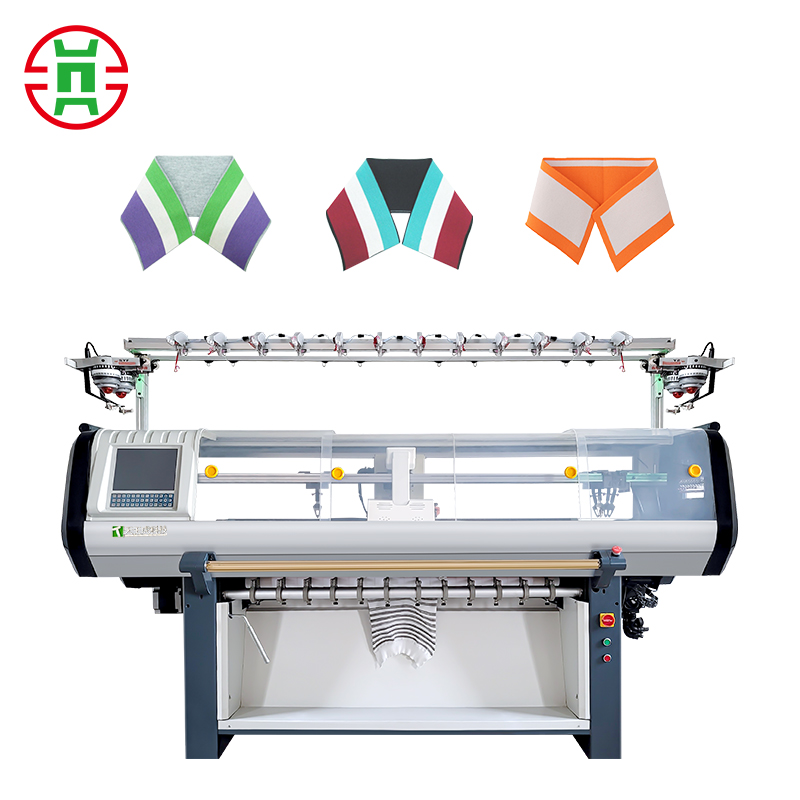

Specialized Machines

Features: Designed for specific applications, such as collar knitting, glove production, or sock manufacturing.

Best For: Niche markets or businesses focusing on accessories.

Key Considerations When Buying

Production Needs

Assess whether you need high-speed machines for bulk production or slower, precision-focused models for intricate designs.

Ease of Use

Look for machines with intuitive controls and short learning curves, especially if your operators lack technical expertise.

After-Sales Support

Choose suppliers with robust training, maintenance, and spare parts availability.

Budget

Balance upfront costs with long-term savings from automation and efficiency.

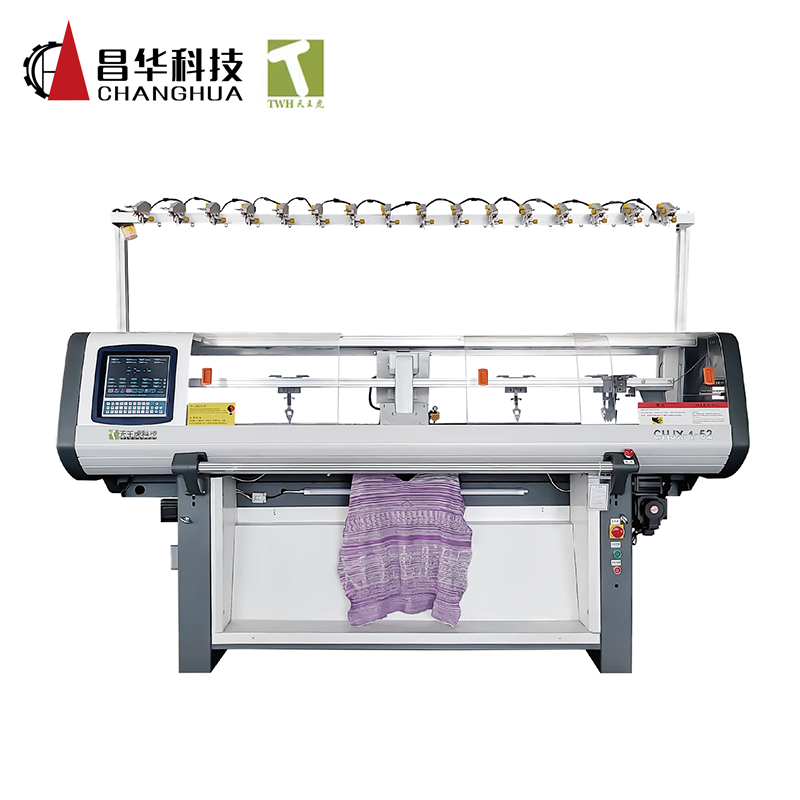

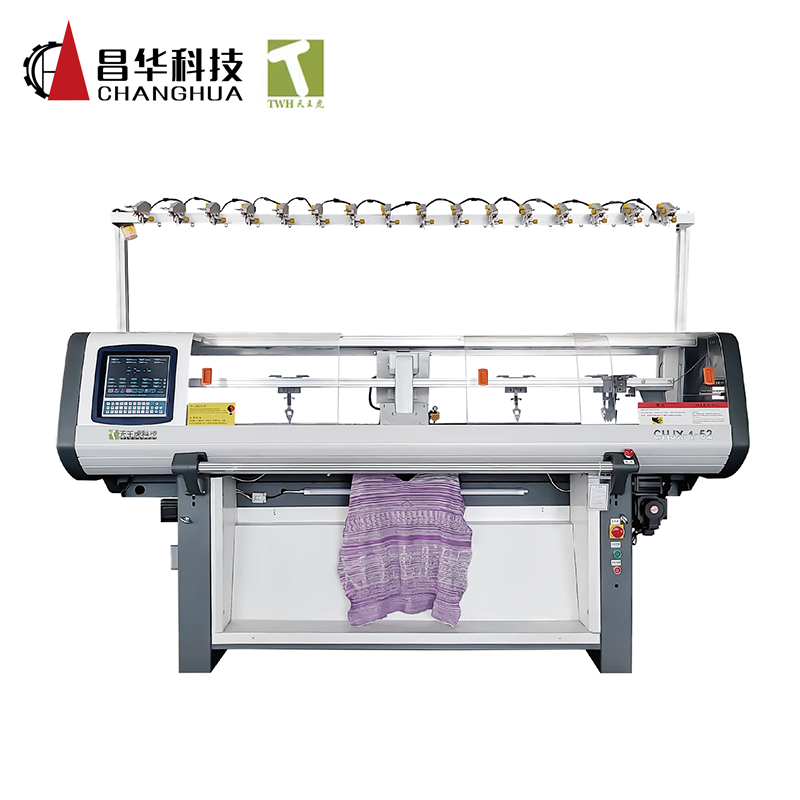

Spotlight on Changhua: Your Trusted Partner for Knitting Machines

When it comes to computerized flat knitting machines, Changhua is a name synonymous with innovation, quality, and customer satisfaction. With over 20 years of experience, Changhua has established itself as a leading manufacturer in China, offering a diverse range of machines tailored to modern textile needs.

Why Choose Changhua?

High-Speed Carriages

Ultra-small 5.2-inch carriages with rapid return capabilities boost productivity.

Cost-Effective Solutions

Changhua’s machines offer excellent value without compromising on quality. Their energy-efficient designs also lower operating costs.

Exceptional After-Sales Service

Changhua provides comprehensive training, online support, and readily available spare parts, ensuring minimal downtime for your operations.

Global Reputation

With exports to Asia, Europe, and North America, Changhua has earned trust for its reliable machines and commitment to customer success.

Maintenance and Care for Your Knitting Machine

Cleaning

Wipe the machine with a soft, dry cloth to remove dust. Use a vacuum for hard-to-reach areas.

Lubrication

Apply a small amount of oil to moving parts like needles and yarn tensioners to reduce friction.

Inspection

Regularly check needles, cams, and rollers for wear and tear to prevent production issues.

Conclusion

Computerized flat knitting machines from China are transforming the textile industry, offering unmatched efficiency, versatility, and quality. Whether you’re producing sweaters, shoe uppers, or medical textiles, these machines deliver the precision and scalability needed to succeed in today's competitive market. For businesses searching for knitting machines for sale, Changhua stands out as a trusted partner, combining cutting-edge technology with affordability and exceptional support.

Ready to elevate your production? Explore Changhua's range of knitting machines for sale, request a quote, or download our  product catalog.pdf. With Changhua, you're not just buying a machine—you're investing in innovation, reliability, and growth.

product catalog.pdf. With Changhua, you're not just buying a machine—you're investing in innovation, reliability, and growth.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe