Knitting machines have revolutionized the textile industry, enabling faster, more efficient production of fabrics and garments. Among the various types of knitting machines, flat knitting machines and circular knitting machines are the most widely used, each serving distinct purposes based on their design and functionality. Understanding the differences between these two types of machines is crucial for manufacturers, designers, and hobbyists looking to select the right equipment for their needs. This comprehensive guide explores the mechanics, applications, and advantages of flat and circular knitting machines, with a special focus on computerized flat knitting machines and how Changhua Knitting Machines stand out in the market.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

What Machine Is Used to Make Sweaters?

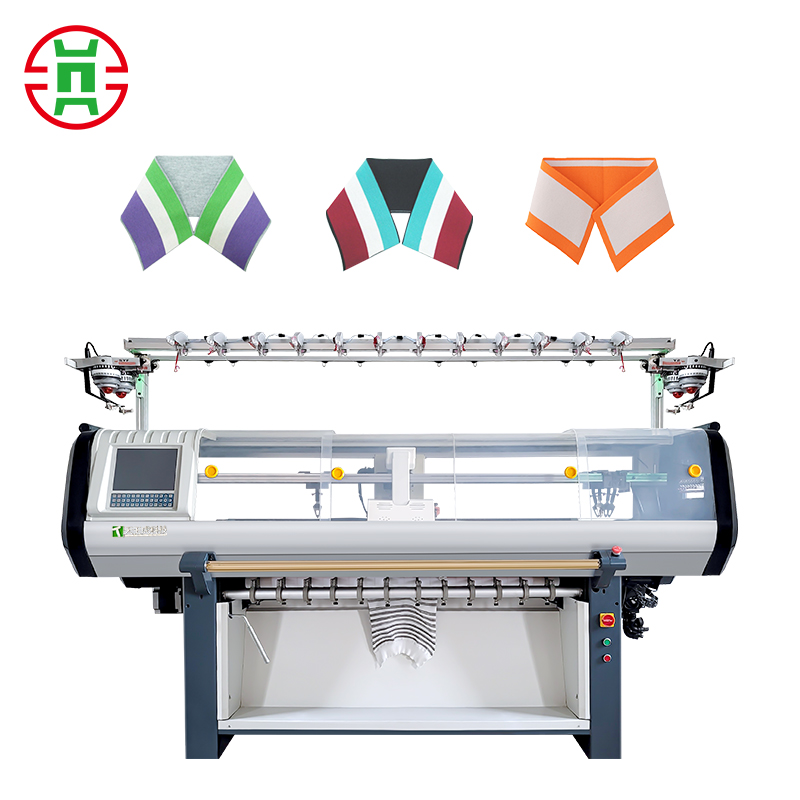

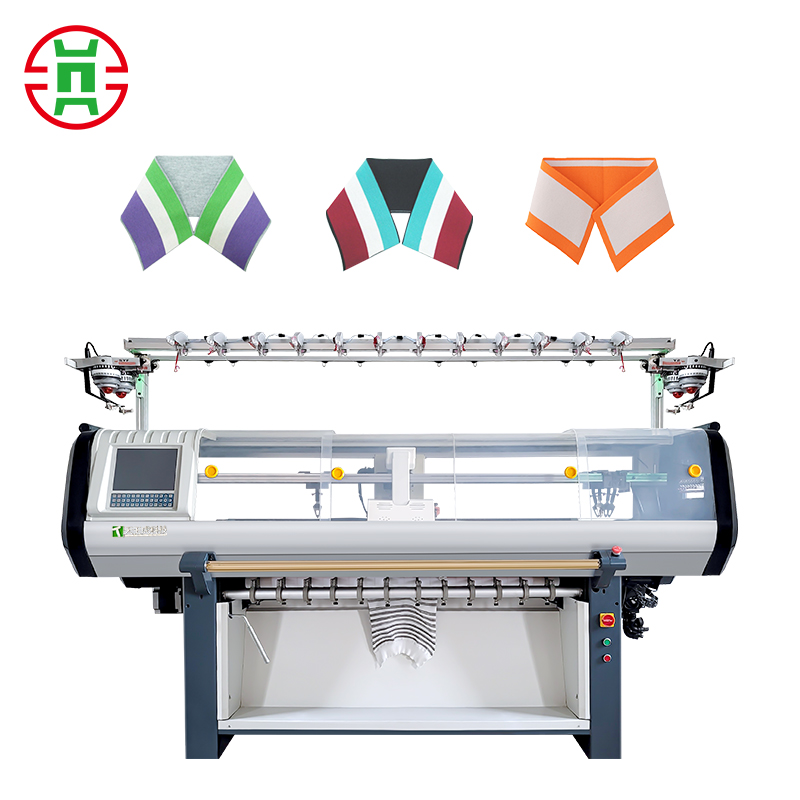

The primary machine used to make sweaters is the computerized flat knitting machine. Unlike traditional hand-knitting or mechanical machines, these advanced devices leverage digital controls to automate the knitting process, ensuring precision and consistency in every stitch. They are designed to produce a wide range of knitted garments, including sweaters, cardigans, scarves, and more, with intricate patterns and seamless designs.

The Evolution of Sweater Manufacturing

Historically, sweaters were crafted by hand, a labor-intensive process that limited production speed and scalability. The introduction of mechanical knitting machines in the 19th century marked a significant leap forward, but it was the development of computerized flat knitting machines in the late 20th century that truly transformed the industry. These machines combine cutting-edge technology with user-friendly interfaces, allowing manufacturers to create complex designs quickly and efficiently.

Today, computer flat knitting machines are the backbone of sweater manufacturing, enabling both mass production and customization. They cater to various skill levels and project types, from home-based artisans to industrial-scale factories. But what exactly makes these machines so essential? Let’s dive into their mechanics and applications.

How Do Computer Flat Knitting Machines Work?

A computer flat knitting machine operates using a flatbed with linearly arranged needles. The machine’s carriage moves back and forth, supplying yarn to the needles to create knitted fabrics. Unlike circular knitting machines, which produce tubular fabrics, flat knitting machines create flat panels that can be shaped into garments like sweaters. The computerized control system allows users to upload digital patterns, adjust stitch settings, and automate complex processes such as:

Pattern Creation

Upload intricate designs like jacquard, intarsia, or cable-knit patterns.

Stitch Manipulation

Adjust tension, stitch count, and shaping for consistent results.

Yarn Management

Switch between different yarn types and colors seamlessly.

Shaping and Fashioning

Create fully fashioned or whole-garment sweaters without additional sewing.

Types of Computer Flat Knitting Machines

Single System Machines

Ideal for small-scale production or simpler designs, these machines are cost-effective and easy to operate.

Double System Machines

Designed for higher productivity, they allow simultaneous knitting of two patterns or colors, perfect for complex sweater designs.

Whole Garment Knitting Machines

These advanced machines produce seamless sweaters in one piece, eliminating the need for cutting and sewing. They are highly efficient and produce comfortable, high-quality garments.

Applications of Computer Flat Knitting Machines in Sweater Manufacturing

Mass Production

For large-scale manufacturers, computer flat knitting machines are indispensable for producing sweaters in bulk. These machines can be connected to central computer systems to control parameters like stitch density, pattern accuracy, and production speed. This ensures consistency across thousands of garments, making them ideal for wholesale markets. Brands like H&M, Zara, and Uniqlo rely on these machines to meet the demands of fast fashion.

Customization and Small-Batch Production

In recent years, consumer demand for personalized and unique clothing has surged. Computer flat knitting machines equipped with CAD (Computer-Aided Design) systems allow manufacturers to create custom sweaters with specific patterns, colors, or sizes. This flexibility is perfect for boutique brands or designers catering to niche markets.

Seamless Whole-Garment Knitting

Whole garment knitting machines, a subset of computer flat knitting machines, produce sweaters in one piece without seams. This technology, pioneered by companies like SHIMA SEIKI, reduces production time, labor costs, and material waste. Seamless sweaters are softer, more comfortable, and visually appealing, making them a favorite among premium brands.

Fashion Garment Manufacturing

From chunky cable-knit sweaters to sleek, fine-gauge pullovers, computer flat knitting machines can produce a wide range of styles. They support various knitting structures, including plain, rib, jacquard, and satin, allowing designers to experiment with textures and patterns. This versatility makes them essential for creating trendy, high-quality sweaters that align with seasonal fashion trends.

What Machine Is Used to Make Sweaters? A Closer Look at Key Features

Computerized Control Systems

Modern machines come with advanced software that allows users to program patterns, adjust settings, and monitor production in real-time. This ensures precision and reduces the risk of errors, even for complex designs.

Multi-Gauge Capability

Machines with multi-gauge options (e.g., 7G, 10G, 12G, 14G) offer flexibility to produce sweaters of varying thicknesses and textures. This is essential for manufacturers catering to diverse markets.

High-Speed Knitting

Speed is a key factor in industrial production. High-speed machines can produce thousands of stitches per minute, significantly boosting output without compromising quality.

Automatic Yarn Feeding

Automatic yarn feeders streamline the knitting process by switching between colors or yarn types without manual intervention. This is particularly useful for creating multi-colored or textured sweaters.

Why Choose Changhua Computer Flat Knitting Machines?

When it comes to selecting the best computer flat knitting machine for sweater manufacturing, Changhua stands out as a trusted name in the industry. With decades of experience and a commitment to innovation, Changhua offers a range of machines that combine cutting-edge technology with user-friendly designs. Here’s why Changhua is the go-to choice for sweater manufacturers:

Superior Technology

Changhua's computerized flat knitting machines are equipped with advanced CPU dual-core processors and optimized systems that simplify operation and enhance efficiency. Our Whole Garment Knitting Machines produce seamless sweaters with unmatched comfort and quality, reducing production time and labor costs.

Versatility for All Skill Levels

Whether you're a seasoned manufacturer or a startup designer, Changhua machines cater to all skill levels. Our intuitive interfaces allow beginners to create professional-quality sweaters, while advanced features like unlimited pattern memory and jacquard capabilities meet the needs of experienced knitters.

Seamless and Comfortable Sweaters

Changhua’s all-in-one machines produce seamless sweaters that are softer, more comfortable, and free from pattern errors or color differences. This ensures a premium product that meets the expectations of discerning customers.

Cost-Effective Production

By reducing the need for sewing and minimizing material waste, Changhua machines help manufacturers save on labor and production costs. Our high-speed knitting capabilities also ensure faster turnaround times, making them ideal for meeting tight deadlines.

Comprehensive Support and Maintenance

Changhua provides a robust support system, including training programs, maintenance services, and access to genuine parts. This ensures that your machine remains in top condition, maximizing its lifespan and performance.

Conclusion

In the world of sweater manufacturing, the computer flat knitting machine is the cornerstone of innovation, efficiency, and creativity. From mass production to bespoke designs, these machines offer unparalleled versatility and precision. Among the many options available, Changhua's computerized flat knitting machines stand out for the advanced technology, cost-effectiveness, and commitment to sustainability.

If you're a sweater manufacturer looking to elevate your production process, consider partnering with Changhua. Contact us to explore our range of machines and discover how they can transform your business. Ready to create stunning, high-quality sweaters? The answer to “What machine is used to make sweaters?” is clear—it's a Changhua computer flat knitting machine.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe