In today's competitive textile industry, manufacturers face relentless pressure to reduce expenses while maintaining quality and meeting increasingly tight deadlines. Energy costs represent one of the most significant and growing operational expenditures in knitting factories worldwide. As electricity prices continue to climb across global markets, savvy manufacturers are seeking intelligent solutions to maintain profitability.

Computerized flat knitting technology has revolutionized the textile industry, but not all machines are created equal. The difference between standard computerized machines and truly energy-efficient models can mean thousands of dollars in annual savings per machine, multiplied across an entire factory floor. This comprehensive guide explores how energy-saving computerized flat knitting machines can dramatically reduce your operating costs while introducing you to Changhua Knitting Machine - a leader in innovative, efficient knitting technology.

What Are Computerized Flat Knitting Machines?

Computerized flat knitting machines represent the pinnacle of textile manufacturing technology. Unlike manual or mechanical knitting machines, these sophisticated devices are controlled by computerized systems that precisely manage every aspect of the knitting process. Key components include:

Computer Control System: The brain of the operation, allowing for precise pattern programming and machine control

Carriage Assembly: Moves back and forth across the needle bed, forming stitches with exceptional accuracy

Needle Beds: Stationary plates with precision needles that create the fabric

Yarn Feeding System: Delivers yarn to the needles with minimal tension and waste

Fabric Take-down Mechanism: Controls fabric tension and collects finished material

These machines can produce intricate patterns, complex structures, and complete garments with minimal human intervention once programmed. However, traditional computerized models often consume substantial electricity, particularly during peak operation cycles.

The Hidden Cost: Energy Consumption in Knitting Operations

Most factory managers focus on raw material costs, labor expenses, and maintenance when calculating production expenses. Yet energy consumption frequently represents 15-25% of total operating costs in knitting facilities. Consider these eye-opening statistics:

A standard computerized flat knitting machine operates continuously for 20-24 hours daily

Average power consumption ranges from 1.5kW to 3.5kW per machine depending on model and operation

With electricity costs averaging $0.12-$0.35 per kWh globally, monthly energy expenses per machine can reach $250-$700

A medium-sized factory with 50 machines might spend $150,000-$420,000 annually just on electricity for knitting operations

The energy draw isn't constant either. Peak consumption occurs during:

Machine startup and initialization

High-speed knitting phases

Carriage reversal points

Complex pattern execution with multiple yarn changes

Video Explanation: How Energy is Consumed in Traditional Knitting Machines - This brief video demonstrates the energy-intensive moments in standard knitting machine operation.

Energy-Saving Technologies in Modern Knitting Machines

Innovative manufacturers have developed multiple technologies to address energy inefficiencies in computerized flat knitting:

1. Intelligent Drive Systems

Traditional machines use constant-speed motors that run at maximum capacity regardless of actual need. Energy-efficient models incorporate variable frequency drives (VFDs) and servo motors that adjust power consumption based on real-time requirements. These systems can reduce energy use by 30-40% during non-peak operations.

2. Regenerative Braking Technology

Similar to technology in electric vehicles, regenerative braking systems capture energy typically lost during carriage deceleration and reversal, feeding it back into the system. This innovation alone can reduce net energy consumption by 15-25%.

3. Optimized Heating Systems

Many knitting processes require controlled heating elements. Advanced machines use precision ceramic heaters with excellent thermal retention and targeted application, minimizing heat loss and reducing related energy use by up to 50%.

4. Sleep Mode Automation

During inevitable production pauses (yarn changes, minor adjustments, quality checks), energy-saving machines automatically enter low-power sleep modes, cutting idle energy consumption by 60-80%.

5. Efficient Component Design

From low-friction carriage rails to optimized vacuum systems for waste removal, every component in advanced machines is engineered for minimal energy draw without compromising performance.

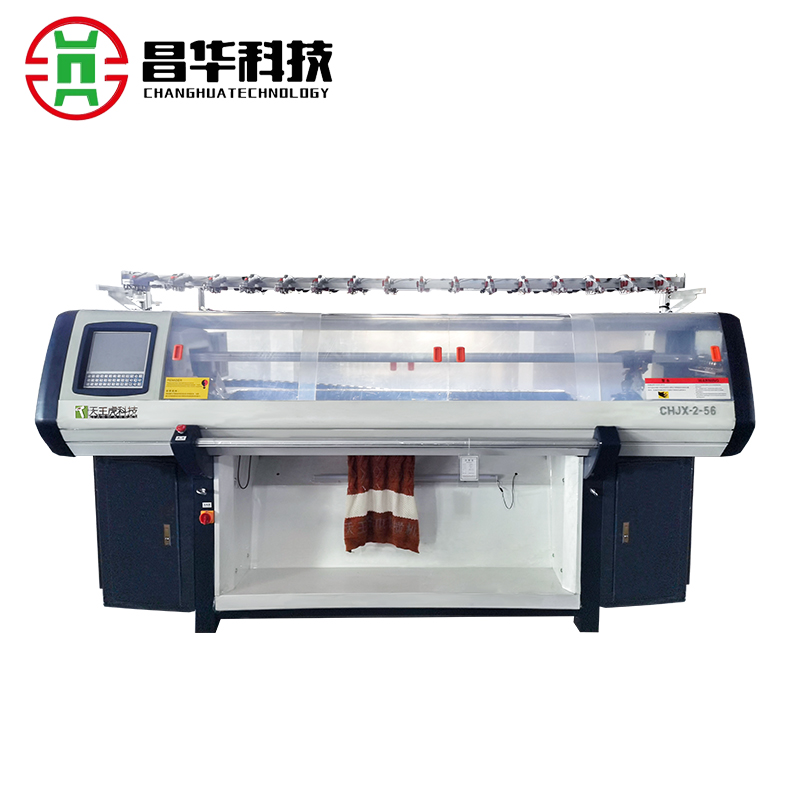

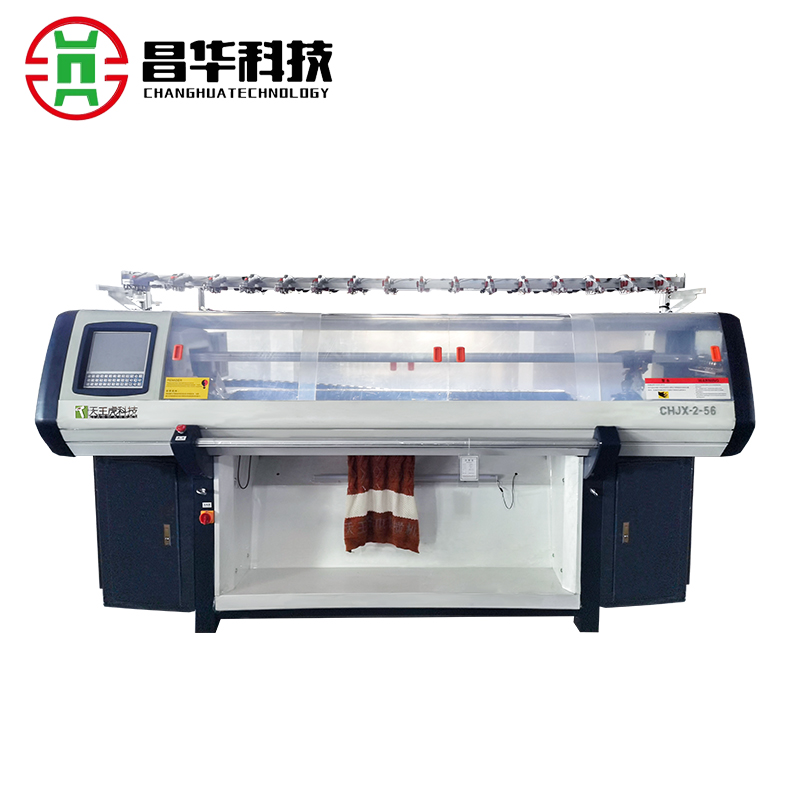

Introducing Changhua Knitting Machine: Your Partner in Energy-Efficient Manufacturing

For over two decades, Changhua Knitting Machine has been at the forefront of innovative knitting technology. Our commitment extends beyond creating machines that simply produce textiles—we engineer solutions that optimize every aspect of the manufacturing process, with energy efficiency as a core design principle.

Our Philosophy: We believe sustainable manufacturing is profitable manufacturing. By reducing energy consumption, we help our clients lower operational costs, decrease their environmental footprint, and gain competitive advantages in an increasingly eco-conscious marketplace.

Our Global Reach: With installations in over 40 countries and technical support spanning five continents, Changhua has become the trusted choice for manufacturers seeking reliable, efficient, and technologically advanced knitting solutions.

Research and Development: 18% of our annual revenue is reinvested in R&D, with a dedicated Energy Efficiency Lab working exclusively on reducing power consumption across our product lines without compromising speed or quality.

Visit our website to learn more about our company's history, values, and complete product range: https://www.changhua-knitting-machine.com/

Changhua's Energy-Saving Computerized Flat Knitting Machines

We've incorporated the energy-saving technologies discussed above across our product line. Below are three standout models that exemplify our commitment to efficiency without compromise.

1. 80-inch Double System Computerized Knitting Machine

Perfect for: Medium to large-scale production of sweaters, cardigans, and structured knitwear

Key Energy-Saving Features:

Dual Servo Motor System: Independently controlled motors for carriage and auxiliary functions reduce energy consumption by 35% compared to traditional single-motor designs

Smart Power Management: AI-driven system that learns production patterns and optimizes energy use throughout the work cycle

Eco-Cooling Technology: Reduced need for external cooling systems through innovative heat dissipation design

Technical Specifications:

Working width: 80 inches (203 cm)

Gauge range: 3-12 G

Maximum speed: 1.2 m/s

Power consumption: 1.8 kW (average), 40% less than comparable models

Noise level: <70 dB

Production Advantages:

This double-system powerhouse enables simultaneous production of two identical pieces or complex patterns that would require multiple passes on conventional machines. The time savings translate to further energy reductions per finished garment.

Discover the complete specifications and request a personalized energy savings estimate: 80-inch Double System Computerized Knitting Machine

2. 100-Inch Simple Double System Computerized Knitting Machine

Perfect for: Large-scale production of blankets, afghans, and extra-wide fabrics

Key Energy-Saving Features:

Extended Regenerative Braking: Specifically calibrated for longer carriage travel, recovering up to 28% of deceleration energy

Zone Heating Control: Allows operators to heat only the sections of the needle bed actually in use, reducing heater energy consumption by 55%

Low-Friction Linear Guide System: Specially engineered rails that reduce carriage movement resistance by 40%

Technical Specifications:

Working width: 100 inches (254 cm)

Gauge range: 3-10 G

Maximum speed: 1.0 m/s

Power consumption: 2.2 kW (average), 38% less than comparable wide-format machines

Special feature: Segmented vacuum system that activates only in active working zones

Production Advantages:

The extra width allows for production of larger pieces or multiple smaller pieces side-by-side, dramatically increasing throughput per energy unit consumed. The simple double system maintains ease of operation while delivering exceptional efficiency.

Ideal for manufacturers looking to scale up production without proportionally increasing energy costs. Learn more: 100-Inch Simple Double System Computerized Knitting Machine

3. 80-inch Whole Garment Computerized Flat Knitting Machine

Perfect for: Complete garment production with minimal post-knitting labor

Key Energy-Saving Features:

Adaptive Power Flow System: Dynamically adjusts energy distribution between knitting, transferring, and garment shaping functions

Heat Recovery and Redistribution: Captures waste heat from electronic components to pre-warm yarns, reducing dedicated heating needs

Predictive Energy Scheduling: Software that analyzes upcoming pattern complexity and prepares the most energy-efficient execution path

Technical Specifications:

Working width: 80 inches (203 cm)

Gauge range: 5-14 G

Maximum speed: 1.1 m/s

Power consumption: 2.0 kW (average), 45% less than comparable whole garment machines

Special feature: Integrated energy monitoring dashboard with real-time consumption analytics

Production Advantages:

By producing complete garments with minimal seams, this machine eliminates multiple downstream processes (cutting, sewing, additional handling), reducing total production energy by up to 60% compared to conventional cut-and-sew methods.

Revolutionize your production while dramatically cutting energy costs. Explore this groundbreaking technology: 80-inch Whole Garment Computerized Flat Knitting Machine

Beyond Energy Savings: Additional Advantages of Changhua Machines

While energy efficiency is a critical cost-saving feature, our machines deliver comprehensive benefits that impact your total cost of ownership:

Superior Reliability and Reduced Downtime

Every Changhua machine undergoes 72 hours of continuous testing before leaving our facility. Our mean time between failures (MTBF) is 42% higher than industry average, ensuring your production runs smoothly with fewer interruptions.

Intuitive Software with Energy Monitoring

Our proprietary knitting software includes real-time energy monitoring dashboards, allowing operators to:

Track energy consumption by product, pattern, or shift

Identify unusually energy-intensive patterns for optimization

Set energy usage alerts and targets

Generate efficiency reports for management review

Advanced Technical Support

With every machine purchase, you receive:

Comprehensive training on maximizing energy efficiency

Remote monitoring setup assistance

Priority access to our technical support team

Regular software updates that often include additional energy optimization features

Download our comprehensive comparison guide: Changhua vs. Conventional Machines: Total Cost Analysis - This detailed PDF breaks down five-year operational costs across multiple scenarios.

Calculating Your Potential Savings

Let's examine a realistic scenario:

Medium-sized factory currently operating 30 conventional computerized flat knitting machines:

Current average consumption: 3.0 kW per machine

Daily operation: 22 hours

Electricity cost: $0.18/kWh

Annual energy cost: 30 machines × 3.0 kW × 22 hours × 365 days × $0.18 = $130,086

After replacing with Changhua energy-efficient models (average 1.9 kW consumption):

These calculations don't include additional savings from:

Reduced cooling requirements (efficient machines produce less waste heat)

Lower maintenance costs (high-efficiency components experience less wear)

Potential utility rebates for energy-efficient equipment (available in many regions)

Increased productivity (less downtime, faster production cycles)

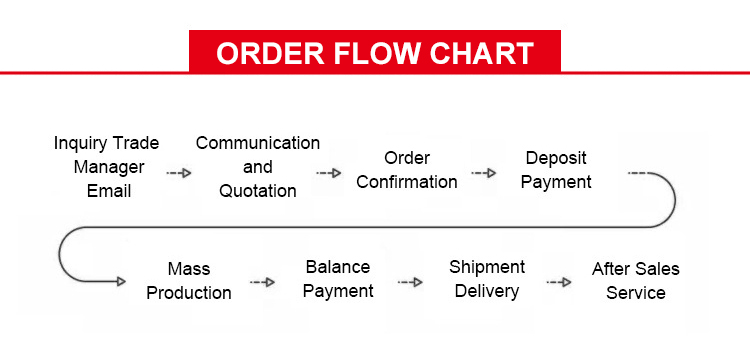

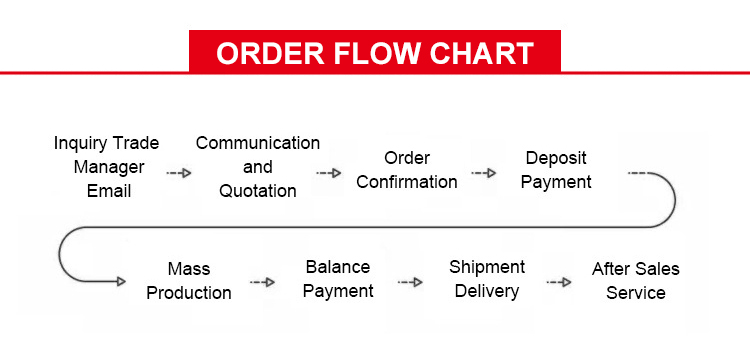

Implementing Energy-Efficient Knitting Technology: A Step-by-Step Guide

Transitioning to energy-efficient machinery requires careful planning. Here's our recommended approach:

Energy Audit: Assess your current consumption patterns using our free audit template

Phased Implementation: Begin with your highest-usage machines or those scheduled for replacement

Operator Training: Ensure your team understands how to maximize efficiency features

Monitoring and Adjustment: Use the built-in analytics to fine-tune operations

Expansion Planning: Apply lessons learned to subsequent machine replacements

Addressing Common Concerns About Machine Transition

"Can we afford the upfront investment?"

Our flexible financing options and documented ROI calculations (typically 14-22 months) make the transition financially viable. Additionally, many regions offer green manufacturing incentives that can substantially offset initial costs.

"Will we need to retrain our entire staff?"

Changhua's control systems are intuitively designed with similar logic to conventional machines. Most operators adapt within 1-2 weeks, and we provide comprehensive on-site training with every installation.

"What about compatibility with our existing patterns?"

Our software converts most common pattern files automatically, and our technical team assists with any complex conversions at no additional cost during the implementation period.

The Environmental Impact: Beyond Cost Savings

While this article focuses primarily on operational cost reduction, it's worth noting the significant environmental benefits of energy-efficient knitting machines:

Carbon Footprint Reduction: Each Changhua energy-efficient machine reduces CO₂ emissions by approximately 4.8 tons annually compared to conventional models

Reduced Heat Pollution: More efficient operation means less waste heat discharged into your facility, lowering cooling requirements

Sustainable Manufacturing Credentials: Increasingly important for brands seeking environmentally responsible supply chain partners

Future Developments in Energy-Efficient Knitting Technology

At Changhua, our R&D team is already working on the next generation of efficiency innovations:

Solar-Ready Machines: Designs optimized for direct DC solar input, bypassing inverter losses

Advanced Heat Recovery: Systems that capture and repurpose up to 70% of waste heat

Predictive Efficiency Algorithms: AI that continuously optimizes energy use based on yarn type, pattern complexity, and environmental conditions

Want to stay updated on emerging efficiency technologies? Subscribe to our monthly efficiency newsletter for the latest developments.

Conclusion: A Smart Investment for Forward-Thinking Manufacturers

The textile manufacturing landscape is evolving rapidly, with energy costs becoming an increasingly critical factor in overall competitiveness. Energy-saving computerized flat knitting machines represent more than just an equipment upgrade—they're a strategic investment in sustainable profitability.

Changhua Knitting Machine has dedicated decades to perfecting the balance between high-performance knitting technology and exceptional energy efficiency. Our machines deliver the speed, precision, and reliability you need, while dramatically reducing one of your most significant operating expenses.

The numbers speak for themselves: reductions of 35-45% in energy consumption translate to tens or hundreds of thousands in annual savings, depending on your operation scale. These savings continue year after year, delivering compounding returns on your investment.

Ready to calculate your exact potential savings? Our energy savings calculator tool provides a customized estimate based on your specific operation.

Considering an upgrade but have technical questions? Schedule a virtual consultation with our engineering team—no obligation, just expert insights.

Interested in seeing our machines in action? Visit our showroom or arrange a virtual demonstration at your convenience.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe