In today's competitive textile and apparel industry, efficiency and sustainability are not just goals—they are imperatives. One of the most significant challenges manufacturers face is material waste. Excess fabric scraps, cutting losses, and production errors contribute to inflated costs and environmental impact. However, a technological revolution is reshaping the landscape: Advanced Computerized Flat Knitting Technology.

This article delves deep into how these intelligent machines are the key to minimizing waste. We will explore their operation, benefits, and how choosing the right technology partner can transform your production. As a leader in this innovative field, Changhua Knitting Machine provides state-of-the-art solutions that empower businesses to achieve unparalleled precision and sustainability. Let's explore how.

Understanding the Waste Challenge in Traditional Knitting

Before appreciating the solution, we must understand the problem. Conventional knitting and cut-and-sew methods are inherently wasteful.

Cut-and-Sew Waste: Large panels of knitted fabric are cut into pattern pieces, often leaving 15-25% of the material as scraps.

Pattern Inefficiencies: Manual or semi-automated knitting can lead to inconsistencies, dropped stitches, and flawed sections that must be discarded.

Inventory Waste: Overproduction due to inaccurate forecasting or design changes results in unsold inventory, a form of economic and material waste.

The industry needs a smarter, more integrated approach.

The Revolution: How Computerized Flat Knitting Machines Work

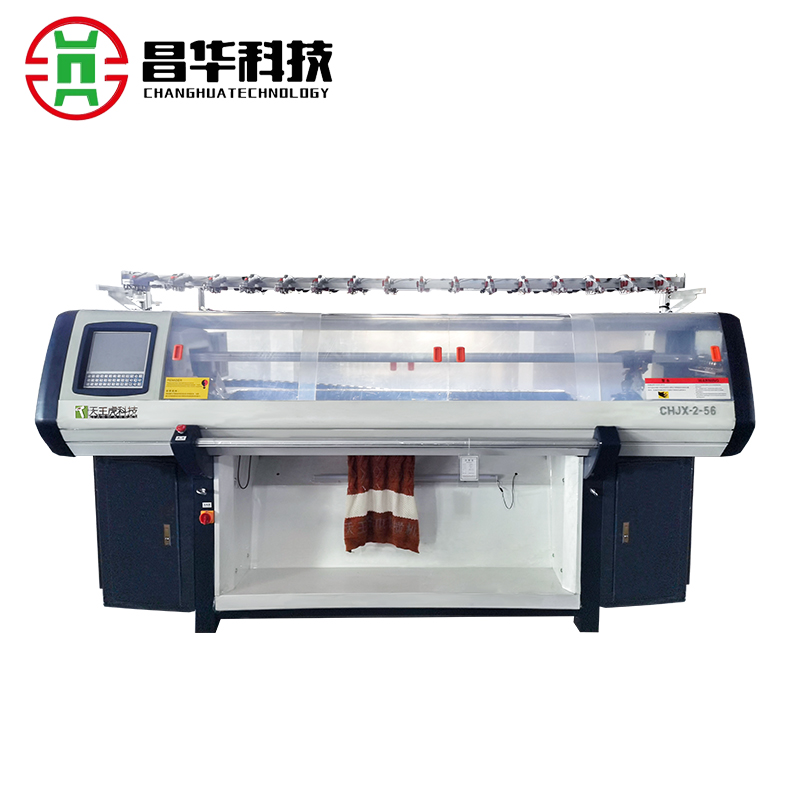

Computerized flat knitting machines are marvels of precision engineering. Unlike their mechanical predecessors, they are controlled by sophisticated software that dictates every movement of the needles, carriage, and yarn feeders.

Core Principles:

Digital Design Input: A garment design is created or translated into a digital file using specialized CAD software.

Precision Execution: The machine's computer reads this file and controls thousands of needles individually. It precisely places stitches, changes colors, increases/decreases width (shaping), and even creates complex structures like cables and jacquards—all automatically.

3D Knitting Capability: Advanced machines can knit fully shaped panels or even complete garments (whole-garment knitting) in one continuous process, virtually eliminating sewing and cutting.

The Direct Link to Waste Reduction

Near-Zero Cut Waste: By knitting a garment to its exact shape (panel or whole), the need for cutting fabric is removed or drastically reduced.

Unparalleled Accuracy: Digital control eliminates human error in stitch formation, leading to perfect, consistent panels every time, reducing seconds and rejects.

Optimized Material Usage: Software can nest patterns with maximum efficiency and calculate the exact yarn length needed, preventing overuse.

Introducing the Solution Partner: Changhua Knitting Machine

Navigating this technological shift requires a reliable and innovative partner. This is where our expertise comes in.

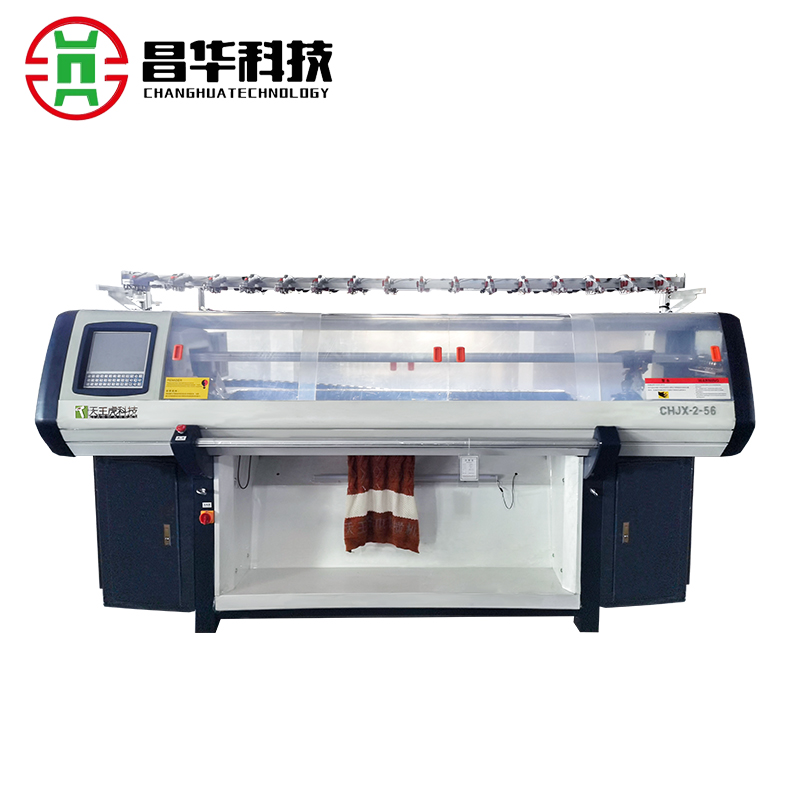

Changhua Knitting Machine has established itself as a global leader in the design and manufacture of high-performance computerized flat knitting machines. Based on a deep understanding of industry needs, we combine robust engineering with user-friendly software to deliver machines that are not just productive, but transformative.

Our philosophy centers on empowering our clients: providing them with the tools to enhance quality, boost productivity, and champion sustainable manufacturing practices. Our machines are built for durability, precision, and adaptability, serving a diverse clientele from fashion houses to technical textile producers.

Ready to see how our technology can specifically benefit your operation? Let's examine our flagship machines.

Exploring Changhua's Waste-Minimizing Machines

We offer a range of machines tailored to different production needs, all engineered with waste reduction as a core principle.

1. The Precision Workhorse: 72-Inch Single System Machine

Ideal for: Intricate patterns, high-detail work, and flexible production runs.

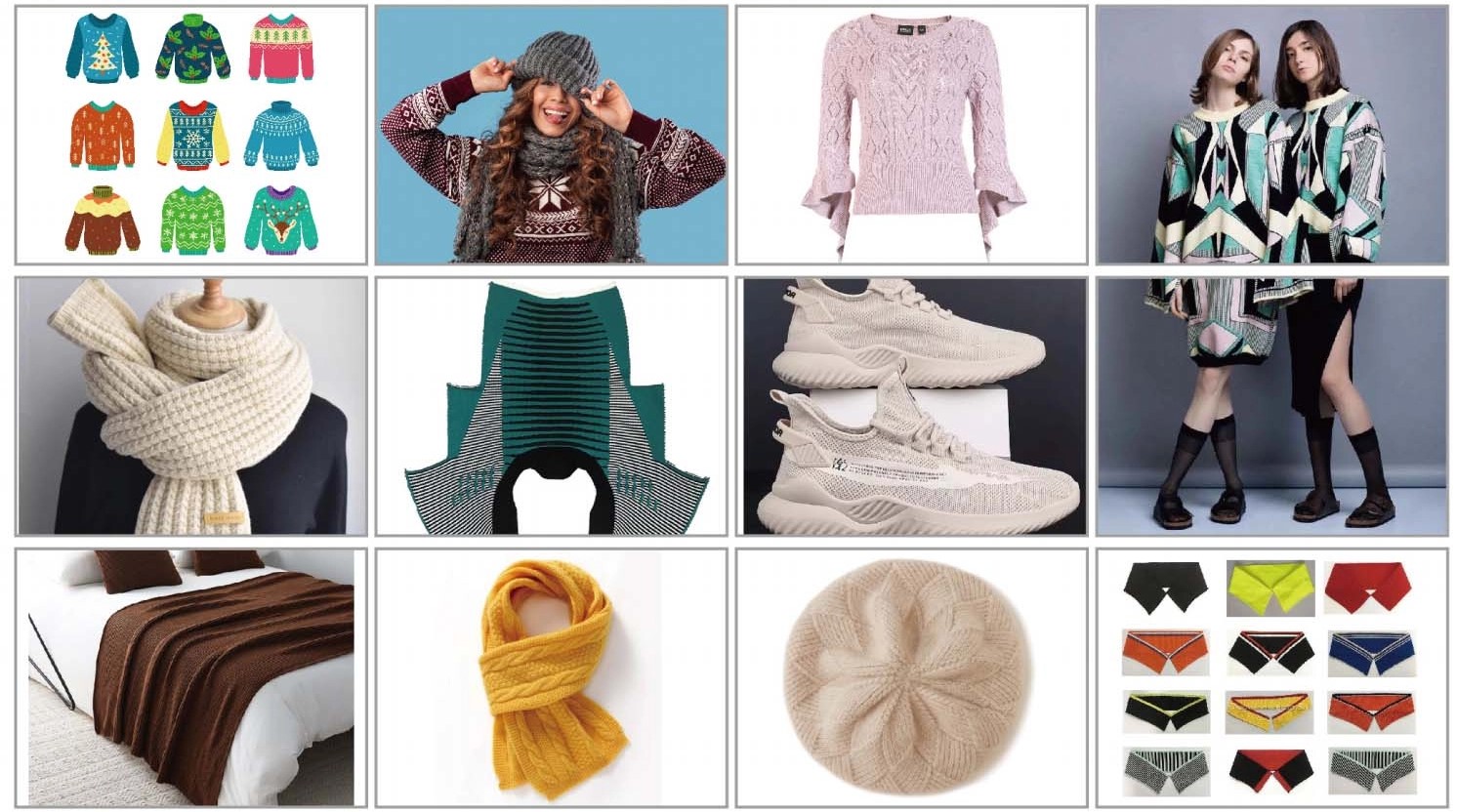

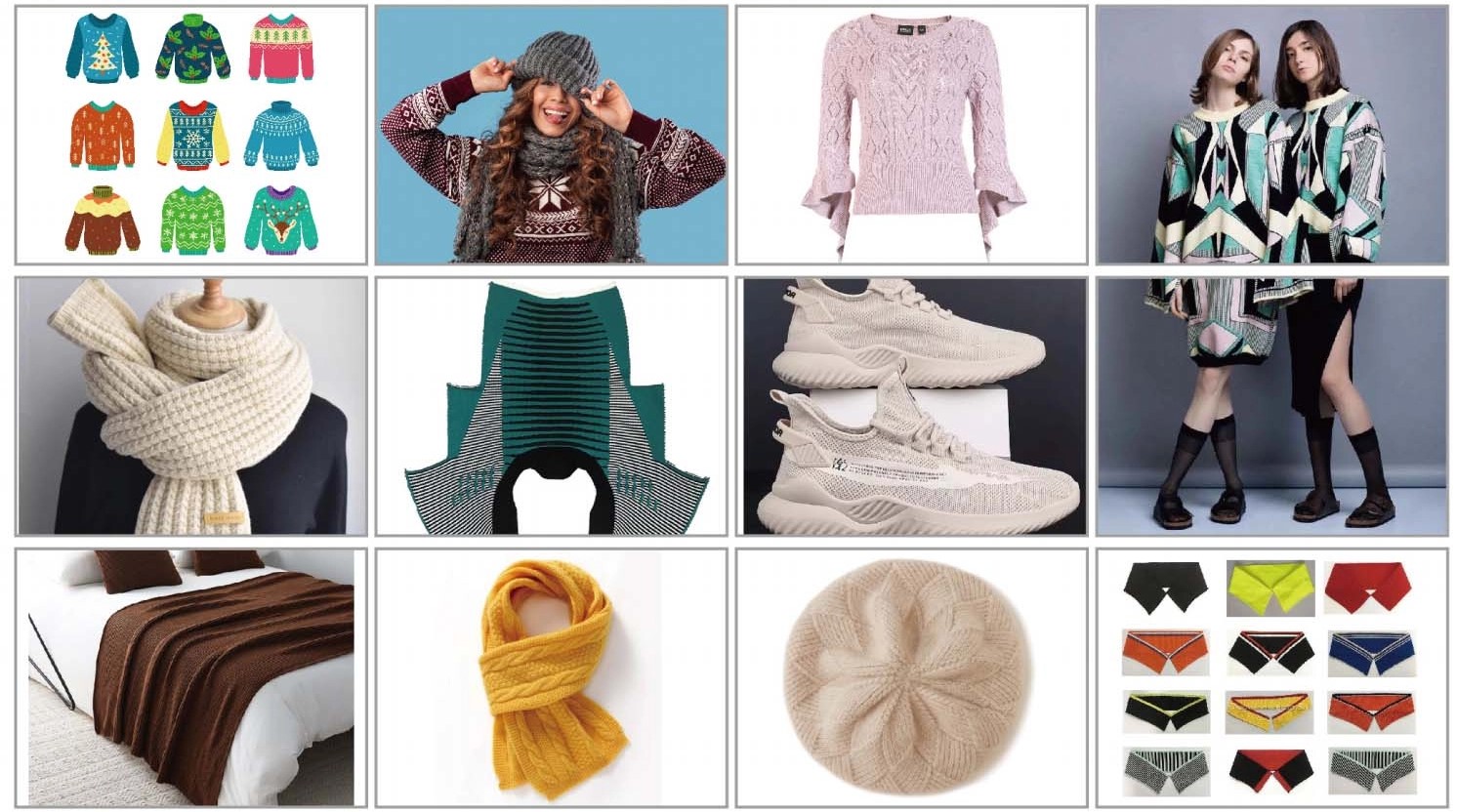

This machine is a testament to precision. Its single-system design allows for exceptional control over fine-gauge knitting, making it perfect for complex jacquards, lace patterns, and detailed trims.

Key Feature Highlight: Exact Stitch Control. By ensuring every stitch is perfectly formed according to the digital design, it prevents flaws that lead to material waste. Its wide 72-inch bed allows for knitting multiple pieces side-by-side, optimizing each production cycle.

Perfect for reducing waste in: High-fashion items, intricate collars, cuffs, and accessories where precision is paramount and mistakes are costly.

Discover the detailed specifications and see it in action here: 72-inch Single System Computerized Flat Knitting Machine

2. The Productivity Powerhouse: 80-Inch Double System Machine

Ideal for: High-volume production of shaped panels like sweater fronts/backs, with superior efficiency.

Doubling the knitting heads means doubling the productivity. This machine is engineered for speed and reliability in producing high-quality garment panels.

Key Feature Highlight: High-Speed, Consistent Output. Two independent knitting systems work in tandem, dramatically increasing output while maintaining consistent quality. Consistency is key to waste reduction—no unexpected flaws, no batches of rejected panels.

Perfect for reducing waste in: Bulk production of sweater panels, structured knits, and any application where time and material efficiency on larger runs are critical.

Learn more about its powerful capabilities: 80-inch Double System Computerized Knitting Machine

3. The Ultimate Sustainable Solution: 80-Inch Whole Garment Machine

Ideal for: Pioneering brands seeking the pinnacle of waste reduction and design innovation.

This represents the forefront of knitting technology. It can knit a complete, seamless garment—ready to wear—in one continuous process.

Key Feature Highlight: Elimination of Cutting and Sewing. This is the holy grail of waste minimization. By creating a finished garment directly on the machine, it cuts material loss from cutting scraps to near zero and reduces labor and energy used in sewing.

Perfect for reducing waste in: Sustainable fashion lines, premium seamless apparel, and technical garments where seamlessness adds functional value.

Explore the future of knitting technology: 80-inch Whole Garment Computerized Flat Knitting Machine

Beyond the Machine: Changhua's Holistic Advantages

Choosing Changhua isn't just about buying hardware; it's about investing in a partnership for growth. Here’s what sets our solutions apart:

1. Intelligent Software Ecosystem

Our machines are powered by intuitive, powerful software. This allows for:

Virtual Sampling: Create and perfect designs digitally before knitting a single thread, saving enormous amounts of sample yarn and time.

Precise Yarn Consumption Calculations: Know exactly how much yarn you need per garment, enabling leaner inventory and preventing overbuying.

Seamless Design-to-Production Workflow: Minimize errors in file translation that lead to costly production mistakes.

2. Uncompromising Build Quality & Durability

We use high-grade components and rigid frames to ensure our machines operate flawlessly 24/7 with minimal downtime. A reliable machine prevents production halts and the waste associated with urgent, subpar alternative production.

3. Expert Support & Training

Our global team provides comprehensive training and responsive technical support. Ensuring your operators are experts maximizes your machine's efficiency and minimizes operational errors that cause waste.

4. Customization & Adaptability

We understand that every production floor is unique. Our engineers can work with you to tailor solutions, from custom gauges to specialized yarn feeders, ensuring the machine fits your specific waste-reduction goals perfectly.

Curious about how these advantages translate into real-world savings for a business like yours? The proof is in the numbers and long-term performance.

The Tangible Results: Measuring Your Savings

Implementing Changhua's computerized flat knitting technology delivers measurable ROI:

Material Cost Reduction: Achieve up to 20-30% savings in yarn consumption by eliminating cut waste and optimizing usage.

Labor Efficiency: Reduce labor tied to manual cutting, sewing, and handling of waste materials.

Energy Savings: Streamlined production (fewer steps) and efficient machines lower overall energy consumption.

Enhanced Sustainability Profile: Significantly reduce your textile landfill contribution, a powerful message for eco-conscious consumers and brands.

Faster Time-to-Market: Digital sampling and efficient production allow for quicker response to trends.

Is Your Operation Ready for a Waste-Less Future?

The transition to advanced computerized knitting is an investment in resilience, profitability, and sustainability. It future-proofs your business against rising material costs and increasing environmental regulations.

If you are:

Troubled by high material costs and scrap disposal.

Facing pressure from clients for more sustainable practices.

Looking to improve product consistency and quality.

Wanting to innovate with seamless or complex designs.

...then the time to act is now.

Let Changhua be your guide. We have the technology, the expertise, and the proven track record to help you successfully navigate this transition.

Your Next Step: Connect with Changhua Experts

Seeing is believing. We invite you to delve deeper into what our machines can do for you.

The most important step is a conversation. Our technical sales team is ready to discuss your specific challenges, provide a personalized analysis of potential savings, and arrange a demonstration.

Don't let material waste cut into your profits any longer. Take control with precision technology.

Contact Changhua Today for a Personalized Consultation and Quote – Let's build a more efficient and sustainable future for your knitting business together.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe