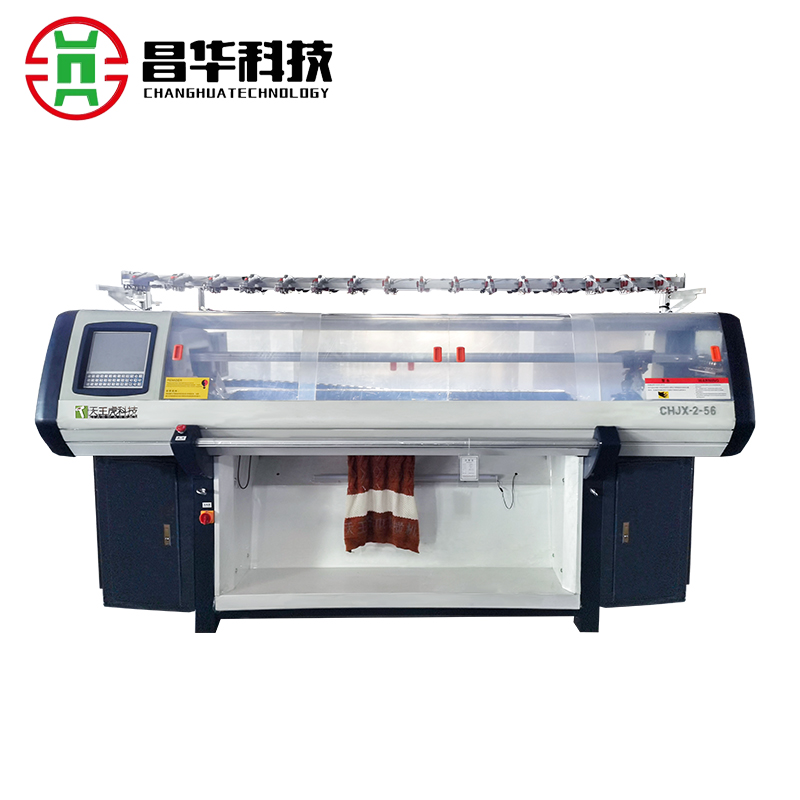

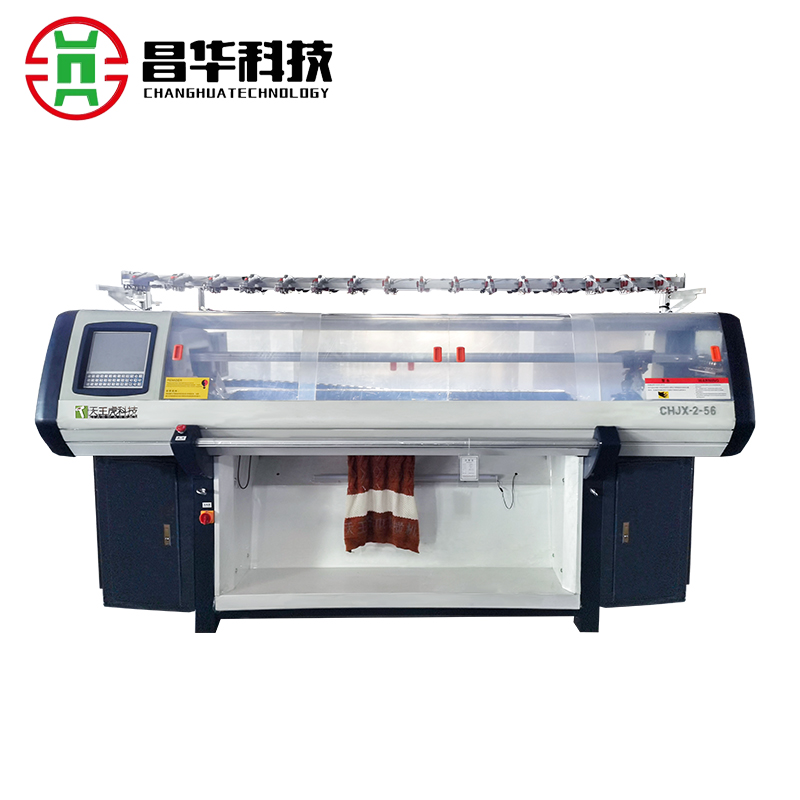

66 Inch Double System Hat Knitting Machine Description

Double system has high roller, high-performance sinker, dynamic stitch, motor control reserving carriage, digital technology, high-speed and efficient, to achieve pointelle, tuck, jacquard, intarsia, full needle jacquard, apparent shape, hidden shape, and other irregular patterns, which is suitable for wool, cashmere, cotton, chemical fiber, silk and all kinds of blended yarn, the production of sweaters, blanket, scarfs, gloves, hats and knitted apparel accessories. Changhua Double System Hat Knitting Machine.pdf

Changhua Double System Hat Knitting Machine.pdf

Changhua 66-inch Dual-System Fully Automatic Knitted Cap Computerized Flat Knitting Machine Product Introduction

1. Industry-Leading Hat Production Expert

The Changhua 66-inch Dual-System Fully Automatic Knitted Cap Computerized Flat Knitting Machine, launched in 2023, is the company's flagship hat production equipment. Featuring an ultra-wide 66-inch (168 cm) width and innovative dual-system synchronous knitting technology, this machine is specifically designed for the large-scale production of high-end hats. Equipped with a ninth-generation intelligent control system, it supports over 300 preset hat shapes, covering a full range of product categories, from basic styles to complex three-dimensional structures, setting a new industry benchmark.

2. Seven Core Competitive Advantages

Dual-System Super-Efficient Production

The main and auxiliary systems intelligently collaborate, increasing production efficiency by 90% compared to a single system and enabling daily production capacity exceeding 4,000 hats.

Ultra-Wide Optimized Design

The 66-inch working width allows for simultaneous production of 10-12 standard hats, meeting the demands of large-volume orders.

Nano-Level Precision Control

A 0.01mm ultra-high-precision sensor system ensures hat shape tolerances within ±0.2mm.

AI Intelligent Process Optimization

A built-in deep learning algorithm automatically optimizes the knitting path, saving 18% in raw material consumption.

Full-Material Adaptability

Supports a full range of needle gauges from 3 to 18G, perfectly adapting to specialty yarns such as cashmere and carbon fiber.

Quiet and Eco-Friendly Design

Energy consumption is reduced by 50%, with noise levels kept below 58 decibels.

Intelligent Remote Operation and Maintenance

Equipped with a 5G IoT module, it enables real-time monitoring of equipment status.

3. Professional Applications and Global Services

This model is designed for the following high-end scenarios:

Core Supplier for International Brands: Meeting the stringent requirements of luxury brands for complex headwear.

Sports Technology R&D Center: Developing functional headwear with integrated intelligent components.

Military Special Equipment: Meeting specialized protective needs in specialized environments.

Changhua Technology offers:

√ 5-year warranty on all equipment

√ Global "Diamond"-level service

√ On-site process guidance

√ 24-hour emergency response

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe