Introduction to Knitting Machines in Jiangsu

Jiangsu, a powerhouse in China's textile industry, is renowned for its advanced manufacturing capabilities and innovative machinery production. As a hub for textile machinery, Jiangsu hosts numerous manufacturers specializing in knitting machines, which are critical for producing high-quality fabrics used in garments, accessories, and technical textiles. For businesses in East China seeking reliable, high-performance knitting machines, selecting a trusted local supplier with a proven track record is essential. Among these, Changshu Changhua Smart Manufacturing Technology Co., Ltd., located in Changshu, Jiangsu, stands out as a premier Jiangsu knitting machine manufacturer with over 20 years of local manufacturing experience.

Knitting machines, particularly flat and computerized models, have revolutionized the textile industry by enabling faster production, intricate designs, and consistent quality. From sweaters and scarves to collars and shoe uppers, these machines cater to diverse applications, making them indispensable for manufacturers aiming to stay competitive. In this article, we'll explore the knitting machine landscape in Jiangsu, highlight the regional advantages of choosing a Changshu-based supplier, and showcase why Changhua is the top choice for businesses in East China and beyond.

The Importance of Knitting Machines in Textile Manufacturing

What Are Knitting Machines?

Knitting machines are specialized devices designed to automate the knitting process, creating flat or tubular fabrics with precision and efficiency. Unlike manual knitting, which is labor-intensive and time-consuming, modern knitting m

achines—especially computerized flat knitting machines—offer advanced features like digital pattern control, high-speed production, and versatility in fabric types. These machines are widely used in industries producing sweaters, scarves, hats, gloves, shoe uppers, and even technical textiles for automotive and medical applications.

Types of Knitting Machines

Knitting machines come in various types, each suited to specific applications:

Flat Knitting Machines: Ideal for producing flat fabrics like sweaters, collars, and scarves. They offer flexibility in design and are perfect for intricate patterns like jacquard and intarsia.

Circular Knitting Machines: Used for seamless tubular fabrics, such as those found in t-shirts and hosiery.

Computerized Knitting Machines: Equipped with digital controls for precise pattern creation and automation, reducing manual intervention and errors.

Applications of Knitting Machines

Knitting machines serve a wide range of industries, including:

Apparel: Producing sweaters, scarves, hats, and gloves with intricate patterns and textures.

Accessories: Creating collars, cuffs, and other garment components with high precision.

Technical Textiles: Manufacturing fabrics for automotive interiors, medical textiles, and 3D knitted products.

Footwear: Crafting shoe uppers with seamless designs for enhanced comfort and aesthetics.

Why Choose a Jiangsu Knitting Machine Manufacturer?

Regional Advantages of Jiangsu

Jiangsu's strategic location in East China offers significant advantages for textile manufacturers. As a coastal province with proximity to Shanghai, Jiangsu benefits from excellent logistics and transportation networks, ensuring fast delivery and easy access to spare parts. Changshu, in particular, is known as the birthplace of China’s apparel industry, making it a hub for knitting machine innovation and production.

Key regional advantages include:

Proximity to Textile Hubs: Changshu's location allows quick access to major textile markets in Shanghai, Suzhou, and other East China cities, reducing lead times for customers.

Skilled Workforce: Jiangsu's long history in textile manufacturing has cultivated a highly skilled workforce, ensuring superior craftsmanship in machine production.

Innovation Ecosystem: The province is home to advanced R&D facilities, enabling manufacturers like Changhua to develop cutting-edge knitting technologies.

Cost Efficiency: Local suppliers in Jiangsu offer competitive pricing due to lower transportation costs and established supply chains.

By choosing a Changshu-based manufacturer, East China customers gain access to high-quality machines, responsive after-sales service, and tailored solutions that meet regional needs.

The Value of Local Suppliers

Partnering with a local supplier like Changhua ensures seamless communication, faster response times, and personalized support. With over 20 years of local manufacturing experience in Changshu, Changhua understands the unique needs of East China customers, from small-scale producers to large garment factories. This local expertise, combined with a commitment to quality, makes Changhua a trusted partner for businesses seeking reliable knitting machines.

Changhua: A Leading Jiangsu Knitting Machine Manufacturer

Located in Changshu, Jiangsu, Changshu Changhua Smart Manufacturing Technology Co., Ltd. is a professional large-scale knitting garment machinery manufacturer with over two decades of experience. Our mission is to drive innovation and modernization in the knitting industry, delivering high-performance machines that empower our customers to create exceptional products.

Our Legacy and Expertise

Since our establishment, we have focused on independent research and development, resulting in a portfolio of advanced knitting machines under brands like TWH, Tiangong, King Tiger, and Miao's Craftsman. Our 20+ years of local manufacturing experience in Changshu have equipped us with deep industry knowledge and technical expertise, allowing us to produce machines that meet global standards while catering to the specific needs of East China customers.

Our commitment to quality is evident in every aspect of our operations, from sourcing premium materials to employing advanced production techniques. We have built a reputation for reliability, precision, and innovation, making us a top choice for businesses seeking a trusted Jiangsu knitting machine manufacturer.

Why Choose Changhua?

Proven Experience: Over 20 years of expertise in knitting machine manufacturing.

Advanced Technology: Our machines incorporate digital controls and intelligent programming for high efficiency and precision.

Comprehensive Product Range: From computerized flat knitting machines to semi-automatic models, we offer solutions for diverse applications.

Local Support: Based in Changshu, we provide responsive after-sales service and technical support to East China customers.

Sustainability Focus: Our machines are designed to reduce energy consumption and support environmentally friendly production.

Featured Changhua Knitting Machines

60 Inch Semi-Automatic Flat Knitting Machine

Overview

Our 60 Inch Semi-Automatic Flat Knitting Machine is specially designed for knitting collars and ribs, addressing common challenges like uneven fabric lines and insufficient flatness. This machine is ideal for manufacturers producing garment accessories with high precision.

Key Features

Milling-Type Needle Bed: Ensures clear fabric lines and consistent quality.

Digital Technology: Supports knitting, semi-jacquard, A/B jack tuck, and full tuck patterns.

Applications: Perfect for collars, cuffs, and other accessories requiring straightness and precision.

Benefits

This machine's robust design and advanced technology make it a reliable choice for East China manufacturers seeking cost-effective solutions for high-quality collar production.

60 Inch Double System Sweater Knitting Machine

Overview

The 60 Inch Double System Sweater Knitting Machine is a versatile solution for producing sweaters, blankets, and scarves. Its double-system design enhances efficiency, making it suitable for high-volume production.

Key Features

Double System Technology: Enables fast carriage rotation for increased productivity.

Versatile Pattern Capabilities: Supports knit, miss, tuck, transfer, pointel, intarsia, jacquard, and shaping patterns.

Optional Features: Includes an insert-type needle bed and non-waste yarn comb device for enhanced functionality.

Benefits

With its ability to handle complex patterns and high-speed production, this machine is a favorite among East China customers looking to scale their sweater manufacturing operations.

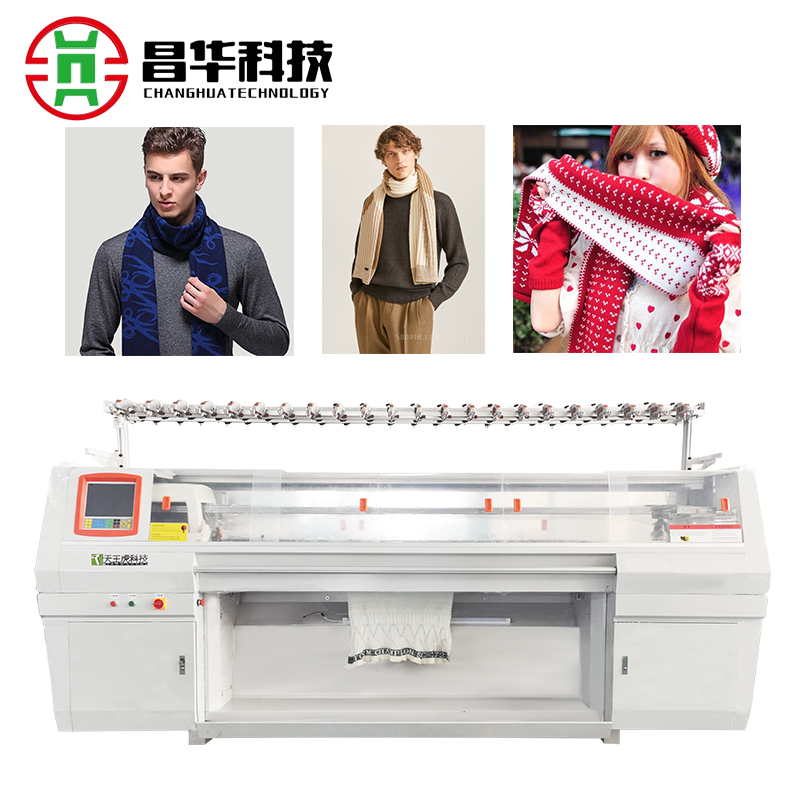

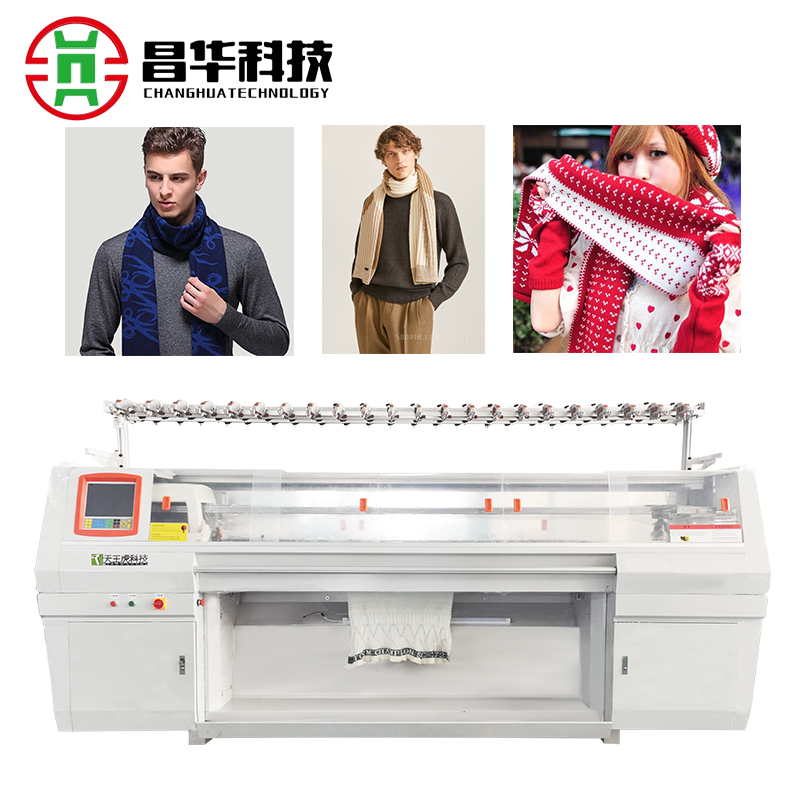

100 Inch Three System Computerized Flat Knitting Machine

Overview

Our flagship 100 Inch Three System Computerized Flat Knitting Machine is designed for advanced applications, including sweaters, scarves, gloves, and shoe uppers. Its three-system configuration ensures maximum efficiency and flexibility.

Key Features

High-Performance Sinker and Dynamic Stitch: Enables precise control over complex patterns.

Motor-Controlled Reserving Carriage: Enhances speed and efficiency.

Applications: Suitable for wool, cashmere, cotton, chemical fiber, and blended yarn products.

Benefits

This machine's intelligent programming and energy-efficient design make it an ideal choice for manufacturers prioritizing sustainability and high output.

How Changhua Machines Benefit East China Customers

Tailored Solutions for Regional Needs

As a Changshu-based manufacturer, we understand the unique demands of East China’s textile industry. Our machines are designed to support local manufacturers in producing high-quality garments and accessories that meet market trends. Whether you’re a small business creating custom designs or a large factory focused on mass production, our machines offer the versatility and reliability you need.

Superior After-Sales Support

Our proximity to East China customers allows us to provide prompt after-sales service, including machine installation, operator training, and maintenance. This local advantage ensures minimal downtime and maximum productivity for your business.

Competitive Pricing

By leveraging Changshu's established supply chains, we offer competitive pricing without compromising on quality. Our machines provide excellent value, making them accessible to businesses of all sizes in East China.

Conclusion

For businesses in East China seeking a reliable Jiangsu knitting machine manufacturer, Changshu Changhua Smart Manufacturing Technology Co., Ltd. is the clear choice. With over 20 years of local manufacturing experience in Changshu, we offer advanced, high-quality knitting machines that cater to diverse applications, from sweaters and collars to technical textiles and shoe uppers. Our commitment to innovation, quality, and customer support makes us a trusted partner for manufacturers across the region.

Explore our range of knitting machines.pdf and discover how we can help you elevate your textile production. Contact us today to learn more about our solutions and experience the Changhua difference.

Explore our range of knitting machines.pdf and discover how we can help you elevate your textile production. Contact us today to learn more about our solutions and experience the Changhua difference.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe