The textile industry is undergoing a transformation, driven by advanced machinery that delivers precision, efficiency, and versatility. For manufacturers, designers, and hobbyists searching for a flat knitting machine near me, the journey involves understanding the technology, its applications, and where to find high-quality equipment. This comprehensive guide explores flat knitting machines, their uses across various industries, and why Changhua's cutting-edge machines, available at Changhua Knitting Machine, are the ideal choice for your knitting needs. Whether you're producing fashion garments, technical textiles, or home decor, you can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to guide you to make an informed decision.

one stop programmes.pptx to guide you to make an informed decision.

What is a Flat Knitting Machine?

A flat knitting machine is a specialized piece of equipment designed to produce flat pieces of knitted fabric using interlocking yarn in a series of rows. Unlike circular knitting machines, which create tubular fabrics, flat knitting machines offer greater flexibility for crafting complex patterns and shapes. They are widely used in industries ranging from fashion to automotive and medical textiles, producing items like sweaters, scarves, blankets, and seamless garments.

Flat knitting machines come in various forms, from manual to semi-automatic and fully computerized models. Their key components include:

Needle Bed: The foundation where needles are aligned to form stitches.

Yarn Feeders: Supply yarn to the needles for knitting.

Carriage: Moves across the machine to facilitate knitting.

Sinkers: Hold the fabric in place during the knitting process.

Control System: Manual or computerized systems that dictate patterns and stitch types.

How Do Flat Knitting Machines Work?

The knitting process begins when yarn is fed into the machine. As the carriage moves back and forth, needles engage with the yarn to create loops that form stitches. Advanced models, particularly computerized ones, allow precise control over stitch density, patterns, and fabric types. For instance, V-bed machines, which feature two needle beds arranged in an inverted V-shape, enable the production of complex structures like ribbed or seamless garments.Flat knitting machines are versatile, capable of working with various yarns, including wool, cotton, synthetic fibers, and blends. Computerized models can be programmed for intricate designs, making them ideal for both small-scale bespoke production and large-scale manufacturing.

Applications of Flat Knitting Machines

Fashion Industry: Crafting Trendsetting Garments

Flat knitting machines are a cornerstone of the fashion industry, enabling designers to create sweaters, cardigans, scarves, hats, and collars with unparalleled precision. These machines support intricate patterns like jacquard, intarsia, and pointelle, allowing brands to produce unique, high-quality knitwear that stands out in the market. For example, Changhua's Whole Garment Flat Knitting Machine produces seamless garments, eliminating the need for post-production sewing and ensuring a comfortable fit.

Sportswear and Performance Apparel

In the sportswear industry, flat knitting machines are used to produce seamless, breathable, and durable garments. Machines like Changhua's Shoe Upper Flat Knitting Machine create 3D knitted shoe uppers with zones for breathability, stretch, and support, meeting the demands of athletes and fashion-conscious consumers. These machines also minimize material waste, aligning with sustainability goals.

Home Textiles: Blankets, Throws, and More

Flat knitting machines are ideal for producing home textiles like blankets, cushion covers, and throws. Their ability to handle thick yarns and create textured patterns makes them perfect for crafting cozy, decorative items. Changhua's Blanket Knitting Machine is designed for high-volume production of home textiles, offering durability and consistency.

Why Choose Changhua Flat Knitting Machines?

When searching for a flat knitting machine near me, you need a reliable manufacturer that offers quality, innovation, and support. Changhua, based in Changshu, Jiangsu, is a leading name in textile machinery with over 20 years of experience. Our extensive range of flat knitting machines, available at Changhua Knitting Machine, caters to diverse needs, from small-scale designers to large manufacturers. Below, we explore Changhua's top machines and why they're the best choice for your textile production.

Changhua's Product Line: A Machine for Every Need

Sweater Knitting Machine

The Sweater Knitting Machine is designed for producing high-quality sweaters with intricate patterns like jacquard and intarsia. Equipped with digital technology and high-performance sinkers, this machine ensures high-speed production and consistent quality. Its versatility makes it ideal for fashion brands aiming to create trendy, durable knitwear.

Key Features:

High-speed knitting with a maximum speed of 1.8 m/s.

Dynamic stitch technology for varied patterns.

Compatible with cotton, wool, and synthetic yarns.

Applications: Sweaters, cardigans, vests, and other fashion garments.

Whole Garment Flat Knitting Machine

The Whole Garment Flat Knitting Machine is a game-changer for seamless garment production. It knits entire garments in a single process, reducing labor costs and material waste. This machine is perfect for high-end fashion, sportswear, and medical textiles, offering unmatched comfort and fit.

Key Features:

Seamless knitting for enhanced comfort.

Computerized controls for precise pattern customization.

Supports wool, cashmere, cotton, and recycled fibers.

Applications: Seamless sweaters, sportswear, compression garments.

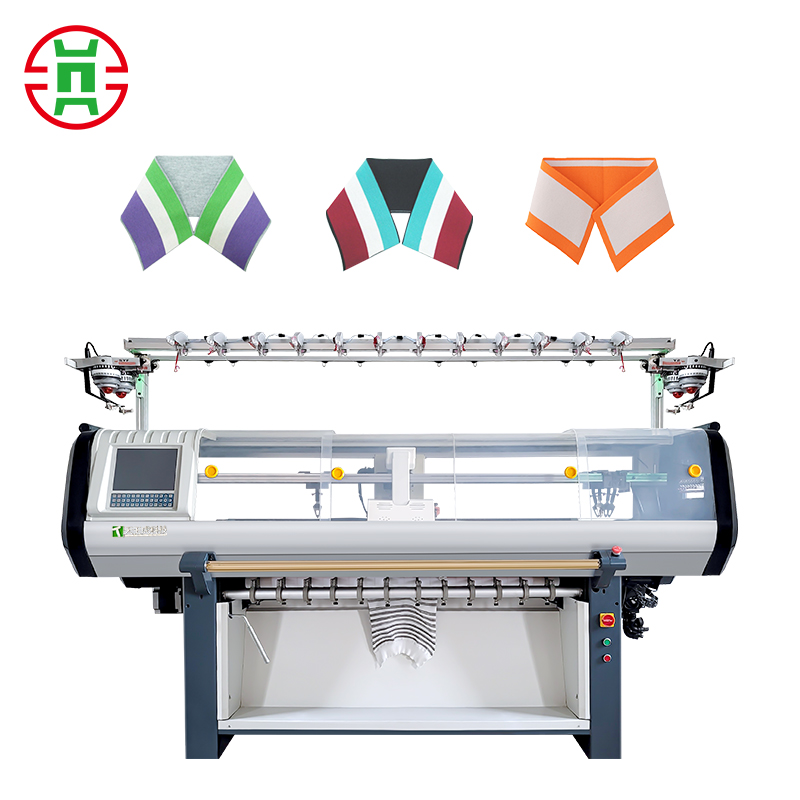

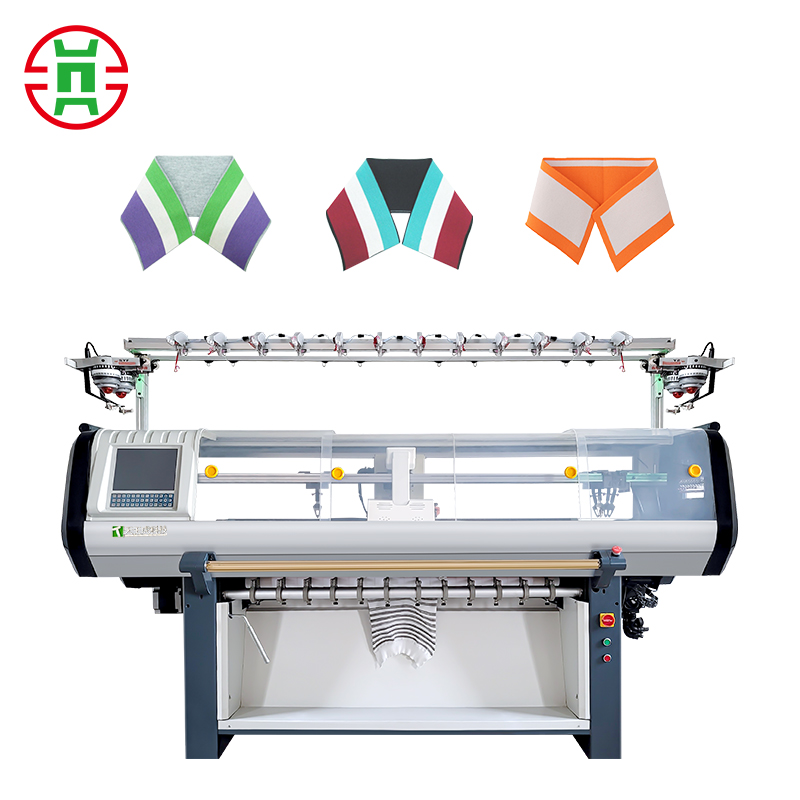

Collar Knitting Machine

The Collar Knitting Machine specializes in producing high-quality collars for T-shirts, polo shirts, and sweaters. It ensures uniform stitches, precise dimensions, and excellent elasticity, making it a must-have for garment manufacturers.

Key Features:

Adjustable stitch density for various collar styles.

User-friendly controls for easy operation.

High durability for high-volume production.

Applications: Ribbed, rolled, and stand-up collars for fashion and sportswear.

Shoe Upper Flat Knitting Machine

The Shoe Upper Flat Knitting Machine is designed for the footwear industry, producing seamless, durable shoe uppers for sports and fashion sneakers. Its 3D knitting capabilities allow for breathable, stretchable designs tailored to specific performance needs.

Key Features:

3D knitting for customized designs.

Energy-saving components for cost efficiency.

High-speed production for large-scale manufacturing.

Applications: Athletic footwear, fashion sneakers, and casual shoes.

Why Choose Changhua?

Changhua stands out as a trusted manufacturer for several reasons:

20+ Years of Expertise

With over two decades in the industry, Changhua has perfected the art of knitting machinery, delivering reliable and innovative solutions.

Global Client Base

Trusted by brands in Europe, the USA, and Asia, Changhua’s machines are used worldwide for their quality and performance.

R&D Focus

Continuous innovation ensures that Changhua’s machines incorporate the latest technology, such as computerized controls and energy-saving components.

After-Sales Support

Changhua offers installation, training, and maintenance services, ensuring smooth operations for all clients.

Sustainability

Their machines support eco-friendly production by minimizing waste and using energy-efficient components.

By choosing Changhua, you're investing in machines that combine cutting-edge technology with practical functionality, backed by a company committed to your success.

How to Find a Flat Knitting Machine Near Me

Step 1: Identify Your Needs

Before searching for a flat knitting machine, determine your production goals. Are you a small-scale designer looking for a semi-automatic machine, or a large manufacturer needing a computerized model for mass production? Consider factors like:

Production Volume: High-volume production requires fully automated machines, while small batches may suit semi-automatic models.

Fabric Type: Ensure the machine supports the yarns and patterns you need.

Budget: Prices range from affordable manual machines to high-end computerized models.

Step 2: Research Local Suppliers

Search for suppliers in your area by using terms like “flat knitting machine near me” on Google or industry platforms like Alibaba and Made-in-China. However, for high-quality machines, consider global manufacturers like Changhua, which offer worldwide shipping and support. Their website provides detailed specifications and contact options for inquiries.

Step 3: Evaluate Machine Features

When comparing machines, look for:

Automation Level: Manual, semi-automatic, or computerized.

Needle Gauge: Determines fabric thickness (e.g., 5G for thick yarns, 14G for fine fabrics).

Compatibility: Ensure the machine supports your desired yarn types and patterns.

Durability: Choose machines with high-quality components to minimize maintenance costs.

Step 4: Contact Manufacturers Directly

Reach out to Changhua via our website (Changhua Knitting Machine) to discuss your needs. Our team can recommend the best machine for your applications and provide details on pricing, shipping, and support.

Maintaining Your Flat Knitting Machine

To ensure longevity and optimal performance, regular maintenance is essential:

Cleaning

Remove lint and debris to prevent buildup.

Lubrication

Apply oil to moving parts to reduce wear.

Inspection

Check needles and other components for signs of damage.

Conclusion

Finding the right flat knitting machine near me involves understanding your production needs, researching reliable suppliers, and choosing a machine that offers versatility, efficiency, and durability. Changhua's range of flat knitting machines, from sweater and collar machines to whole garment and shoe upper models, provides solutions for every textile application. With over 20 years of expertise, global trust, and a commitment to sustainability, Changhua is the go-to manufacturer for high-quality knitting machinery.

Visit Changhua Knitting Machine to explore our full range, download resources, and contact our team for personalized recommendations. Whether you're crafting fashion garments, sportswear, or technical textiles, Changhua has the perfect machine to elevate your production.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe