The global textile industry has undergone a remarkable transformation, with computerized flat knitting machines at the forefront of this revolution. These advanced machines have redefined efficiency, precision, and creativity in sweater manufacturing, enabling top manufacturers to produce high-quality knitwear that meets the demands of fast fashion, customization, and sustainability. Among the leading providers of these machines is Changhua Smart Manufacturing Technology Co., Ltd., a trusted name in knitting machinery with over 20 years of expertise. This article explores the types of computerized flat knitting machines used by top sweater manufacturers, their applications, and why Changhua’s cutting-edge solutions stand out in the industry.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

Understanding Computerized Flat Knitting Machines

Computerized flat knitting machines are sophisticated pieces of equipment designed to automate and enhance the knitting process. Unlike manual or semi-automatic machines, these systems leverage digital controls, advanced software, and precision engineering to produce intricate patterns, seamless garments, and a wide range of knitwear with minimal human intervention. They are essential for top sweater manufacturers aiming to stay competitive in a market that values speed, quality, and sustainability.

Key Features of Computerized Flat Knitting Machines

Automation and Precision

Equipped with digital control systems, these machines allow for precise stitch control, pattern design, and shaping, reducing errors and waste.

Versatility

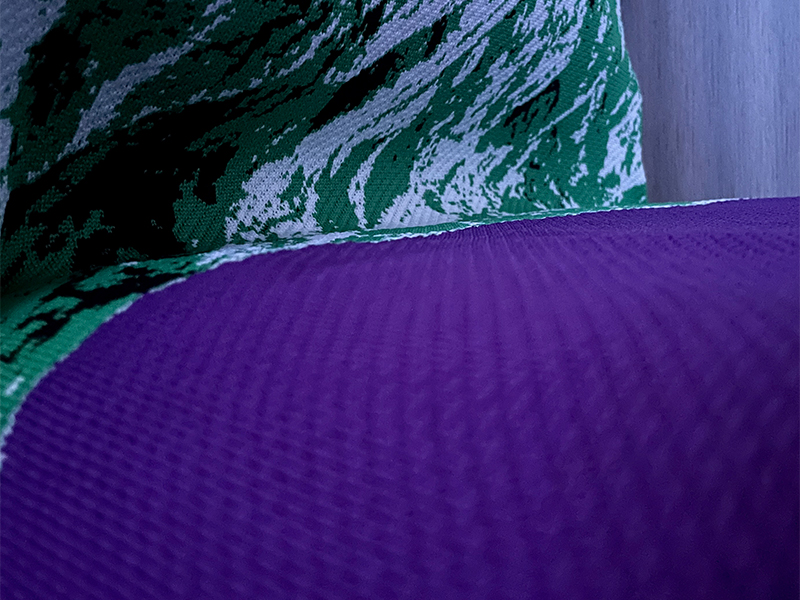

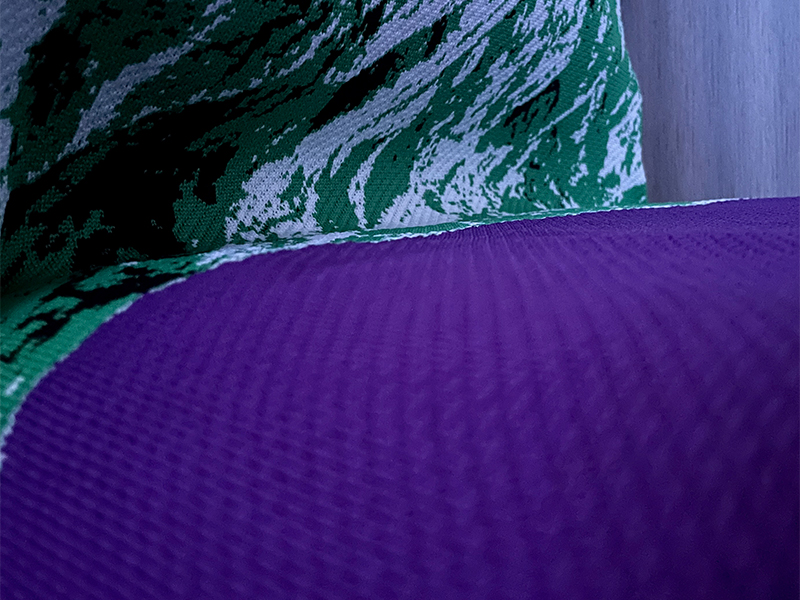

They can handle various yarns, including wool, cashmere, cotton, synthetic fibers, and blends, making them suitable for diverse applications like sweaters, scarves, and technical textiles.

Efficiency

High-speed operations and programmable features enable manufacturers to produce large volumes of knitwear quickly.

Sustainability

By minimizing material waste and optimizing yarn usage, these machines support eco-friendly production practices.

Applications in the Textile Industry

Fashion and Apparel

Producing sweaters, cardigans, vests, and other knitwear with intricate designs and textures.

Home Textiles

Creating blankets, throws, and cushion covers with decorative patterns.

Footwear

Manufacturing seamless shoe uppers for athletic and fashion sneakers.

Technical Textiles

Producing specialized fabrics for automotive interiors, medical compression garments, and more.

What Types of Computerized Flat Knitting Machines Are Used by Top Sweater Manufacturers?

Top sweater manufacturers rely on a variety of computerized flat knitting machines to meet their production needs. These machines vary in terms of gauge, knitting width, system configuration, and specialized features. Below, we explore the main types and their roles in sweater production, with a focus on how Changhua's machines excel in these categories.

Single System Computerized Flat Knitting Machines

Single system machines are ideal for smaller-scale production or manufacturers focusing on simpler designs. These machines feature a single carriage that moves across the needle bed, performing basic knitting functions like plain stitches, ribbing, and simple jacquard patterns.

Advantages

Cost-effective for startups or small manufacturers.

Easy to operate with straightforward programming.

Suitable for basic knitwear like school uniforms or simple sweaters.

Applications

Example

Changhua's Single System Flat Knitting Machine offers a knitting width of up to 52 inches and supports gauges from 7G to 16G, making it versatile for small to medium-scale sweater production. Its user-friendly interface simplifies pattern creation, ideal for manufacturers entering the market.

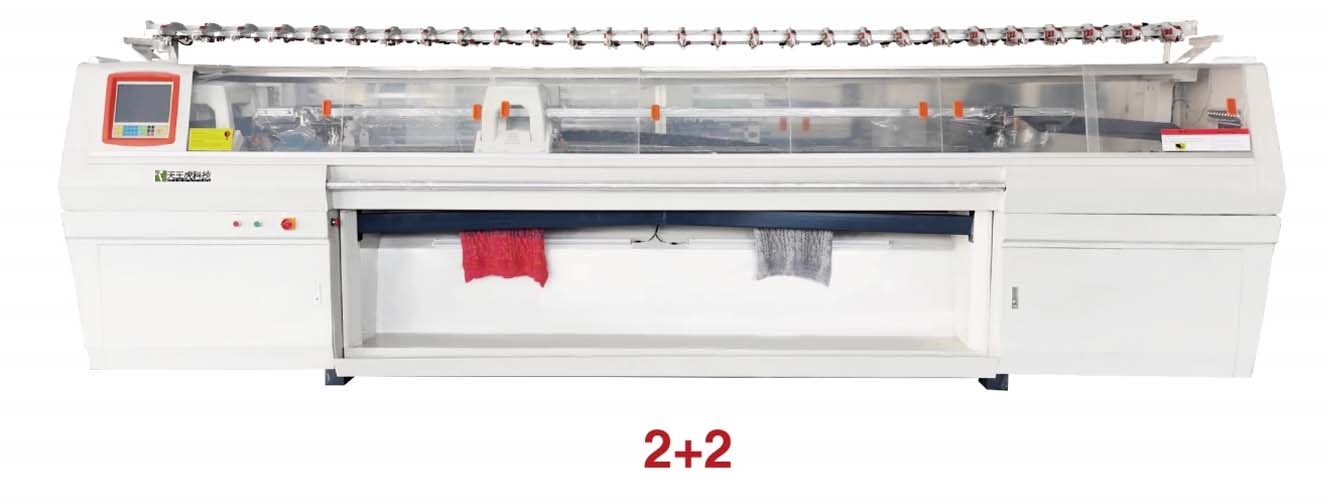

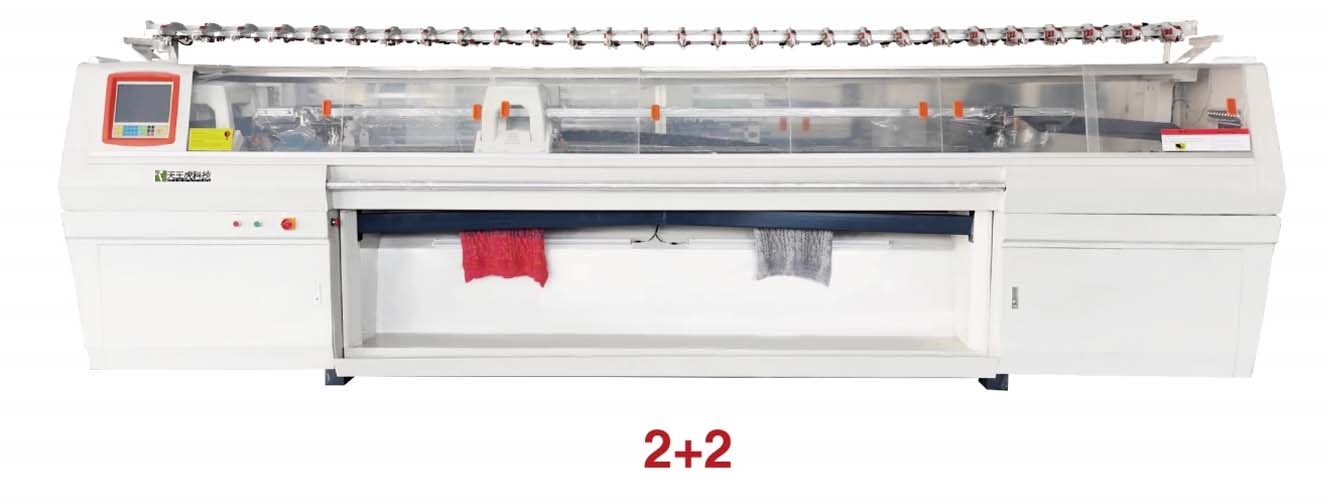

Double System Computerized Flat Knitting Machines

Double system machines are a step up, featuring two independent knitting systems that allow for more complex patterns and higher efficiency. These machines are widely used by top sweater manufacturers due to their ability to handle intricate designs like jacquard, intarsia, and pointelle.

Advantages

High-speed knitting with dual carriages for faster production.

Capable of producing fully fashioned garments with minimal post-production sewing.

Supports dynamic stitch control for varied textures and patterns.

Applications

Example

Changhua's Double System Computerized Flat Knitting Machine is a standout choice, featuring high-performance sinkers, dynamic stitch control, and a maximum knitting speed of 1.4m/s. It supports a wide range of yarns, including wool, cashmere, and blends, making it perfect for luxury sweater production.

Whole Garment Knitting Machines

Whole garment knitting machines, pioneered by brands like Shima Seiki, produce complete sweaters in one piece, eliminating the need for sewing or linking. These machines are revolutionizing the industry by offering:

Advantages

Seamless Production: Reduces post-production time and labor costs.

Minimizes fabric waste, aligning with eco-friendly manufacturing trends.

Applications

Example

Changhua's whole garment knitting machines feature a four-bed configuration and rapid-response carriage systems, making them ideal for producing seamless sweaters with intricate shaping. These machines are a top choice for manufacturers prioritizing sustainability and efficiency.

Why Choose Changhua Knitting Machines?

Located in Changshu, Jiangsu, Changhua Smart Manufacturing Technology Co., Ltd. has been a trusted name in knitting machinery for over two decades. Here's why top sweater manufacturers choose Changhua’s computerized flat knitting machines:

Advanced Technology

Changhua's machines are equipped with state-of-the-art features like motor-driven cam systems, digital stitch control, and high-speed knitting capabilities (up to 1.4m/s). The PICASSO programming system simplifies pattern creation, allowing manufacturers to produce complex designs with ease.Allows for real-time adjustments to stitch density, ensuring consistent quality across all products.

Wide Range of Models

Changhua offers a comprehensive lineup of computerized flat knitting machines, including single system, double system, three system, collar knitting, and whole garment machines. This variety allows manufacturers to choose the perfect model for their specific needs, whether they're producing basic sweaters or high-end seamless garments.

Durability and Reliability

Changhua machines are built to last, with features like automatic needle bed oiling systems and robust construction that reduce wear and tear. This ensures long-term performance and minimal downtime, even in high-volume production environments.

Sustainability Focus

Changhua's machines are designed to minimize yarn waste and energy consumption, supporting eco-friendly manufacturing practices. Whole garment machines are particularly notable for their seamless production capabilities, reducing fabric waste significantly.

Energy Efficiency

Changhua's machines are designed to optimize energy consumption, making them a cost-effective choice for manufacturers looking to reduce operational costs while maintaining high productivity.

Comprehensive Support

Changhua provides excellent after-sales service, including technical support, process guidance, and spare parts availability. Their team of experts is dedicated to helping customers maximize the potential of their machines.

Changhua's Commitment to Sustainability

Changhua is committed to sustainable manufacturing, with machines designed to maximize yarn utilization and minimize waste. This aligns with the growing demand for eco-friendly practices in the textile industry, making Changhua a preferred choice for environmentally conscious manufacturers.

How to Choose the Right Computerized Flat Knitting Machine

Assess Your Production Needs

Determine whether you need a single system machine for basic knitwear or a three system machine for complex, high-value garments.

Consider Gauge and Yarn Type

Choose a machine with a gauge range that matches the yarns you plan to use (e.g., 7G for wool, 14G for finer yarns).

Evaluate Knitting Width

Ensure the machine’s knitting width accommodates the sizes of sweaters you intend to produce.

Check for Advanced Features

Look for features like dynamic stitch control, motor-driven racking, and whole garment capabilities for maximum flexibility.

Budget and Scalability

Balance your budget with the machine's scalability to ensure it can grow with your business.

Maintenance Tips for Computerized Flat Knitting Machines

Clean Regularly

Remove lint and debris from the needle bed and carriage to prevent blockages.

Lubricate Moving Parts

Use the machine’s automatic oiling system or manually lubricate components to reduce wear.

Check Needles and Components

Inspect needles, sinkers, and cams for signs of damage or wear, and replace them as needed.

Run Empty Rows

After rib knitting, run 1-2 empty rows to ensure all needles are properly positioned for yarn feeding.

Update Software

Keep the machine's software updated to access the latest features and improve performance.

Conclusion

For top sweater manufacturers, computerized flat knitting machines are more than just tools—they are the key to unlocking creativity, efficiency, and sustainability. From single-bed machines for basic knits to whole garment machines for seamless luxury sweaters, these technologies empower manufacturers to meet diverse market demands. Changhua Knitting Machine stands out as a trusted partner, offering a wide range of high-performance machines backed by advanced technology and exceptional support.

Whether you're producing high-fashion jacquard sweaters or eco-friendly seamless knits, Changhua has the perfect solution for your business. Explore their range of machines today and take your sweater manufacturing to the next level.

Contact Changhua TodayReady to elevate your sweater production? Visit Changhua's website for more information or to request a quote.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe