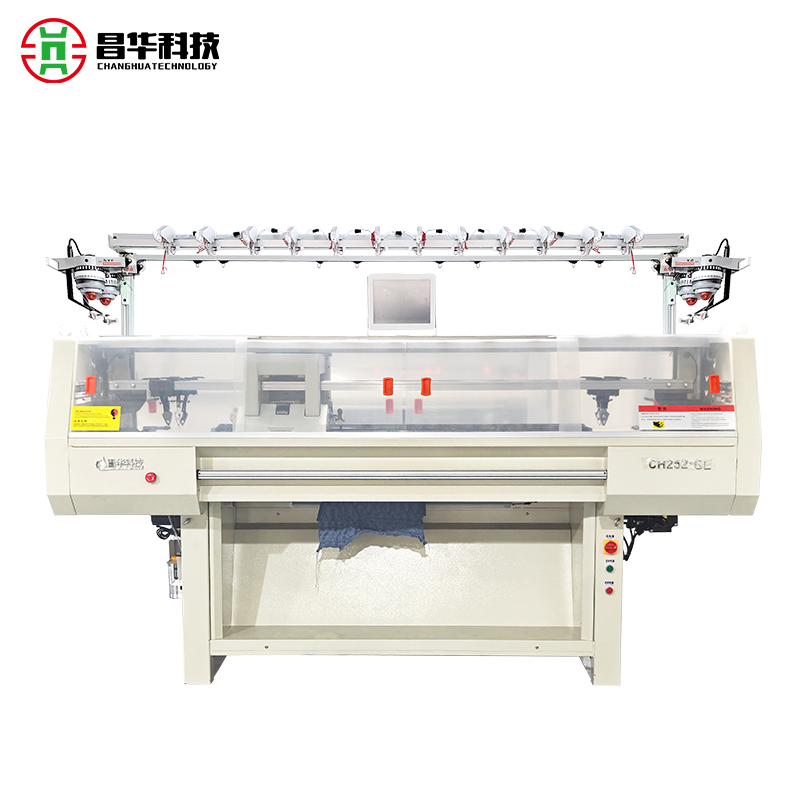

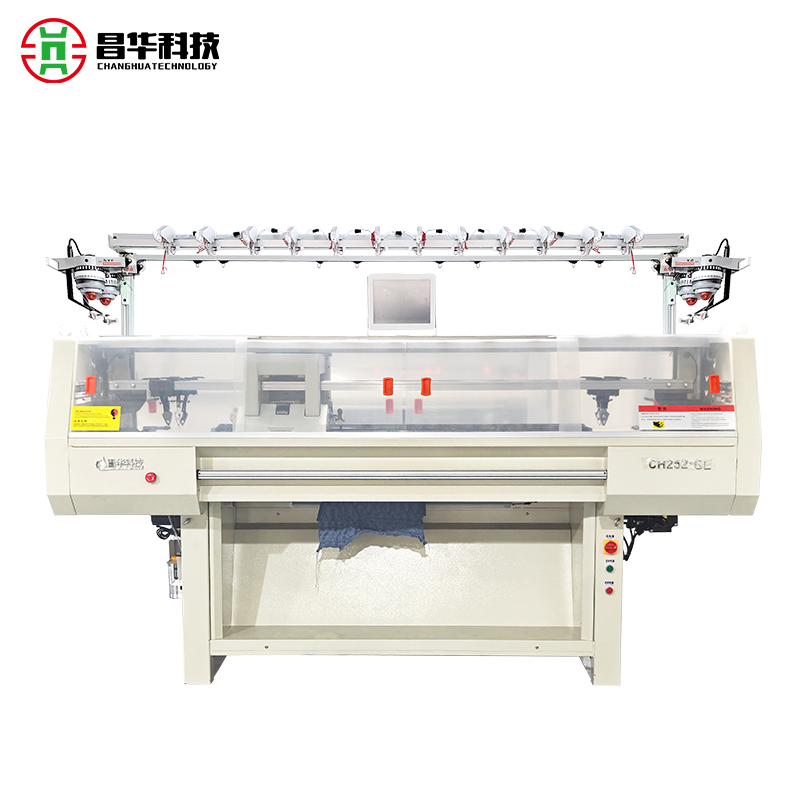

52 Inch Double System GE Computerized Scarf Flat Knitting Machine Description

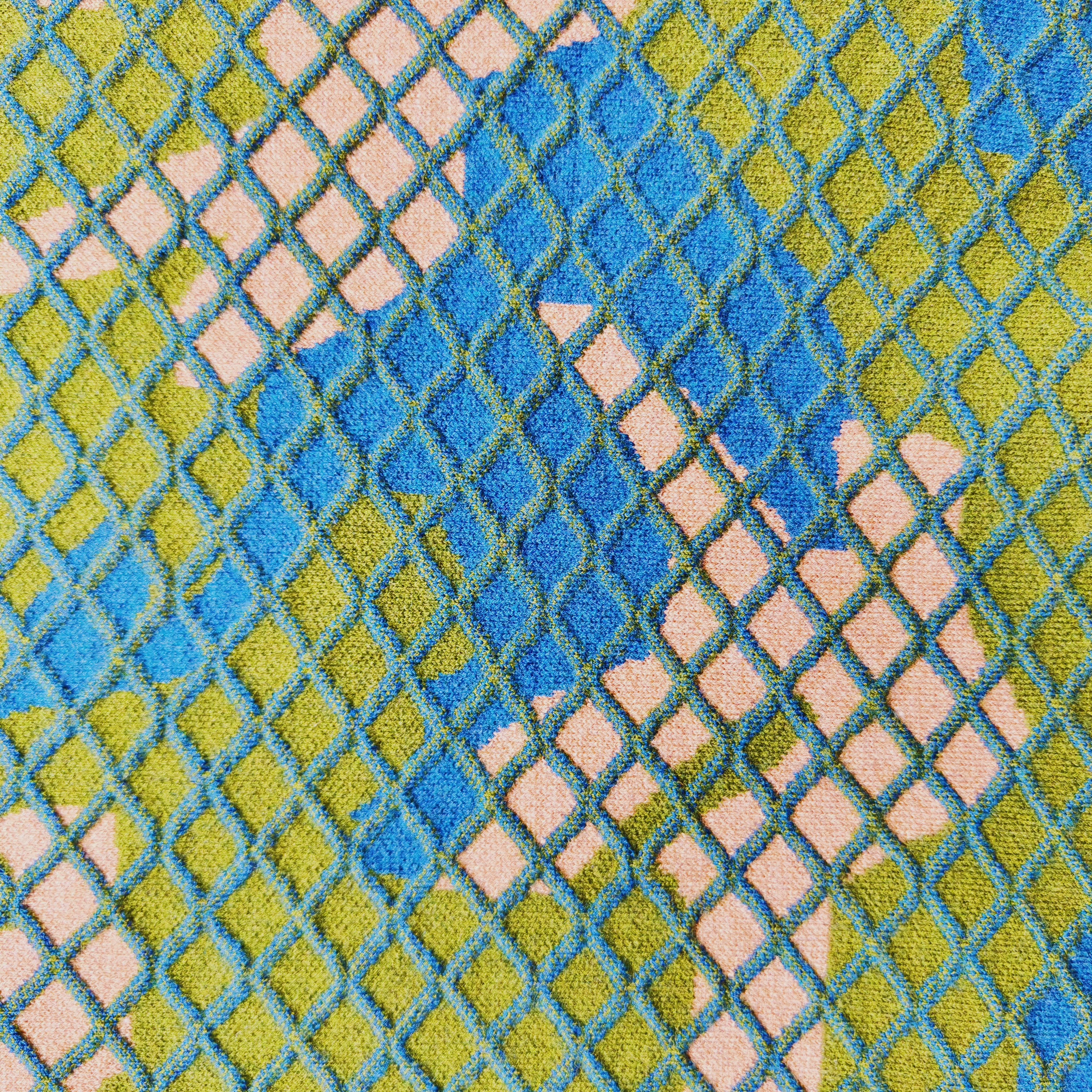

GE Computerized Flat Knitting Machine with double system has high roller, high-performance sinker, dynamic stitch, motor control reserving carriage, digital technology, high-speed and efficient, to achieve pointelle, tuck, jacquard, intarsia, full needle jacquard, apparent shape, hidden shape, and other irregular patterns, which is suitable for wool, cashmere, cotton, chemical fiber, silk and all kinds of blended yarn, the production of sweaters, blanket, scarfs, gloves, hats and knitted apparel accessories. Changhua GE Scarf Knitting Machine.pdf

Changhua GE Scarf Knitting Machine.pdf

Changhua 52-inch Dual-System Fully Automatic GE Knitting Scarf Computerized Flat Knitting Machine Product Introduction

1. German Precision Scarf Manufacturing Experts

Changhua's 52-inch Dual-System Fully Automatic GE Knitting Scarf Computerized Flat Knitting Machine is a specialized scarf production machine developed in collaboration with a team of German engineers. This machine features an optimized 52-inch (132 cm) width and German-standard dual-system synchronous knitting technology, perfectly adapting to the crafting requirements of various scarves. Equipped with a GE series intelligent control system, it supports a database of over 150 scarf patterns, covering a full range of styles from basic to complex, with an accuracy of ±0.01mm, the German industrial standard.

2. Six Core Technical Advantages

German Dual-System Drive:

Utilizes Bosch servo motors, achieving a dual-system synchronization error of ≤0.005mm

Intelligent Pattern Recognition:

Integrated with a Siemens AI vision system, automatically adjusts knitting parameters

Precision Edge Control:

German INA guide rails ensure scarf edge flatness of ≤0.2mm

Full Material Compatibility:

Supports 3-16G needle gauge configurations, perfectly processing high-end materials such as cashmere and silk

Energy-Saving and Quiet Design:

Energy consumption is reduced by 40% compared to conventional equipment, with noise levels kept below 55dB

Intelligent Maintenance System:

Equipped with the German PreMaint predictive maintenance module

3. Professional Applications and Global Service

This model is designed for the following high-end scenarios:

European Luxury Brand Scarf Workshop: Meets the stringent craftsmanship requirements of brands such as Burberry and Hermès

High-End Cashmere Products Base: Professionally processes premium cashmere raw materials with a waste rate of <1%

Designer Creative Studio: Supports the R&D and prototyping of complex artistic scarves

Changhua Technology offers: √ 5-year German standard warranty √ On-site European engineers √ 48-hour global response time √ Lifetime software upgrades

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe