When you slip on a cozy black sweater, have you ever wondered about the intricate process behind its creation? The soft texture, seamless fit, and stylish design are all thanks to advanced textile machinery, specifically the flatbed knitting machine. In this comprehensive guide, we'll explore the machines used to craft black sweaters, focusing on their mechanical applications, the technology behind them, and why Changhua's sweater knitting machines stand out as a top choice for manufacturers and designers. Written with you, the curious reader, in mind, this article will unravel the fascinating world of sweater production while providing practical insights and expert recommendations.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

What Is a Flat Knitting Machine?

A flatbed knitting machine is a specialized device designed to produce flat, knitted fabrics from yarn. Unlike circular knitting machines, which create tubular fabrics, flatbed machines craft flat panels that can be shaped into garments like sweaters, scarves, and cardigans. These machines are equipped with a flat needle bed where needles are arranged in a straight line, allowing for precise stitch formation and complex pattern creation.

Key components of a flatbed knitting machine include:

Needles:Form the stitches that create the fabric.

Sinkers:Hold the fabric in place during knitting.

Carriage:Moves across the needle bed, guiding the yarn to form stitches.

Yarn Feeders:Supply yarn to the needles with consistent tension.

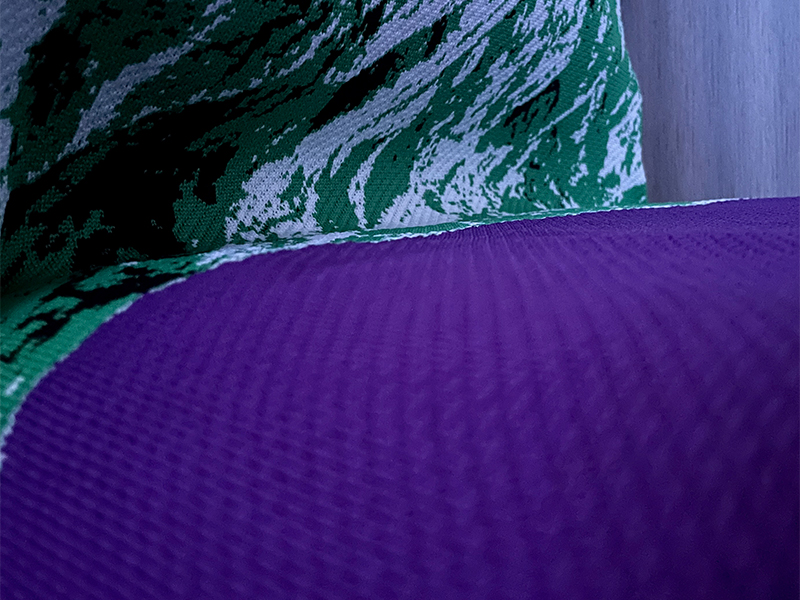

Flatbed knitting machines are ideal for producing black sweaters because they offer flexibility in design, enabling manufacturers to create everything from simple stockinette patterns to intricate jacquard or cable-knit designs. Their ability to handle various yarn types, including wool, cotton, acrylic, and blends, makes them perfect for crafting sweaters in any color, including the timeless black.

Mechanical Applications in Textile Production

Fashion and Apparel

Producing sweaters, cardigans, dresses, and accessories with intricate patterns and seamless construction.

Technical Textiles

Creating fabrics for medical applications (e.g., compression garments) and automotive interiors (e.g., seat covers).

Home Decor

Crafting knitted blankets, throws, and upholstery fabrics.

Soft Robotics and Wearable Electronics

Developing stretchable, programmable fabrics for innovative applications.

The ability to produce two- and three-dimensional structures, as well as seamless “whole garment” products, has made flatbed knitting machines a cornerstone of modern textile manufacturing. For black sweaters, these machines ensure a polished finish, consistent texture, and a comfortable fit that aligns with consumer expectations.

Why Flatbed Knitting Machines Are Ideal for Black Sweaters

Precision and Consistency

Black sweaters demand a flawless appearance, as dark colors can highlight imperfections. Flatbed knitting machines excel in delivering consistent stitch quality, ensuring that every panel of the sweater is uniform in texture and density. Computerized models, in particular, allow manufacturers to upload digital patterns, adjust tension, and monitor production in real time, minimizing errors.

Seamless Whole Garment Technology

One of the most significant advancements in flatbed knitting is whole garment technology, which produces a complete sweater in one piece without the need for sewing seams. This results in a smoother, more comfortable fit, as there are no bulky side seams or stitching errors. For black sweaters, seamless construction enhances the sleek, sophisticated look that consumers love.

Versatility in Design

Whether you’re aiming for a minimalist black crewneck or a bold cable-knit pullover, flatbed knitting machines can handle it all. They support a wide range of stitch types, including:

Stockinette: Smooth and sleek, ideal for lightweight sweaters.

Rib

Stretchy and form-fitting, perfect for cuffs and hems.

Jacquard

Multi-colored or textured patterns for statement pieces.

Cable

Classic, twisted designs for a timeless look.

Efficiency and Scalability

For manufacturers, flatbed knitting machines offer high-speed production without sacrificing quality. Automated features like electronic needle selection and pattern programming reduce manual labor, making it easier to scale production for large orders. This efficiency is crucial for meeting the demand for black sweaters, a staple in wardrobes worldwide.

The Role of Yarn in Black Sweater Production

Wool

Warm and luxurious, ideal for winter sweaters.

Cotton

Breathable and soft, perfect for lightweight designs.

Acrylic

Affordable and durable, commonly used for mass-market sweaters.

Blends

Combining natural and synthetic fibers for balanced performance.

Changhua: Leading the Way in Flatbed Knitting Machines

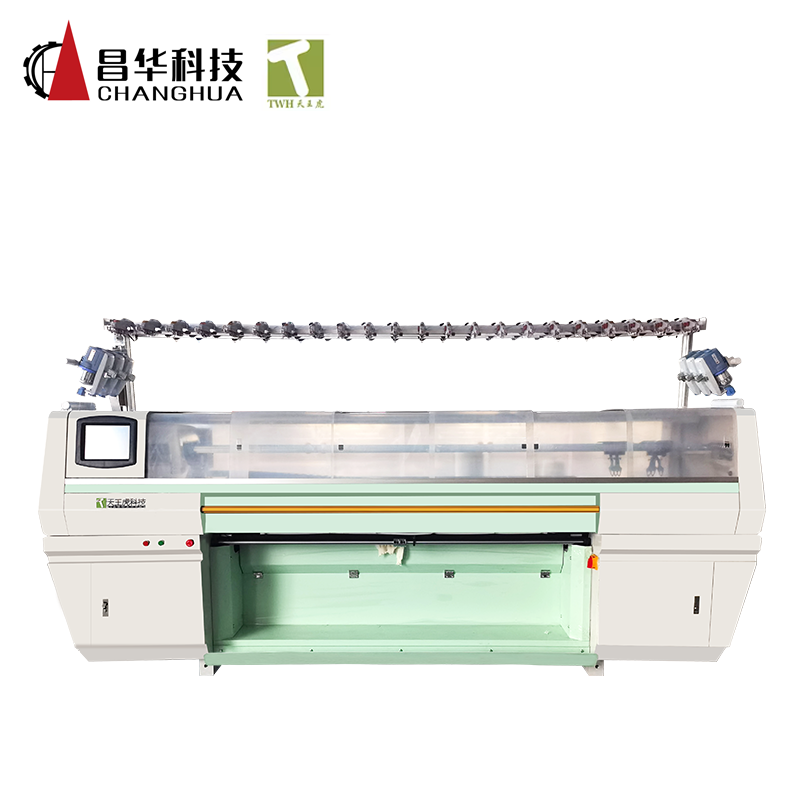

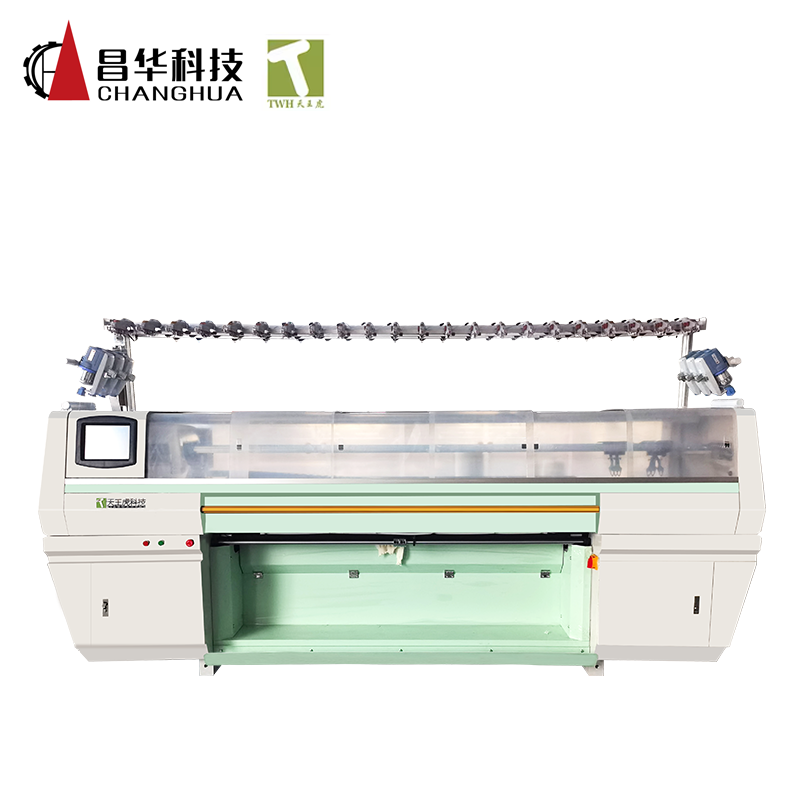

When it comes to producing high-quality black sweaters, Changhua is a name you can trust. As a leading manufacturer of flatbed knitting machines, Changhua combines cutting-edge technology with decades of expertise to deliver machines that meet the needs of modern textile producers.

Changhua's Flatbed Knitting Machines: Features and Benefits

Computerized Controls

Upload digital patterns via USB for precise, error-free knitting. Adjust tension and density to suit different yarn types and designs.

Seamless Technology

Produce complete sweaters without side seams, reducing production time and labor costs while enhancing wearer comfort.

Versatile Stitch Capabilities

Knit everything from plain stitches to complex jacquard and cable patterns, perfect for creating unique black sweater designs.

Durability and Low Maintenance

Built with high-quality materials, Changhua machines require minimal upkeep, with regular cleaning and lubrication ensuring long-term performance.

Why Choose Changhua?

Industry Experience

With over 20 years of production experience, Changhua is a trusted name in the textile industry, serving clients worldwide.

Innovative Technology

Changhua's machines incorporate international advanced technology, ensuring high automation and stable performance.

Custom Solutions

Whether you're a small-scale designer or a large manufacturer, Changhua offers machines tailored to your production needs.

Sustainability Focus

By reducing the need for sewing and minimizing waste, Changhua’s whole garment machines support eco-friendly production practices.

How a Black Sweater Is Made: Step-by-Step Process

Step 1: Design and Pattern Creation

The process begins with designing the sweater. Designers sketch the style, choose a pattern (e.g., ribbed, cable-knit), and select black yarn. Using software, they create a digital pattern that specifies stitch types, tension, and density. This pattern is uploaded to the Changhua machine via USB.

Step 2: Yarn Preparation

High-quality black yarn is selected and prepared. The yarn is wound onto cones and threaded through the machine’s yarn feeders. Changhua machines allow for precise tension adjustments to prevent loose or tight stitches.

Step 3: Machine Setup

Technicians debug the flatbed knitting machine, adjusting needle positions, tension settings, and fabric density based on the sweater’s design. Changhua’s computerized controls make this process quick and accurate.

Step 4: Knitting the Sweater

The machine begins knitting, with the carriage moving across the needle bed to form stitches. For whole garment production, the sweater is knitted as a single piece, eliminating the need for seams. The process is fast, with Changhua machines producing a complete sweater in minutes.

Step 5: Finishing and Inspection

Once knitted, the sweater undergoes finishing processes like washing to remove impurities and soften the fabric. Technicians inspect the sweater for defects, trim excess threads, and add details like ribbed cuffs or necklines. The washing process also stabilizes the sweater’s size and enhances its drape.

Step 6: Packaging and Distribution

The finished black sweater is packaged and prepared for distribution. Thanks to Changhua’s efficient machines, manufacturers can produce large quantities to meet market demand.

Maintenance Tips for Flatbed Knitting Machines

Regular Cleaning

Remove lint and debris from the needle bed and carriage to prevent jams.

Lubrication

Apply lubricant to moving parts to reduce wear and ensure smooth operation.

Needle Inspection

Check needles for damage or wear and replace them as needed.

Software Updates

For computerized models, keep the software updated to access new features and improve performance.

Conclusion

The journey from yarn to a stylish black sweater is a testament to the power of flatbed knitting machines. These versatile, efficient, and innovative machines have transformed the textile industry, making it possible to create high-quality garments with precision and creativity. For manufacturers and designers, Changhua's flatbed knitting machines offer the perfect blend of advanced technology, reliability, and versatility, making them the ideal choice for producing black sweaters that stand out in the market.

Whether you're a textile professional looking to upgrade your production line or a fashion lover curious about the process, Changhua has the tools and expertise to bring your vision to life. Visit Changhua's website to learn more about their machines and how they can help you craft the perfect black sweater.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe