In the fast-evolving textile industry, collar knitting machines have become indispensable tools for manufacturers aiming to produce high-quality, consistent, and stylish collars for garments like shirts, polos, sweaters, and more. Whether you're a small-scale apparel business or a large-scale manufacturer, understanding the cost, functionality, and applications of these machines is critical for making informed purchasing decisions. This comprehensive guide dives into the world of collar knitting machines, exploring their prices, features, applications, and who invests in them, while highlighting why Changhua's export-quality machines stand out as a top choice.

Collar Knitting Machine Price

Understanding the Cost of Collar Knitting Machines

The price of a collar knitting machine can vary significantly based on several factors, including the machine's type, features, automation level, and brand reputation. As of 2025, the cost of collar knitting machines typically ranges from $4,200 to $10,000 per unit, depending on the specifications and capabilities. Here's a breakdown of the factors influencing the price:

Type of Machine: Manual, semi-automatic, and fully computerized machines come with different price tags. Manual machines are generally cheaper, starting at around $600, while advanced computerized models, such as those with jacquard capabilities, can cost up to $4,000 or more.

Gauge and Knitting Width: Machines with higher gauges (e.g., 12G to 18G) or wider knitting widths (e.g., 80 inches) are pricier due to their versatility and capacity for producing intricate designs or larger volumes.

Automation and Technology: Computerized machines with servo systems, automated yarn feeding, and real-time monitoring are more expensive but offer greater efficiency and precision.

Brand and After-Sales Support: Reputable manufacturers like Changhua, known for quality and comprehensive after-sales services, their machines offer better durability and support, ensuring long-term value.

Additional Features: Features like jacquard capabilities, multi-head systems for simultaneous knitting, or compatibility with various yarn types (e.g., wool, cotton, synthetics) can increase the cost but enhance production flexibility.

Factors to Consider When Evaluating Price

Production Volume: High-volume manufacturers may justify investing in pricier, fully automated machines to meet demand.

Customization Needs: If your business focuses on unique collar designs, opt for machines with advanced programming capabilities.

Maintenance and Support: Machines from reputable brands like Changhua come with robust after-sales support, reducing downtime and repair costs.

Yarn Compatibility: Ensure the machine supports the yarn types you use (e.g., cotton, polyester, or wool) to avoid additional costs for modifications.

Automatic Collar and Cuff Making Machine

The Rise of Automation in Collar and Cuff Production

Automatic collar and cuff making machines have revolutionized the textile industry by streamlining production and ensuring consistent quality. These machines are designed to handle tasks like knitting, cutting, folding, and stitching with minimal human intervention, making them ideal for businesses aiming to scale operations. Key features of automatic machines include:

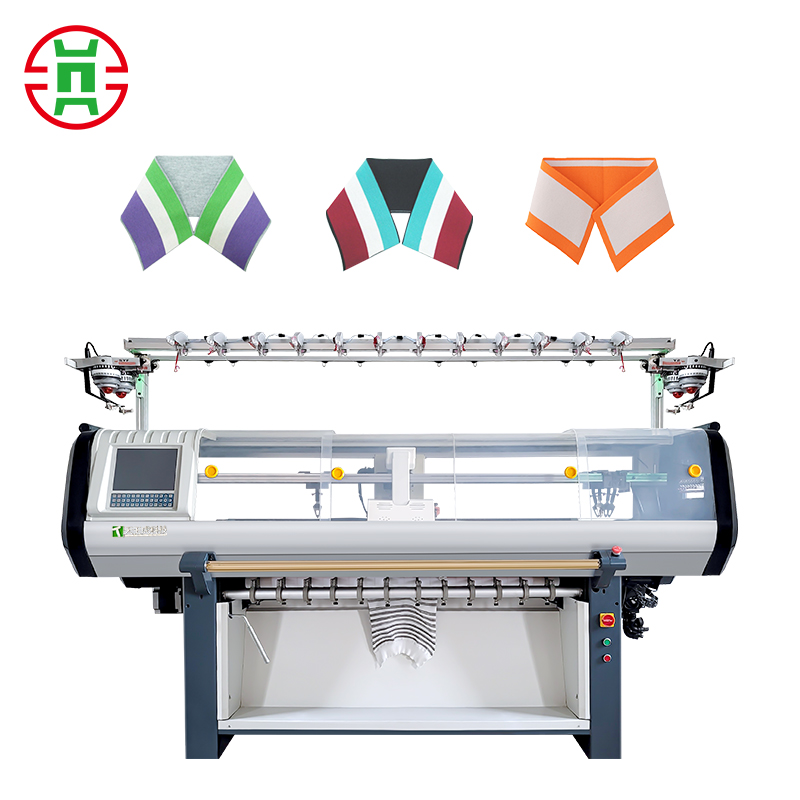

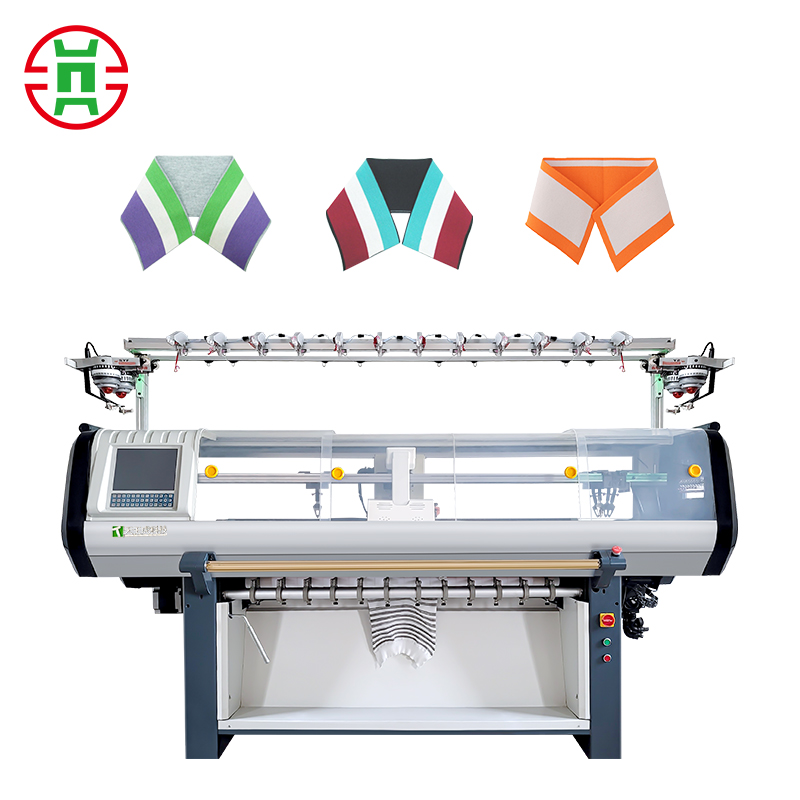

High-Speed Production: Machines like Changhua's 1+1 System Double Carriage Collar Flat Knitting Machine can produce up to 200 collars per hour, significantly boosting output.

Precision and Consistency: Automated systems ensure uniform collar sizes, shapes, and patterns, reducing errors and enhancing brand reputation.

Versatility: These machines can produce a variety of collar styles, including ribbed, jacquard, scalloped, and flat collars, catering to diverse garment types.

User-Friendly Interfaces: Modern machines come with LED controllers and multi-language displays, making them accessible even for operators with limited experience.

Benefits of Automatic Collar and Cuff Making Machines

Efficiency: Automation reduces production time, allowing businesses to meet tight deadlines and fulfill large orders.

Cost Savings: By minimizing manual labor and material waste, these machines offer a high return on investment (ROI).

Customization: Computerized controls allow for easy adjustments to patterns, sizes, and designs, enabling businesses to cater to niche markets.

Durability: High-quality machines, like those from Changhua, are built with robust materials to withstand continuous operation.

Applications of Automatic Collar and Cuff Machines

Automatic collar and cuff making machines are used across various industries:

Apparel Manufacturing: Producing collars for shirts, polos, sweaters, and jackets.

Custom Apparel: Creating unique designs for private-label brands or crowdfunding projects.

Corporate Uniforms: Manufacturing branded collars for promotional apparel or uniforms.

Activewear: Knitting breathable, stretchable collars for sports garments.

Who Buys Collar Knitting Machines?

Target Audience for Collar Knitting Machines

Chinese manufacturers offer competitive pricing without compromising quality, making it easier for businesses to invest in advanced machinery.

Collar knitting machines are sought after by a diverse range of buyers, from small-scale entrepreneurs to large textile conglomerates. Understanding who invests in these machines can help you gauge their relevance to your business:

Textile and Apparel Manufacturers:

Large-scale garment factories use collar knitting machines to produce collars for shirts, sweaters, polos, and other knitwear in bulk.

These businesses prioritize high-speed, automated machines to meet global demand and maintain competitive pricing.

Custom Apparel and Private-Label Brands:

Brands focused on unique or bespoke designs invest in computerized machines to create distinctive collar styles that set them apart from competitors.

Small to medium-sized enterprises (SMEs) often purchase semi-automatic or single-system machines for flexibility and affordability.

Crowdfunding and Startup Ventures:

Entrepreneurs launching apparel lines through crowdfunding platforms use collar knitting machines to fulfill orders efficiently and cost-effectively.

These buyers value machines that offer customization without requiring massive upfront investments.

Corporate and Promotional Apparel Companies:

Home-Based and Small-Scale Producers:

Export-Oriented Manufacturers:

Companies targeting international markets, particularly in regions like Europe, North America, and Asia, invest in export-quality machines to meet stringent quality standards. Changhua’s machines, for instance, are designed to deliver consistent, high-quality collars that meet global expectations.

Why Buyers Choose Collar Knitting Machines

Scalability: Machines allow businesses to scale production without compromising quality.

Brand Differentiation: Customizable designs help brands stand out in competitive markets.

Cost Efficiency: Automated machines reduce labor costs and material waste, improving profitability.

Global Market Compliance: Export-quality machines ensure products meet international standards, appealing to buyers in high-demand markets.

Collar Knitting Machine Export Quality - Changhua

Why Choose Changhua for Collar Knitting Machines?

When it comes to collar knitting machines, Changhua stands out as one of the top manufacturers in China, renowned for its commitment to quality, innovation, and customer satisfaction. With over 20 years of experience, Changhua has established itself as a leader in the textile machinery industry, producing machines that meet the needs of both domestic and international markets. Here's why Changhua's collar knitting machines are a cut above the rest:

Unmatched Precision and Quality

Changhua's machines, such as the 68-Inch 14G Double System Collar Knitting Machine and the 80-Inch Single System Collar Knitting Machine, are engineered with extreme attention to detail. Features like precise needle beds, guide rails, and cam-boards ensure flawless collars with clear fabric lines and consistent edges.

Problem-Solving Design: Changhua addresses common issues like uneven collar edges and poor fabric clarity, delivering high-quality plain-knitted and jacquard collars.

Versatile Patterns: From simple ribbed collars to complex jacquard designs, Changhua machines handle a wide range of styles with ease.

Advanced Automation

Changhua's computerized flat knitting machines are equipped with cutting-edge technology, including:

Servo Systems: For precise control over density and roller drawing force.

Multi-Head Systems: The 1+1 System Double Carriage Collar Flat Knitting Machine can produce two collars simultaneously, doubling efficiency.

Real-Time Monitoring: Automated systems allow operators to track performance and make adjustments on the fly, reducing errors and downtime.

Versatility Across Applications

Changhua's machines are designed to work with various yarns (wool, cotton, synthetics) and produce collars for diverse garments, including:

Comprehensive After-Sales Support

Changhua goes beyond selling machines by offering:

Installation and Training: Ensuring seamless integration into your production line.

Maintenance Services: Easy-to-repair designs and readily available spare parts minimize downtime.

Global Reach: Changhua serves clients worldwide, with a reputation for reliability and excellence.

Competitive Pricing

While Changhua machines are priced competitively, they offer exceptional value through durability, efficiency, and low maintenance costs. Wholesale options further reduce costs for bulk buyers.

Changhua's Flagship Collar Knitting Machines

1+1 System Double Carriage Collar Flat Knitting Machine

Ideal for large-scale production, this machine supports intricate patterns and high-volume output. It's perfect for manufacturers producing collars for shirts, jackets, and sweaters.

80-Inch Single System Collar Knitting Machine

Perfect for producing high-quality plain-knitted collars with consistent edges and fabric clarity.

Mechanical and Application Insights

How Collar Knitting Machines Work

Determine your required output. For high-volume production, opt for fully automatic machines like Changhua’s double system models. For smaller operations, a single system or semi-automatic machine may suffice.

Collar knitting machines operate using a combination of mechanical and electronic components to produce high-quality collars. Here’s a simplified overview of their mechanics:

Yarn Feeding: Yarn is fed through tension disks and take-up mechanisms, ensuring smooth and consistent knitting.

Needle Beds and Cams: The needle bed and cam system control the knitting process, allowing for precise stitch formation and pattern creation.

Computerized Control: Modern machines use servo systems and LED controllers to automate pattern design, density adjustment, and roller force, minimizing manual intervention.

Output Mechanism: Once knitted, collars are detached or directly fitted onto garments, streamlining the production process.

Key Mechanical Features

Interchangeable Needle Beds: Machines with gauges from 12G to 18G allow for varying levels of stitch density and collar thickness.

Jacquard Capabilities: Enable the creation of intricate patterns, ideal for high-fashion or branded apparel.

Automated Takedown Systems: Motor-controlled rollers ensure consistent fabric tension and quality.

Durable Construction: High-quality materials like ceramic wearproof top tensions reduce maintenance needs and extend machine lifespan.

Why Invest in a Collar Knitting Machine?

Consistency

Ensures every collar meets the same high standards, enhancing brand reputation.

Efficiency

Machines that optimize material usage and reduce energy consumption, aligning with the demand for sustainable production.

Customization

Computerized machines enable rapid design changes, catering to diverse customer needs.

Cost-Effectiveness

Automation reduces labor costs and material waste, improving profitability.

Why Changhua is the Best Choice for Your Collar Knitting Needs

A Legacy of Excellence

Founded in Changshu, Jiangsu, Changhua has been a pioneer in the textile machinery industry since its inception. With brands like Changhua, Tiangong, King Tiger, and Miao’s Craftsman, the company produces over 6,000 computerized flat knitting machines annually, including specialized collar knitting machines.

Innovative Technology

Changhua's machines are equipped with state-of-the-art features:

Smart Programming: Fast and intelligent programming reduces energy consumption and enhances efficiency.

Multi-Head Systems: Models like the 2+2 and 3+3 machines maximize output by knitting multiple collars simultaneously.

Customizable Designs: From plain stitches to complex jacquard patterns, Changhua machines cater to all design needs.

Global Reach and Reliability

Changhua serves clients worldwide, from small businesses in India to large manufacturers in Europe and North America. Its machines are designed to meet international quality standards, making them ideal for export-oriented businesses.

Comprehensive Support

Changhua offers end-to-end support, including:

Consultation: Helping you choose the right machine for your production needs.

Installation and Training: Ensuring your team is equipped to operate the machine efficiently.

Maintenance and Spare Parts: Minimizing downtime with readily available parts and expert support.

Competitive Pricing and Value

Changhua's machines are priced to offer maximum value, with models like the 80-Inch Single System Collar Knitting Machine providing advanced features at a competitive cost. Bulk purchases and wholesale options further enhance affordability.

Conclusion

Collar knitting machines are a game-changer for businesses in the textile and apparel industry, offering precision, efficiency, and versatility. Whether you’re producing collars for polos, sweaters, or corporate uniforms, investing in a high-quality machine can transform your production process and boost profitability. When it comes to cost, depending on the machine's features and automation level.

For those seeking export-quality machines, Changhua is the go-to manufacturer. With advanced technology, robust after-sales support, and a commitment to innovation, Changhua’s collar knitting machines are designed to meet the diverse needs of global markets. From the 1+1 System Double Carriage Collar Flat Knitting Machine to the 80-Inch Single System Collar Knitting Machine, Changhua offers solutions that combine affordability with unmatched performance.

Ready to take your collar production to the next level? Contact Changhua today to schedule a demo or request a quote. Visit our official website for more details. Let Changhua help you build the future of garment manufacturing!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe