The world of textiles has been revolutionized by technology, and at the forefront of this revolution are computerized flat knitting machines. Gone are the days of purely manual labor; today, precision, speed, and complexity are driven by sophisticated computer controls. For any business owner, fashion designer, or production manager looking to enter or scale in the knitwear market, the choice of machinery is the most critical decision you will make.

The debate often starts with a fundamental question: Should I invest in a Single Jersey or a Double Jersey machine?

This isn't just a question of technical specs; it's about your business's future. The right machine can unlock new product lines, improve quality, and skyrocket your profitability. The wrong one can lead to limitations, frustration, and wasted capital.

In this ultimate guide, we will demystify these two powerhouse technologies. We'll explore their mechanics, their ideal applications, and their pros and cons. And when you're ready to make a choice, we'll introduce you to a partner you can trust: Changhua Knitting Machine. With decades of expertise, Changhua has been providing the global textile industry with robust, user-friendly, and high-performance machinery.

Ready to find your perfect knitting solution? Let's dive in and unravel the details.

Understanding the Core Technology - How Do They Work?

Before we compare, let's build a solid foundation. What exactly are we talking about?

What is a Computerized Flat Knitting Machine?

A computerized flat knitting machine is an electronically controlled device used to produce knitted fabrics or fully fashioned garments. Unlike circular knitting machines that produce a continuous tube of fabric, flat knitters create flat panels of fabric. These panels can then be assembled into sweaters, cardigans, scarves, and even intricate technical textiles.

The "computerized" aspect means that every function—from the stitch pattern and carriage speed to the cam system and yarn tension—is managed by a computer. This allows for:

Unmatched Precision: Perfect stitch replication every time.

Complex Designs: Ability to create jacquards, intarsia, cables, and 3D structures.

Reduced Waste: "Whole garment" or "fully fashioned" knitting minimizes cutting waste.

Ease of Use: Operators can load designs and switch production with a few clicks.

The Anatomy of a Stitch: Single Jersey vs. Double Jersey

The primary difference between these two machines lies in the bed configuration and the resulting fabric structure.

Single Jersey Knitting Machines

Bed Configuration: One set of needles. Traditionally, this is a single needle bed.

Fabric Structure: The yarn is looped through previous loops in a single direction. This creates a fabric that is smooth on one side (the technical face) and has a characteristic "purl" or mesh-like appearance on the other (the technical back).

Key Characteristics:

The fabric tends to curl at the edges.

It is lightweight and has good drape.

It is generally less stable and can be prone to laddering (runs).

Think of a standard T-shirt fabric—that's the classic example of single jersey.

Double Jersey Knitting Machines (also known as Double Knit or Rib Machines)

Bed Configuration: Two sets of needles. These are typically arranged in two opposing beds, often forming a "V" shape.

Fabric Structure: The yarn is looped simultaneously on both beds, creating two layers of single jersey fabric that are interconnected. This results in a fabric that is the same on both sides (or can be designed to have different patterns on each side).

Key Characteristics:

The fabric is thicker, warmer, and more stable.

It lies flat and does not curl at the edges.

It has excellent recovery and stretch properties.

Think of the cuff of a sweater or a high-quality polo shirt collar—that's double jersey fabric.

Head-to-Head Comparison: Single Jersey vs. Double Jersey

Now that we understand the basics, let's put them side-by-side. Which one aligns with your production goals?

| Feature |

Single Jersey Machine |

Double Jersey Machine |

| Fabric Weight |

Lightweight to Medium |

Medium to Heavyweight |

| Fabric Thickness |

Thin |

Thick, Dense |

| Edges |

Curls |

Lies Flat |

| Stretch & Recovery |

Good, primarily in one direction |

Excellent, in both directions |

| Durability |

Good |

Superior, more resistant to runs |

| Typical Applications |

T-shirts, lightweight sweaters, underwear, linings |

Sweaters, cardigans, jackets, scarves, cuffs, collars, technical textiles |

| Production Speed |

Generally faster for simple fabrics |

Can be slightly slower due to complexity |

| Complex Design Potential |

High for jacquards and intarsia |

Very High, allows for complex 3D and tubular structures |

| Machine Cost |

Often more affordable to purchase and maintain |

Typically higher due to a more complex mechanism |

Which Machine is Right for Your Business? A Guided Decision

Choose a Single Jersey Machine if:

Your primary products are T-shirts, lightweight jerseys, or base layers.

You are focused on high-volume production of simpler fabric constructions.

Cost-efficiency in both machine purchase and fabric consumption is a primary concern.

You work with fine yarns to create lightweight, drapable fabrics.

Does this sound like your business model? A Changhua Single Jersey machine could be your engine for growth.

Choose a Double Jersey Machine if:

You produce structured knitwear like sweaters, cardigans, and jackets.

You need fabrics with excellent shape retention and warmth, like for scarves and beanies.

Your designs incorporate ribbed cuffs, collars, and hemming directly into the garment.

You are exploring advanced technical textiles that require a double-layer structure.

Are you aiming for premium, structured knitwear? Then a Changhua Double Jersey machine is your path to superior quality.

Introducing Your Ideal Partner: Changhua Knitting Machine

Navigating the technical landscape is one thing; finding a reliable machinery partner is another. In an industry where downtime means lost revenue, you need a supplier known for quality, durability, and support. You need Changhua.

Who is Changhua? A Legacy of Innovation and Reliability

For decades, Changhua Knitting Machine has been a cornerstone of the global textile machinery industry. Our mission is simple: to provide knitters with machines that are not only technologically advanced but also robust and accessible. We understand the challenges faced on the production floor, and we engineer our solutions to meet them head-on.

Why do thousands of businesses choose Changhua?

Proven Expertise: With a long history in R&D and manufacturing, our machines are built on a foundation of deep industry knowledge.

Global Reach & Support: We have a worldwide distribution and service network, ensuring you get the help you need, when you need it.

Commitment to Value: We strive to offer the best performance-to-price ratio in the market, making advanced knitting technology a viable investment for businesses of all sizes.

Customer-Centric Innovation: We listen to our customers' feedback, constantly refining our machines to be more user-friendly and productive.

**Ready to see what a partnership with Changhua can do for your bottom line? Explore our range of solutions on our official website: https://www.changhua-knitting-machine.com/**

A Closer Look at Our Flagship Machines

Let's move from the general to the specific. Here are two of our bestselling models, perfectly representing the Single and Double Jersey categories.

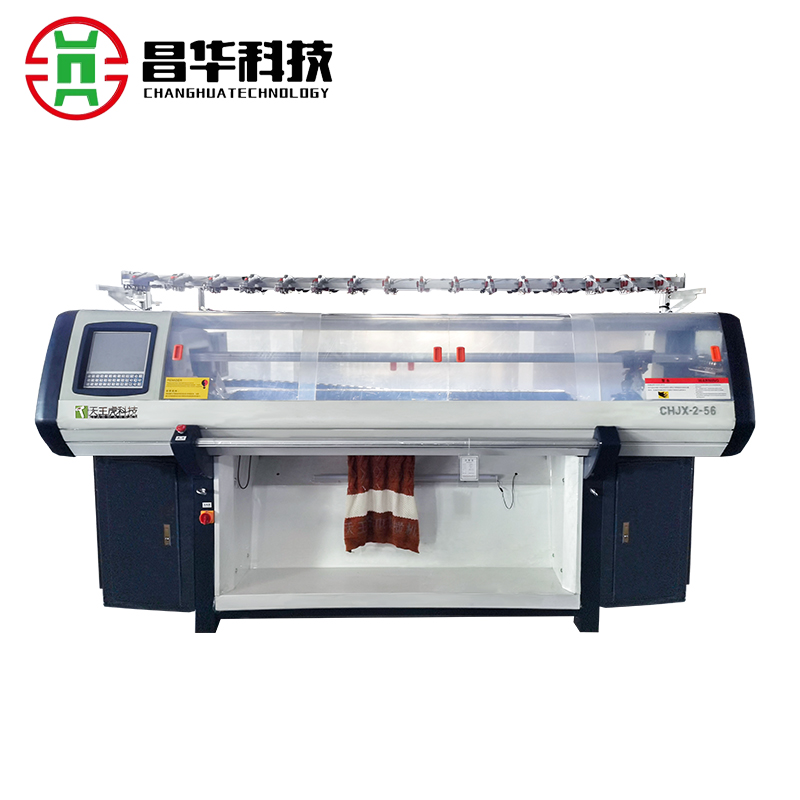

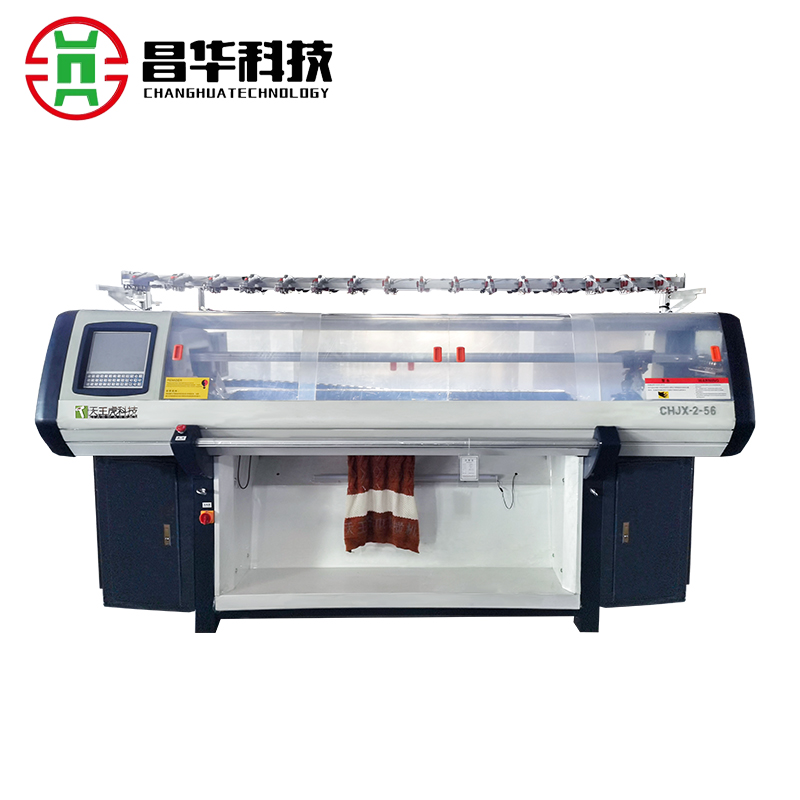

The Productivity Powerhouse: Changhua 72-inch Single System Computerized Flat Knitting Machine

This machine is the workhorse for factories focused on efficiency and volume. It embodies the core strengths of single jersey technology, enhanced by Changhua's reliable engineering.

Key Features and Specifications:

Working Width: A spacious 72 inches, allowing for wide fabric panels or multiple narrow pieces simultaneously.

Single System: Optimized for straightforward, high-speed knitting of fundamental structures.

Computer Control: User-friendly interface for easy pattern input and machine management.

Robust Frame: Built for 24/7 industrial operation with minimal vibration and noise.

What can you produce with this machine?

This is your go-to for producing the foundational fabrics of the fashion world. Think T-shirt material, lightweight sweater fronts/backs, dress linings, and scarf fabric. Its efficiency makes it perfect for fulfilling large orders for basic apparel items.

Interested in boosting your production of staple knit items? Get the detailed specifications and see more of this machine here: Discover the 72-inch Single System Machine

The Versatility Champion: Changhua 80-inch Double System Computerized Knitting Machine

When your ambition goes beyond basic fabrics, this double system machine answers the call. It combines a wide working area with the power of two knitting systems, opening up a world of creative and technical possibilities.

Key Features and Specifications:

Working Width: An expansive 80 inches, ideal for large panels or efficient multi-garment production.

Double System: Two independent knitting systems dramatically increase production speed for complex patterns and double jersey fabrics.

Advanced Computer Control: Handles intricate designs like jacquard, intarsia, cables, and plating with ease.

High-Precision Needle Beds: Ensure consistent stitch quality across the entire width of the fabric, even at high speeds.

What can you produce with this machine?

This is the machine for creators and innovators. Produce thick sweaters, structured cardigans, sophisticated jacquard blankets, technical textiles with pockets or 3D shapes, and seamless tubular fabrics. It's the tool that allows you to say "yes" to more complex and lucrative orders.

Do you have a design in mind that requires this level of capability? Learn all about this versatile powerhouse on our product page: Explore the 80-inch Double System Machine

The Changhua Advantage: More Than Just a Machine

Buying a Changhua machine means investing in a complete package designed for your success. Our advantages extend far beyond the initial hardware.

Unbeatable Reliability and Low Maintenance

Our machines are engineered with heavy-duty components and simplified mechanics where possible. This translates to less unexpected downtime, lower maintenance costs, and a longer operational lifespan. You can count on your Changhua machine to run shift after shift, meeting your toughest deadlines.

Intuitive Operation and Training

We believe powerful technology should be accessible. Our machines come with straightforward software and interfaces, reducing the learning curve for your operators. Furthermore, we provide comprehensive documentation and access to training resources to get your team up to speed quickly.

Exceptional After-Sales Support and Spare Parts

A machine is only as good as the support behind it. Changhua's global network ensures that technical support and genuine spare parts are readily available. This minimizes disruption and protects your investment for the long haul.

Superior Cost-Performance Ratio

By combining advanced features with efficient manufacturing, we deliver incredible value. You get high-end performance without the exorbitant price tag, ensuring a faster return on your investment and a stronger competitive edge.

Seeing is believing. But you don't have to just take our word for it.

Part 6: Conclusion: Your Perfect Knitting Solution Awaits at Changhua

The journey through the world of computerized flat knitting machines brings us to a clear conclusion. The choice between Single Jersey and Double Jersey is not about which is better, but about which is better for you.

For speed, efficiency, and lightweight fabric production, the Single Jersey machine is your champion.

For versatility, structure, and complex, high-value knitwear, the Double Jersey machine is the undisputed choice.

And when it comes to selecting the brand that will be the backbone of your operation, the choice is equally clear. Changhua Knitting Machine offers the perfect blend of proven technology, rugged reliability, and outstanding value.

You've done the research. You understand the technology. Now it's time to take the next step.

Ready to Transform Your Knitwear Production?

Don't let uncertainty hold your business back. The perfect machine to scale your operations, improve your quality, and increase your profits is within reach.

Take action today:

Browse Our Full Product Catalog: Visit our official website to see our complete range of computerized flat knitting machines. Visit www.changhua-knitting-machine.com

Get a Personalized Quote: Contact our expert sales team with your specific requirements. We'll help you match the perfect Changhua machine to your needs and provide a competitive quotation.

Schedule a Virtual Demo: See our machines in action! Contact us to arrange a live video demonstration and get all your technical questions answered.

Click Here to Contact Changhua Today and Request Your Free Consultation!

Your future in knitwear starts with the right machine. Let Changhua be your partner in building it.

Additional Resources:

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe