In recent years, Kenya's textile and apparel industry has witnessed remarkable growth, with a growing demand for locally produced knitwear both in domestic and international markets. Sweaters, in particular, have become a staple in Kenyan fashion, worn across all seasons due to the country's mild climate and the increasing popularity of stylish, warm clothing. To meet this demand efficiently, investing in high-quality sweater knitting machines is crucial for businesses looking to scale their production, improve quality, and stay competitive.

This comprehensive guide will walk you through everything you need to know about sweater knitting machines in Kenya, from understanding the different types of machines available to exploring why Changhua's knitting machines are the ideal choice for your business. We'll also highlight specific models from our product line, their features, and how they can benefit your operations. Whether you're a small startup or an established manufacturer, this article will provide valuable insights to help you make informed decisions for your knitting business.

Understanding Sweater Knitting Machines: Types and Functions

Sweater knitting machines are specialized equipment designed to produce knitted fabrics and garments, including sweaters, cardigans, and other knitwear. These machines come in various types, each suited for different production needs, fabric types, and garment styles. Understanding the differences between these machines is essential for choosing the right one for your business in Kenya.

Flat Knitting Machines vs. Circular Knitting Machines

The two primary categories of sweater knitting machines are flat knitting machines and circular knitting machines.

Flat Knitting Machines: These machines feature a flat bed with needles that move back and forth to create knitted fabric. Flat knitting machines are highly versatile and are ideal for producing seamless garments, complex patterns, and shaped pieces like sweater fronts, backs, and sleeves. They are commonly used for small to medium batch production and are favored by manufacturers who need flexibility in design.

Circular Knitting Machines: As the name suggests, these machines have a circular cylinder with needles that rotate to produce tubular knitted fabric. Circular machines are typically used for high-volume production of basic knit fabrics, such as those used in t-shirts, but can also be adapted for certain sweater styles. They are known for their speed and efficiency but offer less design flexibility compared to flat knitting machines.

Key Features to Consider in Sweater Knitting Machines

When selecting a sweater knitting machine for your Kenyan business, several key features should be taken into account:

Needle Gauge: This refers to the number of needles per inch and determines the thickness of the fabric. A higher gauge (more needles) produces a finer fabric, while a lower gauge results in a thicker, bulkier fabric.

Number of Systems: The number of systems (or feeders) on a machine determines how many yarns can be fed simultaneously, affecting the speed of production and the complexity of patterns that can be created. Machines with more systems can produce more intricate designs and work faster.

Automation Level: Modern sweater knitting machines range from manual to fully automated. Automated machines, equipped with computerized controls, offer precise pattern programming, reduced labor costs, and increased production efficiency.

Fabric Width: The maximum width of fabric that the machine can produce is an important consideration, especially for larger garments or fabrics that need to be cut into specific shapes.

Yarn Compatibility: Different machines are designed to work with specific types of yarn, such as cotton, wool, acrylic, or blends. Ensuring that the machine is compatible with the yarns you plan to use is crucial for achieving the desired fabric quality.

Why Choose Changhua's Sweater Knitting Machines for Your Kenyan Business?

When it comes to investing in sweater knitting machines in Kenya, partnering with a reliable and experienced manufacturer is paramount. At Changhua, we have been a leading provider of high-quality knitting machines for over 20 years, serving businesses worldwide with innovative solutions tailored to their specific needs. Here's why our machines stand out in the Kenyan market:

Our Commitment to Quality and Durability

We understand that in the textile industry, equipment reliability directly impacts productivity and profitability. That's why all our sweater knitting machines are built to the highest standards using premium materials and advanced manufacturing techniques. Our machines are designed to withstand the rigors of continuous operation, ensuring long-term performance and minimal downtime—critical factors for businesses in Kenya looking to maximize their output.

Tailored to Kenyan Production Needs

We recognize that the Kenyan textile market has unique requirements, from the types of yarns commonly used (such as cotton and wool blends) to the preferred garment styles and production volumes. Our machines are engineered to address these specific needs, offering features that make them well-suited for local conditions. Whether you're producing traditional Kenyan knitwear or modern, export-oriented designs, our machines can adapt to your requirements.

Advanced Technology for Enhanced Efficiency

In today's competitive market, efficiency is key. Our sweater knitting machines incorporate the latest technological advancements, including computerized controls, automatic yarn tensioning, and precise pattern programming. These features not only reduce labor costs but also allow for faster production, consistent quality, and the ability to create complex designs with ease—giving your business a competitive edge.

Comprehensive Support and Service

At Changhua, we believe that our relationship with customers extends beyond the sale. We provide comprehensive support to ensure that your machines operate at peak performance. Our services include installation, training for your operators, ongoing maintenance, and prompt technical support. We have a network of service partners in Kenya to ensure that you receive timely assistance whenever you need it.

Competitive Pricing and Flexible Financing

We understand that investing in new machinery can be a significant financial commitment, especially for small and medium-sized businesses in Kenya. That's why we offer competitive pricing on all our machines and flexible financing options to help you spread the cost over time. Our goal is to make high-quality knitting technology accessible to businesses of all sizes.

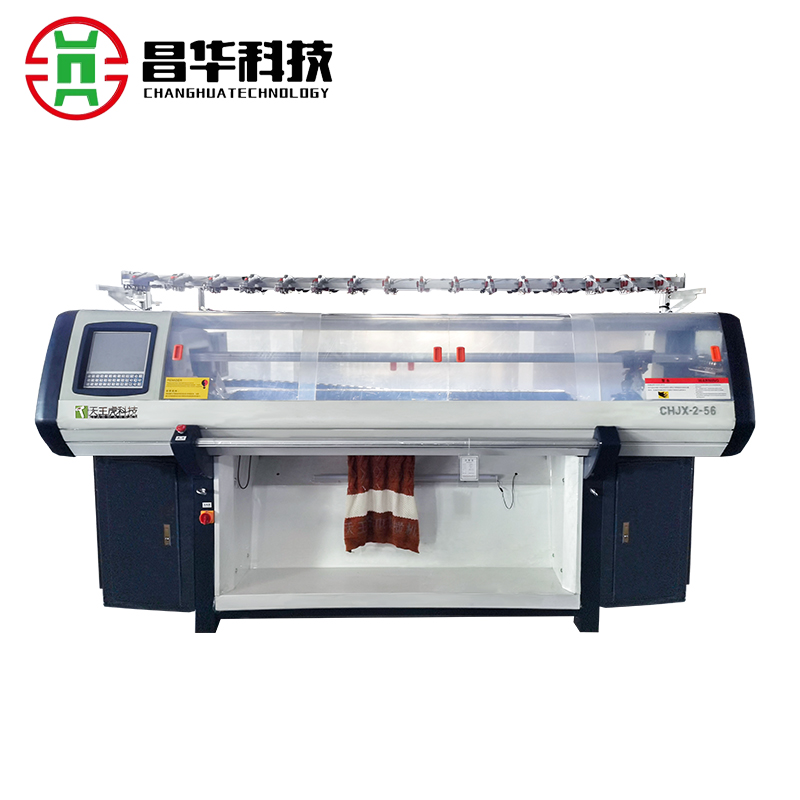

Our Top Sweater Knitting Machines for Kenyan Manufacturers

At Changhua, we offer a wide range of sweater knitting machines designed to meet the diverse needs of Kenyan businesses. Below, we highlight some of our most popular models, each tailored to different production requirements and budget considerations.

1. 52-Inch Single System Sweater Flat Knitting Machine

Our 52-inch single system sweater flat knitting machine is an excellent choice for small to medium-sized businesses looking to start or expand their sweater production. This machine combines versatility with affordability, making it ideal for those who need to produce a variety of styles without a large initial investment.

Key Features:

52-inch working width, suitable for producing standard-sized sweater panels and small garments.

Single system design, perfect for basic patterns and solid-color fabrics.

Compatible with a wide range of yarns, including cotton, wool, acrylic, and blends—common in Kenyan knitwear.

Easy-to-use manual controls with optional computerized upgrades for enhanced pattern capabilities.

Compact design, saving space in your factory or workshop.

Benefits for Kenyan Businesses:

Ideal for startups or businesses with limited space.

Affordable entry point into automated sweater production.

Versatile enough to handle various yarn types and basic designs.

Easy to maintain, with readily available spare parts in Kenya.

2. 60-Inch Double System Sweater Knitting Machine

For businesses looking to step up their production capacity and handle more complex designs, our 60-inch double system sweater knitting machine is an excellent choice. With two systems, this machine can feed two yarns simultaneously, allowing for faster production and the creation of more intricate patterns.

Key Features:

60-inch working width, accommodating larger sweater panels and more versatile garment designs.

Double system design, enabling faster production and the creation of ribbed, jacquard, and other textured patterns.

Computerized control system with a user-friendly interface, making pattern programming simple.

Automatic yarn tension control, ensuring consistent fabric quality across all productions.

High-speed operation, increasing your daily output without compromising on quality.

Benefits for Kenyan Businesses:

Increased production efficiency, helping you meet larger orders and tight deadlines.

Ability to produce a wider range of designs, from basic to moderately complex, expanding your product offerings.

Reduced labor costs due to automated features, improving your bottom line.

Suitable for medium to large batch production, ideal for supplying local retailers or exporting.

3. 60-Inch Three System Sweater Knitting Machine

For large-scale manufacturers and those producing high-end, complex knitwear, our 60-inch three system sweater knitting machine is the ultimate solution. With three systems, this machine can handle multiple yarns and intricate patterns with ease, delivering exceptional speed and versatility.

Key Features:

60-inch working width, suitable for large garments and high-volume production.

Three systems, enabling the creation of advanced patterns, including intarsia, fair isle, and complex textures.

Fully computerized with a large touchscreen display, allowing for easy pattern editing and storage.

Automatic needle selection and yarn changing, minimizing manual intervention and reducing errors.

Energy-efficient design, helping to lower operational costs in the long run.

Benefits for Kenyan Businesses:

Ability to produce high-end, fashion-forward knitwear that meets international standards, opening up export opportunities.

Maximum production efficiency, allowing you to handle large orders quickly and profitably.

Reduced waste and improved quality control, thanks to advanced automation features.

A long-term investment that can grow with your business, adapting to changing market demands.

The Advantages of Choosing Changhua's Machines Over Competitors

In a market with various options for sweater knitting machines, Changhua's products stand out for several reasons. Here are the key advantages that make our machines the preferred choice for Kenyan businesses:

Superior Build Quality for Longevity

Our machines are constructed using high-grade steel and components, ensuring durability even in the demanding conditions of continuous production. Unlike some cheaper alternatives that may require frequent repairs or replacement, Changhua machines are built to last, providing a reliable return on investment for years to come.

Advanced Technology for Precision and Speed

We invest heavily in research and development to incorporate the latest technological innovations into our machines. From computerized pattern programming to automatic yarn management, our technology ensures that each stitch is precise, reducing fabric waste and ensuring consistent quality. This precision, combined with high-speed operation, allows you to produce more garments in less time.

Customization Options to Meet Your Needs

We understand that no two businesses are the same, which is why we offer a range of customization options for our machines. Whether you need a specific needle gauge, a larger working width, or additional features for handling specialized yarns, we can tailor our machines to your exact requirements. This level of customization ensures that you get a machine that perfectly fits your production process.

Local Support in Kenya

Unlike international manufacturers that may not have a presence in Kenya, Changhua has established a network of local partners to provide prompt support. Our technical team is available to assist with installation, training, and maintenance, ensuring that your machine is always operating at its best. This local support minimizes downtime and gives you peace of mind knowing that help is just a phone call away.

Cost-Effective Operations

While our machines represent a significant investment, their efficiency and durability result in lower long-term costs. Reduced labor requirements, minimal waste, and lower maintenance expenses all contribute to a lower total cost of ownership compared to less reliable machines. Additionally, our energy-efficient designs help to reduce electricity costs, which is particularly important in Kenya where energy expenses can be a significant operational burden.

Compliance with International Standards

All Changhua machines meet or exceed international safety and quality standards, ensuring that your production process is compliant with global regulations. This is especially important if you plan to export your knitwear, as many international buyers require suppliers to use equipment that meets specific standards.

How to Get Started with Changhua: Next Steps for Your Business

If you're ready to take your Kenyan sweater production to the next level with Changhua's knitting machines, here's how to get started:

1. Assess Your Production Needs

Before selecting a machine, evaluate your current production volume, the types of garments you want to produce, and your future growth plans. Consider factors such as the yarns you use, the complexity of your designs, and your budget. This assessment will help you determine which of our machines is the best fit for your business.

2. Browse Our Product Range

Visit our website to  explore our full range of sweater knitting machines, including the models highlighted in this article and other options that may suit your needs. Each product page provides detailed specifications, images, and videos to help you make an informed decision.

explore our full range of sweater knitting machines, including the models highlighted in this article and other options that may suit your needs. Each product page provides detailed specifications, images, and videos to help you make an informed decision.

3. Request a Quote

Once you've identified the machine that's right for you, request a personalized quote by contacting our sales team. We'll provide you with a competitive price based on your specific requirements and any customization options you need.

4. Schedule a Demo

We offer live demonstrations of our machines, either at our local partner facilities in Kenya or via video call. A demo is a great way to see the machine in action, ask questions, and get a better understanding of how it will fit into your production process.

5. Secure Financing (Optional)

If you need assistance with financing, our team can help you explore flexible payment options tailored to your business's cash flow. We work with local financial institutions to offer competitive rates and terms.

6. Installation and Training

Once you've purchased your machine, our technical team will handle installation and provide comprehensive training for your operators. We ensure that your team is fully confident in using the machine before we leave, minimizing any disruption to your production.

7. Ongoing Support

Our commitment to your success doesn't end with the sale. We offer ongoing maintenance services, technical support, and access to spare parts to keep your machine running smoothly.

Ready to transform your sweater production? Contact us today to discuss your needs and get started with Changhua's high-quality knitting machines.

Conclusion: Weaving Success in Kenya's Textile Future

The opportunity in Kenya's knitwear sector has never been brighter. With growing domestic demand, preferential trade access to international markets, and government support for manufacturing, now is the time to invest in modern sweater knitting technology.

Changhua Knitting Machines offers you not just equipment, but a comprehensive partnership aimed at building your manufacturing capability and business success. Our machines are engineered for Kenyan conditions, our support is tailored to your needs, and our commitment is to your growth.

Join the growing community of successful knitwear manufacturers across Kenya who have chosen Changhua as their technology partner. From small startups to large export operations, we have the right machine and the right support to help you thrive in this dynamic industry.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe