Are you in the textile industry, looking to upgrade your production, increase efficiency, or venture into the lucrative world of knitted fabric and apparel? If so, you've undoubtedly encountered the term "flat yarn making machine." This technology is the backbone of modern knitting, responsible for everything from simple scarves to intricate, fully-fashioned garments.

But with so many options and manufacturers on the market, how do you make the right choice? This ultimate guide is designed to walk you through everything you need to know about flat knitting machines. We will demystify the technology, explore different types of machines, and highlight the critical factors to consider before investing. By the end of this article, you will be equipped with the knowledge to make an informed decision that will propel your business forward.

What is a Flat Yarn Making Machine?

Let's start with the basics. A flat yarn making machine, more commonly known as a flat knitting machine, is a sophisticated piece of industrial equipment used to produce knitted fabric in a flat, sheet-like form. Unlike circular knitting machines that create a continuous tube of fabric, flat knitters produce fabric with two selvage edges.

The fundamental process involves a carriage, holding the yarn feeders and knitting cams, moving back and forth across a needle bed. The needles, arranged in a straight line, are selectively activated to create loops of yarn, forming the knit structure. This back-and-forth motion allows for incredible versatility in design and patterning.

Key Components of a Flat Knitting Machine:

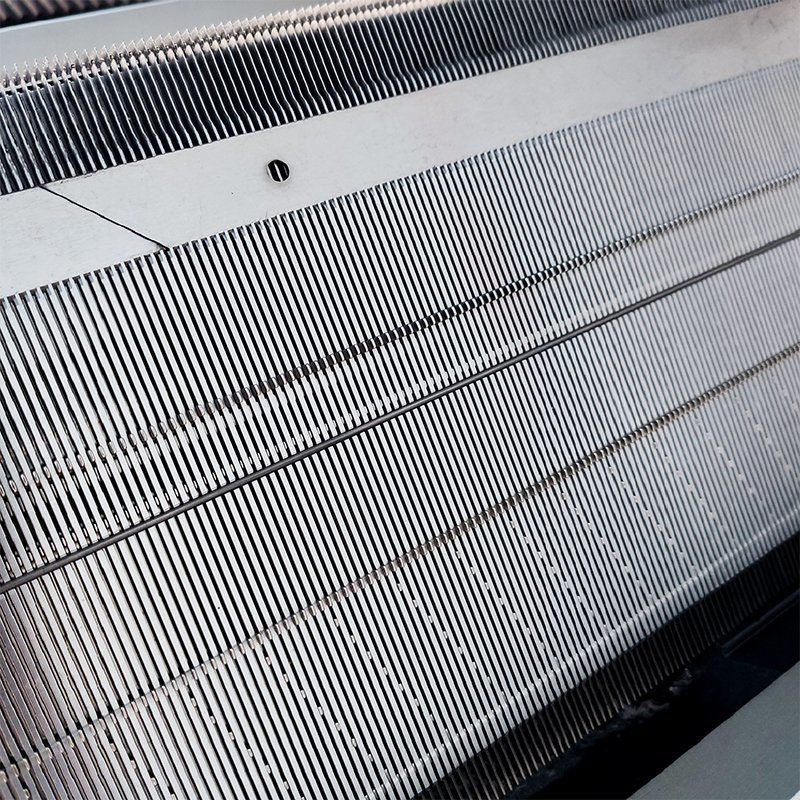

Needle Bed: The flat plate where the needles are housed. High-quality machines have precisely engineered needle beds for smooth operation.

Carriage: The moving unit that carries the yarn and controls the needles to form stitches.

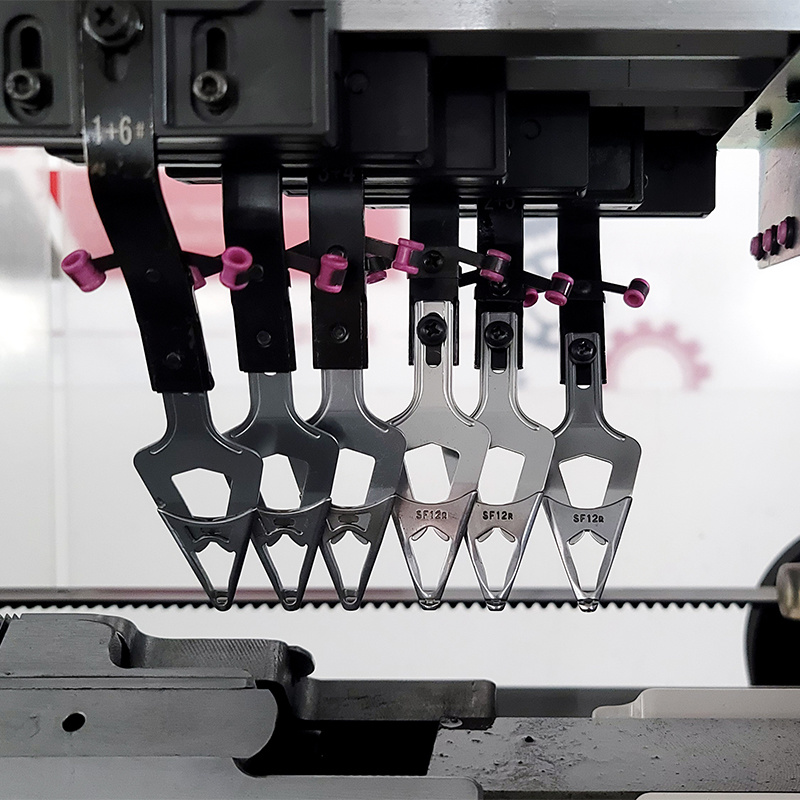

Yarn Feeders: Guide and supply the yarn to the needles during the knitting process. Multi-system machines have several feeders for efficiency.

Take-Down System: Gently pulls the finished fabric down and rolls it, maintaining consistent tension.

Computer Control System: The brain of the modern machine, where designs are loaded, and all knitting parameters are controlled.

Why is Flat Knitting Technology So Crucial in Modern Textiles?

The adoption of advanced flat knitting machines has revolutionized the textile and apparel industry. Here’s why they are indispensable:

Unmatched Design Flexibility: From basic jerseys to complex cables, jacquards, intarsia, and 3D structures, flat knitters can create an endless variety of patterns.

Production of Fully-Fashioned Garments: This is a game-changer. Machines can knit entire garment panels, like a sweater front or back, to the exact shape and size, eliminating the need for cutting and reducing fabric waste by up to 30%.

Seamless/Whole Garment Knitting: Top-tier machines can knit an entire garment, such as a sweater or dress, in one single piece, with no side seams. This enhances comfort, quality, and production speed.

Automation and Efficiency: Computerized controls allow for storing thousands of patterns, quick style changes, and reduced manual labor, leading to higher and more consistent output.

Navigating the Different Types of Flat Knitting Machines

Understanding the different categories of flat knitting machines is the first step in selecting the right one for your factory. They are generally classified by system, bed configuration, and function.

Single System vs. Multi-System Machines

Single System Flat Knitting Machine: The carriage has one yarn feeding system. It completes one course (a row of loops) for every pass across the needle bed. These machines are excellent for prototyping, sampling, and producing simpler, high-quality fabrics. They are often more affordable and easier to maintain.

Multi-System Flat Knitting Machine: The carriage has two or more yarn feeding systems. This allows it to knit two or more courses in a single pass, dramatically increasing production speed. A three-system machine, for instance, can be up to three times faster than a single-system machine for basic structures.

Single Bed vs. Double Bed Machines

Single Bed (V-Bed) Machines: Feature two needle beds arranged at an angle (like a "V") that knit against one carriage. This is the most common configuration for producing a wide range of knitwear.

Double Bed (Flat Bed) Machines: Have two parallel needle beds. They are primarily used for producing double-knit fabrics, which are thicker and reversible, like ribbed trims and cuffs.

Mechanical vs. Computerized Flat Knitting Machines

The industry has largely moved on from purely mechanical machines. Computerized Flat Knitting Machines are the standard today. They offer digital control over every aspect of the knitting process—needle selection, yarn carrier movement, stitch density, and carriage speed—through an intuitive user interface. This allows for unparalleled precision, repeatability, and complex pattern creation.

Introducing Our Partner in Innovation: Changhua Knitting Machine

In a market filled with options, choosing a reliable and innovative manufacturer is as important as choosing the right machine type. This is where Changhua stands out.

For decades, we atChanghua have been at the forefront of knitting machine technology. Our commitment to research, development, and precision engineering has made us a trusted name for manufacturers worldwide. We understand the pressures of modern production—the need for speed, reliability, and versatility—and we build our machines to meet and exceed these demands.

Our philosophy is simple: Provide robust, high-performance, and cost-effective flat knitting solutions that empower our clients to compete and thrive in the global market.

[Download our company profile PDF to learn more about our history and manufacturing capabilities.]

[Download our company profile PDF to learn more about our history and manufacturing capabilities.]

What Sets Our Machines Apart? The Changhua Advantage

When you invest in a Changhua flat yarn making machine, you are not just buying hardware; you are acquiring a productivity partner. Here’s what makes our machines the smart choice:

Unbeatable Price-to-Performance Ratio: We leverage efficient manufacturing and direct-to-customer relationships to offer superior machines at a highly competitive price, ensuring a faster return on your investment.

Robust and Durable Construction: Our machines are built with high-grade materials and components to withstand the rigors of 24/7 industrial production, minimizing downtime and maximizing longevity.

User-Friendly Computer System: Our intuitive control software, often available in multiple languages, reduces the learning curve for your operators and allows for quick pattern uploads and adjustments.

Low Maintenance and Easy Servicing: We design our machines for simplicity and ease of maintenance. With a global network of technical support and readily available spare parts, we ensure your production stays on schedule.

Energy Efficiency: Modern drive systems and optimized operations mean our machines consume less power, reducing your factory's operating costs and environmental footprint.

Ready to see how a Changhua machine can transform your production line? Contact our team today for a free consultation and a quote tailored to your needs.

A Closer Look at Our Flagship Flat Knitting Machines

Let's dive into the specifics of some of our most popular models. Each is engineered for a specific set of applications, giving you the flexibility to choose the perfect tool for your business.

The Versatile Workhorse: 52-Inch Single System Sweater Flat Knitting Machine

For manufacturers specializing in high-fashion knitwear, sampling, and small to medium batch production, our 52-Inch Single System Sweater Flat Knitting Machine is an ideal solution.

Key Features and Specifications:

Working Width: 52 inches, providing a versatile fabric width for most sweater and apparel panels.

Single System: Perfect for complex patterning where precision is more critical than raw speed.

Gauge Range: Available in various gauges (E.g., 5G, 7G, 12G) to produce everything from chunky knits to finer fabrics.

Advanced Control: Equipped with our latest computer system for precise needle selection and stitch control.

Ideal Applications:

Fashion sweaters with cable, jacquard, and intarsia patterns.

Prototyping and sample development for design houses.

Scarves, shawls, and other fashion accessories.

High-value, low-volume production runs.

This machine is the artist's brush of the knitting world. If your priority is intricate design and top-tier quality over mass volume, this is the model for you. Explore its full technical specifications on the product page.

The Productivity Powerhouse: 72-Inch Whole Garment Flat Knitting Machine

Step into the future of knitting with our 72-Inch Whole Garment Flat Knitting Machine. This machine is engineered for maximum productivity and is capable of knitting complete, seamless garments, dramatically streamlining your production process.

Key Features and Specifications:

Working Width: A spacious 72-inch bed, ideal for large panels and whole-garment knitting.

Multi-System Design: Typically a two or three-system machine, offering high-speed production.

Whole Garment Capability: Knits complete garments with minimal or no seaming, reducing labor costs and material waste.

High-Speed Carriage: Optimized for rapid movement without compromising on stitch quality.

Ideal Applications:

Seamless apparel (sweaters, dresses, sportswear).

High-volume production of sweater fronts, backs, and sleeves.

Technical textiles and 3D knitted structures.

Imagine producing a finished sweater with no side seams, ready for minor finishing, straight off the machine. The efficiency gains are monumental. Are you ready to revolutionize your factory's output? Inquire about the 72-inch whole garment machine to get started.

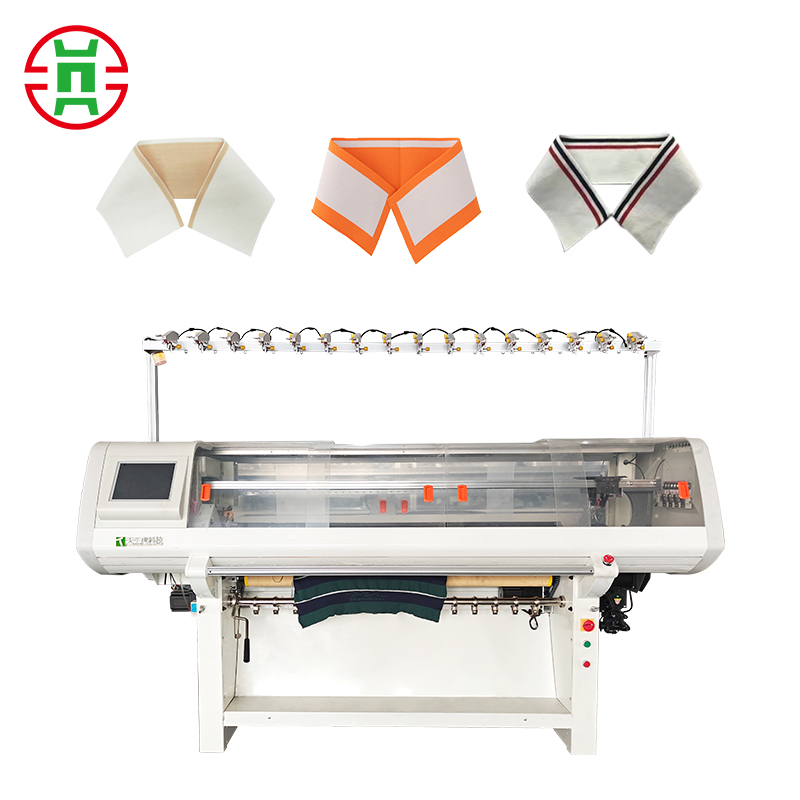

The Specialized Expert: 100-Inch Three System Collar Knitting Machine

For businesses focused on high-volume production of specific components, specialization is key. Our 100-Inch Three System Collar Knitting Machine is a specialist designed for one purpose: extreme efficiency in producing knit trims and collars.

Key Features and Specifications:

Extra-Wide Working Width: 100 inches allows for the simultaneous knitting of multiple collars or trims across the bed.

Three-System Design: This is where speed is maximized. Three courses per pass means output is significantly higher than standard machines.

Optimized for Rib and Trim: Specifically calibrated for producing 1x1 rib, 2x2 rib, and other common cuff and collar structures.

Dedicated Take-Down: Ensures perfect tension and rolling for narrow-width fabrics.

Ideal Applications:

High-speed production of T-shirt collars, cuffs, and plackets.

Knitting waistbands, sock cuffs, and other tubular trims.

Any application requiring massive volumes of consistent, high-quality ribbed fabric.

If your business lives and dies by the volume of trims and collars you produce, this machine is not just an upgrade—it's a necessity. It’s built for one job and does it better and faster than anyone else. Calculate your potential ROI and talk to our sales team now.

Key Factors to Consider Before Buying a Flat Yarn Making Machine

Making such a significant investment requires careful thought. Here are the critical questions you should ask yourself and any potential supplier:

What is my primary product? (Fashion knitwear, basic panels, collars, technical textiles?)

What is my required production volume? (This will guide you toward single or multi-system machines).

What gauge (needles per inch) do I need? This determines the thickness and fineness of the fabric.

What is the level of technical expertise of my operators? How user-friendly is the machine's software?

What after-sales support does the manufacturer offer? This includes installation, training, warranty, and spare parts availability.

Why Your Choice of Manufacturer Matters: The Complete Package

A machine is only as good as the company that stands behind it. When you choose Changhua, you are choosing a partnership. We offer:

Pre-Sales Consultation: Our experts help you select the perfect model for your application and budget.

Global Installation and Commissioning: We ensure your machine is set up correctly and running optimally.

Comprehensive Operator Training: We make sure your team is confident and proficient in using the new equipment.

Responsive After-Sales Support: Our technical support team is just a call or email away to troubleshoot any issues.

Genuine Spare Parts: We guarantee the performance and longevity of your machine with readily available original parts.

Conclusion: Weave Your Success with the Right Technology

The world of flat knitting is dynamic and full of opportunity. Investing in the right flat yarn making machine can unlock new levels of creativity, efficiency, and profitability for your business. From the versatile single-system machine for the discerning fashion knitter to the high-speed, specialized powerhouses for mass production, there is a perfect tool for every need.

We atChanghua have dedicated our company to providing that perfect tool. Our blend of robust engineering, innovative technology, and unwavering customer support has made us the go-to choice for savvy manufacturers around the globe.

Don't just adapt to the future of knitting—define it. The first step is a conversation.

Frequently Asked Questions (FAQ)

Q: What is the lead time for a Changhua flat knitting machine?

A: Lead times vary depending on the model and order volume. Generally, it ranges from 15 to 45 days. Contact us for a precise timeline.

Q: Do you provide training for the machine operators?

A: Absolutely. We provide comprehensive training, either at your facility or via detailed video guides, to ensure your operators can use the machine to its full potential.

Q: How do I request a quote or more information?

A: It's simple. Visit our Contact Us page on our website or simply email us directly at [insert email]. Our sales team will respond promptly with the information you need.

Q: What is the warranty on your machines?

A: We offer a standard warranty on all our machines, covering manufacturing defects. The specific terms and duration can be discussed with our sales team.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe