Kenya's textile and apparel industry is on a remarkable growth trajectory. With a strong foundation in cotton production and a strategic position for international trade, Kenyan manufacturers are supplying the world with high-quality garments. At the core of this success lies advanced technology, and the flat knitting machine is arguably the most critical piece of equipment for producing sweaters, cardigans, hats, and collars.

If you're searching for "knitting machine price in Kenya," you're not just looking for a cost—you're investing in the future of your business. The right machine can skyrocket your production capacity, improve quality, and increase your profitability. This comprehensive guide will not only explore the factors affecting knitting machine prices in Kenya but will also introduce you to a brand that stands for reliability, innovation, and exceptional value: Changhua Knitting Machine.

We will delve into the different types of machines, their applications, and why our solutions at Changhua are the preferred choice for savvy business owners across Africa. By the end of this article, you will be equipped with all the knowledge needed to make an informed investment.

Understanding Knitting Machines: More Than Just a Machine

Before we discuss prices, it's crucial to understand what you're buying. A knitting machine is a long-term partner for your business.

What is a Flat Knitting Machine?

Unlike circular knitting machines that produce tubular fabric, flat knitting machines create flat panels of fabric. These panels are then stitched together to form the final garment. This method is ideal for complex designs, intricate patterns, and full-fashion garments.

Key Types of Knitting Machines for Kenyan Manufacturers

Single System Knitting Machines: These machines have one carriage. They are excellent for basic knit structures and are often more affordable, making them a great starting point for small businesses or for specific, less complex tasks.

Double System Knitting Machines: Featuring two carriages, these machines are significantly faster and more efficient. They can produce complex patterns, transfer stitches with ease, and are the workhorses for medium to large-scale production of items like sweaters, hats, and collars.

Which one is right for you? The choice depends on your production volume, the complexity of your designs, and your budget. A double system machine often provides a better return on investment due to its superior speed and versatility.

Factors Influencing Knitting Machine Price in Kenya

The price of a knitting machine in Kenya isn't a single number. It's influenced by a combination of factors:

Machine Type (Single vs. Double System): As mentioned, double system machines command a higher price due to their advanced mechanics and productivity.

Working Width: Machines come in different widths (e.g., 52-inch, 68-inch). A wider machine can produce larger panels or multiple smaller pieces simultaneously, increasing output.

Gauge (Needles per Inch): The gauge determines the fineness of the knit. A higher gauge (more needles per inch) produces finer, lighter fabrics suitable for fashion items, while a lower gauge is for chunkier sweaters. Higher gauge machines are typically more expensive.

Automation and Features: Machines with electronic controls, automatic stitch transfer, and pattern software will be priced higher than purely mechanical models.

Brand and Origin: Established brands with a proven track record of reliability and good after-sales service, like Changhua, offer tremendous value that justifies their price point.

Shipping, Customs, and Installation: For imported machines, these costs are a significant part of the total investment.

So, what is the actual price range? While prices can fluctuate, understanding these factors helps you see why one machine might be priced at Ksh 400,000 and another at Ksh 1,200,000. It's not about finding the cheapest machine; it's about finding the best value for your specific needs.

Why Choose Changhua Knitting Machines for Your Kenyan Business?

In a market with various options, Changhua has emerged as a leader. But why are so many Kenyan manufacturers turning to us?

Our commitment goes beyond just selling a machine. We provide end-to-end solutions that ensure your business grows.

Unbeatable Value Proposition

We engineer our machines to offer the perfect balance of performance, durability, and affordability. You get industrial-grade quality without the exorbitant price tag, ensuring a faster return on your investment.

Robust and Reliable for Demanding Environments

Our machines are built to last. We understand the demands of a busy production floor. With heavy-duty frames and high-quality components, a Changhua machine is designed for continuous operation, minimizing downtime and maximizing your output.

User-Friendly Operation and Training

Ease of use is a priority. Our machines feature intuitive controls that reduce the learning curve for your operators. Furthermore, we provide comprehensive training resources and support to get your team up and running quickly.

Localized Spare Parts and Technical Support

We have established a robust network for spare parts and technical support in Kenya. You won't be left waiting for weeks for a critical component. Our local partners ensure that help is always within reach, keeping your production on schedule.

Versatility for a Diverse Product Range

Whether you're knitting classic sweaters, fashionable collars for shirts, or trendy beanies, our range of machines is designed to handle it all with precision and efficiency.

Doesn't that sound like the kind of partnership your business needs? Let's look at some of our best-selling models that are changing the game for manufacturers in Kenya.

Spotlight on Top Changhua Knitting Machine Models

Here’s a closer look at some of our most popular machines, perfect for various applications in the Kenyan market.

1. The All-Rounder: 52-Inch Single System Sweater Flat Knitting Machine

Ideal for: Small to medium workshops starting in sweater production or businesses needing a reliable machine for specific, less complex panels.

This machine is the cornerstone of many successful businesses. Its 52-inch width is ideal for producing sweater fronts, backs, and sleeves efficiently.

Key Features:

Versatile Production: Perfect for a wide range of plain and basic patterned sweaters.

Cost-Effective Entry Point: Provides an accessible way to automate and scale your knitting operations.

Durable Construction: Built with a rigid frame for stable, long-lasting performance.

Easy Maintenance: Simple mechanical design makes it easy to service and maintain locally.

This model is perfect if you are building your brand around quality, classic knitwear. Want to see the detailed specifications and how it can fit into your workshop

Discover more about the 52-Inch Single System Sweater Machine on our product page: https://www.changhua-knitting-machine.com/52-inch-single-system-sweater-flat-knitting-machine.html

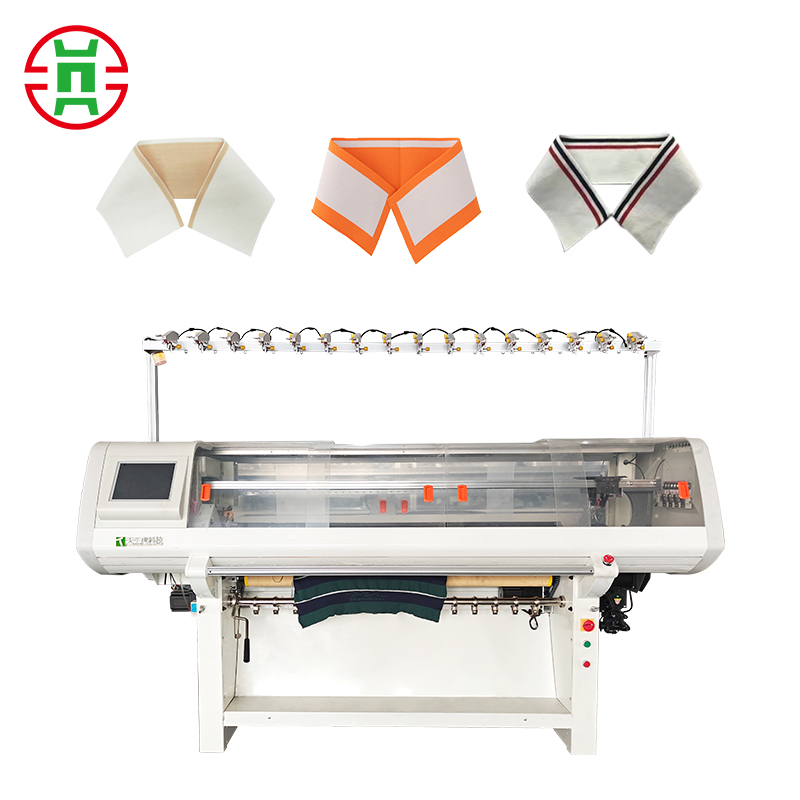

2. The Productivity Powerhouse: 68-Inch Double System Collar Knitting Machine

Ideal for: Manufacturers supplying collars to the shirt industry or those producing high volumes of tubular edgings and trims.

Collar production requires speed and precision. Our 68-inch double system machine is a specialist designed exactly for that. The extra-wide bed allows for multiple collars to be knitted side-by-side in a single pass, dramatically increasing output.

Key Features:

High-Speed Production: Double system carriage enables fast, efficient knitting cycles.

Wide Application: Excellent for shirt collars, cuffs, and other tubular structures.

Superior Stitch Quality: Ensures consistent, high-quality finishes that meet international standards.

Automated Efficiency: Reduces labor costs per unit and boosts overall factory throughput.

If your business relies on supplying perfect collars at scale, this machine is a game-changer. Ready to multiply your collar production capacity?

Learn all about the high-speed 68-Inch Double System Collar Machine here: https://www.changhua-knitting-machine.com/68-inch-double-system-collar-knitting-machine.html

3. The Specialist: 52-Inch Double System Hat Knitting Machine

Ideal for: Businesses focused on the fast-moving fashion market of beanies, caps, and other knitted headwear.

The demand for fashionable hats is constant. This specialist machine is engineered to meet that demand head-on. It combines the speed of a double system with the ideal width for hat production, allowing for the creation of complete hat panels or multiple segments with incredible efficiency.

Key Features:

Specialized for Hats: Optimized settings and capabilities for various hat designs and patterns.

Double System Speed: Cuts production time significantly compared to single system machines.

Excellent Pattern Capability: Can produce jacquards, ribs, and other popular hat textures.

Compact Powerhouse: Delivers high output without requiring a massive footprint in your factory.

Capitalize on the evergreen hat market with a machine built for speed and quality. Imagine being able to fulfill large orders for retailers and distributors with ease.

Explore the features of the 52-Inch Double System Hat Machine on our website: https://www.changhua-knitting-machine.com/52-inch-double-system-hat-knitting-machine.html

Beyond the Machine: The Changhua Advantage in Kenya

Purchasing a machine is just the beginning. The real value of partnering with Changhua is the ongoing support.

Comprehensive After-Sales Service

We offer installation, commissioning, and training right at your facility in Kenya. Our technicians ensure your machine is perfectly set up and your operators are confident in using it.

Easy Access to Genuine Spare Parts

Worn-out parts are a fact of life in manufacturing. Our efficient supply chain for genuine spare parts means you won't face prolonged downtime. We help you identify the right parts and get them to you promptly.

Technical Support Just a Call Away

Got a technical question or an urgent issue? Our support team, in coordination with our local partners, is available to provide remote assistance and guide you to a solution.

Making the Right Investment: A Step-by-Step Guide

Assess Your Needs: What will you produce? Sweaters? Hats? Collars? What is your target volume?

Define Your Budget: Consider the total cost of ownership, including shipping, installation, and initial maintenance.

Research and Compare: Look beyond the price. Compare specifications, brand reputation, and after-sales service.

Request a Quote and Consult: Contact us with your requirements. We provide transparent pricing and expert consultation to match you with the perfect machine.

Plan for Installation and Training: Ensure you have the space and personnel ready for the new equipment.

Feeling overwhelmed? We are here to make this process smooth for you. Our experts can guide you through every single step.

Frequently Asked Questions (FAQs) About Knitting Machines in Kenya

What is the typical delivery time for a Changhua machine to Kenya?

Delivery times vary based on the model and stock availability, but we strive to ensure timely delivery through our reliable logistics partners. Typically, it ranges from 6 to 8 weeks, including customs clearance.

Do you provide a warranty?

Yes. All our Changhua knitting machines come with a standard warranty, covering manufacturing defects. We stand firmly behind the quality of our products.

Can I get financing for the machine?

While we do not provide direct financing, we can assist with documentation and information to help you secure financing from your local bank or financial institution in Kenya.

How do I know which gauge is right for me?

This depends on the yarn you use and the final product. A lower gauge (3.5G, 5G) is for chunky yarns, while a higher gauge (7G, 12G) is for finer yarns. Our sales team can advise you based on your sample or product description.

Conclusion: Empower Your Garment Business with Changhua

The "knitting machine price in Kenya" is an important question, but the more critical question is: "Which machine will give my business the best chance to thrive and profit?"

Investing in a Changhua Knitting Machine is not just a purchase; it's a strategic decision to elevate your production capabilities. With our robust machinery, reliable support, and deep understanding of the Kenyan market, we are more than a supplier—we are your partner in growth.

Don't let outdated equipment or inefficient processes limit your potential. The Kenyan textile industry is booming, and the opportunity is now.

Ready to take the next step and get a precise quotation for your needs?

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe