The textile industry has evolved significantly with the introduction of automatic sweater knitting machines. These machines offer high efficiency, precision, and cost-effectiveness, making them essential for fashion manufacturers, small businesses, and large-scale textile producers.

If you're searching for "Automatic Sweater Knitting Machine Price", you likely want to understand the cost, features, and best brands available. This guide will cover everything you need to know before making a purchase.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

Types of Automatic Sweater Knitting Machines

Fully Automatic Sweater Knitting Machines

These machines require minimal human intervention and can produce high-quality sweaters in bulk. They are ideal for large factories looking for maximum output with low labor costs.

Features

Computerized pattern design

High-speed production

Multi-gauge compatibility (3G, 5G, 7G, 12G)

Semi-Automatic Sweater Knitting Machines

A cost-effective option for small to medium businesses. These machines need some manual input but still offer good efficiency.

Features

Manual yarn feeding

Adjustable stitch density

Moderate production speed

What Are Automatic Sweater Knitting Machines?

Automatic sweater knitting machines are advanced textile manufacturing devices designed to produce knitted fabrics and garments, such as sweaters, scarves, hats, and more, with minimal human intervention. Unlike manual or semi-automatic machines, these fully automated systems leverage digital technology and computer controls to execute complex knitting patterns, ensuring consistency, speed, and high-quality output. These machines are typically flat knitting machines, producing flat fabric panels that can be sewn together to create finished garments.

The Mechanics Behind Automatic Knitting Machines

At their core, automatic sweater knitting machines operate using a flatbed needle system, where needles are arranged in a straight line or slight arc. The machine's carriage moves back and forth, feeding yarn to the needles to create stitches. Modern machines incorporate:

Computerized Control Systems

These allow precise control over stitch types, patterns, and fabric designs, storing multiple patterns for quick recall.

Digital Technology

Features like jacquard, intarsia, tuck, and eyelet stitches enable the creation of intricate designs.

High-Performance Sinkers and Rollers

These components ensure smooth operation, reduce wear, and enhance the machine’s lifespan.

Motor-Controlled Carriages

These automate stitch transfers and pattern execution, boosting efficiency.

Factors Influencing Automatic Sweater Knitting Machine Prices

The price of an automatic sweater knitting machine varies based on several factors. Understanding these can help you make an informed purchasing decision:

1. Machine Type and Features

Single System vs. Double System: Single-system machines, like Changhua's CHJX-1-52, are more affordable but offer fewer features. Double-system machines, with advanced capabilities like dynamic stitch control, are pricier but more versatile.

Gauge Size: Machines with finer gauges (e.g., 14G or 16G) for delicate fabrics cost more than those with coarser gauges (e.g., 7G or 9G) for thicker knits.

Automation Level: Fully computerized machines with digital pattern storage and automatic stitch transfer are more expensive than semi-automatic models.

2. Brand and Manufacturer

Reputable brands like Changhua, Shima Seiki, and Stoll command higher prices due to their reliability, advanced technology, and after-sales support. Lesser-known brands may offer lower prices but compromise on quality or service..

3. Production Capacity

High-capacity machines designed for industrial use, capable of producing thousands of garments monthly, are more expensive than those intended for small-scale or home use.

4. Additional Accessories

Accessories like ribber beds, lace carriages, or software for pattern design (e.g., Shima Seiki's KnitManager) increase the overall cost.

5. Market and Region

Prices vary by region due to shipping costs, taxes, and local demand. Machines manufactured in China, like those from Changhua, are often more cost-competitive than European or Japanese brands.

Why Choose Changhua's Automatic Sweater Knitting Machines?

When it comes to reliable, high-performance knitting machines, Changhua stands out as a leader in the industry. With over 20 years of experience, Changhua, based in Changshu, Jiangsu, China, has established itself as a top manufacturer of computerized flat knitting machines. Here's why Changhua's machines are a smart investment for businesses and designers:

Changhua's Commitment to Quality and Innovation

Changhua's machines are built with state-of-the-art technology, ensuring high knitting efficiency, low defect rates, and long-lasting durability. Our TIANGONG, TWH, CH, and MSGJ brands are synonymous with quality, offering solutions tailored to various industries, from fashion to automotive.

Key Features of Changhua's Machines

Advanced Computerized Systems

Changhua's machines, like the CHJX-1-52 Single System and Double System models, feature digital controls for precise pattern execution, including jacquard, intarsia, and ribbing.

Versatility

Suitable for knitting sweaters, scarves, hats, blankets, and shoe uppers using materials like wool, cashmere, cotton, and synthetic fibers.

High Efficiency

Double-system machines with high rollers and dynamic sinkers ensure fast production with minimal waste, ideal for mass customization.

Durability

Automatic oiling systems reduce wear on needle beds, extending machine life.

Comprehensive Support

Changhua offers 24/7 technical support, extensive training, and long-term parts supply, ensuring smooth operation.

Changhua Models to Consider

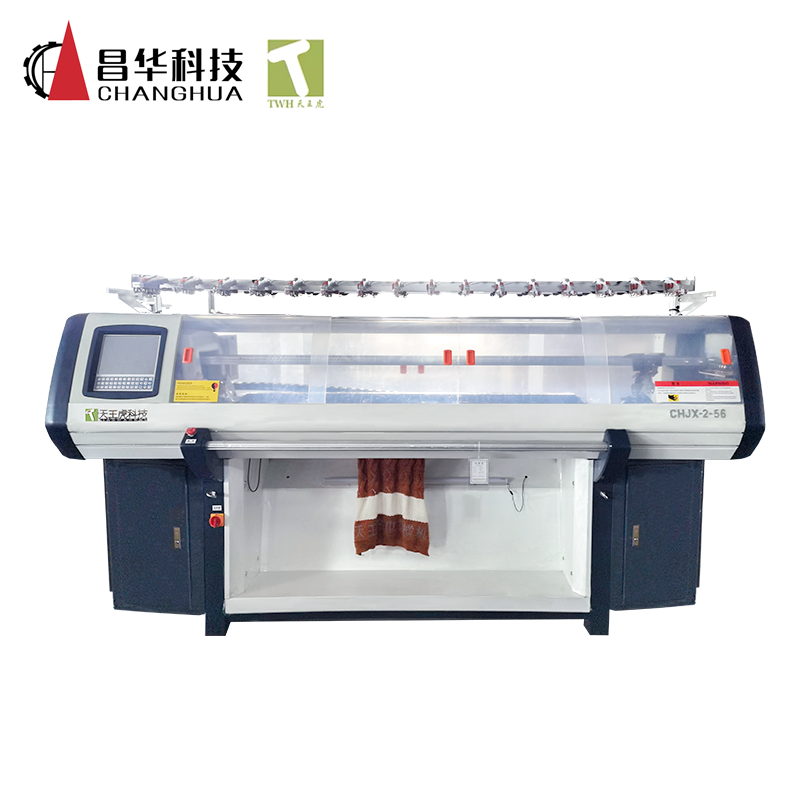

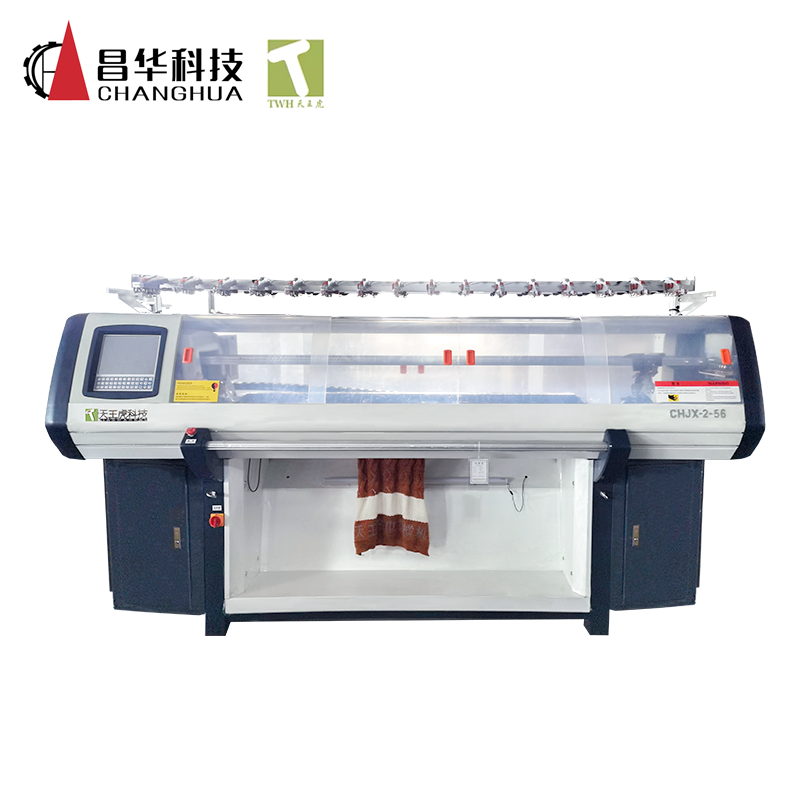

CHJX-1-52 Single System Sweater Knitting Machine

Features: Ideal for small to medium-scale production, supports basic and complex stitches like jacquard and ribbing.

Applications: Sweaters, scarves, hats, and accessories.

CHJX-2-52 Double System Sweater Knitting Machine

Features: High-speed, dynamic stitch control, and fully formed rollers for seamless garment production.

Applications: High-volume production of sweaters, blankets

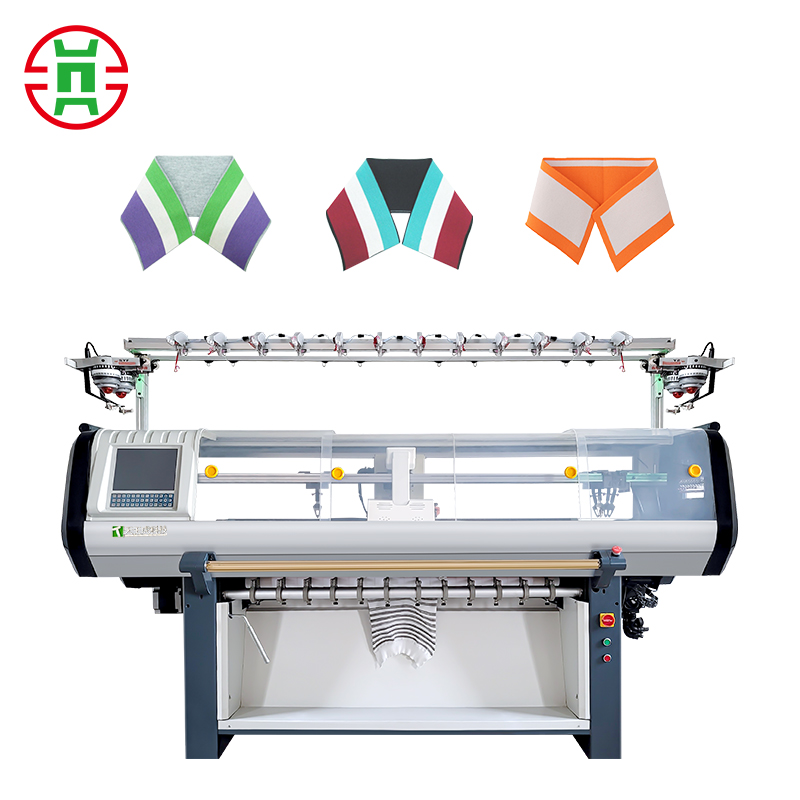

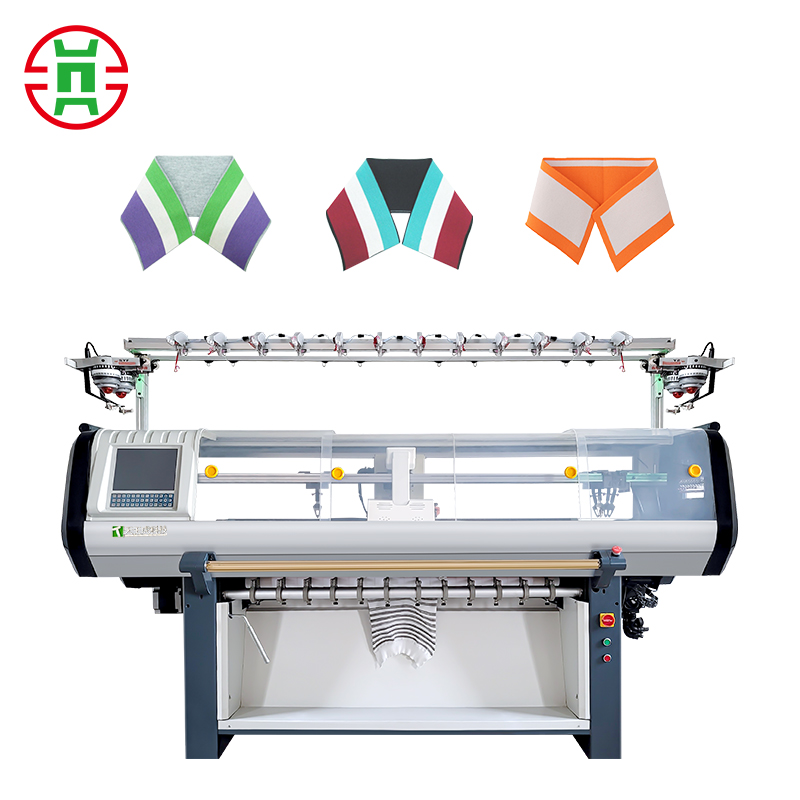

Collar Knitting Machine

Features: Specialized for producing crisp, professional collars for polo shirts and sweaters.

Applications: Ideal for garment manufacturers focusing on detailed finishing.

Why Changhua Stands Out

Cost-Effective Solutions

Compared to brands like Shima Seiki, Changhua offers competitive pricing without compromising quality.

Global Reach

With service bases worldwide and an average delivery time of 15–30 days, Changhua ensures accessibility and reliability.

Sustainability

Changhua's machines support eco-friendly production by minimizing waste and optimizing energy use, aligning with modern sustainability trends.

Benefits of Investing in Automatic Sweater Knitting Machines

1. Increased Productivity

Automatic knitting machines are up to 20 times faster than hand knitting, making them ideal for scaling production. For example, a sweater that takes days to hand-knit can be completed in hours.

2. Consistent Quality

Computerized controls ensure uniform stitches and patterns, reducing defects and ensuring every piece meets high standards.

3. Creative Flexibility

With features like multi-color jacquard and intarsia, designers can experiment with complex patterns and textures, pushing creative boundaries.

4. Cost Savings

While the initial investment is significant, the long-term savings from reduced labor costs and faster production cycles make these machines cost-effective.

5. Sustainability

Modern machines, like those from Changhua, support mass customization and seamless knitting, reducing fabric waste and aligning with eco-conscious manufacturing practices.

Choosing the Right Automatic Sweater Knitting Machine

For Small Businesses and Startups

If you're a small business or designer, consider Changhua's CHJX-1-52 Single System machine. Its affordability and versatility make it perfect for producing custom sweaters and accessories in smaller quantities. The machine's intuitive controls and compact design are ideal for limited workspace.

For Large-Scale Manufacturers

For high-volume production, the CHJX-2-60 Double System is a top choice. Its high-speed capabilities and advanced features support mass production of complex garments, making it suitable for large factories.

For Specialized Applications

If your focus is on accessories like collars or shoe uppers, Changhua's Collar Knitting Machine or Shoe Upper Knitting Machine offers specialized solutions with precision and efficiency.

Tips for Buyers

Assess Your Needs: Determine your production volume, yarn types, and desired patterns before choosing a model.

Consider After-Sales Support: Opt for brands like Changhua that offer training, technical support, and spare parts.

Check Compatibility: Ensure the machine supports the yarn types and gauges you plan to use.

Budget Wisely: Balance initial costs with long-term benefits like durability and efficiency.

Conclusion

Automatic sweater knitting machines are transforming the textile industry, offering unmatched speed, precision, and versatility. Whether you’re a designer, small business owner, or large-scale manufacturer, these machines empower you to create high-quality knitwear efficiently. Changhua, with its 20+ years of expertise, stands out as a trusted partner, offering innovative, cost-effective, and sustainable knitting solutions. From our CHJX-1-52 Single System to the advanced CHJX-2-60 Double System, Changhua's machines cater to diverse needs, ensuring you stay ahead in the competitive textile market.

Ready to elevate your knitwear production? Visit https://www.changhua-knitting-machine.com/ to explore Changhua's range, request a quote, or download  our product catalog.pdf. With Changhua, you're not just investing in a machine—you're investing in quality, innovation, and a sustainable future.

our product catalog.pdf. With Changhua, you're not just investing in a machine—you're investing in quality, innovation, and a sustainable future.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe