The textile industry is undergoing a transformative phase, driven by technological advancements, automation, and the increasing demand for high-quality, sustainable, and customized fabrics. For businesses looking to invest in knitting machines in 2024, understanding equipment cost-effectiveness is critical, especially when sourcing from manufacturers with an annual output exceeding 6,000 units. This comprehensive guide explores the key considerations for selecting knitting machines, their applications, and how to evaluate cost-effectiveness, with a special focus on high-output manufacturers like Changhua Knitting Machine.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

Understanding Knitting Machines: Types and Applications

Knitting machines are the backbone of modern textile production, enabling manufacturers to produce a wide range of fabrics efficiently. These machines are categorized into several types, each suited for specific applications:

Flat Knitting Machines

Flat knitting machines are versatile, producing two-dimensional fabrics ideal for garments like sweaters, scarves, and collars. They excel in creating complex patterns and 3D structures, making them a favorite in fashion, sportswear, and technical textiles. Their ability to adapt to shorter production cycles and customization needs aligns with the fast-fashion trend.

Circular Knitting Machines

Circular knitting machines produce tubular fabrics, commonly used for seamless garments, hosiery, and sportswear. Their high-speed operation and automation capabilities make them ideal for large-scale production. In 2024, the global circular knitting machine market is projected to reach USD 7.8 billion by 2030, driven by demand in apparel industries.

Weft Knitting Machines

Weft knitting machines dominate the apparel sector, with seamless knitting technology reducing waste and labor costs. In 2023, the weft knitting segment generated over USD 3.4 billion in revenue.

Applications Across Industries

Knitting machines serve diverse industries:

Apparel Textiles: Sweaters, t-shirts, and custom knitwear dominate this segment, with fully automatic machines holding a 72% market share in 2023.

Sports Textiles: High-performance fabrics for activewear benefit from moisture-wicking and stretchable synthetic fibers, driving demand for advanced machines.

Technical Textiles: Used in automotive, medical, and industrial applications, these require precision and durability, often achieved through warp knitting.

Home Textiles: Blankets, upholstery, and curtains are produced efficiently with large-scale knitting machines, particularly in Asia-Pacific markets.

Key Factors in Evaluating Cost-Effectiveness

When purchasing a knitting machine, cost-effectiveness is not just about the initial price but also long-term value. Here are the critical factors to consider:

Production Capacity and Efficiency

High-output manufacturers (those producing over 6,000 units annually) often leverage economies of scale, offering machines that balance cost and performance. Large-scale machines dominate the market, accounting for 60.7% of the 3D knitting segment in 2024, due to their ability to meet high-volume demands efficiently.

Automation and Technology

Fully automatic machines, which held a 72% market share in 2023, reduce labor costs and enhance precision. AI-driven features, such as real-time yarn tension adjustment and defect detection, further improve efficiency. For instance, Monarch Knitting Machinery introduced AI-connected models in 2024, showcasing the trend toward smart automation.

Sustainability

Sustainability is a growing priority, with consumers demanding eco-friendly textiles. Machines that minimize material waste, like seamless and 3D knitting technologies, align with this trend. Energy-efficient models also reduce operational costs, making them a cost-effective choice in the long run.

Durability and Maintenance

High-quality machines from reputable manufacturers require less frequent maintenance, reducing downtime. Partnerships like TotalEnergies and Mayer & Cie’s Tixo Stainless knitting machine oil range enhance machine durability, ensuring long-term cost savings.

Customization Capabilities

The demand for personalized designs is rising, particularly in fast fashion and sportswear. Machines with digital controls and flexible programming allow manufacturers to produce unique patterns without significant retooling costs.

Why Choose High-Output Manufacturers?

Manufacturers producing over 6,000 units annually, such as those in China, benefit from robust supply chains and advanced production capabilities. China alone holds a 70% share of the global knitting machine market, driven by its ability to mass-produce high-quality machines at competitive prices. These manufacturers often invest in R&D, ensuring their machines incorporate the latest technologies, such as AI and seamless knitting.

Advantages of High-Output Manufacturers

Economies of Scale: Lower per-unit costs due to large production volumes.

Technological Innovation: Access to cutting-edge features like computerized controls and IoT integration.

Reliable Supply Chains: Established infrastructure ensures timely delivery and support.

Global Reach: Machines are exported to over 40 countries, indicating proven reliability.

Spotlight on Changhua Knitting Machine

For businesses seeking cost-effective, high-quality knitting machines, Changhua Knitting Machine stands out as a leading manufacturer with over 20 years of experience. Based in China, Changhua specializes in computerized flat knitting machines, offering solutions tailored to modern textile demands. Visit our official website for more details.

Why Choose Changhua?

Changhua's machines are designed for efficiency, precision, and versatility, making them ideal for startups and established manufacturers alike. Here's why Changhua is a top choice in 2024:

Advanced Technology

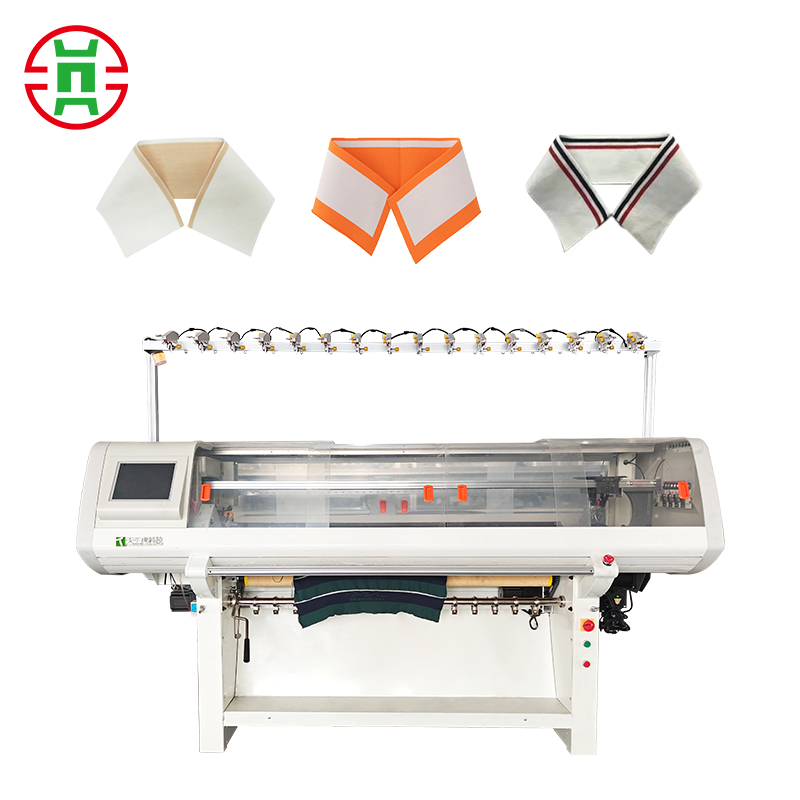

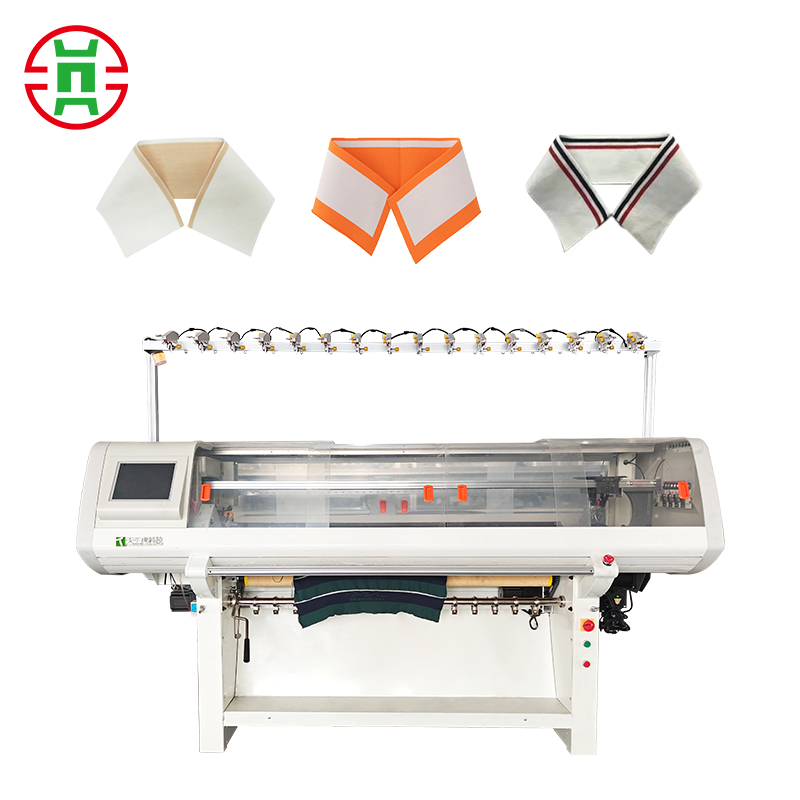

Changhua's computerized flat knitting machines, such as our Collar Knitting Machine, incorporate digital controls for precise fabric production. These machines support complex patterns, making them perfect for high-quality collars, sweaters, and technical textiles. Our seamless knitting capabilities reduce waste, aligning with sustainability goals.

Cost-Effectiveness

By leveraging China's manufacturing strengths, Changhua offers competitive pricing without compromising quality. Our machines are built for high output, ensuring businesses can meet large-scale demands while keeping operational costs low.

Customization and Flexibility

Changhua's machines cater to the growing demand for customized designs. With advanced programming interfaces, manufacturers can easily switch between fabric types and patterns, meeting diverse market needs.

Durability and Support

Changhua's machines are engineered for longevity, with robust construction and low maintenance requirements. Our comprehensive after-sales service, including installation and training, ensures smooth integration into your production line.

Global Reputation

With exports to over 40 countries, Changhua has earned a reputation for reliability and innovation. Our machines meet international standards, including CE, ISO9001, and ISO14001 certifications, ensuring compliance and quality.

Recommended Models from Changhua

Whole Garment Flat Knitting Machine (72 Inch, 13.2G)

Produces seamless garments, reducing waste and labor costs. Perfect for fashion, sportswear, and medical textiles.

Produces seamless garments, reducing waste and labor costs. Perfect for fashion, sportswear, and medical textiles.

Collar Knitting Machine (1+1 System Double Carriage)

Specializes in collars and ribs, with dual-head options for doubled productivity.

Specializes in collars and ribs, with dual-head options for doubled productivity.

Shoe Upper Knitting Machine

Designed for 3D shoe uppers, offering high efficiency and material versatility for breathable, durable designs.

Designed for 3D shoe uppers, offering high efficiency and material versatility for breathable, durable designs.

Comparing Changhua to Competitors

Changhua's machines stand out for their balance of innovation and affordability. Here's how they compare:

Shima Seiki (Japan)

Shima Seiki's WholeGarment machines are advanced but expensive. Changhua offers similar seamless knitting capabilities at a lower cost, ideal for budget-conscious buyers.

Mayer & Cie (Germany)

Mayer & Cie excels in circular knitting, but Changhua's flat knitting machines provide greater versatility for complex patterns and apparel production.

Santoni (Italy)

Santoni's seamless circular machines are high-quality, but Changhua's flat knitting machines match their sustainability benefits at a more competitive price.

How to Choose the Right Knitting Machine

Selecting the right knitting machine involves aligning your business needs with the machine’s capabilities. Here's a step-by-step guide:

Assess Your Production Needs

Determine your target output, fabric types, and application areas. For high-volume apparel production, fully automatic flat or circular knitting machines are ideal. For technical textiles, consider warp knitting machines.

Evaluate Budget and ROI

Consider both upfront costs and long-term savings. Machines from high-output manufacturers like Changhua offer competitive pricing and low maintenance, ensuring a faster return on investment.

Prioritize Automation

Fully automatic machines with AI and IoT capabilities reduce labor costs and improve quality control. Changhua’s computerized models are a great example of this trend.

Check Certifications and Support

Ensure the manufacturer provides certifications (e.g., CE, ISO) and robust after-sales support. Changhua’s global certifications and service network make them a reliable choice.

Test and Compare

Changhua offers detailed product demonstrations on our website, showcasing real-world performance.

Market Trends Shaping Knitting Machine Purchases in 2024

The knitting machine market is evolving rapidly, with several trends influencing purchasing decisions:

Automation and AI Integration

AI-driven machines, like those introduced by Monarch Knitting Machinery, enhance precision and reduce waste. Changhua's models incorporate similar technologies at a lower cost.

Sustainability

The push for eco-friendly textiles is driving demand for seamless and 3D knitting machines. Changhua's seamless models align with this trend, minimizing material waste.

Growth in Asia-Pacific

Asia-Pacific holds a 41% share of the global knitting machine market, led by China’s manufacturing prowess. Partnering with a Chinese manufacturer like Changhua ensures access to cost-effective, high-quality machines.

Demand for Customization

Consumers' preference for unique designs is fueling demand for flexible machines. Changhua's digital controls make it easy to produce custom patterns efficiently.

Conclusion

Investing in a knitting machine in 2024 requires a careful balance of cost, technology, and production needs. High-output manufacturers like Changhua Knitting Machine offer cost-effective, innovative solutions that cater to diverse industries, from apparel to technical textiles. With over 20 years of experience, Changhua's computerized flat knitting machines provide unmatched precision, sustainability, and flexibility at competitive prices. By choosing Changhua, businesses can stay ahead in the rapidly evolving textile market, meeting consumer demands for quality and customization while maximizing ROI.

For more information or to request a quote, visit Changhua website and  explore our range of cutting-edge knitting machines.pdf.

explore our range of cutting-edge knitting machines.pdf.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe