Colorful sweaters have become a mainstay in modern fashion, loved for their vibrancy, personality, and versatility. From high-end fashion houses to everyday streetwear, multicolor knits are used to express bold design aesthetics and individual style. But behind every colorful sweater lies a highly specialized piece of equipment: the knitting machine.

Not all knitting machines are created equal. When it comes to combining multiple colors in one garment—especially with precision, consistency, and speed—the type of knitting machine you choose makes a world of difference. For designers, manufacturers, and entrepreneurs looking to create high-quality, colorful sweaters, understanding which machines are best suited for this task is essential.

In this article, we'll dive into the specific types of machines used for making colorful sweaters, explore their key features, and explain how they're applied in different industries. Along the way, we'll introduce you to Changhua's advanced sweater flat knitting machines, which are especially optimized for producing intricate, vibrant patterns. Whether you're a fashion brand, an apparel manufacturer, or a boutique workshop, this guide is designed to help you make the right choice.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

What Machines Are Used to Make Colorful Sweaters?

Flat Knitting Machines

Flat knitting machines are the gold standard for producing colorful sweaters. Unlike circular knitting machines that are optimized for seamless tubes and basic fabric structures, flat knitting machines are highly programmable and offer unmatched control over each stitch. This makes them ideal for creating detailed patterns and using multiple yarn colors in a single garment.

Key features of flat knitting machines include

Independent Needle Selection

Enables specific needles to pick up different yarns, crucial for multicolor intarsia and fair isle designs.

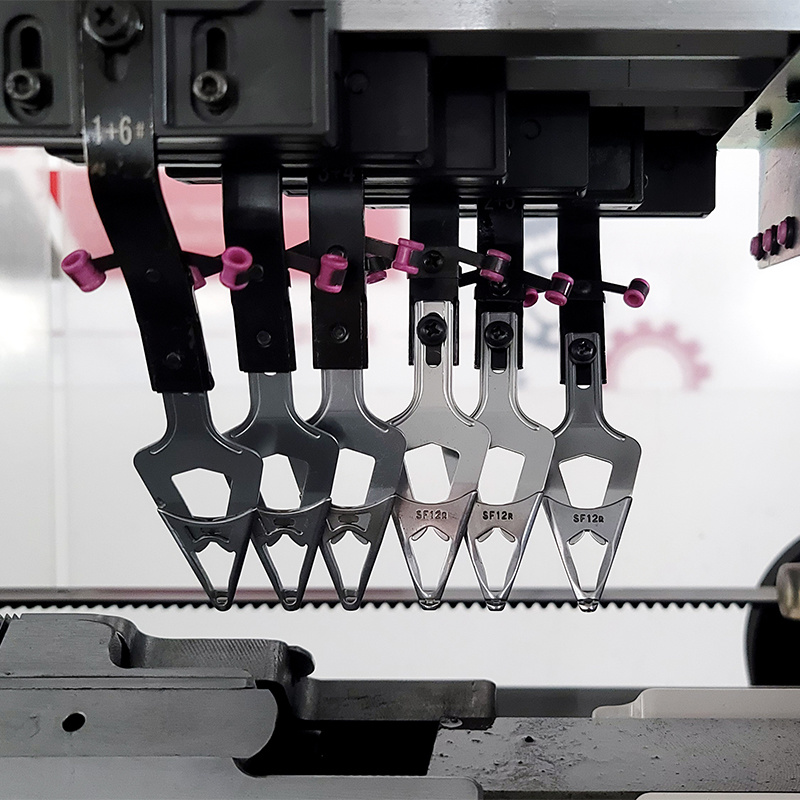

Multiple Yarn Feeders

Support for several yarns being fed into the machine simultaneously, allowing for intricate pattern work.

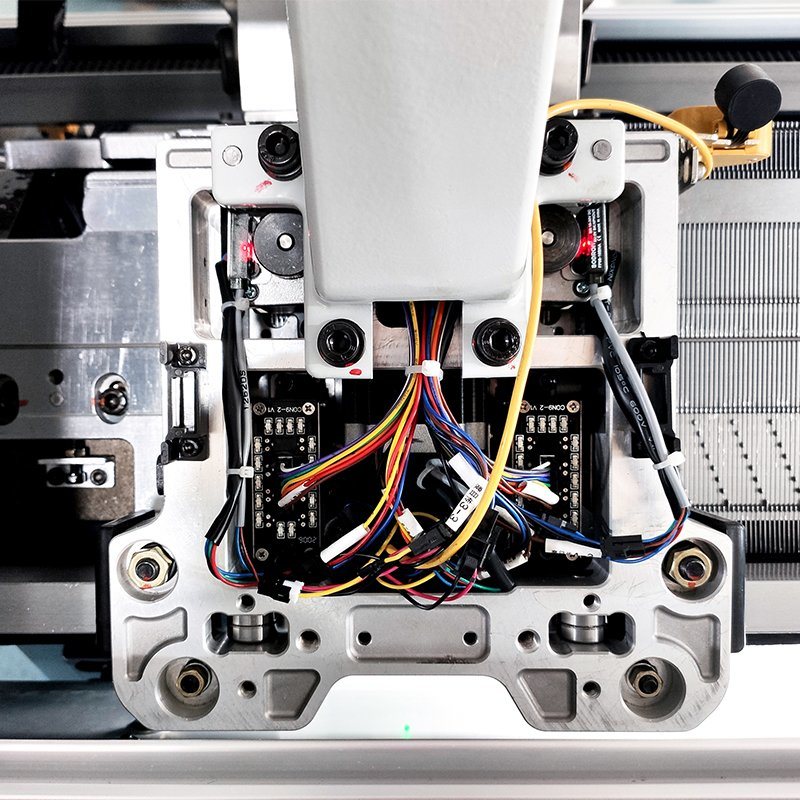

Digital Control Systems

Modern flat knitting machines are equipped with computerized programming systems that allow designers to upload pattern files directly to the machine.

Intarsia Capabilities

Perfect for color-blocking, logos, and non-repeating graphic elements.

Flat knitting machines can range from simple semi-automatic models used in small workshops to high-speed industrial systems that are capable of producing thousands of garments monthly. They are ideal for use cases where design flexibility and color diversity are critical.

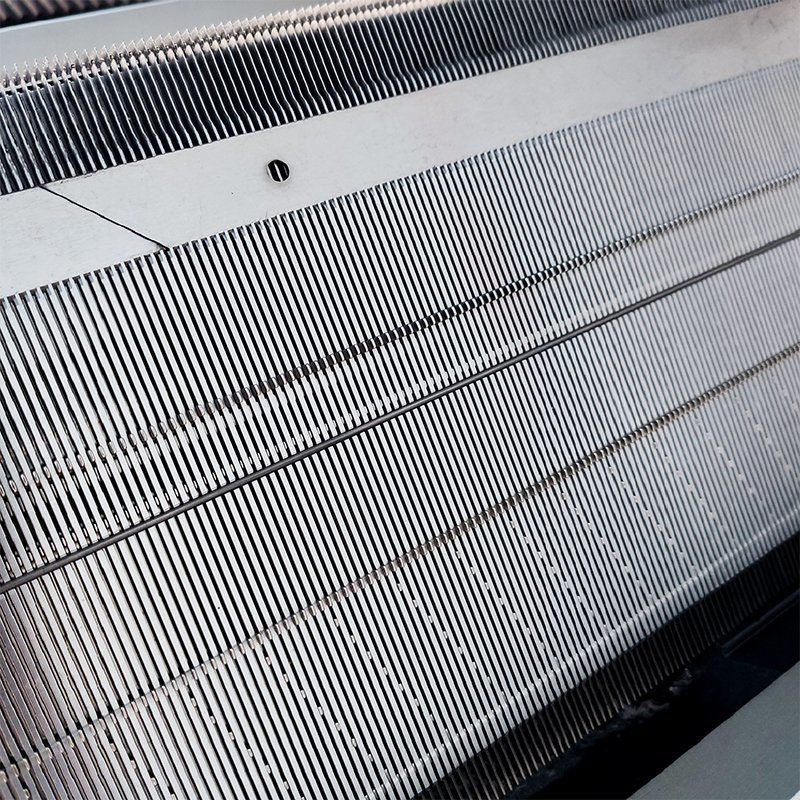

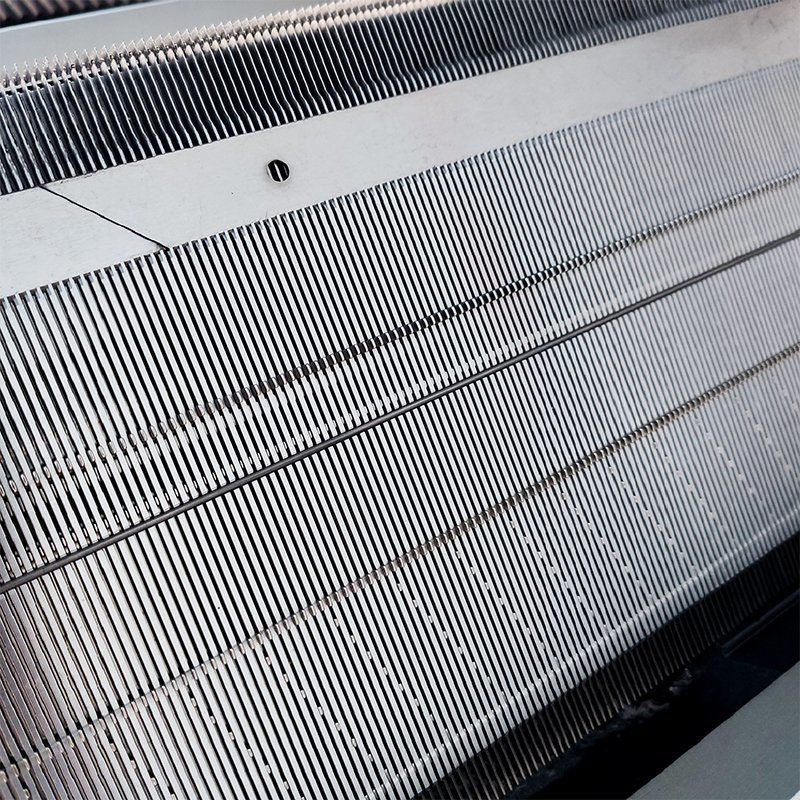

Needlebed

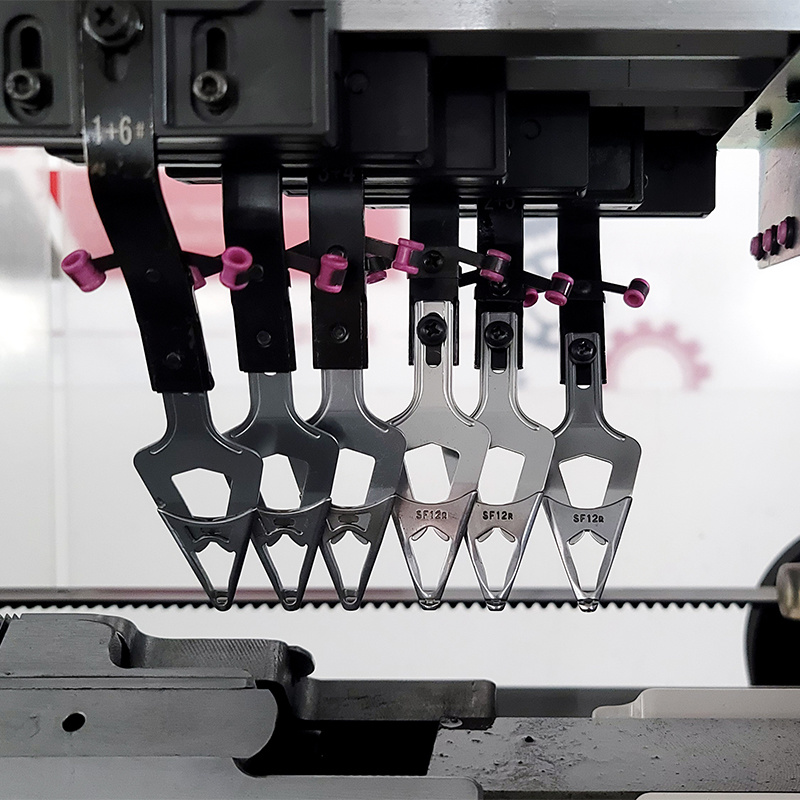

Yarn feeders

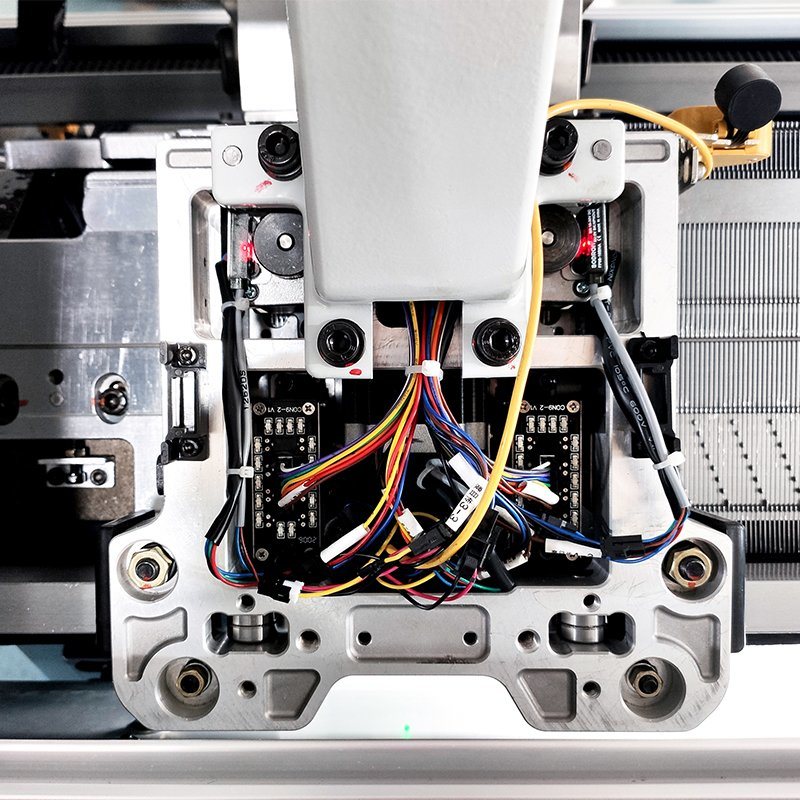

Digital Control System

Key Technologies for Knitting Colorful Sweaters

Creating a colorful sweater is more than just combining yarns — it requires a precise harmony of machinery, software, and engineering. Let’s explore the core technologies that enable complex multicolor knitting:

Yarn Feeding Systems

Modern flat knitting machines come equipped with multiple yarn feeders, allowing different colored yarns to be fed into the knitting area without manual intervention. This setup is essential for real-time color switching and high-efficiency production.

Advanced machines use automatic yarn changers that:

Instantly switch between different colors mid-pattern

Minimize yarn tangling or tension issues

Increase knitting speed by reducing manual handling

Computerized Pattern Control

One of the greatest advancements in sweater manufacturing is the integration of computerized pattern design and machine control.

CAD (Computer-Aided Design) Systems: Allow designers to draft intricate colorwork and test them digitally

Stitch Simulation: Simulates the outcome before actual production, saving yarn and time

USB/Network Uploads: Seamless transfer of designs to the machine for instant programming

Intarsia and Fair Isle Techniques

Though technically different, Intarsia and Fair Isle are both common methods for introducing multiple colors:

Intarsia Knitting: Allows for large blocks of color that do not carry across the back, useful for graphic motifs or color blocks

Fair Isle Knitting: Uses repeated motifs and small color areas, with strands carried across the back

Application Fields of Colorful Sweaters

Fashion & Designer Brands

From seasonal collections to signature styles, fashion designers use colorful patterns to stand out. Flat knitting machines enable them to:

• Produce unique patterns per season

• Integrate logos, gradients, or abstract designs

• Control texture and color simultaneously

Streetwear & Lifestyle Apparel

Streetwear thrives on bold, graphic, high-contrast designs, which are perfect for multicolor knitting. Urban brands often use flat knitting machines for:

• Limited-edition drop collections

• Logo-heavy or typography-based sweaters

• Custom color schemes per region or release

Athleisure & Sportswear

Modern activewear blends performance and fashion. Colorful knitted panels can be used to:

• Highlight anatomical or functional zones

• Integrate branding or team colors directly into the garment

• Offer high breathability with visual appeal

Recommended Machinery for Colorful Sweaters: Changhua Flat Knitting Machines

When it comes to manufacturing colorful sweaters, precision and versatility are key. That's why Changhua's computerized flat knitting machines are a smart choice for both established apparel manufacturers and innovative design studios. Engineered to handle complex color patterns, intarsia graphics, and variable yarn configurations, Changhua machines combine performance with user-friendly control.

Why Choose Changhua for Colorful Sweaters?

Changhua's machines are designed with color knitting in mind. Whether you're creating bold logos, gradient motifs, or multi-yarn intarsia patterns, these machines offer:

• High-precision needle selection for stitch-by-stitch color changes

• Multiple yarn carrier support to switch between colors efficiently

• Real-time computer control that allows design updates directly from your PC

• Stable, low-vibration build quality, reducing misalignment and yarn breakage

Product Highlights

CHJX1-52 (Single System Flat Knitting Machine)

This model is ideal for startups, design studios, or small-scale manufacturers who need versatility without high energy consumption.

Key features:

• 52-inch working width – perfect for sweaters, vests, and children’s wear • Single needle bed system – great for lightweight or midweight fabrics

• Supports intarsia and basic Fair Isle designs

• Cost-effective and easy to maintain

• Supports up to 6 color yarn feeders

CHJX2-60 (Double System Flat Knitting Machine)

A more powerful choice, this dual-system machine boosts both speed and pattern complexity — ideal for medium to large batch production.

Key features:

• 60-inch working width – for adult-size garments and full-width patterns

• Double system configuration – enables simultaneous knitting and transferring

• Optimized for multicolor Jacquard and intarsia techniques

• High-speed output with advanced servo motors and dynamic tension control

• Supports up to 8 color yarn feeders with automatic switching

Competitive Advantages for Manufacturers

Buyers who choose Changhua benefit from:

• FOB-based pricing: Transparent cost structure without hidden fees

• Remote software upgrades and ongoing machine optimization

• On-demand spare parts and multilingual customer support

• Flexible production planning: fast model changeover for new collections

By investing in Changhua flat knitting machines, you're not just purchasing equipment — you're partnering with a team that supports your production goals every step of the way.

How to Produce a Colorful Sweater: Step-by-Step

Step 1: Pattern Design & Yarn Selection

• Designers create digital patterns using specialized CAD software (compatible with Changhua's control systems).

• Multiple yarn colors are selected, considering contrast, durability, and fiber compatibility.

• Color sequences are defined in the software to align with the machine's yarn feeders.

Step 2: Machine Programming

• The pattern file is uploaded to the knitting machine via USB or network connection.

• Yarn feeder paths and needle movements are automatically calculated by the control system.

• Machine settings (e.g. gauge, stitch density, tension) are adjusted based on yarn and design.

Step 3: Swatching & Test Knitting

• A test sample is knitted to check for:

• Color alignment and transitions

• Tension consistency

• Pattern accuracy

• Adjustments are made to feeder timing or needle selection if necessary.

Step 4: Full Production Knitting

• Once approved, the machine runs full batches automatically.

• Multi-color feeders alternate precisely during the process, executing complex patterns without manual interference.

• Operators monitor yarn supply and machine speed but rarely intervene.

Step 5: Linking, Washing, and Finishing

• After knitting, sweater panels are linked together (manually or using linking machines).

• Washing and steaming ensure shape retention and remove loose fibers.

• Labels and embellishments are applied during finishing.

Step 6: Quality Control & Packaging

• Each sweater is checked for:

• Color consistency

• Pattern alignment

• Structural integrity (no dropped stitches or uneven seams)

• Approved garments are folded, tagged, and packaged for shipping.

FAQs

Q1:Can I knit different colors in one sweater without changing the yarn manually?

Yes. With modern machines like the CHJX2-60, multiple yarn feeders can be programmed to switch automatically during knitting. This allows for precise color changes without manual intervention, ideal for Fair Isle and intarsia designs.

Q2:How many colors can I use in one pattern?

Changhua's machines support up to 6–8 yarn feeders, allowing you to work with multiple colors in a single pattern. The number of simultaneous colors depends on the design complexity and machine configuration.

Q3:Is flat knitting suitable for mass production?

Absolutely. While flat knitting is known for flexibility and customization, models like the CHJX2-60 are optimized for medium to high-volume production, making them suitable for brands, factories, and OEM operations.

Q4:Where can I buy Changhua knitting machines?

You can contact Changhua directly for FOB quotes and specifications. The company ships internationally and offers support for installation, training, and maintenance.

Conclusion

In today's fashion landscape, colorful sweaters are more than a trend — they're a statement of creativity, craftsmanship, and quality. Behind every bold pattern and vivid hue is a machine capable of delivering precision and flexibility: the flat knitting machine.

Among the many options available, Changhua's CHJX1-52 and CHJX2-60 models stand out for their ability to handle complex colorwork with speed, accuracy, and ease. Whether you're creating unique designer pieces, high-volume seasonal collections, or experimenting with artistic intarsia patterns, these machines offer the tools you need to succeed.

With advanced features like multiple yarn feeders, computerized control, and strong technical support, Changhua provides not only a machine — but a complete solution for colorful sweater production.

Ready to bring your designs to life?

Contact us now to request a free brochure or quote — and take the first step toward knitting in full color.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe