Introduction to Knitting Machines

Knitting machines are powerful tools that can revolutionize your textile production, whether you're a small business owner, an aspiring fashion designer, or a crafting enthusiast. These machines automate the knitting process, significantly increasing production speed while maintaining consistent quality. Unlike hand knitting which requires considerable time and effort, machine knitting can produce garments and fabrics in a fraction of the time while offering precision and complexity that would be challenging to achieve manually.

The world of knitting machines can seem complex at first, with various types, gauges, and capabilities to consider. Understanding these fundamentals is crucial before investing in equipment that will meet your specific production needs and creative aspirations. This comprehensive guide will walk you through everything you need to know before purchasing a knitting machine, with special emphasis on the high-quality machines offered by our company.

Types of Knitting Machines

Basic Classification

Knitting machines generally fall into two main categories: weft knitting machines and warp knitting machines. For most small to medium-sized operations and individual users, weft knitting machines are the most relevant and practical choice. Weft knitting machines can be further divided into flatbed machines and circular machines.

Flat knitting machines operate with needles arranged in a straight line on a flat bed. The carriage moves horizontally across the needle bed, forming loops across the width of the fabric. These machines are exceptionally versatile, allowing for intricate patterns, designs, and even garment shaping. They're ideal for producing sweaters, scarves, and other flat items that may require complex stitch work.

Circular knitting machines feature needles arranged in a circle, producing a continuous tube of fabric. These machines excel at high-speed production of seamless garments like T-shirts, leggings, and hosiery4. While they're fantastic for bulk production of simpler designs, they typically offer less design flexibility compared to flatbed machines.

Home vs. Industrial Machines

It's also important to distinguish between home knitting machines and industrial knitting machines. Home machines are typically smaller, lighter, and designed for occasional use or small projects. Industrial machines, like those we produce at Changhua, are built for heavy-duty use, higher production volumes, and offer more advanced features and durability.

Key Factors to Consider Before Buying a Knitting Machine

Gauge: The Most Important Decision

Perhaps the most critical decision when selecting a knitting machine is choosing the appropriate gauge. Gauge refers to the number of needles per inch and determines the thickness of yarn the machine can handle.

Standard Gauge (7G): Features approximately 200 needles and handles lace weight to sport weight yarns. Perfect for fine knitted clothing and sweaters.

Bulky Gauge (5G): Typically has about 114 needles and is designed for worsted to chunky weight yarns. Ideal for heavy sweaters that look like hand knits.

Fine Gauge (12G-16G): Designed for very fine yarns, producing fabrics similar to commercial garments.

Mid-Gauge (7G-10G): A versatile compromise, capable of handling a range of yarn weights.

The gauge you choose should be determined by the type of projects you plan to undertake and the yarn weights you prefer working with.

Patterning Capabilities

Knitting machines vary significantly in their patterning capabilities1:

Punchcard Machines: Use punched paper cards to create repeating patterns (typically up to 24 stitches wide).

Electronic/Mylar Machines: Read designs from mylar sheets or computer input.

Computerized Machines: Feature onboard computers that can be programmed with complex designs across the entire needle bed.

For professional use, computerized machines offer the most flexibility and design potential, allowing for intricate patterns, color work, and garment shaping instructions.

Production Speed and Efficiency

Consider your production requirements. Circular machines generally offer higher speeds for basic knits, while flatbed machines provide more versatility at somewhat slower speeds4. The number of feeders on a machine significantly impacts production efficiency—more feeders mean more courses can be knitted in each revolution2.

Ease of Use and Learning Curve

Knitting machines have a learning curve. Computerized models offer more features but may require more technical knowledge. Consider the availability of training resources, technical support, and the user community when selecting a machine.

Space Requirements

Measure your available workspace. Industrial knitting machines require significant space not just for the machine itself, but also for yarn storage, finished products, and associated equipment.

Budget Considerations

Prices for knitting machines vary widely based on capabilities, from a few hundred dollars for basic manual models to tens of thousands for advanced computerized industrial machines. Remember to factor in the cost of accessories, maintenance, and possible upgrades.

Our Recommended Knitting Machines

After understanding the basic types and considerations, let's explore some of our specific models that might be perfect for your operation.

52-Inch Single System Sweater Flat Knitting Machine

This versatile machine is an excellent workhorse for sweater production and a wide range of other knitting projects.

Key Features:

Gauge options: Available in 7G, 8G, 9G, 10G, 12G, 14G, and 16G

Knitting width: 52 inches (also available in 60, 80, and 100 inches)

Knitting speed: Maximum of 1.6m/s with 32 speed sections

Knitting functions: Includes knit, miss, tuck, transfer, intarsia, jacquard, and shaping

Control system: Advanced computer system with LCD industrial display

Yarn feeders: 6 yarn feeders on 3 guide rails

Capabilities:

This machine excels at producing basic knitting patterns (full needle, single side), multi-color irregular jacquard, and twisted weft knitting. It's suitable for knitting sweaters, blankets, scarves, hats, and various clothing accessories5.

The machine features a dynamic stitch system that supports multi-segment stitch control in one line, allowing for multiple fabrics with different densities in the same row. This significantly improves weaving efficiency and diversity of weaving forms.

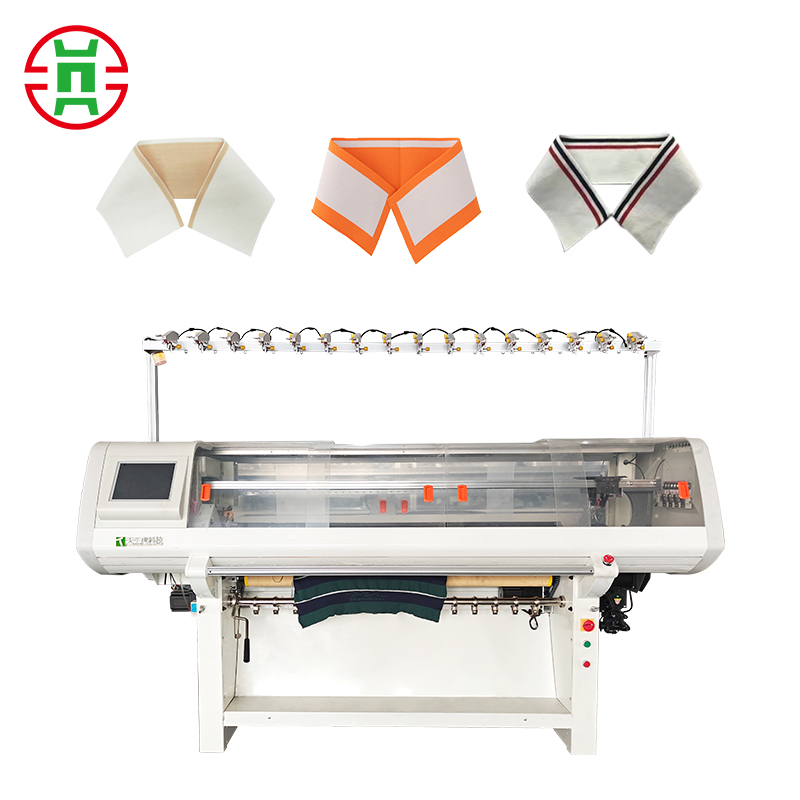

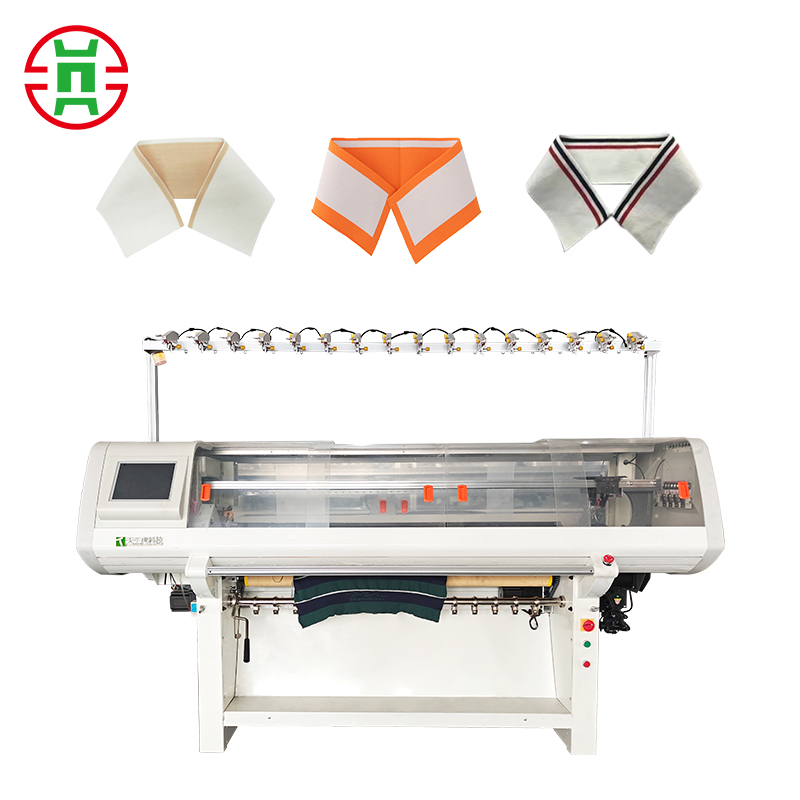

68-Inch Double System Collar Knitting Machine

Specialized for collar and cuff production, this machine delivers

precision and efficiency for these essential components.

Key Features:

Gauge options: 12G, 14G, 16G, and 18G

Knitting width: 68 inches (available from 36 to 100 inches)

Knitting system: Double carriage for increased productivity

Specialized design: Engineered for extreme precision in straightness, flatness, and alignment

Control system: Dedicated Haoyue system with multi-language support6

Capabilities:

This machine is specifically designed to solve common problems in collar production such as unclear fabric lines, uneven edges, and insufficient flatness. It excels at producing high-quality collars, cuffs, and other clothing accessories with consistent precision6.

The double carriage design allows for significantly increased productivity—approximately double that of single head machines—while also accommodating wider fabrics. The machine can make patterns directly on the machine interface, making it easy to operate even for beginners.

52-Inch Shoe Upper Knitting Machine

With the growing market for knitted footwear, this specialized machine offers

precision engineering for shoe upper production.

Key Features:

Specialized construction: Designed specifically for the demands of shoe upper knitting

Precision engineering: Tight tolerances for consistent stitch quality

Versatile patterning: Capable of complex designs required in modern footwear

Durable components: Built to withstand high-production environments

Capabilities:

This machine produces the precise, durable knits required for shoe uppers, accommodating the various patterns and structures demanded by footwear designers. Its specialized construction ensures consistent quality throughout long production runs.

Advantages of Choosing Our Knitting Machines

When you invest in a Changhua knitting machine, you're not just buying equipment—you're gaining a competitive advantage for your business.

Superior Build Quality and Durability

Our machines are constructed with precision-engineered components and robust materials designed to withstand the demands of continuous operation. The needle beds on our machines, for instance, are made of imported steel through fine blanking and grinding processes, which reduces wear and tear on the stitches and decreases resistance, effectively improving knitting efficiency.

Advanced Control Systems

We equip our machines with state-of-the-art control systems that feature industrial LCD displays with graphic touch controls. These systems provide real-time monitoring of knitting amount, time, speed, roller status, stitch formation, and yarn feeder operation5. The intuitive interface supports multiple languages including Chinese, English, Spanish, and Russian, making our machines accessible to users worldwide.

Exceptional Versatility

Whether you're producing sweaters, collars, shoe uppers, or other knitted items, our machines offer the flexibility to handle diverse projects. With functions including knit, miss, tuck, transfer, intarsia, jacquard, and shaping capabilities, our machines can produce both regular and irregular patterns with precision.

High Production Efficiency

Our machines are designed for optimal productivity. With knitting speeds up to 1.6m/s, quick turning capabilities, and intelligent switching systems, our machines maximize output without compromising quality5. The dynamic stitch control allows for multiple density adjustments within a single row, further enhancing efficiency.

Comprehensive Protection Systems

We incorporate advanced protection systems that automatically alert operators to issues such as yarn breakage, knots, floating yarn, end of knitting, racking failures, needle breakage, and programming errors. These systems include safety auto-lock protection devices to prevent damage to the machine or product.

Network Connectivity and Remote Monitoring

Our computerized machines feature network interfaces that enable remote monitoring via network connection and integration with ERP systems. This allows for better production management and troubleshooting support.

After-Sales Support and Service

We stand behind our products with comprehensive after-sales support, including video technical support and on-site service when needed6. Our global network of technicians ensures that help is available when you need it.

Making Your Final Decision

As you approach your purchasing decision, consider the following steps:

Clearly define your production needs: What will you primarily produce? What are your volume requirements?

Assess your space constraints: Measure your available space and ensure proper ventilation and lighting.

Evaluate your technical capability: Are you comfortable with computerized systems, or would you prefer a simpler interface?

Consider future growth: Will the machine you choose accommodate your business as it grows?

Plan for training: Ensure you and your team will have adequate training to operate the machine efficiently.

Factor in all costs: Remember to budget for installation, training, maintenance, and possible accessories.

Next Steps: Requesting a Quotation

Now that you're familiar with what to look for in a knitting machine and have learned about our quality products, the next step is to request a personalized quotation.

When you contact us for a quotation, please have the following information ready:

Your primary intended use for the machine

Your preferred gauge range

Your production volume requirements

Your available space parameters

Any specific features that are particularly important to your operation

We'll provide a detailed quotation including machine specifications, pricing, delivery information, and available support options. We can also arrange a virtual demonstration so you can see our machines in action before making your decision.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe