In the ever-evolving world of textile manufacturing, finding the top knitting machines for sale near me is a priority for businesses aiming to enhance production efficiency, create intricate designs, and meet market demands. Flat knitting machines are at the heart of modern textile production, offering unmatched versatility and precision for crafting everything from sweaters to shoe uppers. This comprehensive guide explores the world of flat knitting machines, highlights why Changhua Smart Manufacturing Technology Co., Ltd. is a trusted name in the industry, and dives into the features of their cutting-edge machines to help you make an informed decision.

What Are Flat Knitting Machines?

Flat knitting machines are specialized textile equipment designed to produce flat pieces of knitted fabric by interlocking yarn in a series of rows. Unlike circular knitting machines, which create seamless tubular fabrics, flat knitting machines excel at producing items like sweaters, scarves, collars, and even advanced shoe uppers. These machines are widely used in garment production, home textiles, and technical textiles due to their ability to handle complex patterns and diverse materials like wool, cashmere, cotton, and synthetic fibers.

Flat knitting machines come in various configurations, including semi-automatic and fully automatic models, with advanced computerized systems for precision and efficiency. Whether you’re a small business looking to produce custom designs or a large-scale manufacturer aiming for high-volume output, there’s a flat knitting machine tailored to your needs.

Why Invest in a Flat Knitting Machine?

Investing in a flat knitting machine offers numerous benefits for textile businesses:

Versatility: Flat knitting machines can produce a wide range of products, from basic sweaters to intricate jacquard patterns and seamless shoe uppers.

Efficiency: Modern machines, especially computerized models, significantly reduce production time and labor costs compared to manual knitting.

Customization: With advanced programming, these machines allow for tailored designs, making them ideal for small-batch or bespoke production.

Quality Control: Automated systems ensure consistent fabric quality with minimal defects, meeting the demands of high-end markets.

Sustainability: Many modern machines are designed to minimize energy consumption and support eco-friendly materials, aligning with global sustainability trends.

For businesses searching for knitting machines for sale near me, choosing a reliable manufacturer is key to ensuring long-term value and performance.

Why Choose Changhua as Your Knitting Machine Supplier?

When it comes to selecting a top-tier flat knitting machine, Changhua Smart Manufacturing Technology Co., Ltd. stands out as a leader in the industry. With over 20 years of expertise, Changhua has established itself as a trusted name in knitting machinery, headquartered in Changshu, Jiangsu—the birthplace of China’s clothing industry. Their commitment to innovation, quality, and customer satisfaction makes them a go-to choice for textile manufacturers worldwide.

About Changhua

Founded in 2005, Changhua is a national high-tech enterprise with a modern production base spanning 50,000 square meters and an annual output of over 3,000 knitting machines. The company’s product portfolio includes a wide range of flat knitting machines, from single-system to multi-system models, catering to diverse market needs. With more than 80 patented technologies, including 15 invention patents, Changhua’s machines are exported to over 30 countries, backed by a robust global service network.

Visit our official website at https://www.changhua-knitting-machine.com/ to explore their full range of products and services.

Changhua’s Core Advantages

Cost-Effectiveness: Changhua’s machines offer superior performance at competitive prices, ensuring a quick return on investment.

Sustainability: Their energy-efficient designs reduce power consumption by up to 35%, supporting eco-friendly production.

Consistent Quality: Built for durability and precision, Changhua machines deliver long-lasting stability and high-quality output.

Quick Response: With 24/7 technical support and an average delivery time of 15-30 days, Changhua ensures minimal downtime.

Flexible Production: Their machines support multi-mix, small-batch production, ideal for custom and limited-edition designs.

Comprehensive Support: Changhua provides extensive training, lifetime software upgrades, and a global network of service bases.

Ready to elevate your textile production? Contact Changhua today to discover how their machines can transform your business: https://www.changhua-knitting-machine.com/.

Top Changhua Flat Knitting Machines for Sale

Changhua offers a diverse range of flat knitting machines, each designed to meet specific production needs. Below, we highlight three of their standout models, perfect for businesses searching for knitting machines for sale near me. For a full catalog, visit https://www.changhua-knitting-machine.com/flat-knitting-machine.html.

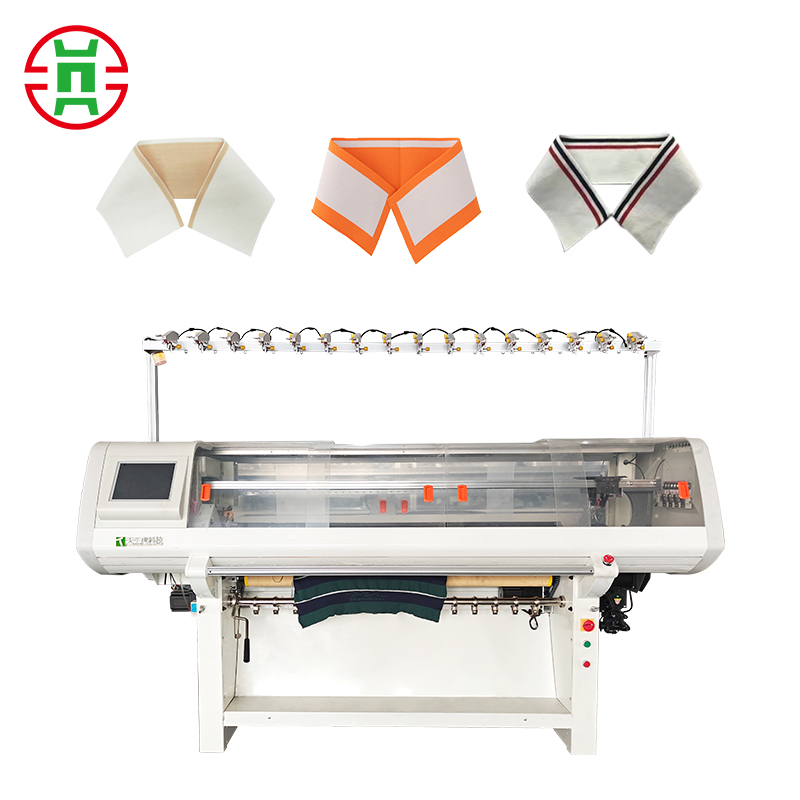

1. 80-Inch Single System Collar Knitting Machine

Key Features:

Gauge Options: Available in 12G, 14G, 16G, and 18G for varied fabric textures.

Knitting Width: 80 inches, ideal for large-scale collar production.

Precision Engineering: Features a milling-type needle bed for ±0.1mm accuracy.

Functions: Supports knitting, semi-jacquard, A/B jack tuck, and full tuck patterns.

Ease of Use: Allows direct design input on the machine’s control panel.

Applications:

Producing round necks, V-necks, and other collar styles.

Suitable for small and medium-sized enterprises transitioning to semi-automation.

Ideal for vocational training and small-batch custom production.

Why Choose This Machine?

This machine is a cost-effective solution for startups and small workshops, offering a balance of affordability and advanced functionality. Its compact design (occupying just 8 square meters) makes it perfect for space-constrained facilities, while its low energy consumption (5.5kW) supports sustainable operations.

Interested in this machine? Reach out to Changhua for a quote.

2. 52-Inch Three System Shoe Upper Knitting Machine

Key Features:

Three-System Technology: Boosts knitting efficiency by 60% compared to dual-system models.

Knitting Width: Available in 36, 52, 72, and 80 inches, with gauges of 14G, 16G, and 18G.

High Precision: Achieves ±0.005mm accuracy for consistent upper quality.

Advanced Functions: Supports 3D knitting, jacquard, intarsia, and open narrowing.

Production Capacity: Capable of producing 3,000 pairs daily, ideal for high-end sports shoes.

Energy Efficiency: 35% lower energy consumption and noise levels below 58 decibels.

Applications:

Manufacturing uppers for athletic shoes, casual footwear, and fashion sneakers.

Developing smart wearable uppers with integrated circuits for gait analysis.

Supporting eco-friendly materials like recycled polyester for sustainable production.

Why Choose This Machine?

This fully automatic machine is a technological benchmark, certified by CE and ISO standards. Its intelligent inspection system ensures a defect rate of less than 0.5%, making it ideal for high-end markets like Nike and Air Jordan. With a 4-year warranty and lifetime software upgrades, it’s a reliable investment for innovative footwear production.

3. 60-Inch Semi Automatic Flat Knitting Machine

Key Features:

Gauge Options: 12G, 14G, 16G, and 18G for versatile fabric production.

Knitting Width: 60 inches, with options up to 100 inches.

Semi-Automatic Operation: Combines manual input with digital technology for ease of use.

Functions: Supports knitting, semi-jacquard, A/B jack tuck, and full tuck patterns.

Production Capacity: Produces 500-800 collars daily, perfect for small-batch orders.

Applications:

Producing collars, cuffs, and ribs for sweaters and other garments.

Ideal for startups, small workshops, and vocational training programs.

Supporting seasonal orders like holiday scarves and Christmas sweaters.

Why Choose This Machine?

Priced at just one-third of fully automatic models, this machine offers an affordable entry point into mechanized knitting. Its user-friendly interface and compact footprint make it a practical choice for businesses looking to scale efficiently.

Ready to upgrade your production? Contact Changhua for pricing details.

Video: See Changhua’s Machines in Action

To get a closer look at how Changhua’s flat knitting machines operate, check out this video showcasing their precision and versatility:

Download Changhua’s Flat Knitting Machine Catalog

For detailed specifications and additional models, download Changhua’s comprehensive catalog:

Key Features of Changhua’s Flat Knitting Machines

Changhua’s machines are designed with cutting-edge technology to meet the demands of modern textile production. Here are some standout features:

1. Advanced Computerized Control

i-Knit Intelligent System: Enables equipment networking, remote monitoring, and intelligent scheduling for digital factory integration.

Dynamic Stitch Control: Multi-stitch functionality in a single line, ensuring precise pattern execution.

User-Friendly Interface: LCD displays allow real-time parameter adjustments and support multiple languages, including English, Chinese, and Spanish.

2. High-Speed Performance

Max Speed: Up to 1.6m/s, controlled by servo-motors for smooth and efficient operation.

Quick Turnaround: Intelligent switching systems reduce downtime and boost weaving efficiency.

3. Precision and Durability

High-Performance Sinkers: Ensure consistent stitch quality across complex patterns.

Milling-Type Needle Beds: Deliver exceptional flatness and precision, minimizing fabric defects.

Automatic Lubrication: Reduces wear and extends machine lifespan.

4. Versatile Applications

Supports a wide range of yarns, including wool, cashmere, cotton, silk, and recycled polyester.

Capable of producing intricate patterns like jacquard, intarsia, and 3D knitting.

5. Eco-Friendly Design

How to Choose the Right Flat Knitting Machine for Your Needs

Selecting the perfect knitting machine depends on several factors:

Production Goals: Are you producing high-volume shoe uppers or small-batch custom collars? Machines like the 52-Inch Three System Shoe Upper Knitting Machine are ideal for large-scale footwear production, while the 60-Inch Semi Automatic Flat Knitting Machine suits smaller operations.

Budget: Semi-automatic models offer a cost-effective entry point, while fully automatic machines provide higher efficiency for larger investments.

Design Complexity: For intricate patterns, choose a computerized model with multi-system capabilities, such as the 80-Inch Single System Collar Knitting Machine.

Space and Resources: Consider your factory’s space constraints and energy requirements. Changhua’s compact designs are ideal for small workshops.

Support and Training: Opt for a supplier like Changhua, which offers comprehensive training, 24/7 support, and lifetime software upgrades.

Not sure which machine is right for you? Contact Changhua’s experts for personalized guidance: https://www.changhua-knitting-machine.com/.

Comparing Flat Knitting Machines: Semi-Automatic vs. Fully Automatic

Semi-Automatic Flat Knitting Machines

Fully Automatic Flat Knitting Machines

For a cost-effective solution, consider the 60-Inch Semi Automatic Flat Knitting Machine. For high-volume, complex production, the 52-Inch Three System Shoe Upper Knitting Machine is a top choice.

Maintenance Tips for Flat Knitting Machines

To maximize the lifespan and performance of your Changhua knitting machine, follow these maintenance tips:

Regular Cleaning: Remove dust and yarn residue from the needle bed and cams to prevent blockages.

Lubrication: Use the automatic refueling system to keep moving parts well-lubricated, reducing wear.

Routine Inspections: Check for needle wear, yarn feeder alignment, and servo-motor performance regularly.

Software Updates: Take advantage of Changhua’s lifetime software upgrades to keep your machine’s control system up to date.

Operator Training: Ensure staff are trained to handle the machine’s advanced features, minimizing errors.

Changhua’s 24/7 technical support and comprehensive training programs make maintenance straightforward and stress-free.

The Future of Flat Knitting Machines

The textile industry is rapidly evolving, with trends like smart textiles, sustainable materials, and digital manufacturing shaping the future. Changhua is at the forefront of these innovations, with our i-Knit intelligent production system enabling cloud-based optimization and remote monitoring. Their machines are also compatible with eco-friendly materials like recycled polyester, supporting the industry’s shift toward sustainability.

By investing in a Changhua flat knitting machine, you’re not just buying equipment—you’re future-proofing your business for the demands of tomorrow’s textile market.

Ready to Find the Perfect Knitting Machine?

If you’re searching for top knitting machines for sale near me, Changhua Smart Manufacturing Technology Co., Ltd. offers the perfect blend of innovation, quality, and affordability. Their range of flat knitting machines, from the versatile 80-Inch Single System Collar Knitting Machine to the high-tech 52-Inch Three System Shoe Upper Knitting Machine, is designed to meet the needs of businesses at every scale.

Take the next step in transforming your textile production. Visit our official website to explore our full range of machines, download our catalog, or contact our team for a personalized consultation. Whether you’re a startup or an established manufacturer, Changhua has the solution to elevate your production.

Contact Changhua todayto request a quote or schedule a demo. Let’s knit the future together!

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe