Welcome to the ultimate guide on sweater making machine prices in Kenya! If you're a budding entrepreneur in the garment industry, a established textile manufacturer, or a fashion designer looking to scale production, you've likely asked: "How much does a sweater knitting machine cost in Kenya?" and "Which machine is right for my business?"

The Kenyan textile and apparel sector is booming, driven by both local demand and export opportunities. Investing in the right machinery is the most critical step to capitalize on this growth. A high-quality sweater flat knitting machine can be the engine of your success, transforming yarn into profit.

In this comprehensive 5000-word guide, we will not only break down the factors affecting sweater making machine prices in Kenya but also introduce you to a world-class manufacturer that balances cost with exceptional quality: Changhua Knitting Machine. We will explore their technology, delve into specific models, and show you why Changhua Computerized Flat Knitting Machines are a smart investment for Kenyan businesses.

Understanding Sweater Making Machines: Types and Technologies

Before we dive into prices, it's crucial to understand the types of machines available. This knowledge will help you make an informed decision based on your production needs.

Manual vs. Semi-Automatic vs. Computerized Machines

Manual Flat Knitting Machines: These are the most basic type, requiring significant operator skill for every stitch and carriage pass. They are low-cost but have very slow production speeds and are prone to inconsistencies. The "price" saved upfront is often lost in labor costs and low output.

Semi-Automatic Machines: These machines offer a middle ground, with some functions automated (like automatic carriage reversal). They are faster than manual machines but still require considerable operator intervention.

Computerized Flat Knitting Machines (Computerized Flat Knitting Machines): This is the modern standard for efficient and high-quality sweater production. Operators use software to design patterns, and the machine executes them with precision and speed. They can produce complex designs, intarsia, cables, and even full garments ("whole garment") with minimal waste.

For any serious business in Kenya looking to compete, computerized flat knitting machines are the undeniable choice. They offer the best return on investment through speed, consistency, and reduced labor costs.

Key Specifications to Consider

When evaluating a machine, look at:

System: Single system or double system. Double-system machines are generally faster as they can knit in both directions of the carriage movement.

Working Width (in inches): Determines the maximum width of the fabric you can knit. Common sizes are 52", 60", and 80".

Gauge (Needles per Inch): Defines the fineness of the knit. A lower gauge (e.g., 3-7 G) is for bulky sweaters, while a higher gauge (e.g., 12-15 G) is for finer, lighter sweaters.

Why the Shift is Towards Computerized Machines in Kenya

The Kenyan government's focus on reviving the textile industry means that to be competitive, both locally and for export, manufacturers need to adopt technology that ensures high quality and efficiency. Computerized machines reduce the skill barrier, minimize errors, and dramatically increase output, making them essential for the future.

Factors Influencing Sweater Making Machine Price in Kenya

The price of a sweater making machine in Kenya isn't a single number. It's influenced by a combination of factors:

Machine Type and Automation Level: As discussed, a manual machine may cost a few thousand dollars, while a state-of-the-art computerized machine can range from tens to hundreds of thousands of dollars.

Brand and Origin: Established German or Japanese brands command a premium. However, manufacturers like Changhua offer a compelling alternative, providing advanced technology and reliability at a more accessible price point without compromising on core functionality.

Technical Specifications: A double-system, 80-inch wide machine will cost more than a single-system, 52-inch model.

New vs. Used: The allure of a used machine's lower price is tempting. However, it comes with risks: no warranty, potential hidden maintenance costs, outdated software, and lack of technical support. For a business that depends on its equipment, a new machine from a reputable supplier often proves cheaper in the long run.

Import Duties, Shipping, and Installation: Remember to factor in the cost of shipping the machine to Mombasa or Nairobi, customs clearance, taxes, and professional installation and training.

Ready to get a precise quote tailored to your production needs? Contact our team today for a transparent breakdown of the total cost, including shipping to your location in Kenya.

Introducing Your Ideal Partner: Changhua Knitting Machine

Navigating the world of knitting machinery can be complex. You need a partner you can trust, one that offers a perfect blend of advanced technology, durability, and value. This is where our company, Changhua Knitting Machine, stands out.

For years, Changhua has been at the forefront of designing and manufacturing high-performance computerized flat knitting machines. We understand the dynamic needs of the global textile market, including the specific challenges and opportunities faced by businesses in Kenya. Our mission is to empower your growth by providing robust, user-friendly, and highly efficient machines that deliver an exceptional return on investment.

Why Kenyan Manufacturers Choose Changhua:

Optimal Price-to-Performance Ratio: We offer the advanced features of premium brands at a fraction of the cost, maximizing your profitability.

Built for Reliability: Our machines are engineered for continuous operation in demanding industrial environments, minimizing downtime.

Intuitive Software: Our user-friendly design software shortens the learning curve, allowing your operators to become productive quickly.

Comprehensive Support: We provide extensive after-sales support, including installation, training, and access to spare parts. We are committed to your success long after the machine is installed.

Discover the full range of our innovative machines and see why we are a top choice for the Kenyan market. Visit our official website: https://www.changhua-knitting-machine.com/

Detailed Look at Top Changhua Sweater Making Machines

Let's take a closer look at some of our best-selling models to help you find the perfect fit for your workshop.

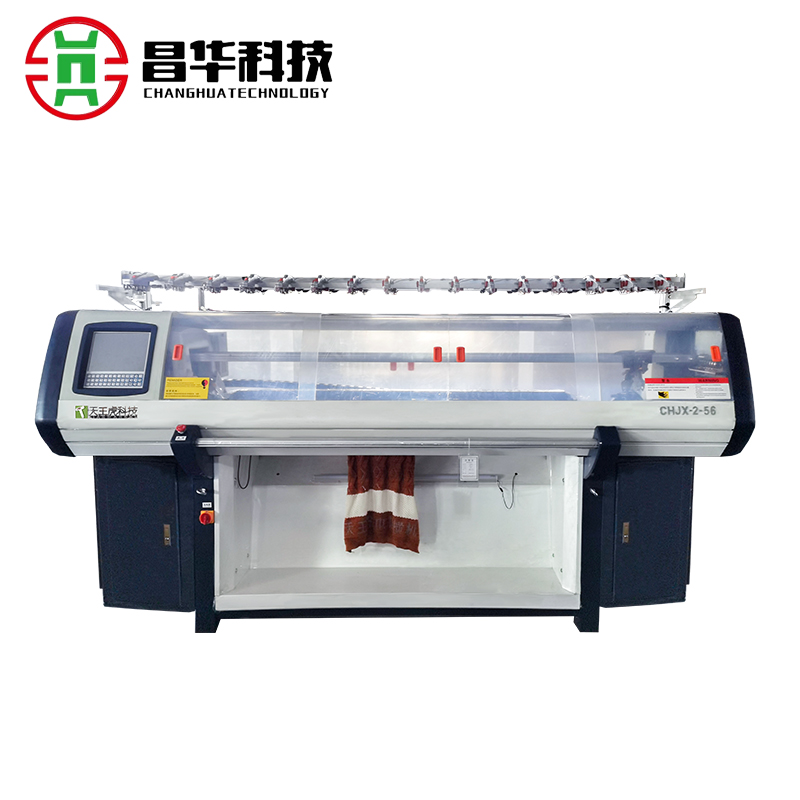

1. The Entry-Level Powerhouse: 52-Inch Single System Sweater Flat Knitting Machine

Ideal for: Startups, small workshops, and businesses focused on producing classic sweater panels and simple structures.

This model is the perfect entry point into automated sweater production. Don't let "entry-level" fool you; this machine is packed with features that deliver professional results.

Key Features:

Working Width: 52 inches, ideal for standard sweater panels.

Single System: Efficient and cost-effective for a wide range of basic to moderately complex patterns.

Computerized Control: Allows for precise pattern input and repeatable quality.

Versatile Gauge Options: Available in different gauges to suit your desired fabric weight.

This machine strikes an excellent balance between affordability and capability. It allows you to automate your production, improve consistency, and grow your business without a massive initial investment.

Want to see the specifications and capabilities of this versatile model? Click here for more details: 52-Inch Single System Sweater Flat Knitting Machine

2. The Production Workhorse: 60-Inch Double System Sweater Knitting Machine

Ideal for: Medium to large-scale manufacturers who need higher output speeds and more efficient production.

If your business is scaling up, the 60-inch double-system machine is your go-to solution. The double-system design is a game-changer for productivity.

Key Features:

Working Width: 60 inches, offering more fabric width flexibility.

Double System: Knits in both directions of the carriage movement, effectively doubling the knitting speed compared to a single-system machine.

Enhanced Productivity: Perfect for high-volume orders where delivery timelines are critical.

Advanced Stitching Capabilities: Excellently handles more complex stitches and patterns with ease.

This model is designed for businesses that are serious about maximizing their output and meeting growing market demands efficiently.

Ready to supercharge your production line? Learn all about our high-speed 60-inch double system machine here: 60-Inch Double System Sweater Knitting Machine

3. The Ultimate Innovation: 80-Inch Whole Garment Sweater Flat Knitting Machine

Ideal for: High-end fashion producers, innovative designers, and manufacturers looking to eliminate sewing and reduce labor costs.

This is the pinnacle of sweater knitting technology. The "Whole Garment" or "Seamless" technology allows you to knit an entire sweater – front, back, and sleeves – in one single piece.

Key Features:

Working Width: A spacious 80-inch bed, necessary for whole-garment production.

Whole Garment Technology: Knits complete, seamless sweaters directly on the machine.

Minimal Post-Knitting Labor: Drastically reduces or eliminates the need for linking and sewing, saving significant time and money.

Superior Product Quality: Seamless garments offer superior comfort, a premium feel, and are highly sought after in the market.

Investing in this technology positions your Kenyan business at the forefront of global fashion manufacturing, allowing you to create premium products that command higher prices.

Step into the future of knitting. Discover how our whole garment technology can revolutionize your business: 80-Inch Whole Garment Sweater Flat Knitting Machine

The Changhua Advantage: Why Our Machines are Perfect for Kenya

Beyond the specifications, it's the tangible benefits that make our Changhua computerised flat knitting machines the right choice.

Unbeatable Reliability and Low Maintenance

We design our machines for durability. The robust construction and quality components ensure they can handle the rigors of daily production, which is crucial for maintaining your business's output and meeting deadlines.

Energy Efficiency

Our machines are engineered to be energy-efficient, helping you keep your operational costs (a significant factor in Kenya) under control. Lower power consumption means higher overall profitability.

Comprehensive Training and Local Support

We don't just sell you a machine; we set you up for success. Our package includes detailed operational training for your staff. Furthermore, we are building a network of technical support and ensuring easy access to genuine spare parts to minimize any potential downtime.

Future-Proof Technology

With Changhua, you are investing in technology that grows with you. Our software is regularly updated, and our machines are built to adapt to new trends and techniques in the knitting industry.

Making the Smart Investment: Total Cost of Ownership

When considering the sweater making machine price in Kenya, think beyond the initial invoice. The Total Cost of Ownership (TCO) includes:

Purchase Price

Installation & Training

Maintenance & Repairs

Energy Consumption

Labor Efficiency

A Changhua machine offers an outstanding TCO. The competitive purchase price, combined with low maintenance costs, high energy efficiency, and reduced labor due to automation, means your investment pays for itself faster, boosting your bottom line for years to come.

Conclusion: Your Path to Sweater Manufacturing Success in Kenya Starts with Changhua

The journey to finding the right sweater making machine at the right price in Kenya ends with a strategic decision. While the initial cost is important, the long-term value, reliability, and support are what truly define a wise investment.

Changhua Knitting Machine offers you a partnership for growth. From the accessible 52-inch single system model to the revolutionary 80-inch whole garment machine, we have a solution that will elevate your production capacity, enhance your product quality, and increase your profitability.

Don't let outdated equipment or unreliable machinery hold your business back. Embrace the technology that is shaping the future of the textile industry in Kenya and across Africa.

Click Here to Visit Changhua Knitting Machine Official Website

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe