The professional flat knitting machine represents a pinnacle of textile manufacturing technology, blending precision engineering with versatility to meet the demands of modern industries. From producing intricate fashion garments to creating technical textiles, these machines have revolutionized how knitted fabrics are made. This comprehensive guide explores the mechanics, applications, and benefits of professional flat knitting machines, with a special focus on why Changhua machines are a top choice for businesses. Designed with the reader in mind—whether you're a manufacturer, designer, or knitting enthusiast—this article dives deep into the world of flat knitting, offering insights, visuals, and resources to inform and inspire.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

What Is a Professional Flat Knitting Machine?

A professional flat knitting machine is a sophisticated piece of equipment used to create knitted fabrics through a semi- or fully-automated process. Unlike circular knitting machines, which produce tubular fabrics, flat knitting machines produce flat, versatile panels that can be shaped into garments or other products. These machines feature two needle beds arranged in an inverted V-shape (often called a V-bed), allowing for complex stitch patterns, loop transfers, and three-dimensional shaping.

Flat knitting machines are widely used in industries ranging from fashion to automotive, medical, and even aerospace. Their ability to produce seamless garments, intricate patterns, and customized textiles makes them indispensable in modern manufacturing. According to industry reports, the global knitting machine market is expected to grow steadily, driven by demand for sustainable and efficient production methods.

Key Features of Professional Flat Knitting Machines

Computerized Control

Modern machines use software to program complex patterns, reducing manual intervention and ensuring precision.

Versatility

Capable of knitting various materials, including cotton, wool, synthetic fibers, and blended yarns.

Seamless Production

Technologies like Whole Garment knitting eliminate the need for sewing, reducing waste and labor costs.

High Efficiency

Advanced models can operate at speeds up to 1.4m/s, significantly boosting production rates.

Customization

Allows for rapid prototyping and small-batch production, catering to bespoke fashion trends.

Applications of Professional Flat Knitting Machines

Fashion and Apparel

Flat knitting machines are widely used to produce sweaters, scarves, hats, and other garments. The ability to create intricate jacquard patterns, intarsia, and 3D textures has made them a favorite among fashion designers. For example, Changhua's Whole Garment flat knitting machines can produce seamless sweaters in a single process, enhancing both comfort and aesthetics.

Footwear Manufacturing

The rise of 3D-knitted shoe uppers has revolutionized the footwear industry. Flat knitting machines, such as Changhua's Shoe Upper Knitting Machine, use digital technology to create lightweight, breathable, and durable shoe components. These machines support high-speed production and can handle materials like polyester and blended yarns, making them ideal for athletic and casual footwear.

Home Textiles

From blankets to upholstery, flat knitting machines create a wide range of home textile products. Their ability to handle thick yarns and produce large panels ensures high-quality, durable results. Changhua's blanket knitting machines, for instance, are designed for efficiency and scalability, catering to both commercial and domestic markets.

Why Choose a Professional Flat Knitting Machine?

Increased Productivity

With knitting speeds reaching up to 1.4m/s and automated features like motor-driven cam systems, flat knitting machines significantly reduce production time. This is especially critical for manufacturers aiming to meet tight deadlines.

Reduced Waste

Technologies like Whole Garment knitting minimize fabric waste by producing garments in a single piece, eliminating the need for cutting and sewing. This not only lowers material costs but also aligns with sustainable manufacturing practices.

Enhanced Design Flexibility

Computerized flat knitting machines allow designers to experiment with complex patterns, textures, and colors without manual reprogramming. This flexibility is ideal for creating limited-edition collections or responding to fast-changing fashion trends.

Cost-Effective for Small Batches

Unlike traditional knitting methods, flat knitting machines excel in small-batch production, making them perfect for boutique brands and custom orders. Changhua’s machines, with their user-friendly interfaces, make it easy to switch between designs, reducing downtime.

Durability and Longevity

High-quality machines from reputable manufacturers like Changhua are built to last, with robust components and advanced engineering. Regular maintenance and calibration ensure consistent performance over years of heavy use.

Spotlight on Changhua: A Leader in Flat Knitting Machines

When it comes to professional flat knitting machines, Changhua stands out as a trusted name with over 20 years of experience in the industry. Based in Changshu, Jiangsu, the birthplace of China's apparel industry, Changhua combines innovation, quality, and affordability to deliver world-class knitting solutions. Their product range includes computerized flat knitting machines, Whole Garment machines, shoe upper knitting machines, and more, catering to both large-scale manufacturers and small businesses.

Top Changhua Models to Consider

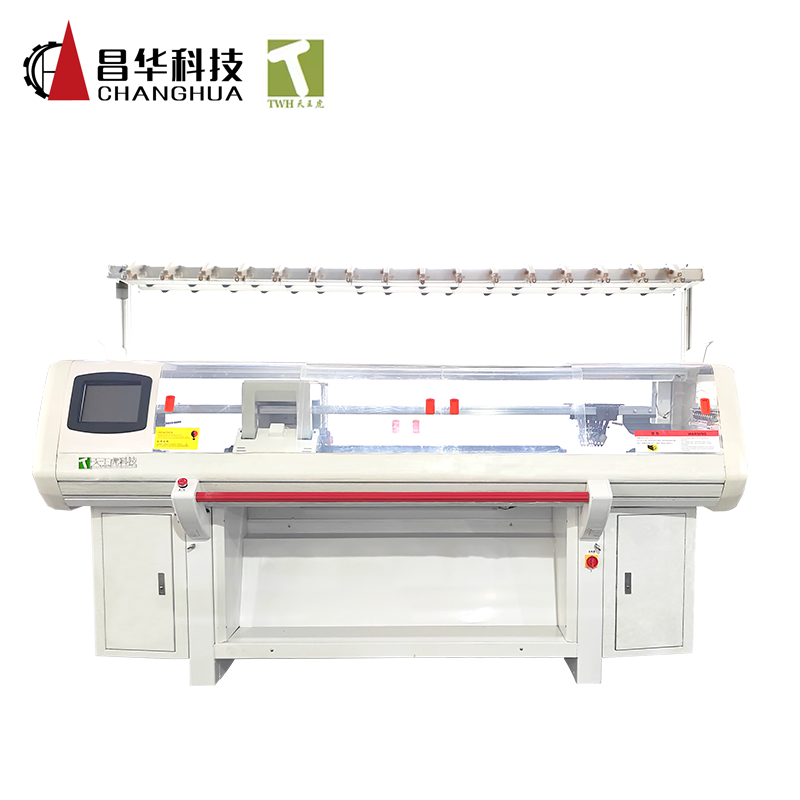

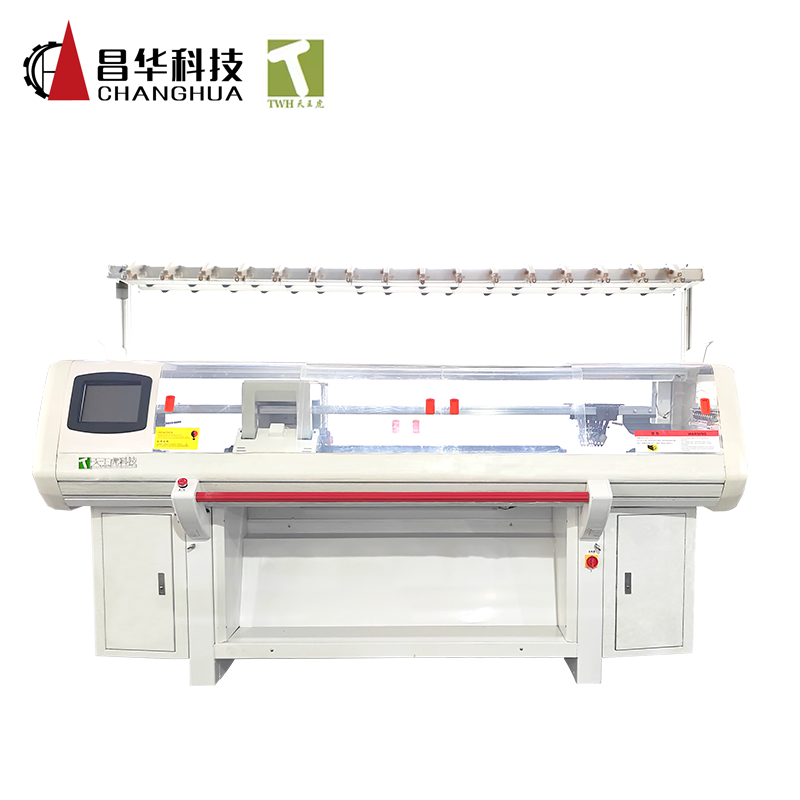

TWH 52-Inch Three-System Sweater Knitting Machine

Gauge: 5G, 7G,8G, 9G, 10G,12G, 14G, 16G,18G Knitting

Width: 52 inches

Features: Dynamic density control, and jacquard knitting capabilities.

Applications: Sweaters, cardigans, and scarves.

Price: Negotiable, with a minimum order of 1 set.

Whole Garment Flat Knitting Machine

Gauge: 6.2G to 13.2G

Knitting Width: 72inch,80 inch

Features: Seamless production, automated yarn carriers, and high-speed operation.

Applications: Seamless knitwear, medical textiles, and technical fabrics.

Price: Contact Changhua for a quotation.

Why Choose Changhua's Flat Knitting Machines?

Cutting-Edge Technology

Changhua’s machines are equipped with advanced features like dynamic density control, motor-driven racking mechanisms, and high-speed carriages. For example, our Shoe Upper Knitting Machine uses digital technology to produce 3D shoe uppers with minimal waste, offering up to 20% higher production efficiency compared to competitors.

Customization and Scalability

Changhua’s machines support gauges ranging from 3G to 16G, allowing manufacturers to produce everything from fine-knit scarves to chunky blankets. Our modular designs make it easy to upgrade or customize machines based on specific production needs.

Exceptional Support and Service

With a strong focus on customer satisfaction, Changhua provides comprehensive after-sales support, including training, maintenance, and technical assistance. Our global network ensures prompt service, minimizing downtime for manufacturers.

Competitive Pricing

Despite their advanced features, Changhua's machines are priced competitively, making them accessible to businesses of all sizes. Whether you're a startup or an established brand, Changhua offers cost-effective solutions without compromising quality.

Conclusion

Professional flat knitting machines are transforming the textile industry, offering unmatched efficiency, flexibility, and quality. Whether you’re producing high-fashion knitwear, technical textiles, or innovative footwear, these machines are a worthy investment. Among the many manufacturers, Changhua stands out for its innovative technology, diverse product range, and commitment to customer satisfaction. With over two decades of experience, Changhua’s machines are designed to meet the needs of modern manufacturers while keeping costs accessible.

Ready to take your textile production to the next level? Contact us to explore their full range of flat knitting machines and request a quotation. Whether you're a small business or a global brand, Changhua has the perfect solution to help you succeed in the competitive world of textiles.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe