The Southeast Asian textile industry is a dynamic force, fueled by rapid economic growth, a burgeoning middle class, and rising demand for high-quality, customized apparel. For manufacturers and procurement professionals, selecting the right knitting machines is pivotal to achieving efficiency, scalability, and competitiveness. This article delves into the procurement of computerized flat knitting machines in Southeast Asia, emphasizing the superior advantages of Chinese equipment, particularly from Changhua, over local brands. With over 20 years of export expertise, Changhua delivers innovative, reliable, and sustainable solutions tailored to the region's unique demands.

Understanding the Southeast Asian Textile Landscape

Southeast Asia, including nations like Vietnam, Indonesia, Thailand, and Bangladesh, is a global textile manufacturing hub. Its competitive labor costs, supportive trade policies, and expanding consumer markets drive demand for advanced knitting machinery. Industry insights project the global knitting machines market to grow at a CAGR of 3.9% through 2030, with Asia Pacific at the forefront due to its robust production ecosystems. Applications span apparel (sweaters, sportswear, socks) to technical textiles (automotive fabrics, medical textiles), necessitating versatile, high-performance equipment.

Key Applications of Knitting Machines

Knitting machines are essential for producing diverse textile products. Computerized flat knitting machines, in particular, excel in creating seamless garments, intricate patterns, and technical fabrics. Key applications include:

Apparel: Sweaters, scarves, and sportswear with complex designs.

Home Textiles: Curtains, upholstery, and bedding requiring durability.

Technical Textiles: Automotive upholstery, medical bandages, and geotextiles.

3D Knitting: Seamless garments that reduce waste and production time.

Why Chinese Knitting Machines Stand Out

Chinese knitting machines, especially from established manufacturers like Changhua, offer significant advantages over local Southeast Asian brands. These benefits stem from China's extensive expertise, technological innovation, and economies of scale. Below, we highlight why our equipment excels.

Cutting-Edge Technology and Automation

Our computerized flat knitting machines integrate advanced technologies, such as computerized controls, AI-driven design software, and Industry 4.0 capabilities. These features ensure precision, minimize material waste, and enhance production efficiency. Computerized systems enable intricate pattern creation and real-time adjustments, reducing errors. Local brands often lag in adopting such sophisticated automation, limiting their ability to meet Southeast Asia’s demand for high-quality, customized textiles.

Cost-Effectiveness and Scalability

China's large-scale manufacturing ecosystem allows us to produce high-performance machines at competitive prices. Changhua's equipment offers superior value compared to European or Japanese alternatives, making it ideal for Southeast Asian manufacturers, particularly SMEs with budget constraints. While local brands may offer lower upfront costs, they often lack the durability and scalability required for high-volume production.

Durability and Reliability

Our machines are built with high-quality components sourced from global leaders in Taiwan, Japan, and Germany, ensuring long-lasting stability and minimal maintenance. Changhua's equipment delivers consistent performance, reducing downtime and operational costs. Local brands may struggle to match this reliability, often requiring frequent repairs that disrupt production.

Sustainability and Energy Efficiency

Sustainability is a growing priority in Southeast Asia, driven by consumer preferences and regulatory pressures. Our knitting machines incorporate energy-efficient motors and precise material utilization to minimize waste. These eco-friendly features align with global sustainability standards, giving Changhua an edge over local brands that may not prioritize green technology.

Proven Export Expertise

With over 20 years of experience exporting to more than 50 countries, including Southeast Asian markets like Vietnam and Indonesia, Changhua designs machines to meet diverse production needs and international standards. Our global reach ensures adaptability to regional challenges, unlike local brands that primarily focus on domestic markets.

Changhua: Pioneering Knitting Machine Innovation

Changhua is a trusted leader in computerized flat knitting machines, with a legacy of quality, innovation, and customer-focused solutions. Based in China, our company is committed to modernizing the textile industry through advanced technology and sustainable practices. Our product portfolio, including flat knitting machines, glove machines, and hosiery machines under brands like Changhua, Tiangong, King Tiger, and Miao's Craftsman, is designed to meet Southeast Asia’s diverse textile demands.

By choosing Changhua, you benefit from:

Intelligent Programming: Our machines enhance efficiency and reduce energy consumption, lowering costs.

Global Support: Our 24/7 technical team ensures rapid response times, with average delivery in 15-30 days.

Tailored Solutions: We customize machines to meet specific production needs, from apparel to technical textiles.

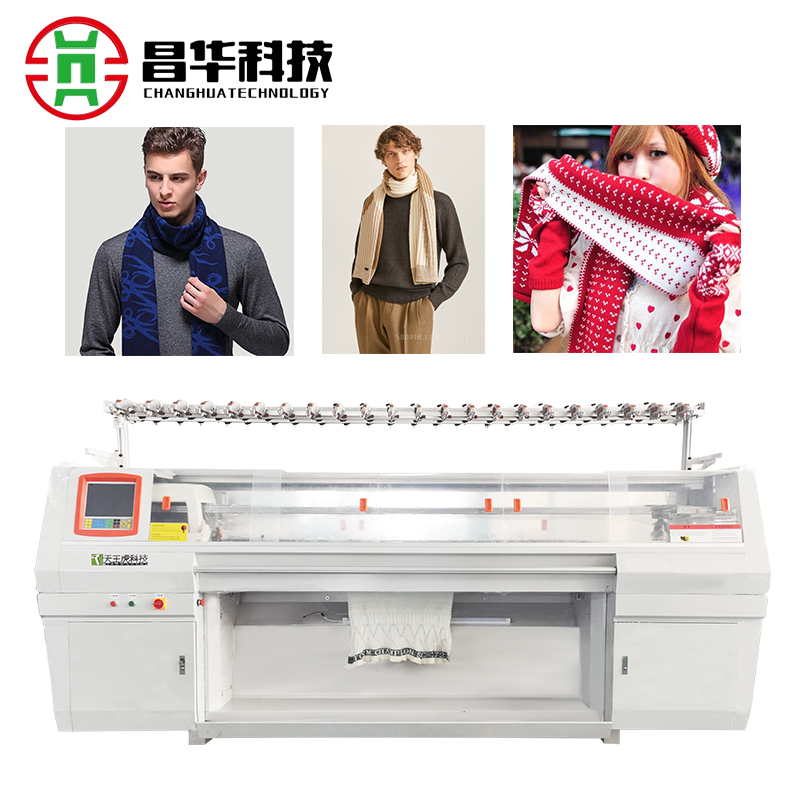

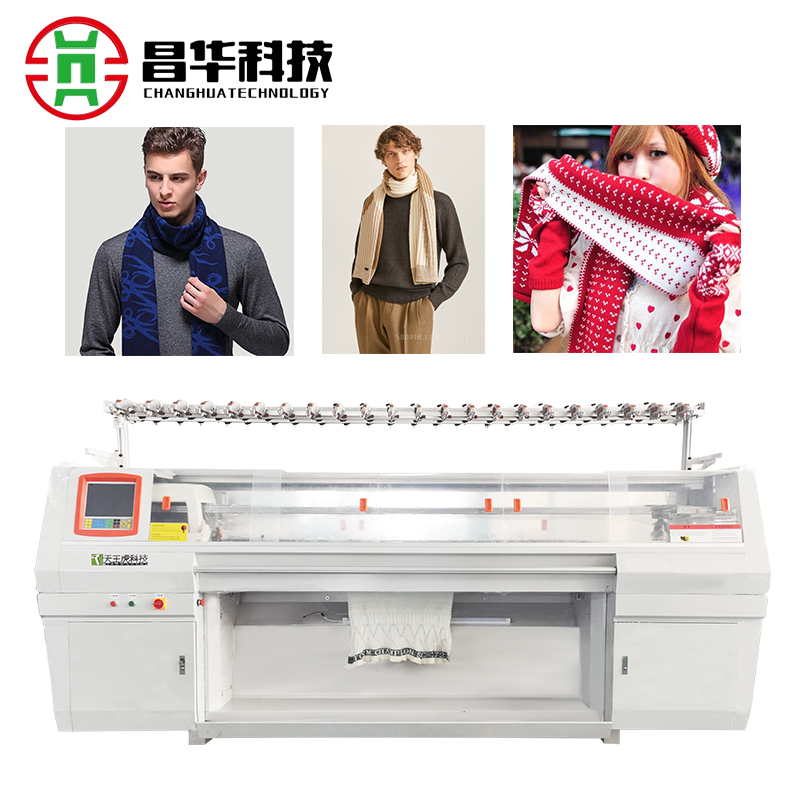

Spotlight on Changhua's Computerized Flat Knitting Machines

Our computerized flat knitting machines, featured on our website, are engineered for precision, speed, and versatility. Below, we showcase three flagship models that highlight our technological leadership.

CHJX-2-80 Computerized Flat Knitting Machine

The CHJX-2-80 is a high-performance, double-system machine designed for complex, multi-color patterns. Key features include:

Dual-System Knitting: Enables intricate jacquard and textured fabrics with high flexibility.

Smart Control System: Offers precise pattern programming and storage for consistent quality.

Energy-Saving Design: Reduces power consumption, supporting sustainable production.

This machine is ideal for Southeast Asian manufacturers producing premium apparel and technical textiles.

CHJX-3-100 High-Speed Computerized Flat Knitting Machine

The CHJX-3-100 is built for speed and efficiency, catering to high-volume production needs. Its advantages include:

The CHJX-3-100 is built for speed and efficiency, catering to high-volume production needs. Its advantages include:

Ultra-Fast Knitting: Maximizes output for fast fashion and sportswear.

AI-Driven Automation: Minimizes errors with real-time adjustments.

Durable Construction: Ensures long-term reliability, reducing maintenance costs.

This model suits factories aiming to meet tight deadlines without compromising quality.

CHJX-1-72 Single-System Flat Knitting Machine

The CHJX-1-72 is a versatile, single-carriage machine perfect for small to medium-scale production. Highlights include:

Seamless Knitting: Reduces fabric waste, ideal for eco-conscious manufacturers.

User-Friendly Interface: Simplifies operation for quick setup and training.

High Precision: Delivers consistent quality for sweaters, scarves, and more.

This machine is a cost-effective choice for SMEs entering Southeast Asia’s textile market.

Why Changhua Surpasses Local Brands

Compared to local Southeast Asian brands, Changhua's machines offer superior technology, reliability, and global support. Our 20+ years of export experience ensure our equipment meets the specific needs of markets like Vietnam, Indonesia, and Bangladesh, where demand for knitted apparel and technical textiles is booming. Local brands often lack the R&D capabilities and global supply chain integration that Changhua leverages to deliver high-performance machines at competitive prices.

Procurement Considerations for Southeast Asian Manufacturers

When procuring knitting machines, Southeast Asian manufacturers should evaluate several factors to maximize ROI:

Production Capacity and Scalability

Choose machines that grow with your business. Our CHJX-series machines cater to both small-scale and high-volume production, offering flexibility for expanding enterprises.

Technology Integration

Invest in machines with computerized controls and automation to stay competitive. Our equipment integrates with Industry 4.0 technologies, enabling real-time monitoring and predictive maintenance.

Cost vs. Value

While local brands may have lower initial costs, their machines often lack longevity and efficiency. Changhua’s solutions deliver long-term value through reduced maintenance and energy savings.

After-Sales Support

Reliable support minimizes downtime. Our 24/7 technical assistance and rapid spare parts delivery ensure uninterrupted production.

Sustainability Compliance

With increasing focus on sustainability, opt for machines that reduce waste and energy use. Our eco-friendly designs help manufacturers meet environmental standards while cutting costs.

Changhua's Export Success in Southeast Asia

Our extensive export experience makes us a trusted partner in Southeast Asia. Having supplied machines to countries like Vietnam, Indonesia, and Bangladesh, we understand regional challenges, such as high humidity affecting machine performance and the need for fast delivery. Our average delivery time of 15-30 days keeps your production on track. Our machines comply with international quality standards, making them ideal for exporters targeting global markets.

Overcoming Common Procurement Challenges

Southeast Asian manufacturers often face challenges like high costs, complex operation, and limited support. Changhua addresses these with:

Affordable Pricing: Our machines offer premium features at competitive prices, ideal for SMEs.

Intuitive Interfaces: User-friendly controls reduce operator training time.

Global Support Network: Our team ensures rapid response and ongoing assistance.

How to Procure Changhua Machines

Procuring our knitting machines is seamless. Visit our computerized flat knitting machine page to explore our range. Contact our 24/7 support team for customized recommendations and a quote. With our efficient logistics, your machines will arrive within 15-30 days, ready to enhance your production.

Conclusion

For Southeast Asian manufacturers, procuring knitting machines is a strategic decision that impacts productivity, quality, and sustainability. Chinese equipment, particularly from Changhua, outperforms local brands with advanced technology, cost-effectiveness, durability, and global support. Our CHJX-2-52, CHJX-3-52, and CHJX-1-52 machines are tailored to meet the region's diverse needs, from fast fashion to technical textiles. With over 20 years of export expertise, Changhua is your trusted partner in driving textile innovation. Visit our website today to explore our solutions and transform your production capabilities.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe