The textile industry is evolving rapidly, and flat knitting machines have become indispensable tools for producing high-quality, versatile knitted fabrics. Whether you're a small-scale designer, a hobbyist, or a large-scale manufacturer, selecting the right flat knitting machine manufacturer in 2025 is critical to achieving efficiency, precision, and profitability. This comprehensive guide explores the world of flat knitting machines, key considerations for choosing manufacturers, and why Changhua stands out as a top choice for innovative knitting solutions.You can download our comprehensive PDF guide on the  Changhua flat knitting machine.pdf and

Changhua flat knitting machine.pdf and  one stop programmes.pptx to help you make an informed decision.

one stop programmes.pptx to help you make an informed decision.

What Are Flat Knitting Machines?

Flat knitting machines are specialized textile manufacturing devices that create flat, weft-knitted fabrics. Unlike circular knitting machines, which produce tubular fabrics, flat knitting machines excel at crafting intricate patterns and shapes, making them ideal for producing sweaters, scarves, cardigans, and technical textiles. These machines use a needle bed, sinkers, and a carriage to form stitches, offering unmatched flexibility for both simple and complex designs.

Flat knitting machines come in various types, including manual, semi-automatic, and fully automatic models. Advanced computerized versions, like those offered by leading manufacturers, integrate digital controls, automated yarn feeding, and tension systems for seamless production. With applications spanning fashion, automotive, medical textiles, and home furnishings, these machines are vital for modern textile production.

Why Choosing the Right Manufacturer Matters

Selecting the right flat knitting machine manufacturer can make or break your production process. A reliable manufacturer ensures high-quality machines, excellent after-sales support, and innovative technology that aligns with your business needs. Here's why your choice matters:

Quality and Durability: High-quality machines reduce downtime and maintenance costs, ensuring long-term reliability.

Technological Innovation: Advanced features like AI-driven automation and IoT connectivity enhance efficiency and customization.

Cost Efficiency: The right machine balances initial investment with long-term savings through reduced labor and material waste.

Support and Training: Reputable manufacturers provide comprehensive training and responsive technical support.

Sustainability: Eco-friendly machines minimize waste and energy consumption, aligning with modern sustainability goals.

Key Factors to Consider When Choosing a Flat Knitting Machine Manufacturer

To make an informed decision, consider the following factors when evaluating manufacturers in 2025:

1. Reputation and Experience

A manufacturer's reputation reflects their reliability and expertise. Look for companies with a proven track record in the textile industry. Check customer reviews, case studies, and industry certifications to gauge their credibility. Manufacturers with decades of experience, like those established for over 20 years, are likely to offer stable, high-quality machines.

2. Product Range and Customization

Different projects require different machines. Ensure the manufacturer offers a diverse range of flat knitting machines, from manual models for small-scale production to fully automatic systems for mass manufacturing. Customizable solutions tailored to specific applications, such as sweater or shoe upper knitting, are a significant advantage.

3. Technological Advancements

In 2025, cutting-edge technology is non-negotiable. Look for manufacturers offering computerized machines with features like digital pattern control, automated yarn feeding, and tension systems. These advancements reduce manual intervention, improve precision, and boost production speed. Integration with AI and IoT for real-time monitoring is a bonus.

4. After-Sales Support

Reliable after-sales support is crucial for minimizing downtime. Choose a manufacturer that offers 24/7 technical assistance, on-site training, and readily available spare parts. Fast delivery times (e.g., 15-30 days) and responsive customer service can significantly enhance your experience.

5. Cost and ROI

While cost is a factor, focus on the return on investment (ROI). High-quality machines may have a higher upfront cost but offer long-term savings through efficiency, durability, and reduced waste. Compare pricing models and check for competitive pricing without compromising quality.

6. Sustainability Features

Sustainability is a growing priority in the textile industry. Look for manufacturers that prioritize eco-friendly practices, such as seamless knitting to reduce material waste or energy-efficient programming to lower consumption. Machines that support sustainable production align with regulatory pressures and consumer demands.

7. Global Reach and Market Presence

Manufacturers with a global presence are better equipped to provide localized support and understand diverse market needs. Check if the manufacturer has a strong distribution network and experience exporting to your region.

Why Choose Changhua as Your Flat Knitting Machine Manufacturer

When it comes to selecting a trusted manufacturer, Changhua stands out as a global leader in flat knitting machine technology. With over 20 years of experience, our company, Changshu Changhua Smart Manufacturing Technology Co., Ltd., is based in Changshu, Jiangsu—the heart of China’s apparel industry. We are committed to revolutionizing textile production with innovative, high-quality, and sustainable solutions.

Our Product Range

At Changhua, we offer a comprehensive lineup of flat knitting machines designed to meet diverse needs. Our machines include:

Whole Garment Flat Knitting Machine: Enables fully fashioned, seamless garments, reducing waste and post-production processes.

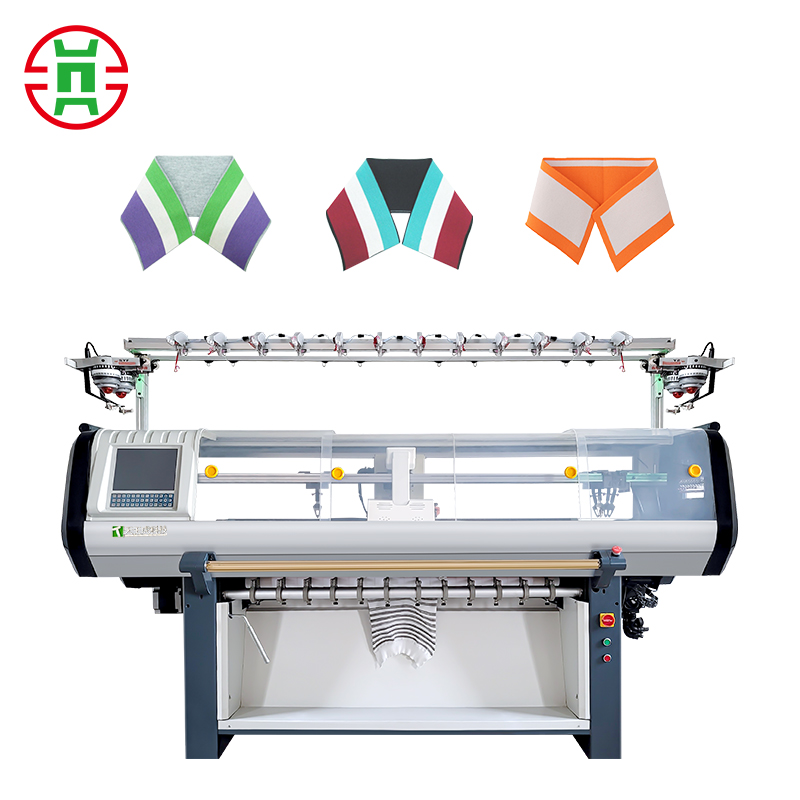

Collar Knitting Machine: Engineered for precision in knitting collars and ribs, ensuring straightness, flatness, and high-quality output.

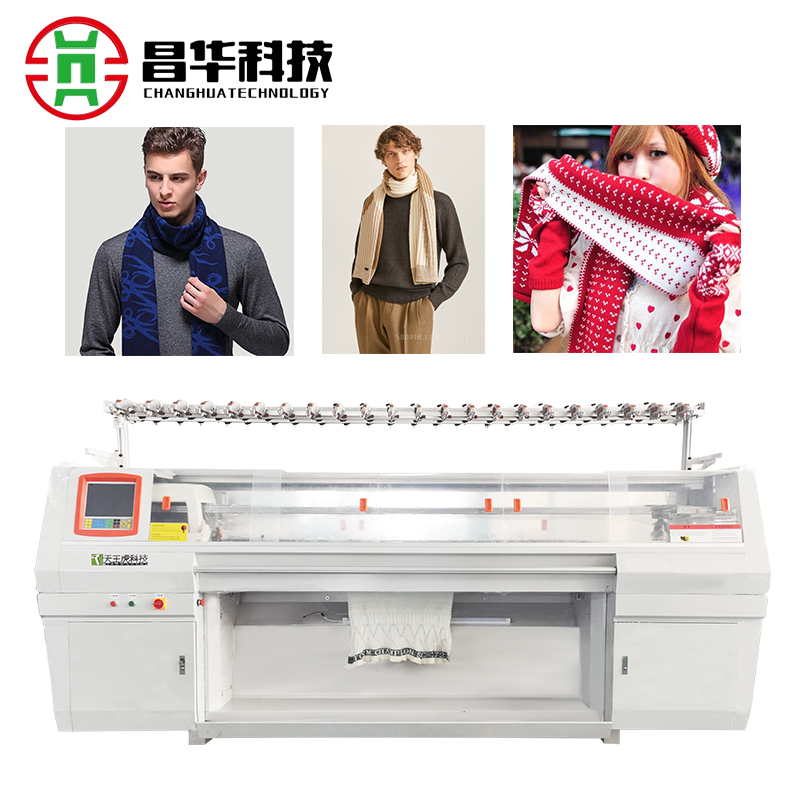

Scarf Knitting Machine: Supports quick production of scarves with customizable patterns and textures.

Shoe Upper Knitting Machine: Perfect for athletic and fashion footwear, producing seamless, durable uppers.

Cutting-Edge Technology

Our flat knitting machines integrate advanced features to enhance productivity and quality:

High-Performance Sinker and Dynamic Stitch: Ensures precise stitch formation for flawless fabrics.

Digital Technology: Enables high-speed knitting and efficient production of intricate patterns.

Motor-Controlled Reversing Carriage: Enhances flexibility for complex designs like pointelle, tuck, and full needle jacquard.

Intelligent Programming: Reduces energy consumption and boosts efficiency, aligning with sustainability goals.

Unmatched Quality and Durability

At Changhua, we prioritize quality and reputation. Our machines are built with top-grade materials like steel and lightweight metal blends to withstand years of heavy use. Rigorous quality control ensures long-lasting stability and minimal maintenance, reducing downtime and operational costs.

Exceptional After-Sales Support

We understand that reliable support is critical for your success. Changhua offers:

24/7 Technical Support: Our highly responsive team is available around the clock.

On-Site Training: We provide comprehensive training to ensure your staff can operate our machines effectively.

Fast Delivery: Orders are delivered within 15-30 days, ensuring minimal disruption to your production schedule.

Commitment to Sustainability

Our machines are designed with eco-friendly features, such as seamless knitting to minimize waste and intelligent programming to reduce energy consumption. By choosing Changhua, you’re investing in sustainable manufacturing practices that align with global environmental standards.

Competitive Pricing

We offer competitive pricing without compromising quality, ensuring you get the best value for your investment. Our machines deliver high ROI through faster production, reduced labor costs, and minimal material waste.

Comparing Changhua to Other Leading Manufacturers

While many manufacturers offer flat knitting machines, Changhua’s combination of experience, innovation, and customer-centric solutions sets us apart. Here’s how we compare to other top players in 2025:

SHIMA SEIKI (Japan)

SHIMA SEIKI is known for its high-end, fully fashioned knitting machines and design software like SHIMA KnitManager™. While they excel in precision and automation, their machines come with a higher initial investment and require technical expertise. Changhua offers similar advanced features at a more competitive price, making our machines accessible to a wider range of businesses.

Karl Mayer (Germany)

Karl Mayer specializes in warp and flat knitting machines, with a focus on technical textiles. Their machines are robust but may not offer the same level of customization for fashion applications as Changhua’s diverse product range. Our machines cater to both apparel and technical textiles with flexible, user-friendly designs.

Ningbo Cixing (China)

Ningbo Cixing is a leader in conventional computerized flat knitting machines. While they’ve expanded into fully fashioned knitting, Changhua’s 20+ years of independent research and development give us an edge in innovative, customizable solutions tailored to specific client needs.

Stoll (Germany)

Stoll, part of the Karl Mayer Group, is renowned for sophisticated knitting solutions. However, their machines are often more expensive and geared toward large-scale operations. Changhua’s machines are versatile for both small and large businesses, with a focus on affordability and ease of use.

How to Evaluate Your Specific Needs

Before choosing a manufacturer, assess your production requirements:

1. Project Type

Fashion and Apparel: For sweaters, scarves, and hats, prioritize machines with advanced pattern capabilities, like our Double System Computerized Flat Knitting Machine.

Technical Textiles: For medical or automotive applications, choose machines with high precision and durability, such as our Whole Garment Flat Knitting Machine.

Home Textiles: For blankets and furnishings, opt for machines with larger knitting widths, like our Blanket Knitting Machine.

2. Production Scale

Small-Scale or Hobbyist: Manual or semi-automatic machines are cost-effective for low-volume production.

Large-Scale Manufacturing: Fully automatic, computerized machines like our Triple series are ideal for high-volume, efficient production.

3. Budget

Determine your budget and compare it with the long-term ROI. Changhua’s competitive pricing and high-quality machines ensure you get the best value without sacrificing performance.

4. Skill Level

Consider the expertise of your team. Our machines are user-friendly, with intuitive controls and comprehensive training to support beginners and seasoned operators alike.

Trends Shaping the Flat Knitting Machine Market in 2025

The flat knitting machine industry is undergoing significant changes, driven by technological advancements and market demands. Here are key trends to watch:

1. Fully Fashioned Knitting

Fully fashioned machines, like our Whole Garment Flat Knitting Machine, produce seamless garments, reducing waste and labor costs. This technology is gaining traction as manufacturers prioritize efficiency and sustainability.

2. Customization and Small-Batch Production

The fashion industry’s shift toward fast fashion and personalized designs has increased demand for machines that support small-batch production. Our computerized machines enable rapid customization to meet consumer preferences.

3. Sustainability and Eco-Friendly Practices

Seamless knitting and energy-efficient programming are critical for reducing environmental impact. Changhua’s machines are designed to minimize waste and energy consumption, aligning with global sustainability goals.

4. Expansion in Emerging Markets

Emerging economies like Bangladesh, Vietnam, and India are ramping up textile production, driving demand for flat knitting machines. Changhua’s global reach and competitive pricing make us a preferred choice in these markets.

5. AI and IoT Integration

Advanced machines with AI-driven automation and IoT connectivity are revolutionizing textile production. Our machines incorporate intelligent programming for real-time monitoring and adjustments, enhancing efficiency and quality.

Maintenance Tips for Flat Knitting Machines

To maximize the lifespan and performance of your flat knitting machine, follow these maintenance tips:

Regular Cleaning: Remove lint and debris after each use to prevent buildup.

Lubrication: Oil moving parts as recommended to reduce wear and tear.

Needle and Component Checks: Inspect needles and other components for damage to ensure consistent performance.

Software Updates: For computerized models, keep software updated to access the latest features and improvements.

Professional Servicing: Schedule regular maintenance with the manufacturer’s technical team to address any issues promptly.

Conclusion

Choosing the right flat knitting machine manufacturer in 2025 is a critical decision that impacts your production efficiency, product quality, and profitability. By prioritizing factors like reputation, technological innovation, and after-sales support, you can find a partner that meets your needs. Changhua stands out as a trusted leader, offering a diverse range of high-quality, sustainable, and customizable flat knitting machines backed by over 20 years of expertise.

Ready to elevate your textile production? Explore our machines at Changhua Flat Knitting Machine and  download our free PDF guide.pdf and video tutorial to learn more. Contact our team today for personalized recommendations and start your journey toward seamless, efficient, and innovative knitting solutions.

download our free PDF guide.pdf and video tutorial to learn more. Contact our team today for personalized recommendations and start your journey toward seamless, efficient, and innovative knitting solutions.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe