Investing in a flat knitting machine is a significant decision for textile manufacturers, small business owners, and even hobbyists looking to produce high-quality knitwear. Whether you're aiming to create school sweaters, fashion garments, or technical textiles, understanding the ins and outs of flat knitting machines is crucial to making an informed purchase. This comprehensive guide will walk you through everything you need to know before buying a flat knitting machine, from how they work and their applications to key factors like cost, features, and brand reliability. We'll also highlight why Changhua's flat knitting machines are a top choice for businesses worldwide, offering cutting-edge technology and exceptional support.

If you're new to flat knitting machines or looking to upgrade your equipment, this article will equip you with the knowledge to choose the right machine for your needs. Let's dive into the world of flat knitting and explore what makes these machines a game-changer in textile production.

What Is a Flat Knitting Machine?

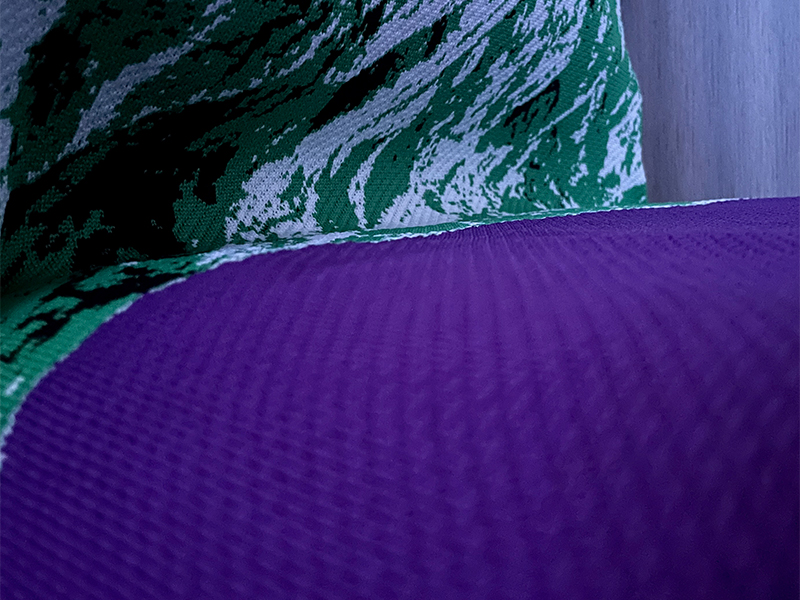

A flat knitting machine is a textile manufacturing device that creates flat, weft-knitted fabrics in sheet form. Unlike circular knitting machines, which produce tubular fabrics, flat knitting machines are ideal for creating garments and textiles with side seams, such as sweaters, scarves, collars, and technical textiles. These machines use a stationary needle bed and a moving carriage or cam system to form stitches, offering versatility in patterning, shaping, and fabric design.

Flat knitting machines come in various types, including manual, semi-automatic, and computerized models. They are widely used in industries like fashion, sportswear, automotive, and home furnishings, as well as by hobbyists who want to streamline their knitting projects. Their ability to produce intricate patterns, seamless garments, and 3D structures makes them a cornerstone of modern textile production.

Why Choose a Flat Knitting Machine?

Before diving into how to choose a flat knitting machine, let's explore why these machines are so popular across different applications. Understanding their benefits will help you determine if a flat knitting machine is right for you.

Versatility in Applications

Flat knitting machines are incredibly versatile, catering to a wide range of industries and creative needs:

Fashion Industry: From sweaters and cardigans to dresses and scarves, flat knitting machines produce high-quality garments with precise shaping and intricate patterns. They’re perfect for both mass production and custom designs.

Sportswear: These machines create stretchy, breathable fabrics for athletic wear, such as compression garments and seamless sportswear.

Automotive and Technical Textiles: Flat knitting machines are used to produce durable, patterned fabrics for car seats, upholstery, and medical textiles.

Home Furnishings: Think cozy blankets, cushions, and upholstery—flat knitting machines can handle it all.

Hobbyist Projects: For crafters, these machines speed up knitting projects, allowing you to create professional-quality items like hats, socks, and mittens.

Efficiency and Productivity

Compared to hand knitting, flat knitting machines save significant time and effort. They can produce complex patterns and large fabric pieces quickly, making them ideal for businesses looking to scale production. Even hobbyists benefit from the speed and consistency these machines offer.

Sustainability

Modern flat knitting machines, especially whole garment models, minimize material waste by knitting seamless items in a single process. This aligns with the growing demand for sustainable textile production, reducing the need for cutting and sewing.

Key Factors to Consider When Choosing a Flat Knitting Machine

Now that you understand the benefits and applications of flat knitting machines, let’s dive into the practical steps for choosing the right one. Here are the key factors to consider, tailored to your needs as a hobbyist, small business owner, or large manufacturer.

1. Determine Your Purpose and Skill Level

The first step is to clarify why you need a flat knitting machine and your experience level. Ask yourself:

What will you knit? Are you creating simple scarves, complex sweaters, or technical textiles? The complexity of your projects will influence the machine’s features.

What's your skill level? Beginners may prefer user-friendly manual or semi-automatic machines, while experienced knitters or businesses might opt for computerized models.

What's your production scale? Hobbyists need smaller, affordable machines, while manufacturers require high-capacity, industrial-grade models.

For example, a hobbyist might choose a manual machine like the Brother KX350, which is beginner-friendly and versatile for small projects. In contrast, a factory producing seamless sportswear would benefit from a computerized whole garment machine.

2. Manual vs. Computerized Machines

Flat knitting machines come in two main categories: manual and computerized. Each has its pros and cons, depending on your needs.

Manual Flat Knitting Machines

Pros: Affordable, easy to maintain, ideal for beginners and small-scale projects. They’re also great for learning the basics of machine knitting.

Cons: Limited in patterning capabilities and slower than computerized models. They require more manual input, which can be time-consuming for complex designs.

Best For: Hobbyists, small boutiques, or those on a budget.

Computerized Flat Knitting Machines

Pros: Highly efficient, capable of producing intricate patterns and seamless garments. They feature CAD software for design input, automated knitting, and minimal waste.

Cons: More expensive and require technical knowledge to operate and maintain.

Best For: Large manufacturers, fashion brands, and tech-savvy knitters.

3. Needle Bed Size and Knitting Width

The needle bed size determines the width of the fabric you can produce. Most flat knitting machines have 150–200 needles, offering a knitting width of 36–45 inches, suitable for most garments.

Ensure the needle bed size aligns with your project requirements. For example, a hobbyist knitting socks might not need a large bed, while a factory producing upholstery would benefit from a wider needle bed.

4. Patterning and Design Software

If you're creating intricate designs, look for machines with advanced patterning capabilities. Manual machines use punch cards or hand manipulation for patterns, while computerized machines use CAD software for precise, automated designs.

Punch Card Machines: Offer repeating patterns (e.g., 24-stitch repeats) and are affordable for small businesses.

Computerized Machines: Support complex, custom patterns via software, ideal for fashion and technical textiles.

Changhua's computerized machines integrate fast and intelligent programming, allowing you to upload designs via CAD software and produce high-quality, seamless garments with minimal setup time.

5. Durability and Build Quality

Invest in a machine made from durable materials, such as stainless steel needle beds, to ensure long-lasting performance. Plastic bed machines, while cheaper, may not withstand heavy use. Check for:

Material Quality: Metal beds are more robust than plastic ones.

Brand Reputation: Choose a manufacturer with a proven track record, like Changhua, known for high-quality, reliable machines.

Warranty and Support: Look for warranties of 1–3 years and access to technical support, spare parts, and training.

6. Ease of Use and Maintenance

A user-friendly machine saves time and frustration, especially for beginners. Consider:

Intuitive Controls: Computerized machines with touchscreens or simple software interfaces are easier to operate.

Maintenance Requirements: Manual machines require less maintenance than computerized ones, which may need software updates and periodic servicing.

Training Resources: Check if the manufacturer provides manuals, videos, or training sessions. Changhua, for example, offers 24/7 online support and comprehensive training for operators.

7. Sustainability Features

With sustainability being a priority in textiles, look for machines that support eco-friendly practices:

Whole Garment Technology: Knits seamless items, reducing fabric waste.

Energy Efficiency: Machines with low energy consumption lower operational costs.

Material Optimization: Precise knitting minimizes yarn waste.

Changhua's machines are designed with sustainability in mind, featuring energy-efficient programming and waste-free knitting processes.

8. After-Sales Support and Community

Choose a manufacturer that offers robust after-sales support, including:

Technical Assistance: 24/7 support via phone, email, or live chat.

Spare Parts Availability: Ensure parts like needles and cams are readily available.

Community Resources: Look for knitting machine clubs, online forums, or tutorials to connect with other users.

Changhua stands out with its highly responsive support team, ensuring fast delivery (15–30 days on average) and comprehensive training for all users.

Why Choose Changhua Flat Knitting Machines?

If you're looking for a reliable, innovative, and high-performance flat knitting machine, Changhua is a name you can trust. With over 20 years of experience, Changhua is a leading manufacturer of computerized and manual flat knitting machines in China, serving industries worldwide. Here's why Changhua stands out as the ideal choice for your knitting needs.

1. Industry-Leading Technology

Changhua's computerized flat knitting machines are equipped with cutting-edge features, including:

Whole Garment Technology: Produce seamless knitwear in a single process, ideal for fashion, sportswear, and medical textiles.

Fast Programming: Intelligent CAD software simplifies design input and enhances efficiency.

Energy Efficiency: Advanced programming reduces energy consumption, supporting sustainable production.

For example, Changhua's whole garment machines can knit a seamless sweater in minutes, minimizing waste and maximizing quality.

2. Wide Range of Products

Changhua offers a diverse portfolio of flat knitting machines to suit various needs:

Computerized Whole Garment Machines

Perfect for large-scale manufacturers producing seamless knitwear.

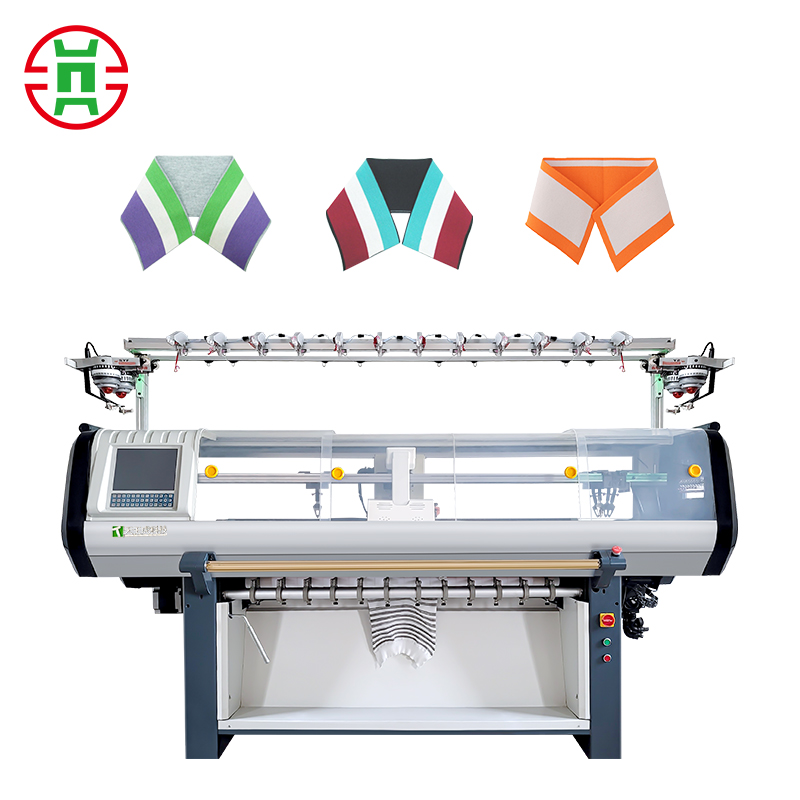

Flat Knit Collar Machines

Specialized for high-volume production of collars for T-shirts, polos, and sweaters.

Glove and Hosiery Machines

Versatile for producing accessories and technical textiles.

Versatile for producing accessories and technical textiles.

Whether you're a startup or an established brand, Changhua has a machine tailored to your production goals.

3. Unmatched Durability and Quality

Changhua machines are built with high-quality materials, such as stainless steel needle beds, ensuring long-lasting performance even under heavy use. Our rigorous quality control processes guarantee consistent, flawless results, from simple scarves to complex technical textiles.

4. Comprehensive Support and Resources

Changhua goes beyond selling machines—we provide exceptional support to ensure your success:

24/7 Technical Support: Highly responsive staff are available online to troubleshoot issues.

Training Programs: Comprehensive training for operators, from beginners to advanced users.

Free Resources: Downloadable PDF guides, video tutorials, and pattern books to help you get started.

5. Commitment to Sustainability

Changhua is dedicated to promoting sustainable textile production. Ourr machines are designed to:

Minimize material waste through seamless knitting.

Reduce energy consumption with efficient programming.

Support eco-friendly materials for green manufacturing.

By choosing Changhua, you're investing in a machine that aligns with the global push for sustainability.

6. Proven Track Record

With brands like “Changhua,” “Tiangong,” “King Tiger,” and “Miao’s Craftsman,” the company has built a reputation for excellence. Our 50,000-square-foot production facility in Changshu, Jiangsu, produces over 6,000 machines annually, serving clients worldwide. Whether you’re in fashion, automotive, or home furnishings, Changhua’s machines deliver unmatched performance.

Common Mistakes to Avoid When Choosing a Flat Knitting Machine

To ensure you make the right choice, here are some common pitfalls to avoid:

Buying a Used Machine Without Inspection

Used machines may have worn parts or limited support, leading to costly repairs. If buying used, choose a reputable seller and test the machine thoroughly.

Ignoring Gauge Compatibility

Using the wrong gauge for your yarn can result in poor-quality fabrics. Always match the machine’s gauge to your project needs.

Overlooking Maintenance Needs

Computerized machines require regular servicing, so factor in maintenance costs and availability of spare parts.

Choosing Based on Price Alone

A cheap machine may lack durability or features, costing you more in the long run. Invest in quality for better ROI.

Not Researching the Manufacturer

Stick with trusted brands like Changhua to ensure reliability, support, and access to resources.

Tips for Getting Started with Your Flat Knitting Machine

Once you've chosen your machine, here are some tips to hit the ground running:

Read the Manual

Familiarize yourself with the machine's features and settings.

Start Simple

Begin with basic projects like scarves or swatches to practice techniques.

Join a Community

Connect with knitting machine clubs or online forums like Ravelry for tips and inspiration.

Experiment with Yarns

Test different yarns to understand how they interact with your machine's gauge.

Leverage Tutorials

Watch Changhua's video tutorials or download our PDF guides for step-by-step instructions.

Conclusion

Choosing a flat knitting machine is a significant decision that can transform your knitting projects, whether you're a hobbyist, small business, or large manufacturer. By considering factors like purpose, gauge, needle bed size, and sustainability features, you can find a machine that meets your needs and budget. Changhua's innovative, high-quality flat knitting machines stand out as an excellent choice, offering cutting-edge technology, durability, and exceptional support.

Ready to take the next step? Explore Changhua's range of flat knitting machines at https://www.changhua-knitting-machine.com/ and download  our free PDF guide.pdf to learn more. With Changhua, you're not just buying a machine—you're investing in a partnership that will help you achieve your knitting goals.

our free PDF guide.pdf to learn more. With Changhua, you're not just buying a machine—you're investing in a partnership that will help you achieve your knitting goals.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe