The rhythmic, predictable hum of your collar knitting machine is the sound of productivity and profit. But what happens when that sound is replaced by an alarming clunk, an error code flashing on the screen, or worse—complete silence? A breakdown doesn't just mean a stopped machine; it means delayed orders, wasted materials, frustrated operators, and a direct hit to your bottom line.

In the high-speed world of textile manufacturing, every minute of downtime is costly. This comprehensive guide is designed to be your first line of defense. We will walk you through a systematic exclusion guide to diagnose and potentially fix common issues with your collar knitting machine. We'll start with the simplest solutions before moving to more complex mechanical or electronic faults.

Furthermore, we will explore a scenario where constant breakdowns are a sign of a deeper issue: an aging or inefficient machine. For those looking for a permanent solution to reliability and performance, we will introduce you to the world of Changhua Knitting Machine and our industry-leading Changhua Jacquard Computerized Flat Knitting Machines, engineered for unparalleled durability and efficiency.

Understanding Your Collar Knitting Machine - The Basics

Before we dive into troubleshooting, it's crucial to have a basic understanding of the core components of a computerized collar knitting machine. Knowing the "what" and "why" makes the "how to fix" much clearer.

Key Components and Their Functions

The Needle Bed: The foundation of the machine, featuring channels where the needles slide up and down to form loops

Needles (Tongue Needles): The workhorses that hold the yarn and create the stitches. Wear and tear on needles are a common cause of faults.

Sinkers: These elements hold down the old loops while the needles rise to form new ones, ensuring stitch formation is precise

Carriage (or System): The moving unit that houses the cams. It drives the needles into action as it passes over the needle bed. Machines can have single or multiple systems for higher speed.

Yarn Feeders/Carriers: Guide the yarn from the cone to the needles, often equipped with tensioners and sensors to detect breaks.

Take-Down Mechanism: A critical system that pulls the knitted fabric downward with consistent tension, determining the final quality and dimensions of the collar.

Control Computer & Sensors: The brain of the machine. It runs the knitting program and monitors various sensors (yarn breakage, lack of fabric, over-temperature) to stop the machine automatically if a problem is detected.

What to Do When Your Collar Knitting Machine Breaks Down ?

If your collar knitting machine stops working, don’t worry—here’s a simple guide to get you started:

Initial Checks

Power Supply:

Make sure the machine is plugged in and turned on. Check if there’s a power outage or if the outlet works.

Error Indicators:

Look for any lights or messages on the machine. These can tell you what’s wrong, so check the user manual for explanations.

Inspect the Machine

Yarn and Feed:

Ensure the yarn isn’t tangled and the tension is set correctly.

Needles and Bed:

Look for bent or damaged needles and make sure the machine bed is clean and free of debris.

User Manual

Every machine has a manual with specific troubleshooting tips. Look there for model-specific advice.

Manufacturer Support

If the problem persists, contact the manufacturer’s customer support for expert help or repair services.

Replacement Option

If the machine is old or repairs are too expensive, consider buying a new one for long-term savings.

Did your Collar Knitting Machine know it Breaks Down Common Issues?

Common problems include dropped stitches, yarn breaking, and the carriage being hard to push, often due to simple fixes like cleaning or adjusting tension.

Detailed Survey Note: Comprehensive Guide to Handling Collar Knitting Machine Breakdowns

This section provides an in-depth exploration of the steps and considerations for addressing a breakdown in a collar knitting machine, ensuring a thorough understanding for both novice and experienced users. Collar knitting machines, specialized flat knitting machines used for creating garment collars, can encounter various issues, and this guide leverages extensive research to offer a complete solution pathway.

Collar knitting machines are a subset of flat knitting machines, designed specifically for producing collars with precise shapes and stitch patterns. The breakdown of such a machine can disrupt production, whether for personal projects or small-scale manufacturing. Given their specialized nature, troubleshooting requires a systematic approach, drawing from general knitting machine repair knowledge and specific user experiences.

Initial research involved understanding the nature of collar knitting machines through searches like "what is a collar knitting machine," revealing they are typically flat knitting machines with features for collar production. Further, searches for "troubleshoot collar knitting machine" and related queries highlighted that specific troubleshooting guides for collar machines are scarce, suggesting general knitting machine troubleshooting applies, as seen in resources like The Knitting Closet.

Step-by-Step Troubleshooting Process

The following steps are derived from a combination of general machine troubleshooting principles and specific insights from knitting machine repair resources:

Power Supply Verification

Begin by ensuring the machine is plugged into a functioning outlet and the power switch is activated. This step addresses basic electrical issues, a common initial check for any electronic device. Searches confirmed the importance of this step, with no specific collar machine deviations noted.

Error Indicator Analysis

Many modern knitting machines, including collar types, feature error lights or display messages. These indicators can signal issues like motor failure or sensor problems. The user manual, often provided by manufacturers like those listed in searches for "collar knitting machine manufacturers" (Collar Knitting Machine Manufacturers & Suppliers in china), is crucial here. For example, Changhua Flat knitting Machine mentions automatic stop and alarm features, suggesting error indicators are standard.

Introducing Changhua: Your Partner in Reliable Knitting Solutions

For over two decades, Changhua Knitting Machine has been at the forefront of designing and manufacturing high-performance computerized flat knitting machines. We understand the critical need for reliability in a production environment. Our philosophy is simple: build machines that are robust, user-friendly, and technologically advanced to maximize your uptime and return on investment.

When you choose a Changhua Jacquard Computerized Flat Knitting Machine, you are choosing peace of mind. Our machines are engineered with durability as a core principle, using high-grade materials and precision manufacturing to withstand the demands of 24/7 production cycles.

**Ready to move from constant repairs to uninterrupted production? Explore our full range of solutions on our official website.

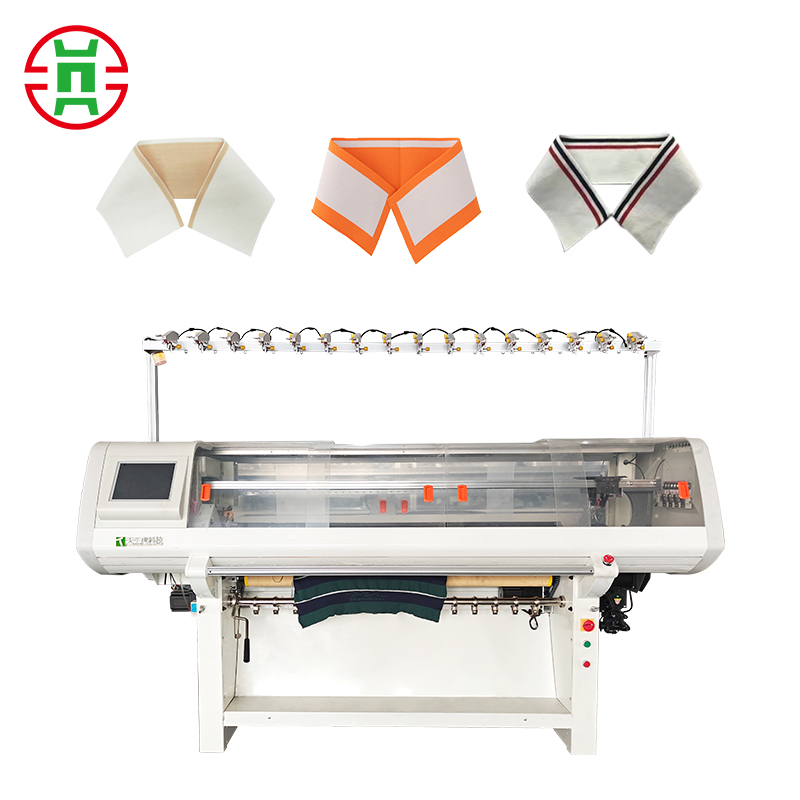

A Closer Look at Our Collar Knitting Powerhouses

Our specialization extends to high-efficiency collar knitting machines. Let's examine one of our flagship models designed specifically for this purpose.

The Changhua 68-Inch Double System Collar Knitting Machine

Key Features that Directly Prevent Breakdowns:

Dual-System Design: Two independent knitting systems double the production speed compared to single-system machines. But more importantly for reliability, the robust carriage drive system is engineered for smooth, vibration-free operation at high speeds, reducing mechanical stress.

Advanced Take-Down System: It features a servo-motor-controlled take-down mechanism that provides exceptionally precise and consistent tension. This eliminates common issues like curling or dimensional instability in the final collar and prevents errors related to fabric pull.

Intelligent Yarn Feeding: Equipped with highly sensitive yarn breakage detectors and precision tensioners, it minimizes stoppages due to yarn faults and ensures perfect stitch formation every time.

User-Friendly Control System: The intuitive computer interface allows for easy programming and provides clear, detailed error messages, drastically reducing diagnostic time when an issue does occur.

What does this mean for your factory floor? It means you can schedule production with confidence, knowing your machine will run when you need it to.

The Tangible Advantages of Choosing a Changhua Machine

Investing in a Changhua machine is not just about buying hardware; it's about acquiring a competitive advantage. Here’s how we deliver value beyond the initial sale.

1. Unmatched Reliability and Durability

We use hardened steel for critical components like needle beds and cams, and high-quality Japanese and German bearings in our drive systems. This commitment to quality ensures our machines deliver years of trouble-free operation, even under the most demanding conditions. Say goodbye to the frustration of weekly breakdowns.

2. Superior Knitting Quality and Versatility

Our machines are capable of producing a wide range of patterns, including plain jacquard, tie jacquard, intarsia, and plush fabrics. Whether you are knitting simple ribbed cuffs or complex fashion collars, Changhua Jacquard Computerized Flat Knitting Machines deliver consistent, high-quality results that meet the standards of global brands.

3. Exceptional After-Sales Support and Training

We believe the relationship starts after the purchase. Our global support network includes:

Comprehensive Installation and Training: We ensure your operators are fully trained to use the machine efficiently.

Readily Available Spare Parts: We maintain a large inventory of genuine spare parts to ensure minimal downtime in the rare event a replacement is needed.

Remote Technical Support: Our engineers can often diagnose and guide you through issues via remote connection, saving time and cost.

4. Energy Efficiency and Cost Savings

Modern Changhua machines are designed with energy-saving servo motors and efficient control systems, reducing your power consumption by up to 30% compared to older models. This lower operational cost directly improves your profit margins.

Conclusion: From Reactive Repairs to Proactive Production

A breakdown is a temporary setback, but a pattern of breakdowns is a strategic threat. This exclusion guide empowers you to solve immediate problems, but it also highlights a critical business decision: continue pouring money into an aging asset or invest in a modern solution that guarantees productivity and growth.

At Changhua, we provide more than just machines; we provide the reliability and technological edge that successful knitwear manufacturers depend on.

Don't let another breakdown dictate your production schedule. Take control of your factory's future.

Your Next Step: Request a Personalized Consultation

The best solution for your factory depends on your specific products, volume, and goals. Our technical experts are ready to provide a free, no-obligation consultation to help you analyze your needs and recommend the perfect Changhua Knitting Machine for your business.

Contact us today to request a quote, schedule a live video demonstration, or simply ask a question. Let's discuss how we can help you eliminate downtime and boost your profitability.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe