Are you in the market for a high-quality digital knitting machine that can revolutionize your textile production? Whether you’re a small business owner looking to scale up or a large manufacturer aiming to optimize efficiency, China offers some of the most advanced and affordable options available today. In this comprehensive guide, we’ll explore everything you need to know about digital knitting machines for sale in China, from their basic mechanics to the latest innovations. We’ll dive deep into what makes these machines indispensable in modern garment manufacturing, and highlight top choices that deliver exceptional value. If you’re searching for terms like “Changhua” or “Changhua computerized flat knitting machine”, you’re in the right place—we’ll showcase why our company, Changhua, stands out as a leader in this field.You can download our comprehensive PDF guide on the  Changhua flat knitting machine and

Changhua flat knitting machine and  one stop programmesto help you make an informed decision.

one stop programmesto help you make an informed decision.

What Is a Digital Knitting Machine?

Let’s start from the basics. A digital knitting machine, often referred to as a computerized knitting machine, is an automated device that uses computer-controlled systems to produce knitted fabrics with precision and speed. Unlike traditional manual knitting tools, these machines integrate software for pattern design, yarn management, and stitch control, allowing for complex designs that would be time-consuming or impossible by hand.

Digital knitting machines come in various forms, but the most popular in China are flat knitting machines. These operate on a flat bed where needles move horizontally to create flat panels of fabric. The “digital” aspect refers to the integration of CAD (Computer-Aided Design) software, which enables users to input designs digitally and have the machine execute them flawlessly. This technology has roots in the industrial revolution but has evolved dramatically with advancements in electronics and AI.

For example, imagine designing a sweater with intricate jacquard patterns. With a digital knitting machine, you can program the pattern, select yarns, and let the machine handle the rest. This not only saves time but also reduces waste, making it a sustainable choice for eco-conscious manufacturers. In China, where the textile industry is a powerhouse, these machines are produced at scale, offering competitive pricing without compromising quality.

The Evolution of Knitting Machines in China

China’s knitting machine industry has grown exponentially over the past few decades, driven by the country’s dominance in global textile exports. From simple mechanical models in the 1980s to today’s fully computerized systems, the evolution has been marked by innovation and cost-efficiency. Today, China produces over 70% of the world’s knitting machines, with manufacturers focusing on digital integration to meet international standards.

Key milestones include the introduction of computerized flat knitting in the early 2000s, which allowed for seamless garment production. Brands like Shima Seiki from Japan set the benchmark, but Chinese companies quickly caught up, offering similar features at lower costs. Now, in 2025, digital knitting machines incorporate AI for predictive maintenance, IoT for remote monitoring, and energy-efficient motors to reduce operational costs.

If you’re a buyer, understanding this evolution helps you appreciate why Chinese machines are so sought after. They’re not just affordable; they’re built with robust materials and advanced tech, ensuring longevity and high output. For instance, many models now support 3D knitting, enabling the creation of shaped garments without seams, which is perfect for sportswear or medical textiles.

Types of Digital Knitting Machines Available for Sale in China

When searching for “China digital knitting machine for sale,” you’ll encounter a variety of types tailored to different applications. Here’s a breakdown to help you choose the right one:

Flat Knitting Machines

These are the workhorses of the industry, ideal for producing flat fabrics like sweaters, scarves, and collars. They feature a single or double bed of needles and can handle multiple yarns for colorful patterns.

Circular Knitting Machines

Better suited for tubular fabrics like socks or seamless t-shirts, these machines knit in a continuous circle. Digital versions allow for precise diameter control and pattern variations.

Whole Garment Knitting Machines

A subset of flat machines, these produce entire garments in one piece, minimizing assembly time. They’re gaining popularity for sustainable production.

Specialized Machines

Include collar knitting machines for precise ribbed edges or shoe upper machines for footwear components. In China, you can find these from various suppliers, but quality varies—always check for certifications like CE or ISO.

Video: Watch this short demo video on how a digital flat knitting machine operates, featuring high-speed knitting and pattern switching. Embedded from YouTube:

Key Features to Look for in a Digital Knitting Machine

Not all digital knitting machines are created equal. When browsing options for sale in China, prioritize these features:

Gauge and Width: Gauge (needles per inch) determines fabric fineness—finer gauges for delicate knits, coarser for bulky items. Bed width affects production scale; wider beds like 80 inches allow for larger pieces.

Computerized Controls: Look for user-friendly interfaces with touchscreen displays and software compatibility for design imports.

Speed and Efficiency: Machines with servo motors can reach speeds of 1.2-1.5 m/s, boosting output.

Yarn Management: Automatic yarn changers and tension controls prevent breaks and ensure even fabric.

Durability: High-precision parts like needle beds and cams should be made from hardened steel for longevity.

Additionally, consider energy consumption—modern models use up to 30% less power, aligning with global sustainability goals.

Benefits of Buying a Digital Knitting Machine from China

Why opt for a Chinese digital knitting machine? The advantages are compelling:

Cost-Effectiveness

Chinese manufacturers offer machines at 40-60% lower prices than European or Japanese counterparts, without sacrificing quality. This makes them accessible for startups and established factories alike.

Customization Options

Many suppliers provide OEM services, allowing you to tailor machines to your needs, such as adding extra feeders or specialized cams.

Rapid Delivery and Support

With vast production capacity, lead times are short—often 15-30 days. Plus, 24/7 online support is standard.

Innovation Hub

China leads in R&D, incorporating AI and smart tech faster than elsewhere. For example, machines now feature predictive analytics to foresee maintenance needs, reducing downtime.

From a reader’s perspective, if you’re tired of manual processes eating into your profits, switching to a digital machine could double your output while halving labor costs. Imagine producing custom orders on demand— that’s the power of these machines.

[PDF:  Download our free guide on “Selecting the Right Digital Knitting Machine” for detailed comparisons and checklists.

Download our free guide on “Selecting the Right Digital Knitting Machine” for detailed comparisons and checklists.

Common Applications of Digital Knitting Machines

Digital knitting machines are versatile, serving multiple industries:

Fashion and Apparel: For sweaters, cardigans, and hats with complex patterns.

Footwear: Shoe uppers with breathable, flexible knits.

Accessories: Scarves, gloves, and collars requiring precise edges.

Technical Textiles: Medical bandages or automotive interiors needing durability.

In China, these machines support the export market, producing goods for brands worldwide. If your business involves any of these, investing in one could be a game-changer.

How to Choose the Best Digital Knitting Machine Supplier in China

Selecting a supplier is crucial. Look for:

Experience: Over 20 years is ideal for proven reliability.

Certifications: Ensure compliance with international standards.

Customer Reviews: Check platforms like Alibaba or Made-in-China for feedback.

After-Sales Service: Comprehensive training and parts supply are must-haves.

This brings us to our recommendation: Changhua. As a leading manufacturer, we embody these qualities and more.

Why Choose Changhua as Your Digital Knitting Machine Supplier?

If you’re serious about upgrading your production, look no further than Changhua. Located in Changshu, Jiangsu—the heart of China’s clothing industry—Changhua Smart Manufacturing Technology Co., Ltd. has over 20 years of experience in developing high-quality knitting machinery. Our mission is to drive innovation and modernize the knitting industry through superior products and service.

We produce under brands like “Changhua,” “Tiangong,” “King Tiger,” and “Miao’s Craftsman,” focusing on flat, glove, and hosiery machines. What sets us apart? Our commitment to quality, reputation, and customer success. We’ve exported to over 30+ countries (as per our stats), with a massive factory spanning and an annual output

Visit our official website at https://www.changhua-knitting-machine.com/ to explore our full range. There, you’ll find detailed product catalogs, blog insights, and contact options to consult our experts. Ready to see how we can tailor a solution for you? Let’s discuss your needs.

Our Top Digital Knitting Machines: Detailed Reviews

At Changhua, our digital knitting machines (or 昌华电脑横机) are engineered for precision, efficiency, and durability. Here are some standout models, each with links to full specs.

60-Inch Simple Double System Sweater Knitting Machine

Perfect for sweater production, this machine features a 60-inch bed width and double system for enhanced speed. It supports gauges from 3-16, allowing for versatile fabric types. Key specs include servo-driven carriages, automatic yarn feeders, and a touchscreen interface for easy programming.

Advantages: High output for small-batch production, energy-efficient design reducing consumption by up to 20%, and robust construction for 24/7 operation. Our customers love its reliability in creating plain, ribbed, or jacquard sweaters.

Learn more at: https://www.changhua-knitting-machine.com/60-inch-simple-double-system-sweater-knitting-machine.html

If this sounds like the boost your sweater line needs, why not request a customized quote today?

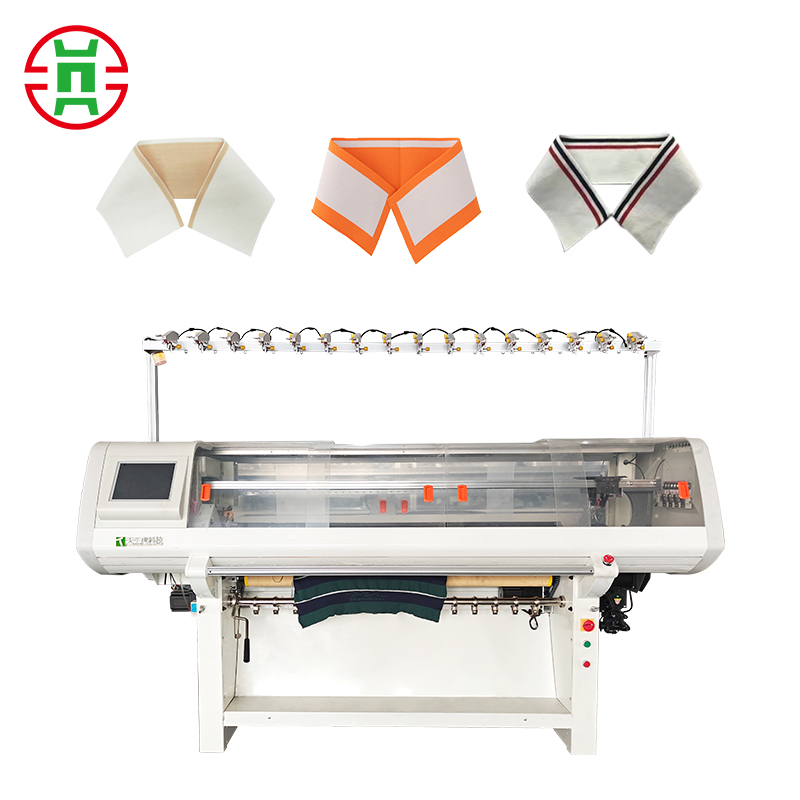

80-Inch Single System Collar Knitting Machine

Designed specifically for collars and ribs, this 80-inch model excels in precision. It addresses common issues like uneven edges and poor flatness through superior engineering in bed-base, guide rails, and cams. The single system ensures straightforward operation while maintaining high quality.

Features: Computerized jacquard for clear fabric grains, fast setup for plain knitting, and compatibility with various yarns.

Our advantage: This machine enables high-quality output with minimal adjustments, saving time and reducing defects. It’s cost-effective, with quick ROI through increased efficiency.

Details here: https://www.changhua-knitting-machine.com/80-inch-single-system-collar-knitting-machine.html

80-Inch Shoe Upper Knitting Machine

For footwear manufacturers, this machine is a must-have. With an 80-inch width, it produces seamless shoe uppers with 3D structures, breathable patterns, and multi-material support.

Specs: Advanced digital controls for intricate designs, high-speed knitting at 1.2 m/s, and sustainable features like low waste generation.

Why ours? It offers unparalleled versatility for custom shoe designs, helping you stay ahead in the competitive footwear market. Plus, our sustainability focus means lower environmental impact.

Explore: https://www.changhua-knitting-machine.com/80-inch-shoe-upper-knitting-machine.html

Advantages of Our Changhua Digital Knitting Machines

What makes our machines superior? Here’s a deep dive into the benefits, backed by our 20+ years of expertise:

Cost-Effective Performance

Our machines deliver the same functions as premium brands but at better costs. Fast, intelligent programming enhances efficiency, lowering energy use and operational expenses. For instance, customers report 30% savings in production costs.

Sustainability Focus

We prioritize eco-friendly designs, contributing to societal sustainability through reduced material waste and energy-efficient operations. Our whole garment models cut waste by 30%, aligning with green manufacturing trends.

Consistent Quality and Durability

Built with precision parts, our products offer long-lasting stability. High-quality cams and needle beds ensure clear fabric grains and even edges, solving common knitting problems.

Quick Response and Support

With 24/7 online technical staff and average delivery in 15-30 days, we minimize downtime. Our service includes comprehensive training and long-term parts supply.

Flexible Production

Ideal for multi-mix, small-batch runs, our machines support diverse orders without major retooling.

Innovation-Driven

Incorporating AI and IoT, our digital systems predict issues and optimize patterns, boosting productivity by up to 90% in some cases.

Future Trends in Digital Knitting Technology

Looking ahead, expect more AI integration, 4D knitting for adaptive fabrics, and blockchain for supply chain transparency. At Changhua, we’re already investing in these.

Maintenance Tips for Your Digital Knitting Machine

To maximize lifespan, regular maintenance is key. Clean needle beds daily, lubricate moving parts weekly, and update software monthly. Our machines come with easy-access designs for quick servicing.

How to Purchase a Changhua Digital Knitting Machine

Ready to buy? Visit https://www.changhua-knitting-machine.com/, browse models, and consult our experts. We offer flexible payment and shipping worldwide.

If this article has sparked your interest, why not reach out for a free consultation? Let’s knit your success story together.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe