The textile industry is a cornerstone of global manufacturing, and at its heart lies the innovation of specialized machinery like collar knitting machines. These machines are pivotal in producing high-quality, consistent, and aesthetically pleasing collars for garments such as polo shirts, sweaters, and t-shirts. As a leading hub for textile machinery, China has emerged as a global leader in manufacturing collar knitting machines, combining cutting-edge technology with cost-effective production. This article explores the world of collar knitting machines, their applications, and why Changhua, a top-tier China-based manufacturer, stands out in delivering state-of-the-art solutions for garment production.

What Are Collar Knitting Machines?

Collar knitting machines are specialized textile equipment designed to produce collars, cuffs, and ribs for various garments. Unlike general-purpose knitting machines, these devices are engineered for precision, focusing on creating seamless, stretchable, and durable collars that enhance the aesthetic and functional value of clothing. Available in both manual and computerized versions, these machines cater to diverse production needs, from small-scale artisanal workshops to large-scale industrial operations.

The primary function of a collar knitting machine is to automate the knitting process, ensuring uniformity in stitch density, collar shape, and fabric texture. Modern machines, particularly those from leading manufacturers like Changhua, incorporate advanced computerized controls, allowing for intricate patterns, high-speed production, and minimal material waste.

Why Are Collar Knitting Machines Essential?

Collars are more than just a design element; they define the look and feel of a garment. A poorly made collar can compromise the overall quality of a shirt or sweater, affecting brand reputation and customer satisfaction. Collar knitting machines address this challenge by delivering:

Consistency

Uniform stitches and precise dimensions across every collar.

Versatility

Ability to work with various materials like cotton, polyester, wool, and blends.

Customization

Support for complex patterns, including jacquard, ribbed, and plain designs.

Applications of Collar Knitting Machines

Collar knitting machines are versatile tools with applications across multiple sectors. Below, we explore their primary uses and the industries they serve.

Apparel Manufacturing

The most prominent application of collar knitting machines is in apparel manufacturing. These machines are used to produce collars for:

Polo Shirts: Crisp, structured collars that maintain shape and elasticity.

Sweaters: Soft, stretchable collars that complement cozy knitwear.

T-Shirts: Durable, ribbed collars that withstand repeated wear and washing.

Jackets and Outerwear: Stand-up or rolled collars for added style and functionality.

By automating collar production, these machines enable manufacturers to scale operations, reduce labor costs, and maintain high-quality standards.

Fashion Design and Customization

In the fashion industry, customization is key to standing out. Collar knitting machines, especially computerized models, allow designers to experiment with intricate patterns, textures, and colors. From elegant geometric designs to playful cartoon motifs, these machines support limitless creative possibilities, making them ideal for high-end fashion brands and bespoke garment producers.

Education and Training

Collar knitting machines are also used in vocational training centers and fashion design schools. These machines serve as teaching tools, helping students master knitting techniques, understand machine operations, and develop skills in collar design and production. Their user-friendly interfaces and automated features make them suitable for beginners and experienced operators alike.

The Advantages of Choosing Chinese Collar Knitting Machines

China has solidified its position as a global leader in textile machinery manufacturing, and collar knitting machines are no exception. Here’s why Chinese manufacturers, like Changhua, are the preferred choice for businesses worldwide:

Cost-Effectiveness

Chinese manufacturers offer competitive pricing without compromising quality, making it easier for businesses to invest in advanced machinery.

Technological Innovation

Companies like Changhua integrate cutting-edge technologies, such as digital controls and automated yarn feeding, to enhance machine performance.

Global Reach

Chinese manufacturers have established sales networks across regions like Southeast Asia, Europe, and North America, ensuring reliable support and spare parts availability.

Customization Options

Machines can be tailored to specific production needs, from knitting width to gauge and system capabilities.

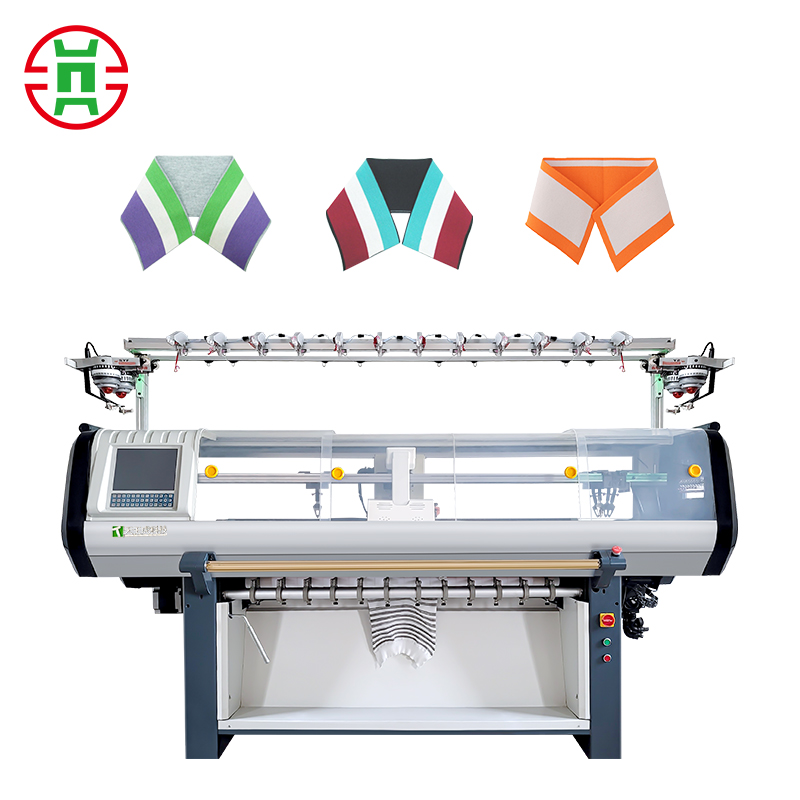

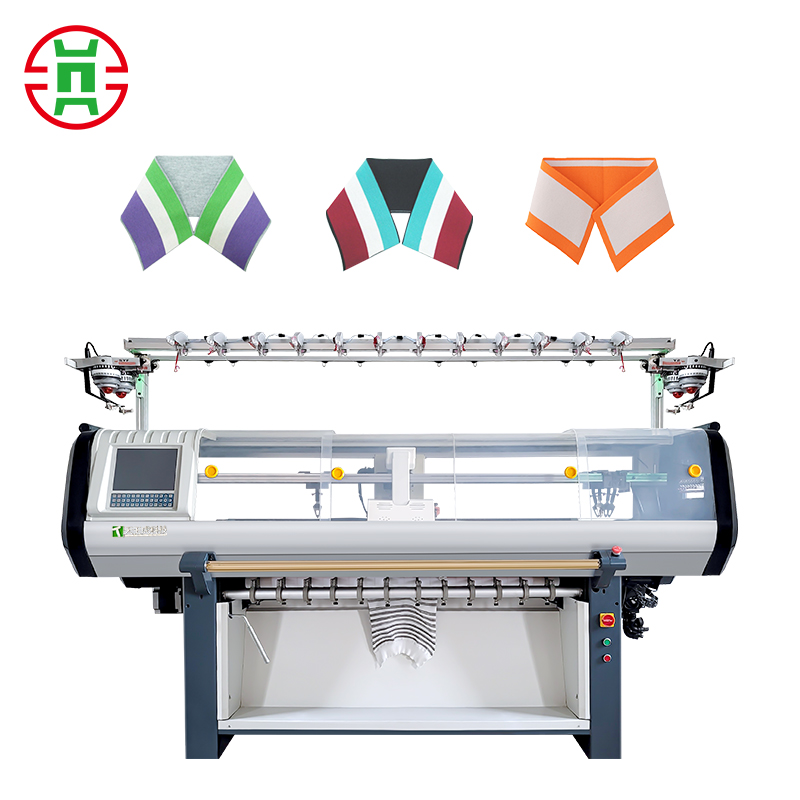

Introducing Changhua: A Leader in Collar Knitting Machines

When it comes to collar knitting machines, Changhua Smart Manufacturing Technology Co., Ltd. stands out as one of China's top five manufacturers. Based in Changshu, Jiangsu, the birthplace of the clothing industry, Changhua has over 20 years of experience in producing high-quality textile machinery. Their collar knitting machines are renowned for precision, efficiency, and versatility, making them a trusted choice for manufacturers worldwide.

Why Choose Changhua's Collar Knitting Machines?

Precision Engineering

Changhua's machines are built with meticulous attention to detail, addressing common issues like unclear fabric grain, uneven collar edges, and insufficient flatness. Through precise engineering of components like the bed-base, guide rail, needle-bed, cam-board, and cams, Changhua ensures flawless collar production. Their machines guarantee:

Uniform stitches and consistent collar dimensions.

High-quality plain-knitting collars using computerized jacquard technology.

Support for intricate patterns like double jersey, air layer, and jacquard.

Advanced Automation

Changhua’s collar knitting machines are equipped with state-of-the-art computerized controls, enabling manufacturers to:

Automate pattern creation and adjustments.

Monitor performance in real-time.

Reduce manual intervention, minimizing errors and labor costs.

For example, their fully automatic collar knitting machines feature digital technology for functions like transfer, tuck, and full jacquard, ensuring high-speed production and efficiency.

Versatility in Design

From simple plain stitches to complex jacquard patterns, Changhua’s machines support a wide range of collar styles and materials. Whether you’re producing ribbed collars for polo shirts or elegant geometric textures for sweaters, these machines deliver unmatched flexibility.

Durability and Longevity

Built with high-quality materials, Changhua’s machines are designed for durability and minimal maintenance. Features like automatic needle plate oiling reduce wear and tear, extending the machine’s service life and ensuring consistent performance.

Global Support and Accessibility

Changhua has established a robust sales network across China, India, Bangladesh, Mexico, Southeast Asia, the Middle East, Europe, and the United States. Their comprehensive after-sales services include installation, training, and maintenance, ensuring customers receive ongoing support.

Changhua's Product Range

Changhua offers a variety of collar knitting machines to suit different production needs, including:

100-Inch Three System Collar Knitting Machine

Ideal for large-scale production, this machine supports intricate patterns and high-volume output. It’s perfect for manufacturers producing collars for shirts, jackets, and sweaters.

80-Inch Single System Collar Knitting Machine

Designed for flexibility, this model is suitable for smaller operations or businesses focusing on customized designs.

Semi-Automatic Collar knitting Machines

Perfect for businesses seeking a balance between automation and manual control, these machines offer precision and ease of use for skilled operators.

How to Choose the Right Collar Knitting Machine

Selecting the perfect collar knitting machine for your business requires careful consideration of several factors:

Production Capacity

Determine your required output. For high-volume production, opt for fully automatic machines like Changhua's double system models. For smaller operations, a single system or semi-automatic machine may suffice.

Collar Styles and Materials

Ensure the machine supports the collar styles and materials you plan to use. Changhua's machines, for instance, handle a wide range of yarns and patterns, from cotton ribbed collars to wool jacquard designs.

Automation Level

Computerized machines offer greater automation and precision, reducing labor costs and errors. Changhua’s advanced control systems make pattern adjustments and monitoring seamless.

Budget and ROI

While the initial investment in a high-quality machine may be significant, the long-term savings from reduced labor, material waste, and increased efficiency make it worthwhile. Changhua’s machines are priced competitively, offering excellent value for money.

After-Sales Support

Choose a manufacturer with reliable after-sales services. Changhua provides comprehensive support, including installation, training, and spare parts availability, ensuring minimal downtime.

Why Invest in a Collar Knitting Machine from Changhua?

Proven Track Record

As one of China's top five manufacturers, Changhua has a reputation for delivering reliable and innovative machinery.

Tailored Solutions

Their machines cater to diverse production needs, from small-scale to industrial operations.

Global Support

With a presence in multiple countries, Changhua ensures customers receive timely support and services.

Competitive Pricing

High-quality machines at affordable prices, maximizing your return on investment.

The Future of Collar Knitting Machines

The textile industry is evolving rapidly, driven by trends like sustainability, automation, and customization. Collar knitting machines are at the forefront of this transformation, with innovations like:

Eco-Friendly Designs

Machines that optimize material usage and reduce energy consumption, aligning with the demand for sustainable production.

Smart Technology

Integration with IoT and AI for real-time monitoring and predictive maintenance.

3D Knitting

Emerging technologies that enable seamless, three-dimensional collar designs, reducing the need for additional stitching.

Conclusion

Collar knitting machines are revolutionizing the textile industry by offering precision, efficiency, and versatility. As a global leader in textile machinery, China continues to set the standard with innovative solutions from manufacturers like Changhua. By investing in a Changhua collar knitting machine, businesses can streamline production, enhance product quality, and stay ahead in a competitive market. Whether you're producing polo shirts, sweaters, or custom fashion pieces, Changhua's machines are your gateway to success in garment manufacturing.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe