The textile industry is in the midst of a technological revolution, with automatic knitting machines leading the charge in transforming how fabrics and garments are produced. These advanced systems offer unmatched efficiency, precision, and versatility, making them a must-have for manufacturers, designers, and businesses looking to stay competitive. For those exploring the market, understanding automatic knitting machine prices and their value is critical. This comprehensive guide dives deep into the technology, applications, and why Changhua's computerized flat knitting machines, available at our product page, are the top choice for modern textile production. From detailed insights into our machines to practical tips for buyers, this article is designed to answer all your questions from a user's perspective.

Understanding Automatic Knitting Machines

Automatic knitting machines are sophisticated devices that automate the knitting process, producing high-quality fabrics with minimal human intervention. Unlike traditional manual knitting, which is labor-intensive and time-consuming, our machines leverage advanced computer systems to execute complex patterns, ensuring precision and consistency. These machines are widely used across industries, from fashion to technical textiles, and are essential for scaling production while maintaining quality.

What Makes Automatic Knitting Machines Essential?

High Precision: Computerized controls ensure flawless stitch formation and intricate designs.

Speed and Efficiency: Our machines produce garments up to 10 times faster than manual methods.

Versatility: Capable of creating everything from sweaters to seamless shoe uppers.

Sustainability: Advanced designs minimize yarn waste and energy consumption.

At Changhua, our computerized flat knitting machines embody these qualities, offering cutting-edge solutions for businesses of all sizes.

Key Applications of Automatic Knitting Machines

Automatic knitting machines have transformed various sectors by enabling rapid, high-quality production. Below, we explore their primary applications:

Fashion and Apparel

The fashion industry relies heavily on automatic knitting machines to meet consumer demand for stylish, high-quality garments. Key applications include:

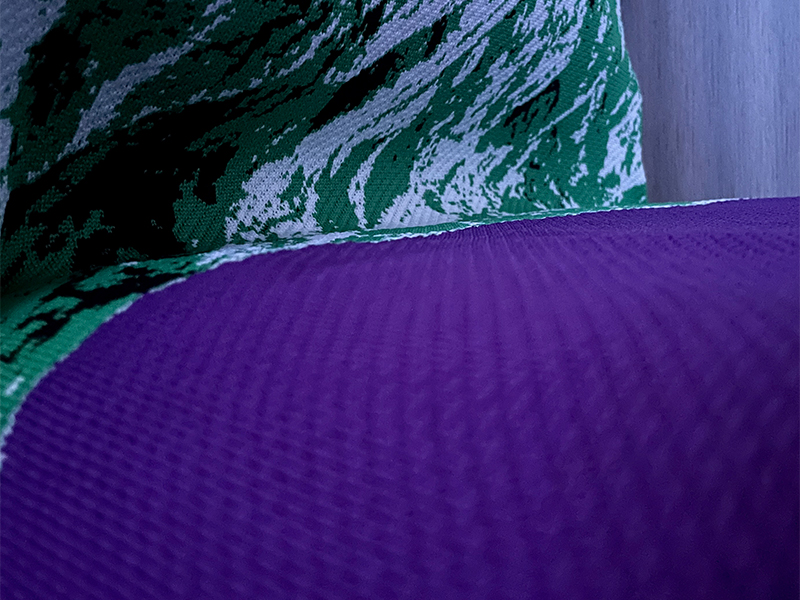

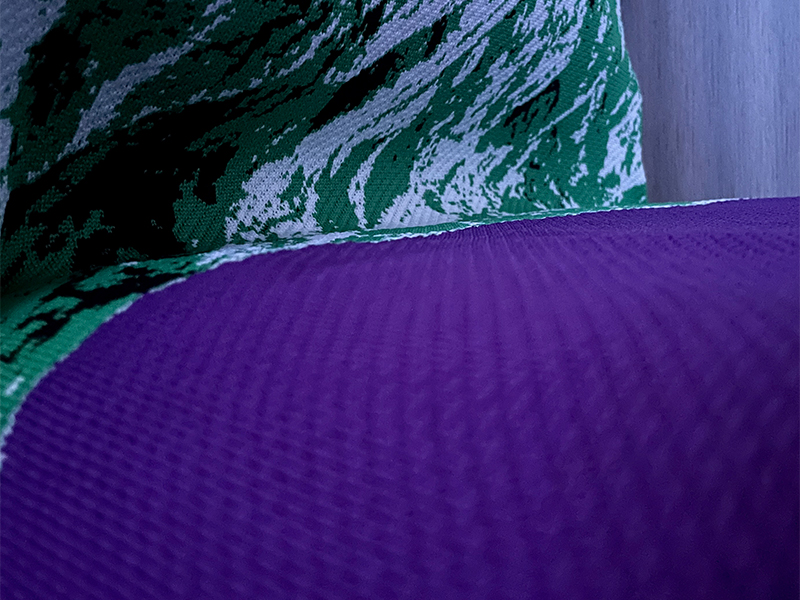

Sweaters and Cardigans: Our machines create seamless, intricate designs for luxury and casual wear.

Scarves, Hats, and Gloves: Fast production of accessories with customizable patterns.

Collars and Ribs: Precise knitting for uniform components on polo shirts, jackets, and sweaters.

Technical Textiles

Beyond fashion, our machines serve specialized industries:

Medical Textiles: Producing compression garments, bandages, and orthopedic supports with exact specifications.

Automotive Fabrics: Durable, lightweight fabrics for car seats and interiors.

Sportswear: Breathable, stretchable materials for athletic apparel, including yoga wear and performance gear.

Seamless 3D Knitting

Our machines excel in 3D knitting technology, creating seamless garments and components like shoe uppers. This reduces material waste and assembly time, aligning with the growing demand for sustainable production.

Industrial and Home Textiles

From upholstery to home decor like blankets and curtains, our machines deliver consistent quality for large-scale textile needs.

Factors Affecting Automatic Knitting Machine Prices

The price of an automatic knitting machine depends on several factors, each influencing its functionality and value. Understanding these can help you make an informed decision:

1. Level of Automation

Fully Automatic: Our computerized flat knitting machines offer complete automation, reducing labor costs but commanding a higher price.

Semi-Automatic: More affordable for smaller operations but requiring some manual input.

2. Technical Specifications

Gauge Range: Machines with finer gauges (e.g., 10G, 12G, 14G) are ideal for delicate fabrics, while lower gauges (e.g., 5G, 7G) suit thicker materials.

Knitting Width: Wider beds (52”, 60”, or 80”) increase production capacity.

Speed: Our machines achieve speeds up to 1.4m/s, boosting output but adding to cost.

3. Advanced Features

Computerized Controls: Touchscreen interfaces and pattern storage simplify complex designs.

Energy Efficiency: Our eco-friendly designs reduce operational costs.

Customization: Support for jacquard, intarsia, and 3D knitting adds versatility.

4. Brand Reputation and Support

As a leading manufacturer, Changhua's machines are priced to reflect our 20+ years of expertise, robust construction, and comprehensive after-sales support

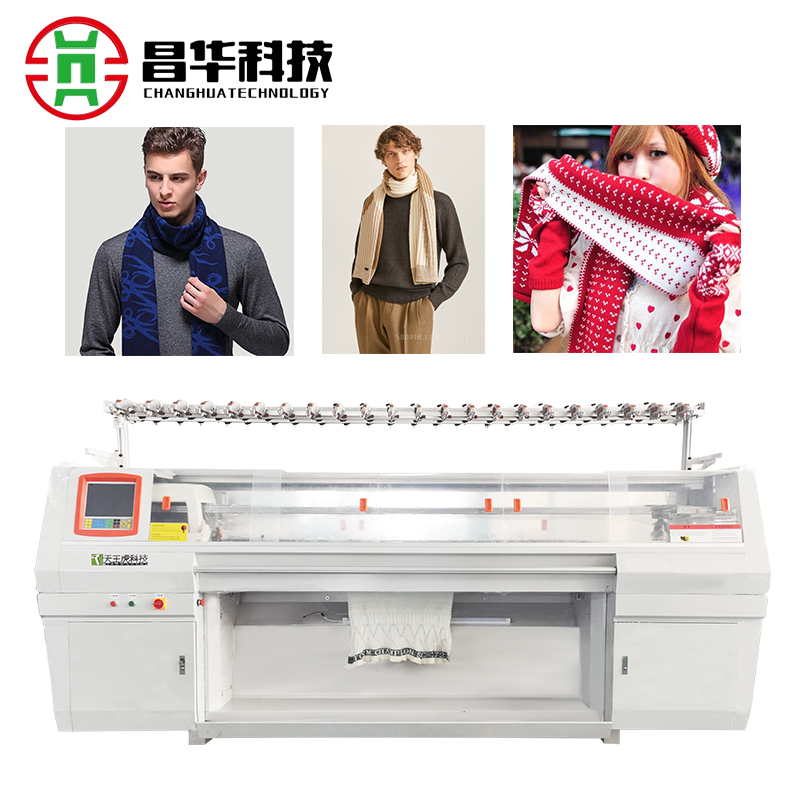

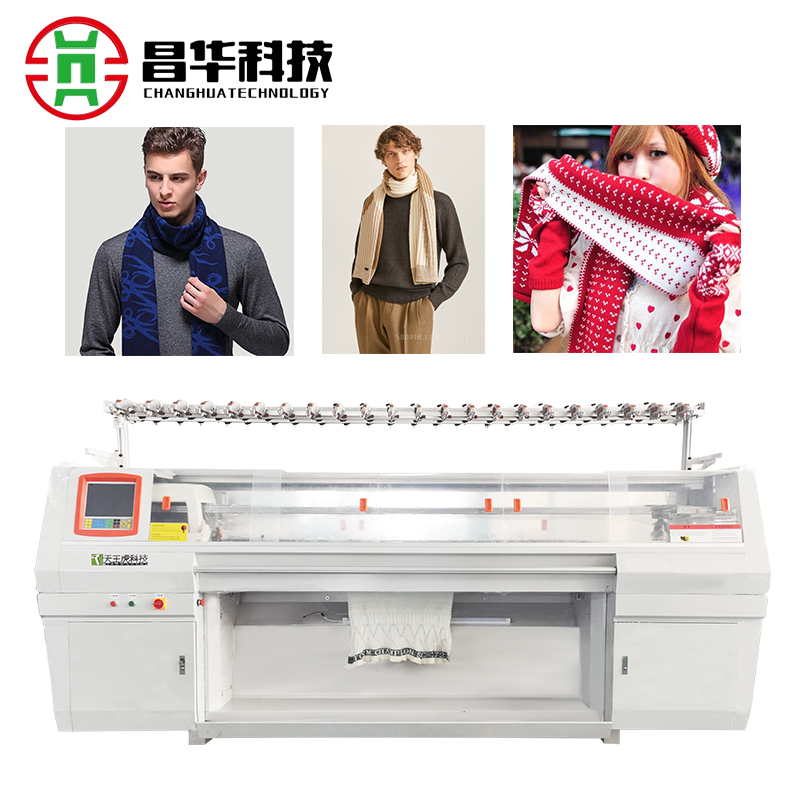

Why Changhua's Computerized Flat Knitting Machines Stand Out

AtChanghua, we take pride in offering state-of-the-art computerized flat knitting machines that combine innovation, durability, and user-friendliness. Available at our product page, our machines are designed to meet the diverse needs of textile manufacturers worldwide. Here’s why our machines are the industry’s best choice:

Advanced Technology for Precision

Our machines feature cutting-edge computerized systems, enabling precise control over every stitch. Key features include:

Multi-Gauge Flexibility: Support for gauges from 6.2G to 16G, suitable for everything from fine knits to heavy fabrics.

Seamless Knitting: Produce whole garments with zero waste, perfect for sustainable fashion.

Jacquard and Intarsia: Create complex patterns like logos and multicolored designs effortlessly.

High-Speed Production

With knitting speeds up to 1.4m/s, our machines maximize output without compromising quality. Automated needle selection and yarn feed systems streamline production, allowing you to meet tight deadlines and scale operations.

Intuitive User Experience

We prioritize ease of use. Our machines feature:

Touchscreen Interfaces: Program designs with minimal training.

Pattern Storage: Save and recall thousands of patterns for quick project transitions.

Error Detection: Built-in sensors alert operators to issues like yarn breaks, reducing downtime.

Durability and Low Maintenance

Constructed with high-quality materials like carbon fiber composites and aluminum alloys, our machines are built to last. Features include:

Automatic Oiling System: Reduces wear on needles and beds, extending service life.

Robust Frame: Withstands continuous operation in high-volume settings.

Easy Maintenance: Modular components simplify repairs and part replacements.

Commitment Vitality Commitment

At Changhua, we're committed to sustainability. Our machines minimize yarn waste through precise knitting and support eco-friendly yarns like recycled polyester. Energy-efficient motors reduce power consumption, lowering operational costs and environmental impact.

Comprehensive After-Sales Support

We provide:

Training Programs: On-site and virtual training for operators.

Global Spare Parts Access: Quick delivery of components to minimize downtime.

24/7 Technical Support: Our team ensures your machine runs smoothly.

For a detailed overview, download  our Changhua Flat Knitting Machine Guide.pdf or watch our machine demo video.

our Changhua Flat Knitting Machine Guide.pdf or watch our machine demo video.

Spotlight on Changhua's Top Models

Our range ofcomputerized flat knitting machines caters to various production needs. Below are highlights of our flagship models:

CHJX 1-52: Compact Powerhouse

Gauge: 7G–16G

Knitting Width: 52 inches

Speed: Up to 1.2m/s

Ideal For: Small to medium businesses producing sweaters, scarves, and collars.

Key Feature: Compact design with full automation, perfect for space-constrained factories.

CHJX 3-120: High-Volume Champion

Gauge: 5G–18G

Knitting Width: 100 inches

Speed: Up to 1.4m/s

Ideal For: Large-scale production of seamless garments and technical textiles.

Key Feature: Advanced 3D knitting for shoe uppers and whole garments.

How to Choose the Right Changhua Machine

Selecting the perfect machine depends on your goals. Here’s a step-by-step guide:

1. Assess Production Volume

2. Match Gauge to Materials

Choose a gauge compatible with your yarns (e.g., 12G–16G for fine cotton, 6.2G–10G for wool).

3. Prioritize Features

Opt for models with seamless knitting or jacquard capabilities if customization is key.

4. Evaluate ROI

Our machines' durability, low maintenance, and energy efficiency ensure long-term savings.

5. Leverage Our Expertise

Contact our team for personalized recommendations based on your needs.

Benefits of Choosing Changhua Machines

Investing in our machines offers transformative advantages:

Unmatched Productivity

Our machines produce up to 10 times faster than manual knitting, enabling you to meet market demands efficiently.

Superior Quality

Computerized controls ensure consistent stitches and flawless patterns, reducing defects.

Cost Efficiency

Automated processes and minimal waste lower labor and material costs, delivering a strong ROI.

Design Flexibility

Create bespoke designs to cater to diverse customer preferences and stay ahead of trends.

Overcoming Common Challenges

Our machines are designed to minimize issues, but here's how to address common challenges:

Uneven Stitches

Machine Jamming

Software Glitches

Why Changhua Is Your Trusted Partner

With over 20 years of experience, Changhua is a global leader in knitting technology. Our credentials include:

Proven Scale: Producing 6,000+ machines annually for clients worldwide.

Innovation Leader: Incorporating AI and IoT for smarter production.

Customer-Centric: Offering training, support, and spare parts globally.

Conclusion

Automatic knitting machines are revolutionizing textile production, offering speed, precision, and sustainability. Changhua's computerized flat knitting machines, available at our product page, lead the industry with advanced technology, durability, and eco-friendly design. Whether you’re a small boutique or a large manufacturer, our machines deliver unmatched value.  Explore our offerings.pdf, download our PDF guide, or watch our demo video to see why Changhua is the trusted choice for textile innovation.

Explore our offerings.pdf, download our PDF guide, or watch our demo video to see why Changhua is the trusted choice for textile innovation.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe