Investing in a flat knitting machine is a significant decision for textile manufacturers, small business owners, and even hobbyists looking to produce high-quality knitwear. Whether you’re aiming to create school sweaters, fashion garments, or technical textiles, understanding the ins and outs of flat knitting machines is crucial to making an informed purchase. This comprehensive guide will walk you through everything you need to know before buying a flat knitting machine, from how they work and their applications to key factors like cost, features, and brand reliability. We'll also highlight why  Changhua's flat knitting machines.pdf are a top choice for businesses worldwide, offering cutting-edge technology and exceptional support.

Changhua's flat knitting machines.pdf are a top choice for businesses worldwide, offering cutting-edge technology and exceptional support.

If you're new to flat knitting machines or looking to upgrade your equipment, this article will equip you with the knowledge to choose the right machine for your needs. Let's dive into the world of flat knitting and explore what makes these machines a game-changer in textile production.

Understanding Flat Knitting Machines

Before diving into the purchase process, it's essential to understand what a flat knitting machine is and how it works. Unlike circular knitting machines that produce tubular fabrics, flat knitting machines create flat panels of fabric, making them ideal for garments like sweaters, cardigans, and scarves. These machines use horizontal needle beds, where needles and sinkers work together to form stitches, guided by a carriage that moves across the bed.

Key Components of a Flat Knitting Machine

Needles: Form the stitches by looping the yarn.

Sinkers: Hold the fabric in place during knitting.

Carriage: Moves across the needle bed, controlling needle movement.

Yarn Feeders: Supply yarn to the needles, often supporting multiple colors for complex patterns.

Control System: In computerized models, a digital interface allows precise programming of patterns, stitch density, and tension.

Flat knitting machines come in various types, from manual and semi-automatic to fully computerized models. For modern textile production, computerized machines are the gold standard, offering automation, precision, and versatility.

Applications of Flat Knitting Machines

Flat knitting machines are incredibly versatile, serving a wide range of industries and applications. Understanding their capabilities will help you determine whether they align with your production goals.

1. School Uniforms and Sweaters

Flat knitting machines excel at producing school sweaters, vests, and cardigans. They can create durable, comfortable garments with customizable features like school logos, jacquard patterns, and ribbed collars. This makes them a favorite for manufacturers supplying uniforms to schools worldwide.

2. Fashion and Apparel

From high-fashion knitwear to casual garments, flat knitting machines are used to create sweaters, dresses, skirts, and more. Their ability to handle intricate patterns like intarsia, cable knits, and pointelle makes them popular among designers.

3. Sportswear and Technical Textiles

Flat knitting machines are increasingly used in sportswear, producing seamless athletic wear, compression garments, and breathable jerseys. They’re also employed in technical textiles for applications like automotive interiors, medical compression garments, and industrial fabrics.

4. Accessories and Home Textiles

These machines can produce accessories like scarves, hats, and gloves, as well as home textiles like blankets and cushion covers. Their flexibility supports small-batch production for custom designs, ideal for boutique businesses.

Benefits of Flat Knitting Machines

Investing in a flat knitting machine offers numerous advantages, making them a worthwhile addition to your production line. Here are the key benefits:

1. Precision and Consistency

Computerized flat knitting machines ensure precise stitch formation, resulting in consistent quality across batches. This is critical for applications like school uniforms, where uniformity is essential.

2. Efficiency and Speed

Automation reduces manual labor and speeds up production. Modern machines, like Changhua’s, feature high-speed carriages and intelligent software, boosting output by up to 20% compared to traditional methods.

3. Design Flexibility

Flat knitting machines support a wide range of patterns, from simple stockinette to complex jacquard and intarsia designs. This versatility allows manufacturers to cater to diverse market demands.

4. Sustainability

Advanced machines minimize material waste through precise knitting and support eco-friendly yarns. Whole garment knitting further reduces waste by eliminating the need for cutting and sewing.

5. Cost-Effectiveness

While the initial investment can be significant, the long-term savings from reduced labor, faster production, and minimal waste make flat knitting machines a cost-effective choice.

Key Factors to Consider Before Buying a Flat Knitting Machine

Choosing the right flat knitting machine requires careful consideration of several factors. Here’s what you need to know to make an informed decision:

1. Automation Level

Flat knitting machines come in three main types:

Manual Machines: Suitable for hobbyists or small-scale producers who prefer hands-on control.

Semi-Automatic Machines: Offer a balance of manual input and automation, ideal for small businesses.

Computerized Machines: Provide full automation, precision, and speed, perfect for large-scale manufacturers.

Consider your production volume and technical expertise when choosing the automation level. For most commercial applications, computerized machines are the best choice.

2. Gauge and Knitting Width

The gauge (number of needles per inch) determines the fineness or thickness of the fabric. Common gauges include:

5G: For chunky sweaters and thick fabrics.

7G-10G: For medium-weight garments like school sweaters.

12G-14G: For fine, lightweight knitwear.

The knitting width (e.g., 52 inches, 80 inches) determines the size of the fabric panels. Choose a machine that matches your desired garment sizes and yarn types.

3. Pattern Capabilities

Ensure the machine supports the patterns you need, such as jacquard, intarsia, cable knits, or ribbing. Advanced machines, like Changhua’s double-system models, excel at creating complex patterns with ease.

4. Production Volume

Consider your production needs:

Small-Scale: For boutique businesses or startups, a compact, semi-automatic machine may suffice.

Large-Scale: For high-volume production, invest in a fully computerized machine with high-speed capabilities.

5. Brand Reliability and Support

Choose a reputable brand with strong after-sales support. Changhua, for example, offers installation, training, and maintenance services, ensuring your machine operates smoothly.

6. Sustainability Features

Look for machines that support eco-friendly yarns and minimize waste. Whole garment knitting machines are particularly sustainable, as they produce seamless garments with no cutting waste.

Why Choose Changhua for Your Flat Knitting Machine?

When it comes to flat knitting machines, Changhua stands out as a trusted leader in the textile machinery industry. Based in Changshu, Jiangsu, the heart of China’s apparel industry, Changhua has over 20 years of experience delivering innovative, high-quality machines to clients worldwide. Here’s why Changhua is the ideal choice for your flat knitting machine:

Advanced Technology

Changhua's machines are equipped with cutting-edge features, including:

Double System Technology: Enables high-speed knitting with dynamic stitch control for complex patterns like jacquard and intarsia.

Whole Garment Knitting: Produces seamless garments, reducing labor and waste while enhancing comfort.

Intelligent Software: User-friendly interfaces and fast programming reduce setup time and energy consumption.

Diverse Product Range

Changhua offers a variety of machines tailored to different needs:

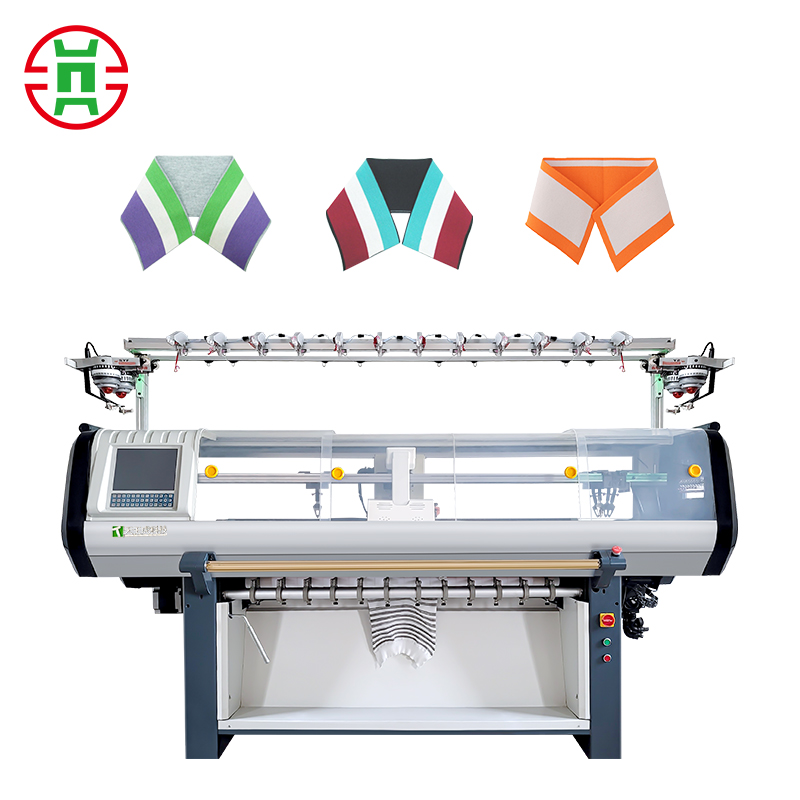

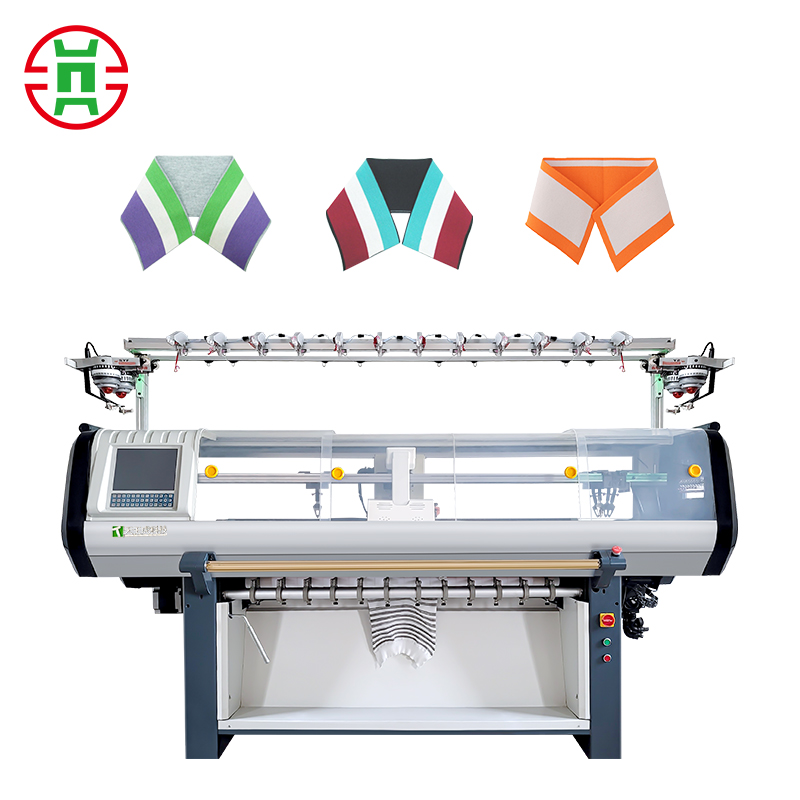

Sweater Knitting Machines

Ideal for school sweaters and fashion garments, with customizable patterns and gauges.

Collar Knitting Machines

Specialized for ribbed or jacquard collars and cuffs.

Whole Garment Machines

Perfect for seamless, high-end knitwear.

Global Trust and Support

Changhua serves clients across Europe, the USA, and Asia, with a strong focus on after-sales support. Their services include:

Installation and Training: Expert technicians ensure your machine is set up correctly and your team is trained to use it.

Maintenance and Repairs: Regular maintenance plans and prompt repair services keep your machine running smoothly.

24/7 Customer Support: A dedicated team is available to answer your questions and troubleshoot issues.

Sustainability Commitment

Changhua's machines support eco-friendly yarns and minimize waste through precise knitting and whole garment technology. This aligns with the growing demand for sustainable textile production.

Proven Track Record

With brands like “Changhua,” “Tiangong,” “King Tiger,” and “Miao’s Craftsman,” Changhua has built a reputation for quality and innovation. Their machines are used by leading manufacturers worldwide, from small startups to global fashion brands.

Common Mistakes to Avoid When Buying a Flat Knitting Machine

1. Ignoring Production Needs

Buying a machine that doesn't match your production volume can lead to inefficiencies. Assess your needs (e.g., small-batch vs. high-volume) before purchasing.

2. Overlooking Maintenance Requirements

Flat knitting machines require regular maintenance to prevent breakdowns. Choose a brand like Changhua that offers comprehensive maintenance support.

3. Skimping on Training

Operating a computerized machine requires training. Ensure your team is trained to use the machine effectively, or opt for Changhua's training programs.

4. Focusing Solely on Price

While budget is important, choosing the cheapest machine can lead to poor quality and frequent repairs. Invest in a reliable brand like Changhua for long-term savings.

5. Neglecting Software Compatibility

Ensure the machine's software is compatibleWITH your design tools and easy to use. Changhua's intuitive software simplifies pattern creation and machine operation.

How to Get Started with YourES Your Flat Knitting Machine

Yarn Selection

Choose high-quality yarn (e.g., wool, cotton, or blends) based on your project requirements. Changhua's experts can recommend the best yarn for your machine and application.

Machine Setup

Work with Changhua's technicians to install and calibrate your machine. Thread the yarn into the feeders and test a few rows to ensure proper tension and stitch quality.

Pattern Programming

Use Changhua's design software to create or import patterns. Adjust settings for stitch density, tension, and pattern complexity to match your design specifications.

Production and Quality Control

Start knitting and monitor the process to ensure consistent quality. For seamless garments, Changhua's whole garment machines simplify production.

Finishing and Maintenance

Inspect finished garments for quality, add finishing touches like ribbing, and perform regular machine maintenance to ensure longevity.

Why Changhua is Your Best Choice

At Changhua, we're committed to helping you succeed in textile production. Our flat knitting machines combine innovation, reliability, and affordability, making them the perfect choice for manufacturers of all sizes. Here's why Changhua stands out:

20+ Years of Expertise

A trusted name in textile machinery.

Global Reach

Serving clients in Europe, the USA, and Asia.

Comprehensive Support

From installation to maintenance, we’re with you every step of the way.

Sustainability Focus

Eco-friendly machines that align with modern demands.

Ready to invest in a flat knitting machine? Contact Changhua today to explore our range of machines and find the perfect solution for your business. Visit https://www.changhua-knitting-machine.com/ for more information or to request a quote.

Conclusion

Buying a flat knitting machine is a significant investment, but with the right knowledge, you can choose a machine that meets your production needs and budget. From understanding the mechanics and applications to evaluating key factors like gauge, automation, and support, this guide has covered everything you need to know. Changhua's flat knitting machines offer unmatched quality, versatility, and support, making them the ideal choice for producing school sweaters, fashion garments, and more.

Take the next step with Changhua and transform your textile production. With their advanced technology and global expertise, you'll be equipped to create high-quality knitwear that stands out in the market.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe