The knitting machine industry is undergoing a transformative phase, driven by rapid advancements in digital technology, increasing consumer demand for customized textiles, and a global push for sustainability. As the textile sector evolves, knitting machines are becoming smarter, faster, and more efficient, enabling manufacturers to meet the demands of diverse industries such as fashion, sportswear, medical textiles, and automotive fabrics. This article explores the latest trends in the knitting machine industry, with a focus on how digital technology can enhance production efficiency by up to 30%. We will also highlight the innovative solutions offered by Changhua, a leading manufacturer of computerized flat knitting machines, and how our cutting-edge equipment aligns with these industry trends.

Understanding the Knitting Machine Industry

The Evolution of Knitting Machines

Knitting machines have come a long way from their manual origins. Early machines relied heavily on human intervention, limiting production speed and design complexity. Today, the industry is dominated by computerized and automated systems that offer unparalleled precision, speed, and versatility. These advancements have made knitting machines indispensable in producing a wide range of fabrics, from casual apparel to high-performance technical textiles.

The global knitting machines market was valued at USD 4.9 billion in 2023 and is projected to grow at a CAGR of over 5.4% from 2024 to 2032, driven by rising demand for textiles, technological innovations, and expanding applications in sportswear and home textiles. The Asia-Pacific region, particularly China, India, and Bangladesh, accounts for a significant share of this growth, with China alone holding a 32% market share in 2023 due to its dominance in textile production.

Applications of Knitting Machines

Knitting machines are versatile tools used across various industries:

Fashion and Apparel: From sweaters and scarves to high-end luxury garments, knitting machines produce intricate designs with minimal waste.

Sportswear: The demand for breathable, stretchable, and moisture-wicking fabrics has led to innovations in knitting technology, as seen in products like Nike’s Flyknit shoes.

Medical Textiles: Compression garments, bandages, and seamless medical wear are manufactured using specialized knitting machines.

Automotive and Industrial Textiles: Knitting machines produce durable fabrics for car seat covers, airbags, and industrial meshes.

Home Textiles: Blankets, curtains, and upholstery benefit from the efficiency and customization capabilities of modern knitting machines.

These applications highlight the critical role of knitting machines in meeting diverse market needs, with digital technology playing a pivotal role in enhancing their capabilities.

The Role of Digital Technology in Knitting Machines

Digital technology is revolutionizing the knitting machine industry by improving production efficiency, reducing waste, and enabling customization. Below, we explore key technological trends and their impact on the industry.

Automation and Computerized Controls

Modern knitting machines are equipped with computerized systems that automate complex processes, reducing the need for manual intervention. These systems use computer-aided design (CAD) and computer-aided manufacturing (CAM) to create intricate patterns with high precision. Automation minimizes errors, speeds up production, and allows manufacturers to produce customized designs at scale.

For instance, computerized flat knitting machines can seamlessly switch between patterns like jacquard, tuck, and intarsia, enabling the production of complex garments in a single process. This reduces production time and labor costs, contributing to a potential 30% increase in efficiency.

3D Knitting and Seamless Technology

3D knitting technology is a game-changer for the industry, allowing manufacturers to produce seamless garments in one continuous process. This eliminates the need for cutting and sewing, reducing fabric waste and labor costs while enhancing garment comfort and fit. Seamless knitting is particularly popular in sportswear and medical textiles, where flexibility and durability are critical.

For example, Nike's Flyknit technology, introduced in 2012, uses advanced knitting machines to create lightweight, performance-driven shoes, with over 30 million pairs sold to date. This demonstrates the consumer demand for high-quality, customized products enabled by digital knitting technology.

IoT and Smart Sensors

The integration of the Internet of Things (IoT) and smart sensors in knitting machines allows for real-time monitoring and predictive maintenance. These systems track machine performance, detect faults, and optimize production processes, reducing downtime and improving overall efficiency. According to the United Nations Industrial Development Organization (UNIDO), energy-efficient knitting machines with smart sensors can reduce energy consumption by up to 20% compared to traditional models.

AI and Data-Driven Analytics

Artificial intelligence (AI) and data-driven analytics are transforming knitting machine operations by enabling predictive maintenance, optimizing yarn usage, and improving design accuracy. AI-powered machines can analyze production data to identify inefficiencies and suggest improvements, further boosting productivity.

Sustainability and Eco-Friendly Production

Sustainability is a growing priority in the textile industry, with manufacturers under pressure to reduce their environmental footprint. Digital knitting machines contribute to this goal by minimizing fabric waste, optimizing energy consumption, and supporting the use of eco-friendly materials like recycled yarns. For instance, seamless knitting technology reduces material waste by producing garments in a single piece, aligning with global sustainability goals.

How Digital Technology Boosts Production Efficiency by 30%

Digital technology enhances production efficiency in several ways:

Reduced Production Time

Automated systems and computerized controls allow for faster pattern changes and continuous production, cutting down cycle times.

Minimized Waste

3D knitting and precise yarn management reduce material waste, lowering costs and supporting sustainability.

Lower Labor Costs

Automation reduces the need for manual labor, allowing manufacturers to allocate resources more effectively.

Improved Quality Control

Smart sensors and AI analytics ensure consistent quality, reducing defects and rework.

Customization at Scale

Digital technology enables manufacturers to produce bespoke designs without sacrificing speed or efficiency.

Changhua: Leading the Way in Digital Knitting Technology

Why Choose Changhua?

Changhua Smart Manufacturing Technology Co., Ltd., based in Changshu, Jiangsu, China, is a pioneer in the knitting machine industry with over 20 years of experience. The company specializes in computerized flat knitting machines that leverage digital technology to deliver high-speed, efficient, and sustainable solutions. Changhua’s machines are trusted by brands worldwide, from Europe to Asia, for our reliability, versatility, and cutting-edge features.Visit Changhua's official website to explore  our full range of products.pdf and services.

our full range of products.pdf and services.

Changhua's Digital Technology Features

Changhua's knitting machines are designed with advanced digital technologies that align with industry trends:

High-Speed and Efficient Systems

Changhua's double-system machines feature high rollers, dynamic stitches, and motor-controlled reserving carriages, enabling rapid production of complex patterns like pointelle, tuck, jacquard, and intarsia.

Seamless Whole Garment Technology

Changhua's computerized whole garment flat knitting machines produce seamless knitwear, reducing waste and enhancing comfort for applications in fashion, sportswear, and medical textiles.

Intelligent Programming

Fast and intelligent programming enhances efficiency and reduces energy consumption, making Changhua's machines ideal for eco-conscious manufacturers.

Versatile Material Compatibility

Changhua machines support a wide range of yarns, including wool, cashmere, cotton, chemical fibers, and recycled materials, catering to diverse industry needs.

Automated Needle Plate Oiling

This feature reduces wear between needles and needle beds, extending machine lifespan and minimizing maintenance costs.

Global Support and Fast Delivery

Changhua offers 24/7 technical support and an average delivery time of 15-30 days, ensuring seamless integration into production lines.

Changhua's Product Range

Changhua offers a variety of knitting machines tailored to different applications:

Sweater Flat Knitting Machines: Ideal for producing high-quality sweaters with intricate designs.

Shoe Upper Knitting Machines: Designed for sportswear, these machines create breathable, durable fabrics for athletic shoes.

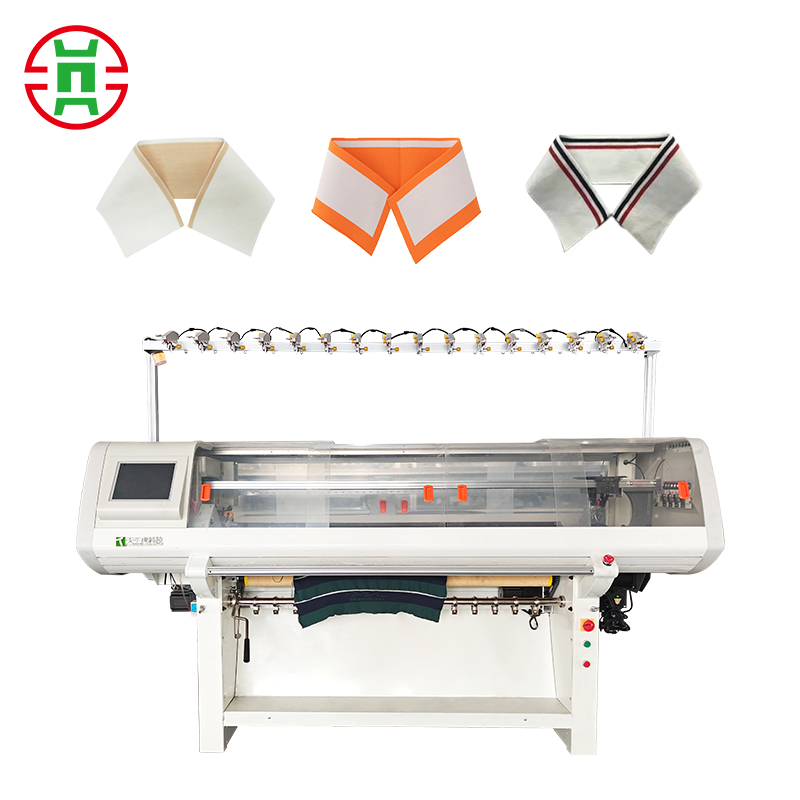

Collar and Cuff Knitting Machines: Perfect for precision knitting of garment components.

Whole Garment Knitting Machines: Enable seamless garment production for fashion, sportswear, and medical textiles.

Industry Insights: The Future of Knitting Machines

Growing Demand for Customization

Consumers are increasingly seeking personalized clothing that reflects their unique styles. Digital knitting machines, like those offered by Changhua, enable manufacturers to produce bespoke designs at scale, meeting this demand without compromising efficiency.

Expansion in Emerging Markets

The Asia-Pacific region, particularly China, India, and Bangladesh, is a hotspot for textile production due to low labor costs and growing domestic demand. Government initiatives, such as China's “Made in China 2025” plan, aim to modernize textile manufacturing, driving demand for advanced knitting machines.

Sustainability as a Priority

As sustainability becomes a core focus, manufacturers are investing in energy-efficient machines and eco-friendly materials. Changhua's machines, with their low-waste and energy-saving features, are well-positioned to meet these demands.

Integration of Industry 4.0 Technologies

The adoption of Industry 4.0 technologies, such as AI, IoT, and robotics, is reshaping the knitting machine industry. These technologies enable real-time monitoring, predictive maintenance, and data-driven decision-making, further enhancing efficiency.

Challenges and Opportunities

While advanced knitting machines offer significant benefits, challenges remain. High upfront costs can be a barrier for small and medium-sized manufacturers, and there is a shortage of skilled technicians to operate and maintain these systems. However, opportunities abound, particularly in the development of smart machines and collaborations between manufacturers and textile companies.

Conclusion

The knitting machine industry is at the forefront of technological innovation, with digital technology driving significant improvements in production efficiency, customization, and sustainability. By leveraging automation, 3D knitting, IoT, and AI, manufacturers can achieve up to a 30% increase in efficiency, meeting the demands of a rapidly evolving market. Changhua Smart Manufacturing Technology Co., Ltd. is leading this transformation with its high-speed, efficient, and sustainable knitting machines. Whether you're producing fashion apparel, sportswear, or technical textiles, Changhua's solutions offer the reliability and innovation needed to stay competitive.

Explore  Changhua's full range of knitting machines.pdf and take the first step toward revolutionizing your textile production.

Changhua's full range of knitting machines.pdf and take the first step toward revolutionizing your textile production.

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe