In the fast-paced world of textile and garment manufacturing, efficiency, versatility, and quality are not just advantages—they are necessities. At the heart of this industry lies a pivotal piece of technology: the flat knit machine. Whether you're producing intricate sweaters, seamless technical textiles, or fashionable scarves, the choice of your knitting machinery can make or break your business's productivity and profit margins.

This comprehensive guide is designed to demystify flat knit machines. We will explore their technology, types, and applications. More importantly, we will guide you on how to select a reliable partner for this critical investment. You will discover why Changhua Knitting Machine has become a synonym for innovation, durability, and exceptional value in the global market.

Are you ready to revolutionize your production line? Let's dive in.

What is a Flat Knit Machine?

A flat knit machine is a specialized textile machine used to produce knitted fabric in a flat, open-width form. Unlike circular knitting machines that create a continuous tube of fabric, flat knitters produce individual panels. These machines use two stationary needle beds arranged in an inverted "V" formation, with carriage systems that move back and forth across the beds, transferring loops to create complex structures.

The primary advantages of this method include:

Versatility in Design: Capable of producing intricate patterns, cables, jacquards, and intarsia.

Seamless Production: Ability to create whole garments (Whole Garment® or 3D knitting) with minimal to no sewing.

Material Flexibility: Can handle a wide range of yarns, from fine cotton and wool to technical fibers and coarse acrylics.

Panel Knitting: Ideal for creating specific pieces like sweater fronts, backs, and sleeves.

Types of Flat Knit Machines: Finding the Right Fit for Your Factory

Understanding the different types of flat knit machines is the first step in making an informed decision. They are generally categorized by their level of automation and the number of knitting systems.

Manual vs. Semi-Automatic vs. Fully Automatic Flat Knit Machines

Manual Machines: Require significant operator intervention for tasks like changing colors and setting patterns. Best for small-scale workshops or highly specialized, low-volume production.

Semi-Automatic Machines: Offer a balance between control and automation. They often feature electronic needle selection and simple pattern control but may require manual carriage return or other minor interventions. They are a cost-effective solution for small to medium-sized businesses.

Fully Automatic Machines: The pinnacle of efficiency. These computer-controlled machines automate almost every process, including carriage reversal, yarn changing, stitch transfer, and presser foot operation. They are designed for high-volume, high-mix production.

Single System, Double System, and Multi-System Machines

The "system" refers to the number of independent knitting system on the machine.

Single System: One system. While reliable, the production speed is lower as only one course of knitting is laid per pass.

Double System: Two systems. This effectively doubles the production speed compared to a single-system machine and is the industry standard for balanced, high-speed manufacturing.

Three System (or more): Three or more systems. These are high-performance machines designed for maximum output, often used for simpler structures or in large-scale industrial settings.

Choosing a Reliable Flat Knit Machine Manufacturer

Investing in a flat knit machine is a significant decision. The manufacturer you choose will impact your machine's performance, longevity, and the total cost of ownership. A reputable manufacturer provides not just a machine, but a partnership.

Key Factors to Consider in a Manufacturer:

Technical Expertise and R&D: Do they invest in innovation?

Build Quality and Durability: Are the machines built with high-quality components to withstand 24/7 operation?

After-Sales Service and Support: What is their global support network like? Is training and technical documentation provided?

Spare Parts Availability: How quickly can you get replacement parts to minimize downtime?

Value for Money: Does the machine offer a competitive performance-to-price ratio?

Why Changhua Stands Out as Your Premier Flat Knit Machine Supplier in China

When you evaluate manufacturers against these criteria, one name consistently rises to the top: Changhua Knitting Machine. For years, we have dedicated ourselves to engineering and producing some of the most robust, user-friendly, and innovative flat knit machines on the market.

Our philosophy is simple: deliver superior machinery that empowers our clients to compete and win in the global marketplace.

The Changhua Advantage: What Makes Our Machines Different

Uncompromising Build Quality: We use premium-grade materials and precision engineering in every machine. From the hardened steel needles to the rigid frame, every component is selected for durability and long-term reliability, ensuring stable performance even under the most demanding production schedules.

Innovative and User-Friendly Software: Our machines are powered by intuitive computer control systems. The software allows for easy pattern design, quick job changes, and real-time monitoring. This reduces the learning curve for your operators and increases overall operational efficiency.

Download our software user guide PDF to see how easy it is to operate our machines.

Download our software user guide PDF to see how easy it is to operate our machines.

Exceptional After-Sales Service: We view our relationship with customers as a long-term partnership. Our global network of service engineers and representatives ensures that you are never alone. We provide comprehensive installation, training, and ongoing technical support to keep your production running smoothly.

Competitive Pricing without Compromise: By leveraging our manufacturing expertise and scale in China, we are able to offer high-performance flat knit machines at a highly competitive price point. We give you access to top-tier technology without the premium cost, ensuring an excellent return on your investment.

Customization and Flexibility: We understand that every factory has unique needs. Our team is ready to discuss custom solutions, whether it's a specific gauge, width, or functionality requirement.

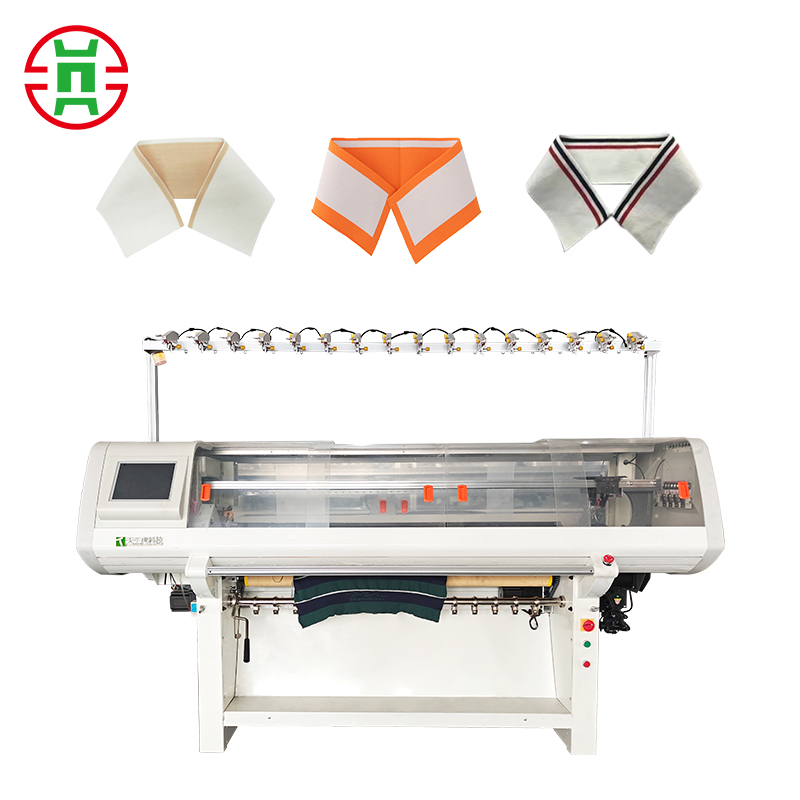

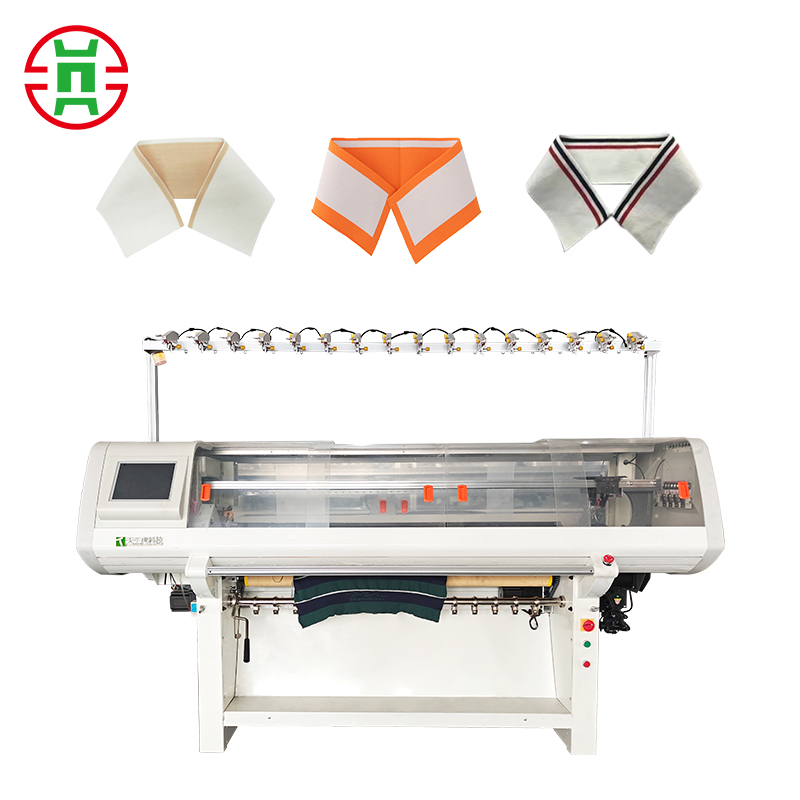

Seeing is believing. Watch the video below to see a Changhua flat knit machine in action, producing a complex collar with precision and speed.

A Closer Look at Our Top-Performing Flat Knit Machines

Let's delve into the specifics of some of our most popular models. These machines exemplify the Changhua commitment to quality and performance and are engineered to excel in their respective applications.

High-Speed Production for Complex Collars: 68-Inch Double System Collar Knitting Machine

The collar is often the centerpiece of a garment, and its quality is immediately noticeable. Our 68-Inch Double System Collar Knitting Machine is engineered specifically for high-volume, high-quality collar production.

Key Features and Benefits:

Double System Carriage: Delivers outstanding production speed, perfect for meeting tight deadlines.

68-Inch Wide Bed: Allows for multiple collars to be knitted simultaneously, drastically improving output.

Precision Stitch Control: Ensures consistent, high-quality stitching on even the most intricate cable and jacquard patterns.

Robust Frame: Guarantees vibration-free operation at high speeds, ensuring consistent quality and reducing wear and tear.

This machine is the go-to solution for sweater manufacturers who need to produce a large volume of detailed, premium collars efficiently. Want to see the full specifications? Explore the 68-Inch Double System Collar Knitting Machine on our product page.

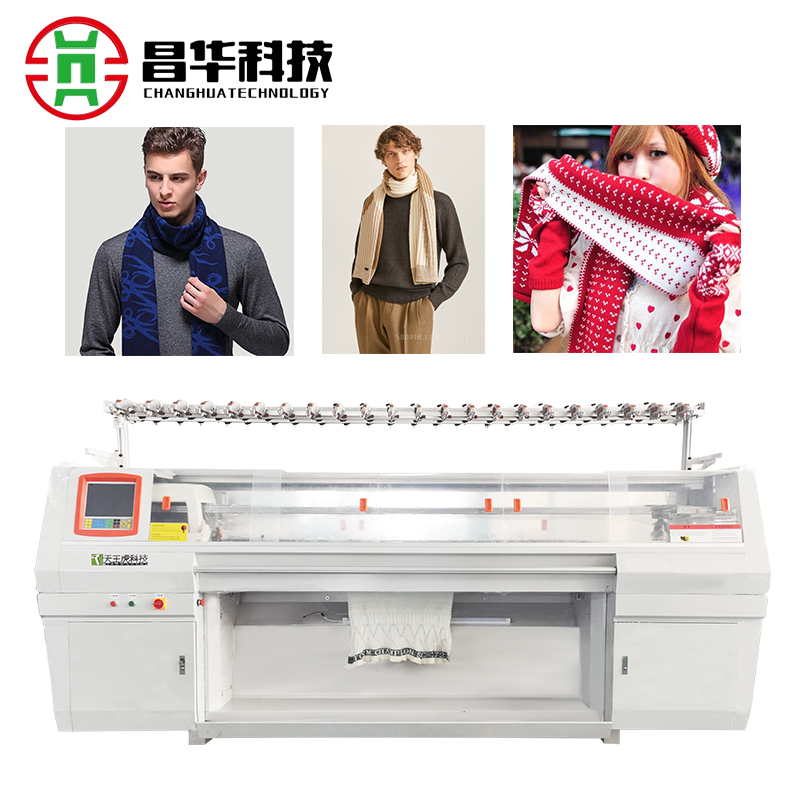

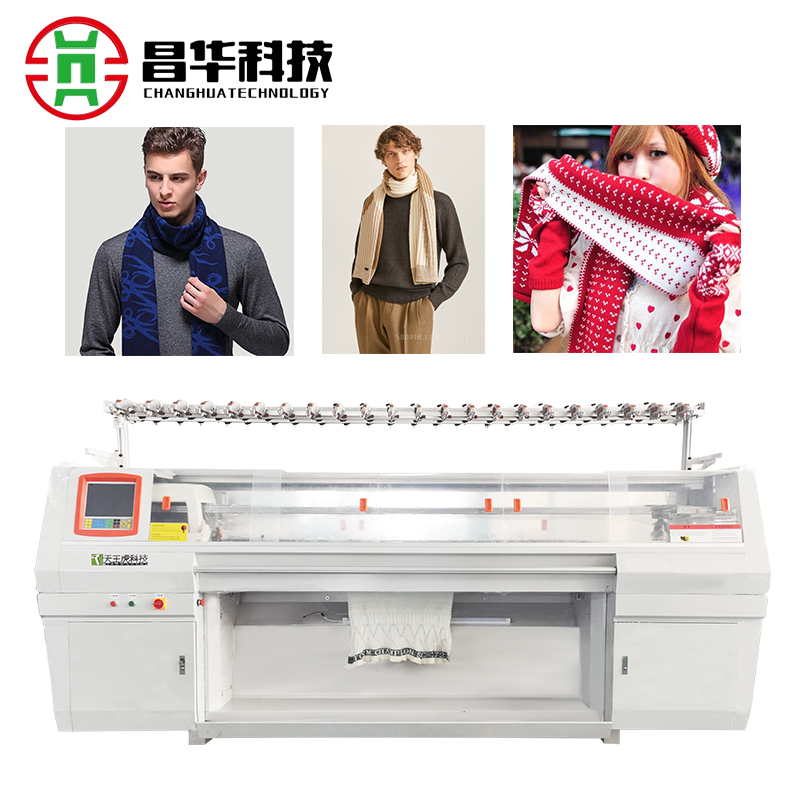

Unmatched Versatility for Fashion Accessories: 66-Inch Three System Scarf Knitting Machine

The scarf market demands both creativity and efficiency. Our 66-Inch Three System Scarf Knitting Machine is a powerhouse built for this exact purpose. Its three-system design makes it one of the fastest machines in its class for producing scarves, stoles, and other narrow fabrics.

Key Features and Benefits:

Three System Carriage: Maximizes production speed, offering a significant output advantage over double-system machines for scarf production.

Excellent Yarn Compatibility: Handles a vast range of yarns, from delicate cashmere and merino wool to bulky acrylic blends.

Advanced Pattern Capabilities: Unleash your designers' creativity with extensive jacquard, tuck, and miss-stitch patterning options.

User-Friendly Interface: The intuitive control system makes pattern input and machine operation straightforward, reducing setup time.

If your business revolves around fashion accessories, this machine provides the speed and versatility to stay ahead of trends. Discover how the 66-Inch Three System Scarf Knitting Machine can expand your product line. Visit the product page for more details.

The Perfect Balance of Automation and Value: 60-Inch Semi-Automatic Flat Knitting Machine

For small to medium-sized enterprises or those looking for a cost-effective entry into automated knitting, our 60-Inch Semi-Automatic Flat Knitting Machine is an ideal choice. It bridges the gap between manual and fully automatic machines, offering excellent functionality at an accessible price.

Key Features and Benefits:

Cost-Effective Automation: Get the benefits of electronic needle selection and pattern control without the full investment of an automatic machine.

Versatile 60-Inch Bed: Suitable for a wide variety of panels, trims, and small pieces.

Ease of Use and Maintenance: Simple design means easier operation and lower maintenance costs, perfect for factories with less technical expertise.

Reliable Performance: Built with the same quality standards as our high-end models, ensuring a long and productive service life.

This model is proof that Changhua provides solutions for every stage of a business's growth. Ready to upgrade your production? Learn more about the 60-Inch Semi-Automatic Flat Knitting Machine here.

Applications of Flat Knitting Technology: Beyond Sweaters

While traditionally used for knitwear, the applications of modern flat knit machines have expanded dramatically.

Fashion Apparel: Sweaters, cardigans, scarves, hats, and gloves.

Seamless & 3D Knitted Apparel: High-performance sportswear and intimate apparel.

Technical Textiles: Medical textiles like compression stockings, automotive interior fabrics, and composite preforms.

Upholstery and Home Textiles: Knitted fabrics for furniture and home decor.

Conclusion: Partner with Changhua for Your Success

The journey to selecting the right flat knit machine is complex, but it culminates in a simple truth: your success is dependent on the reliability and performance of your equipment. By choosing Changhua Knitting Machine, you are not just purchasing a machine; you are investing in a partnership built on quality, innovation, and unwavering support.

Our range of machines, from the high-speed 68-Inch Double System to the versatile 66-Inch Three System and the value-packed 60-Inch Semi-Automatic, is designed to meet the diverse needs of the modern textile industry.

You've read about our technology, our commitment, and our specific models. Now, it's time to take the next step.

[Request a Quote Now]

[Download Our Full Product Catalog PDF]

[Download Our Full Product Catalog PDF]

English

العربية

Français

Русский

Español

Português

Deutsch

italiano

日本語

한국어

Nederlands

Tiếng Việt

ไทย

Polski

Türkçe

ភាសាខ្មែរ

Bahasa Melayu

தமிழ்

Filipino

Bahasa Indonesia

magyar

Română

Čeština

қазақ

Српски

हिन्दी

Kiswahili

Slovenščina

Norsk

Svenska

українська

Ελληνικά

Suomi

עברית

اردو

Shqip

বাংলা

Hrvatski

Gaeilge

Māori

සිංහල

नेपाली

Oʻzbekcha

Aymara

Azərbaycan dili

Беларуская мова

Български

guarani

Lietuvių

Runasimi

Türkmençe